Académique Documents

Professionnel Documents

Culture Documents

HDH Process TiH2

Transféré par

cuong21290Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

HDH Process TiH2

Transféré par

cuong21290Droits d'auteur :

Formats disponibles

The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative Light Metals Conference 2010 X Goso

and A Kale

PRODUCTION OF TITANIUM METAL POWDER BY THE HDH PROCESS X Goso and A Kale Pyrometallurgy division, Mintek, Johannesburg

Abstract Laboratory scale tests were conducted at Mintek for the production of titanium powder from particulate Kroll sponge by the hydrogenation-dehydrogenation (HDH) process. The aim of this work was to produce titanium powder for powder metallurgical consolidations. The work involved the production of titanium powder at optimised conditions, which included hydrogenation in a horizontal tube furnace at 600C for 2 hours, milling using planetary and roller mills, and dehydrogenation in a vacuumed retort fitted in a muffle furnace running at 700C for 36 hours. The produced titanium powder matched the elemental specifications of commercially available titanium powder, except for high carbon content. Nevertheless, the powder has been tested further in mechanical alloying and has been found suitable for the production of powder metallurgical compacts. Keywords: Powder metallurgy, titanium components, HDH process, ball milling 1 Introduction Mintek, specialists in mineral and metallurgical technology, is involved in various research and development work for advanced materials, including the extraction and alloying metallurgy of titanium metal. Titanium metal and allied alloys have been a subject of research globally due to their important role in current industrial applications and the projected increase in their demand in the near future. The extraction, transformation and machining of titanium metal is quite challenging from the perspective of purity (contamination), safety hazards and costs. Mintek has extensive experience in handling reactive metals, including metal vapours and powders. This paper describes the experience gained on the production of titanium metal powder by the HDH process. 1.1 Background

Titanium is a metallic transition element. It is the fourth most abundant structural metal. It falls in the category of light elements. Titanium can easily be alloyed with other widely-used elements such as iron and aluminium1. Currently, most of the titanium is commercially produced as sponge by reducing titanium tetrachloride with magnesium in what is known as Kroll process; named after William Kroll, who invented the process in 19461. The major markets for titanium include commercial aerospace, defence; industrial, medical, domestic and emerging applications. Near-net shape processes such as casting and powder metallurgy are the most common processes used to prepare titanium metal for these applications. Titanium ingot can also be used at a cost. Moreover, the ingot cannot be used directly due to its poor machining or fabrication properties. Casting operations are costly and result in relatively high yield losses. The sources of high cost in casting include the labour intensive induction melting electrode preparation, multiple melt sequence and intermediate

Page 292

The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative Light Metals Conference 2010 X Goso and A Kale

and final conditioning. Hence alternative sponge preparation processes such as powder metallurgy are a subject of intensive investigations1,2. In powder metallurgy, titanium metal powders are produced, further compacted and sintered to form useful products for various sectors1. There are two basic approaches used to produce titanium alloy powders; i.e., pre-alloyed and blended elemental methods. The former approach uses ready-mixed alloy components prior to subsequent alloying. This approach has a higher cost2,3. However, the blended elemental approach uses pure titanium and other alloy components or a master alloy (e.g. 60:40 Al:V) to produce the useful Ti-6Al-4V alloy. This approach is relatively cheaper and results in competitive alloys. Moreover, this approach is open to the incorporation of reinforcing particles into the titanium powder prior to making the subsequent components2,3. The main sources of titanium powder for the blended elemental approach are the sponge product of the Kroll magnesium process and titanium scrap. Adversely, the surface of the titanium scrap is generally contaminated with grease, lubricating oil and/ or oxide film which may be transferred to the subsequent titanium powder. Hence additional processing stages are established to eliminate these sources of contamination, thereby increasing the cost of the process. The primary product purity is vital to subsequent alloy performance and the preservation of economic viability of the process is equally important; hence titanium powder for use in the blended elemental approach is mainly produced from titanium sponge1. In general, there are a number of important characteristics that a titanium powder must have to facilitate powder metallurgical consolidation. Firstly, the powder needs to be relatively fine. This ensures a high packing density, thereby decreasing porosity. This also assists in developing strong bonds during sintering, thereby increasing strength. The finer the powder the higher the final density and the stronger the component1,4. Secondly, the particles of the powder should be semi-spherical. Some angularity on particles can assist packing and sintering, but above a certain point angularity becomes counter-effective1. The particles may only have specific surface coatings or alterations as this may significantly affect the strength of the final components1,5. Finally, it is important that the particles are compositionally homogeneous because in the case of alloy powders, heterogeneity may compromise the benefit introduced by using an alloy1. 1.2 Basis of the current work

The processes used to prepare pure titanium powder for the blended elemental approach include chemical reduction (reduction of TiO2 by Mg), gas atomization, mechanical alloying, plasma-rotating electrode (PREP) and hydrogenation dehydrogenation (HDH). Amongst these processes, gas atomisation, PREP and HDH are the most common1. The powder produced by gas atomisation is spherical in shape and has a particle size distribution (PSD) range of 50 to 300 m which is globally competitive1. However, the process setup is relatively complicated. On the other hand, the powder produced by the PREP process is spherical and has a PSD range of 100 to 300 m. This powder has good flowing and packing properties and is thus ideal for high quality near net shapes1. However, it is relatively expensive6.

Page 293

The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative Light Metals Conference 2010 X Goso and A Kale

The current project followed the HDH process. The main objective of this work was to produce titanium powder for powder metallurgical consolidation to make titanium components by blended elemental approach. With titanium, as with other group IV elements, it is possible to introduce large quantities of hydrogen at elevated temperatures. Hydrogen reacts with titanium to form titanium hydride (TiH2) which is brittle and can be milled easily. TiH2 may contain a hydrogen content of 3.5% to 4.5% by weight1,7,8,9. For milling the brittle TiH2, amongst the options like ball milling, jet milling and wet milling, the dry ball milling with an argon gas blanket was found to be the most appropriate. It is simple and efficient to operate a mill in this configuration, allowing for easy variation in test conditions resulting in great flexibility in powder products. In addition, ball mills tend to produce a milled product with a large variation in particle size10. After sizing TiH2, the interstitial hydrogen is subsequently removed using a vacuum heat treatment (vacuum is used to eliminate the reaction of titanium with oxygen and nitrogen) to produce titanium metal powder1,9. When compared to other powder production methods, the HDH process can introduce higher levels of contaminants and makes the final powder less suitable for use in critical aerospace applications1. However, the ease with which the process setup is made makes it particularly well suited for preparing powders for the current work. In addition, milling of sponge via the HDH process gives much more flexibility with respect to manipulation of the PSD of the powder, an important consideration in the subsequent powder metallurgical consolidation1,7,8,9. In order to bench-mark the Ti powder to be produced, a survey of various commercially available Ti powder was conducted and the typical chemical composition of commercial titanium powder is given in Table 11. Both titanium hydride and titanium metal in fine powder form are highly explosive. It is important to avoid any condition that tends to suspend particles in the air. Precautions should also be taken to prevent the build-up of static electricity or the creation of sparks. It is mandatory to introduce an inert atmosphere of argon where dust clouds are likely to form. Nitrogen cannot be used because it reacts with titanium to form titanium nitride11. A hazard and operability (HAZOP) study was also conducted to identify and evaluate other potential personal and environmental risks associated with the envisaged experimental equipment layout. The results of this study showed that milled TiH2 and titanium metal should be handled in an argon-filled glove box, whenever possible, to respond to the safety risks associated with fine powder of titanium hydride and titanium metal. The content of oxygen in the glove box should be maintained below 5% to eliminate the potential hazards. Table 1: Typical chemical composition of commercial titanium powders (Mass %) Fe Titanium powder 2 0.20-0.50 H 0.01 C 0.08 N 0.03-0.05 O 0.18-0.40 Applications Industrial applications.

Experimental approach

This section gives a summary of the experimental equipment and work procedures.

Page 294

The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative Light Metals Conference 2010 X Goso and A Kale

2.1 Materials and samples Titanium sponge produced by the Kroll process was supplied by Insimbi Alloy Suppliers Ltd. (Pty). The Kroll sponge was in a particulate form with a top size of less than 3 mm. The sample was subjected to chemical analysis to assess the content of the minor elements results are summarised in Table 2. Mg, Cr, Fe, Co, and Ni in various titanium samples were determined by a Spectro citros vision model of inductively coupled plasma optical emission spectrometer (ICP-OES). For the determination of carbon, a combustion LECO technique in CS-200 determinator model was employed. Nitrogen and oxygen were determined by an ELTRA 0N900 O-N determinator. The chlorides were determined by an Ultra-violet spectrophotometer (UV) a DR Lange CADAS 50 s model. Hydrogen content in TiH2 and dehydrogenated powder was determined, at Bruker, by a G8 GALILEO analyser. The morphological and phase chemical compositions of various titanium samples were determined by Joel 840 scanning electron Microscopy (SEM) and Siemens D500 X-Ray powder diffraction (XRD) instruments, respectively. PSD analysis of the milled hydrogenated titanium sponge was done using a Malvern Mastersizer 2000. Table 2: Chemical composition of the as received titanium sponge (Mass %) Ti sponge 2.2 Mg 0.07 Cr 0.13 Fe 0.44 Co 0.16 Ni 0.07 C 0.03 N 0.01 O 0.24 Cl 0.81

Titanium metal powder production

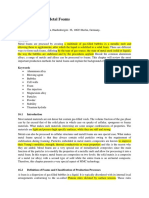

The flow diagram of the HDH process for the production of pure titanium powder is presented in Figure 1. As shown in the flow diagram, the HDH process is used to convert the titanium sponge to titanium powder. Hydrogenation of Kroll Ti Sponge Ti + H2 TiH2

600 C

Mill the TiH2 to ~ 150 m in a planetary mill or roller mill

Dehydrogenation of milled TiH2 powder (700C) TiH2 Ti + H2

vaccum

Figure 1: Flow diagram of HDH process for titanium powder production from sponge 2.2.1 Hydrogenation process

Discrete masses of 15 g of the titanium sponge were weighed in respective sample boats and placed at the centre of a 25 mm diameter quartz tube reactor in a horizontal tube furnace. Two sample boats were processed in each run making a total mass of 30 g per run. A high purity 75 mm alumina tube reactor was also used where an amount of 150 g of titanium sponge material was placed directly in the reactor. The inlet of the quartz or alumina tube was connected to a mass flow controller which was used to control the amount of gas (argon and hydrogen) passing through the reaction tube. The outlet of the reactor was connected to a heating organic oil (bubbler) to ensure that the system was sealed and that the small surplus hydrogen was not emitted directly to the atmosphere. The schematic drawing of the equipment set up is shown in Figure 2.

Page 295

The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative Light Metals Conference 2010 X Goso and A Kale

The reactor tube was purged with argon during the initial heat up period prior to the hydrogen blow. At the end of the set hydrogenation period, the system was cooled down to room temperature in argon atmosphere. The hydrogenated sample was removed from the tube furnace and weighed and the mass recorded. During the optimisation of the parameters of the hydrogenation process, the temperature was varied between 300 and 800C, and the reaction time was varied between 1 and 4 hours. The established optimum conditions for the hydrogenation of titanium sponge involve heating for 2 hours at a temperature of 600C in a flow of about 1572 ml/ min hydrogen through the sponge in a tube furnace.

Figure 2: Schematic drawing of a horizontal tube furnace 2.2.2 Milling of the hydrogenated material The hydrogenated material was milled in order to get a fine powder of a particle size range of 100 m to 1 m. In the initial experiments, a RETSCH planetary mill (PM 100 model) filled with hardened 10 mm steel balls was used. The filling of TiH2 into and subsequent sealing of a milling jar was conducted in an argon filled glove box. The atmosphere in the glove box was maintained at an oxygen level of less than 5%. The sealed milling jar was placed in a planetary mill as shown in Figure 3. The process involves milling a 50 g particulate TiH2 in a mill operating at optimal speed and filled with 100 X 10 mm steel balls. For the optimisation of the milling conditions, the milling time was varied between 5 and 30 minutes, and the mill rotation speed was varied between 300 and 500 rpm. The established optimum operating conditions of the planetary mill involve milling a 50 g particulate TiH2 with 100 X 10 mm steel balls, running at 500 rpm for 10 minutes (reverse rotation switched on stops after first 5 minutes for a minute and changes direction of rotation for the last 5 minutes). The optimum ball-to-powder ratio was 8.34.

Page 296

The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative Light Metals Conference 2010 X Goso and A Kale

Figure 3 Sealed milling jar in a RETSCH planetary mill a) b)

Figure 4 Photographic representation of Minteks roller mill - a) Mill drum on the two driving rolls, b) Discharge frame A roller (tumbling) ball mill, designed and fabricated by Mintek, was also used to mill the TiH2. A photographic representation of the roller mill is shown in Figure 4 (a and b). In this experiment, the roller mill jar containing 540 X 10 mm and 60 X 20 mm hardened steel balls and filled with 500 g of TiH2 was purged with argon for about 15 minutes to remove the traces of oxygen prior to the milling process. The mill was run at an optimal speed of 71 rpm (75% critical speed) at various time periods. The established optimum conditions for this larger scale milling involved milling 500 g of TiH2, with 540 X 10 mm and 60 X 20 mm hardened steel balls, running at 71 rpm (75% critical speed) for 10 minutes. The optimum ball-to-powder ratio was 8.49. 2.2.3 Dehydrogenation of the TiH2 powders

The TiH2 powders after milling with planetary and roller mills were dehydrogenated to get the respective final titanium powders. The milling jar of the planetary mill was removed and discharged in a sample container within the glove box purged with argon to ensure an environment oxygen level of below 5%. In this process, the jar was opened and the powder was cautiously (avoiding creating sparks) transferred into a labelled sample container using anti-static brushes. The sample was fed from the container into a retort outside the glove box (because the retort could not fit into the glove box). The retort was then sealed to ensure minimal exposure to atmospheric oxygen. The sealed retort connected to a vacuum pump system was placed in a muffle furnace. In the case of the roller mill, the powder was directly transferred into the retort, as shown in Figure 5. The arrangement allows for milling of the material under a protective argon

Page 297

The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative Light Metals Conference 2010 X Goso and A Kale

atmosphere, followed by transferring between the mill and the HDH retort while fully sealed in argon. As in the case of the planetary mill, the sealed retort was placed in a muffle furnace. For the optimisation of the parameters for the de-hydrogenation of TiH2, the residence time at the set temperatures of the furnace was varied between 1 and 36 hours. The established optimum conditions for the dehydrogenation process involve heating the sample in a muffle furnace at 700C, under vacuum (below 800 PA) for 36 hours. At the end of the set dehydrogenation period the system was cooled down to room temperature while under vacuum. The pure titanium powder was then cautiously removed from the retort and weighed. It was then stored in the glove box. The respective sub samples of the planetary and roller mill powders were analysed by XRD and SEM to assess the quality of the final powders.

Mill Valve from mill Connection pipe Valve to retort Retort Figure 5: Graphic design of a manufactured roller mill closed system 2.3 Safety

When planetary milled TiH2 powder was transferred inside the glove box while the oxygen content was around 8%, sparks were observed and the material became gradually red. The small fire was covered with silica sand and was easily extinguished. Hence, it was decided that the treatment of fine TiH2 and pure titanium be conducted at oxygen levels below 5% whenever possible. 3 Results and discussions

In the interests of brevity, only results of the optimum conditions are reported here. 3.1 Bulk chemical analysis

The results of chemical compositions of the titanium powder samples produced by the HDH process at Mintek are given in Table 3. The hydrogen content of 3.50% in the hydrogenated titanium sponge was achieved; this indicates that the hydrogenation process was very effective as hydrogen content falls within the literature range.

Page 298

The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative Light Metals Conference 2010 X Goso and A Kale

As shown in Table 3, the content of carbon in Minteks titanium powder is higher than in commercially available powders (Table 1). The source of carbon in the process is not known as its content in the starting sponge was lower than in commercial powders (Table 2). However, the contents of other elements in this titanium powder meet the specifications. Hence, upon solving the carbon setback, the produced powder may find various applications including in the manufacturing of linings and airplane parts. Table 3: Chemical composition of the titanium powder produced by HDH process at Mintek Mg (%) 0.06 Fe (%) 0.44 H (%) 3.50 112 ppm C (%) 0.99 N (ppm) 7.05 O (ppm) 110 Cl (ppm) <50

TiH2 Ti powder

Note:

<50 ppm: the analyte concentration could not be accurately quantified as it is below its Limit of Detection (50 ppm) : analysis was not conducted

3.2

Particle size distribution

The statistical analyses of the PSD of the planetary and roller milled titanium hydride are given in Table 4. The mean diameter of the titanium hydride powder, D[4,3], is 27.74 and 41.84 m for the planetary mill and roller mill, respectively. These statistical results show that the planetary mill produces a finer powder than the roller mill. The ball-to-powder ratio of the planetary mill is 8.34 which is slightly lower than that of the roller mill which is 8.49. There is a slight difference in the ball-to-powder ratios of the planetary and roller mills. Hence the fact that the particle size of the planetary milled powder is relatively small may primarily be attributed to the higher energy intensity used by the planetary mill (milling of a relatively smaller sample at a relatively high speed using small size diameter steel balls). However, both planetary and roller mills proved effective in the size reduction of TiH2 for use in powder metallurgy. Table 4: Summary of the statistical analysis of the PSD for the milled titanium hydride by planetary mill roller mills Planetary mill D10, m D50, m D90, m 3.3 Microstructural characterisation 1.210 8.809 61.96 Roller mill 8.203 30.80 102.1

This section of the report gives a summary of XRD and SEM results of various titanium samples. The products of the current work are compared to the available commercial materials. 3.3.1 X-Ray diffraction

The results of the phase composition of titanium hydride after milling are given in Figure 6. The diffractogram of the powder shows that the sample after milling only consisted of

Page 299

The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative Light Metals Conference 2010 X Goso and A Kale

titanium hydride phase. (Paragraph has been rephrased to refer to just 1 diffractogram as the other one was removed as per the recommendation) The diffractograms of dehydrogenated titanium hydride powders milled by planetary and roller mills are given in Figure 7 (a and b). Fine titanium powder is highly reactive, and may easily react with oxygen and nitrogen in the atmosphere. The evidence of oxygenated and nitrogenised titanium in Figure 7 might be a consequence of this high reactivity of titanium. The chemical analysis results do not show any significant oxygen and nitrogen contents in the dehydrogenated powder. Hence it is believed that the oxygen contamination is not inherent to the process, but on the XRD subsamples. Oxygen has a detrimental effect on the tensile ductility, fatigue strength, and stress corrosion in commercial pure titanium and various titanium alloys. Thus such contamination should be minimised.

TiH2

005

Lin (C ounts)

2-Theta - Scale

JMO1021 - File: JMO1021.raw - Type: 2Th/Th locked - Start: 5.000 - End: 80.000 - Step: 0.020 - Step time: 1. s - Temp.: 25 C (Room) - Time Started: 0 s - 2-Theta: 5.000 - Theta: 2.500 - Chi: 0.00 - Phi: 0.00 Operations: Background 3.020,1.000 | Import 25-0982 (I) - Titanium Hydride - TiH1.924 - Y: 29.17 % - d x by: 1. - WL: 1.5406 - 0 -

Figure 6: X-Ray diffractogram of the milled hydrogenated Titanium sponge by a) planetary mill, and b) roller mill 3.3.2 Scanning electron microscopy

Figure 8 shows the scanning electron micrographs of commercially available and Mintek produced titanium hydride powders. There is a clear similarity in shape between these powders. The hydrogenated sponge particles show some angularity (which is needed in the metallurgical consolidation work), which indicates that it is more brittle. Flat cleavage facets are evident on the hydride particles from the two producers. The SEM micrographs of the planetary and roller milled titanium hydride are shown in Figure 9. The micrographs show that both powders are angular in shape. The angularity in the hydrogenated powders is transferred to the subsequent dehydrogenated powders, as shown in Figure 10. The planetary and roller milled powders are comparable to the commercial powder in terms of angularity. However, the morphology of the particles of

Page 300

07

06

05

04

03

02

01

004 003 002 001 0

The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative Light Metals Conference 2010 X Goso and A Kale

the planetary milled powder appears to be more irregular than the very angular shapes of the uncrushed titanium hydride. However, on closer inspection, it is evident that this is caused by the adhesion of very fine angular particles on the surfaces of larger particles, or by the agglomeration of fine particles. The adhesion of fine particles could be due to high vacuum and high temperature operations during dehydrogenation. (Put writing and figures separately)

160 150 140 130 120 110 100

a)

Lin (Counts)

90 80 70 60 50 40 30 20 10 0 5 10 20 30 40 50 60 70 8

2-Theta - Scale

File: HTC15 3.raw - Type: 2Th/Th locked - Start: 5.000 - End: 80.000 - Step: 0.020 - Step time: 1. s - Temp.: 25 C (Room) - Time Started: 0 s - 2-Theta: 5.000 - Theta: 2.500 - Chi: 0.00 - Phi: 0.00 - X: 0.0 m Operations: Import File: HTC15 3.raw - Type: 2Th/Th locked - Start: 5.000 - End: 80.000 - Step: 0.020 - Step time: 1. s - Temp.: 25 C (Room) - Time Started: 0 s - 2-Theta: 5.000 - Theta: 2.500 - Chi: 0.00 - Phi: 0.00 - X: 0.0 m Operations: Smooth 0.310 | Import 44-1294 (*) - Titanium - Ti - Y: 26.31 % - d x by: 1. - WL: 1.5406 - 0 - I/Ic PDF 0.9 - S-Q 57.6 % 76-1644 (C) - Titanium Oxide - Ti3O - Y: 85.75 % - d x by: 1. - WL: 1.5406 - 0 - I/Ic PDF 4. - S-Q 42.4 % -

b)

2-Theta - Scale

JMO1022 - File: JMO1022.raw - Type: 2Th/Th locked - Start: 5.000 - End: 80.000 - Step: 0.020 - Step time: 1. s - Temp.: 25 C (Room) - Time Started: 0 s - 2-Theta: 5.000 - Theta: 2.500 - Chi: 0.00 - Phi: 0.00 Operations: Background 0.457,1.000 | Import 87-0626 (C) - Osbornite, syn - TiN.76 44-1294 (*) - Titanium - Ti 25-0982 (I) - Titanium Hydride - TiH1.924 40-1245 (N) - Titanium Hydride - TiH 76-1644 (C) - Titanium Oxide - Ti3O -

Figure 7: X-Ray diffractograms of the, a) Planetary milled titanium powder and b) Roller milled titanium powder

Page 301

07

06

05

04

03

02

01

0 01 02 03 04 05 06 07 08 09 001 011 021 031 041 051 061 071 081 091 002 012 022 032 042 052 062 072 082 092

Lin (C ounts)

The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative Light Metals Conference 2010 X Goso and A Kale

a)

b)

Figure 8: SEM micrograph of TiH2 powder produced at a) AG Materials Inc. [website: http://www.agmaterials.com/products/titaniumhydride.html], and b) Mintek a) b)

Figure 9: SEM micrographs of milled titanium hydride by a) planetary mill, and b) roller mill a) a)

b)

c)

Figure 10: SEM micrograph of the, a) Commercial titanium powder, b) Planetary milled titanium powder and c) Roller milled titanium powder 3.4 Comparison of planetary and roller mills A comparison of the suitability of the two types of milling technology for the production of titanium powder for metallurgical consolidations was conducted. The planetary mill has shown great capability for the production of titanium powder for metallurgical consolidations. However the direct milling costs largely depend on the capacity of the mill. The planetary mill is a laboratory scale piece of equipment. It would be relatively costly to increase the capacity of this mill. The energy consumption in this kind of milling is relatively high.

Page 302

The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative Light Metals Conference 2010 X Goso and A Kale

As opposed to the planetary mill, it is much easier to scale up the roller mill, thus reducing the running cost. At similar operational times, the unit milling cost of TiH2 by the planetary mill would be about six times that of the roller mill. One of the major contributors in the cost of the planetary mill is the high electrical power consumption. 4 Conclusion

Laboratory scale tests were conducted to produce titanium powder by HDH process. The hydrogenation and dehydrogenation stages of the process were optimised. Two ball milling technologies namely the planetary and roller mills were evaluated for the TiH2 particle size reduction to produce a suitable titanium powder. Both planetary and roller mills produced sufficiently fine titanium powder with mean diameters, D[4,3] of 27.74 m and 41.84 m, respectively. The powder particles were angular in shape and there was no evidence of detrimental coating. However, the planetary mill powder may only be produced at laboratory scale at relatively high costs. Conversely, roller mill may easily be scaled up to produce a significant amount of powder. The chemical analysis results showed that the elemental contents of the produced titanium powder matched the specifications of commercial titanium powder, except for the high carbon content. Nevertheless, the powder has been tested in mechanical alloying and has been found suitable for making powder metallurgical compacts. Acknowledgements The authors thank Mr A McKenzie and Dr H Dong for their technical assistance. References 1. 2. 3. 4. 5. 6. 7. TZMI & EHK Technologies 2007 Imam M.A., Froes F.H. (2010) Low Cost Titanium and Developing Applications. JOM, 62 (5). p 17 21 Moxson V.S., Senkov O.N., Froes F.H. (2000) Innovations in Titanium Powder Processing. JOM 52 (5). p 24 26 Crowley G. (2003) Low cost titanium. Advanced materials and processes. p 25 27 Segall A.E., Papyrin A.N., Conway J.C. jr., Shapiro D. (1998) A Cold-Gas Spray Coating Process for Enhancing Titanium. JOM, 50. p 52 54 Roskill 2007 Bobet J., Even C., Quenisset J. (2003) On the Production of Ultra-Fine Titanium Hydride Powder at Room Temperature. Journal of Alloys and Compounds, 348. p 247 251 Wonsik L., Jinman J., Sehyun K. (2008) Manufacturing Method for Titanium hydride powders. World intellectual Property Organisation, Patent number WO 2008/030029 A1. p 1 8 Eiichi F., Satoshi S. (2001) Titanium-Base Powders and Process for Production of the Same. US Patent 6168644. p 1 8. Brochure: Retsch GmbH, Rheinische Strae 36, 42781 Haan, Germany, www.retsch.com (2009/03/23) Poulsen E. (2000) Safety-related problems in titanium industry in the last 50 years. JOM, 52. p 13 17

Page 303

8.

9. 10. 11.

The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative Light Metals Conference 2010 X Goso and A Kale

The Authors

Xolisa Camagu Goso, Scientist, Mintek I completed an MTech degree in chemistry at the University of Johannesburg, in December 2007. My masters project, funded and executed at Mintek, involved uncertainty evaluation studies on certification of reference materials, and method development for the determination of minor elements in PGM smelter samples by ICPMS. I started working for Mintek in January 2008 as a scientist in training. I am currently working as a scientist for the Pyrometallurgy division. As a project coordinator, I have been involved in various projects including lab scale smelting production of ferrochrome and nickel. I have also been involved in various Ti development work including the upgraded slag (UGS), 1kg Kroll and HDH processes, as well as the purification of crude titanium tetrachloride. My responsibilities include taking on the role of chief investigator of small to medium sized projects from proposal stage (planning) through execution (arrangement and coordination of all resources and actions required) up to the writing of the final project report as a deliverable. The Author

Aditya Kale, Principal Engineer, Mintek Worked in various specialty chemical industries as Lead Process Engineer, Project Incharge and Operations Executive for more than 11years. Area of Specialization includes HIGH TEMPERATURE CHLORINATION and FLUID BED OPERATIONS. Worked with the worlds 2nd largest producer of TiO2 pigment, Cristal Global Saudi Arabia, as Lead Process Engineer at their TiO2 pigment manufacturing plant. Project incharge for the process development for ilmenite beneficiation at the Indian Operations of Heubach Color, (Germany multinational). Also worked as the Operations

Page 304

The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative Light Metals Conference 2010 X Goso and A Kale

executive for Aluminium chloride and pharmaceutical grade Aluminium hydroxide plants. Presently, working with Mintek on titanium related projects since 2007.

Page 305

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Titanium Hydride For High-Temperature Thermal Energy Storage in Solar-Thermal Power StationsDocument6 pagesTitanium Hydride For High-Temperature Thermal Energy Storage in Solar-Thermal Power StationsSonia Urrutia CisternaPas encore d'évaluation

- An Overview of Aluminum Foam Production MethodsDocument8 pagesAn Overview of Aluminum Foam Production Methodsgouhua yuanPas encore d'évaluation

- CLS Aipmt-15-16 XIII Che Study-Package-3 Set-1 Chapter-9 PDFDocument34 pagesCLS Aipmt-15-16 XIII Che Study-Package-3 Set-1 Chapter-9 PDFAQIBPas encore d'évaluation

- Foaming of Friction Stir Processed Al /mgco3 Precursor Via Ame HeatingDocument27 pagesFoaming of Friction Stir Processed Al /mgco3 Precursor Via Ame HeatingArshad SiddiqueePas encore d'évaluation

- CLS Aipmt 19 20 XII Che Study Package 1 Level 1 Chapter 1Document20 pagesCLS Aipmt 19 20 XII Che Study Package 1 Level 1 Chapter 1ShubanghiPas encore d'évaluation

- Sutarno IPMC ITB2017 1.4974439Document11 pagesSutarno IPMC ITB2017 1.4974439Samuel ArelianoPas encore d'évaluation

- PhysicsDocument34 pagesPhysicsKoustav Pal70% (10)

- A Presentation On Utilization of Metal Hydrides For Hydrogen Storage in Electric VehiclesDocument38 pagesA Presentation On Utilization of Metal Hydrides For Hydrogen Storage in Electric VehiclesDev AnandPas encore d'évaluation

- SiC Content Effect on Foaming & Mechanical Properties of Remelted Al356/SiC CompositeDocument7 pagesSiC Content Effect on Foaming & Mechanical Properties of Remelted Al356/SiC Compositesweety kumariPas encore d'évaluation

- MenuCommands EDocument30 pagesMenuCommands Erahul kumarPas encore d'évaluation

- Biomaterials For Hip Implants - Important Considerations Relating To The Choice of MaterialsDocument14 pagesBiomaterials For Hip Implants - Important Considerations Relating To The Choice of MaterialsLokesh RathiPas encore d'évaluation

- Aluminum Foams Lectures TALATDocument24 pagesAluminum Foams Lectures TALATMiguel PradaPas encore d'évaluation

- Manufacturing Routes For Metallic Foams: John BanhartDocument6 pagesManufacturing Routes For Metallic Foams: John BanhartJuan Jose Martinez PadillaPas encore d'évaluation

- Metal Foams - Manufacture and Physics of FoamingDocument17 pagesMetal Foams - Manufacture and Physics of FoamingDaniela Silva MolinaPas encore d'évaluation

- Soloki-Esmailian2015 Article Carbonate-FoamingAgentsInAlumiDocument6 pagesSoloki-Esmailian2015 Article Carbonate-FoamingAgentsInAlumiAna ReyesPas encore d'évaluation

- 6i TitaniumDocument28 pages6i TitaniumRajesh PatelPas encore d'évaluation

- Processes For Recycling: 4.4.1.2.1 Conventional Kroll ProcessDocument14 pagesProcesses For Recycling: 4.4.1.2.1 Conventional Kroll Processelma watPas encore d'évaluation

- Blowing AgentDocument12 pagesBlowing AgentHimanshu PainulyPas encore d'évaluation

- 10.1016/j.powtec.2017.06.053: Powder TechnologyDocument46 pages10.1016/j.powtec.2017.06.053: Powder TechnologychandiniPas encore d'évaluation

- As DDFDocument36 pagesAs DDFBharati patilPas encore d'évaluation

- Banhart 2017Document17 pagesBanhart 2017Armanda PutraPas encore d'évaluation

- Metal Foam ThesisDocument7 pagesMetal Foam Thesistmexyhikd100% (2)