Académique Documents

Professionnel Documents

Culture Documents

Exhaust Gas Re Circulation 3 23379 High Pressure 3 12193 PIS

Transféré par

florin1975aprilieDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Exhaust Gas Re Circulation 3 23379 High Pressure 3 12193 PIS

Transféré par

florin1975aprilieDroits d'auteur :

Formats disponibles

Page 1 of 11 23379 / 12193 WYNN'S EXHAUST GAS RECIRCULATION 3 & HIGH PRESSURE 3 Date of Issue October 2008

PRODUCT INFORMATION SHEET

WYNN'S EXHAUST GAS RECIRCULATION 3 AEROSOL & HIGH PRESSURE 3 Product Number: 23379 12193

Exhaust Gas Recirculation 3 and High Pressure 3 - Tank treatments

Instantly cleans the air intake system and inlet valves Cleans EGR valve Cleans injectors Assures good starting properties Restores stable idle and acceleration Provides optimal power, torque Lowers fuel consumption and exhaust emissions

1.

a)

INTRODUCTION

Why EGR in diesel engines?

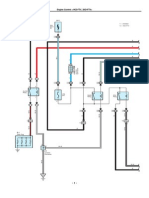

Improved fuel systems combined with soot filters and/or catalytic converters reduce CO, HC and soot emissions. The improved fuel systems lead to poor fuel / air mixtures and lower fuel consumption. These mixtures result in higher combustion chamber temperatures and increased NOx emissions. The EGR (Exhaust Gas Recirculation) system leads exhaust gases to the intake air manifold, enriches the mixture in the combustion chamber and decreases the internal combustion chamber temperature. This results in a reduction of NOx emissions. Most cars meeting the EURO3/EURO4/EURO5 specifications are equipped with this system. It is used on all types of diesel fuel systems: in-line pumps, rotary pumps, common rail, pump injectors

Wynn's Australia Pty Ltd, 100 Hassall Street, Wetherill Park NSW 2164 Tel: (02) 9828 0900 Fax: (02) 9725 4698 Email wynnsaus@wynns.net Website www.wynns.net

ABN 73 000 370 150

Page 2 of 11 23379 / 12193 WYNN'S EXHAUST GAS RECIRCULATION 3 & HIGH PRESSURE 3 Date of Issue October 2008

b)

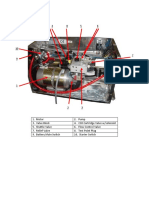

Diesel air intake manifold and inlet valves

In diesel engines there are 2 ways of injecting the fuel: Indirect injection: The fuel is injected in a small pre-chamber. The combustion starts in this pre-chamber en continues in the combustion chamber. This system has a relatively simple construction. Piston heads are mainly flat. Injection timing is less sensitive. Injectors are single hole types. Injection pressure is low. Due to heat losses in the pre-chamber, combustion is not that efficient. Power and torque are low, fuel consumption is high. The longer available time for combustion results in lower engine noise.

Direct injection: The fuel is directly injected in the combustion chamber. This system has a more complicated construction. Piston heads have a special shape to create a poor fuel / air mixture in a short period. Injection timing is very sensitive. Multiple injections per stroke are possible. Injectors are multi-hole type, injection pressures are higher. Combustion is very efficient. Power and torque are high, fuel consumption is low. Engine noise is higher, but can be reduced with multiple injections.

Page 3 of Total 11 51805 / 51820/51850 WYNN'S HEAVY DUTY ENGINE COOLANT (PRE-MIX) Date of Issue April 2008

2. PROBLEMS

a) Inlet valve position

Both systems inject in an area, after the inlet valve position. Injected fuel and cleaning products applied through the fuel systems do not reach the intake air manifold and inlet valves. These components cannot be cleaned through tank treatments or products applied through the fuel injection system.

b) EGR in diesel

The exhaust gases returned to the air intake manifold and inlet valves are hot and contain impurities like soot particles. This results in a large accumulation of carbon / tar like deposits in this area. Leading to insufficient and irregular air flow. The fuel / air mixture is disturbed, which causes problems of engine operation. The EGR valve also becomes very dirty. The opening distance is reduced and this can even lead to valve sticking.

c) Diesel air intake manifold and inlet valves

In engines without EGR system the air intake manifold and inlet valves will mainly dirty up by the oil from the PCV (Positive Crank Ventilation). So even engines without EGR, can have dirty inlet valves and air intake manifold. In engines with EGR system the dirty exhaust gases will increase deposit formation in this area, on top of the fouling due to the PCV. The fouling of the air intake manifold and inlet valves will lead to disturbance of the air management towards the combustion chamber.

d) The consequences for the driver are:

Starting problems Irregular idle Lack in acceleration Loss of power Increased fuel consumption Higher exhaust emissions EGR system failure warning

Page 4 of Total 11 51805 / 51820/51850 WYNN'S HEAVY DUTY ENGINE COOLANT (PRE-MIX) Date of Issue April 2008

3. SOLUTION

The perfect engine cleaning is a two-fold process for all diesel engines: EGR3 200 ml Aerosol Preventive and curative treatment The EGR3 aerosol (marked orange in the schedule) cleans the dry part of the engine: the air intake manifold and the inlet valves. If applied in the right way cleaning of the EGR valve can be obtained as well DP3 500 ml Liquid Preventive use or after-treatment for diesel engines with in-line or rotary injection pump HP3 500 ml Liquid Preventive use or after-treatment for diesel engines with common rail or pump injectors >> The DP3 and HP3 Liquid Treatments (marked yellow in the schedule) cleans the fuel system, the wet part of the engine.

>>

Page 5 of Total 11 51805 / 51820/51850 WYNN'S HEAVY DUTY ENGINE COOLANT (PRE-MIX) Date of Issue April 2008

>> HP3-Liquid

Wynn's HP3 is a chemical treatment for diesel engines with direct injection fuel systems, equipped with a common rail system or pump injectors Recommended for all diesel engines, as well new as used.

PREVENTIVE USE OR AFTERTREATMENT

Properties Inhibits ageing (oxidation) of the diesel fuel caused by high fuel temperatures. Prevents clogging of the fuel-feed lines and fouling of the fuel filter. Compensates for lack of lubricity in low sulphur fuels and protects stressed metal surfaces in the high-pressure pump and injectors against wear. Cleans the fuel pump, the common rail and the injectors. Restores the original spray pattern resulting in a better combustion. Reduces black exhaust smoke. Does not harm catalytic converters or particulate filters.

Directions Add to the diesel tank. One bottle of 500 ml treats 50 litres of diesel fuel. Repeat the treatment every 10.000 km or together with spray usage for after treatment

>> EGR3 Aerosol Air intake, Inlet Valve and EGR Cleaner

Wynn's EGR3 is an aerosol, developed for cleaning the intake air system of all diesel engines. Wynn's EGR3 is recommended to be used at each service interval, to maintain cleanliness of the intake air manifold, inlet valves and EGR valve of diesel engines

PREVENTIVE AND CURATIVE USE

Properties Strong solvents provide immediate and strong cleaning of air intake system and inlet valves, EGR valve and connecting tube between EGR valve and air intake manifold. Strong power jet spray to support cleaning action. Dissolves gum, lacquer, carbon and deposits. Easy to use, cleaning is carried out in 5-10 minutes. No dismantling of components necessary. (only for direct cleaning EGR valve) Restores or maintains the engine performances. Eliminates and avoids starting problems. Improves acceleration properties.

Page 6 of Total 11 51805 / 51820/51850 WYNN'S HEAVY DUTY ENGINE COOLANT (PRE-MIX) Date of Issue April 2008

Lowers exhaust emissions.

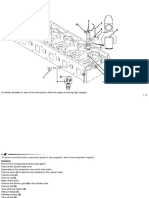

Directions A. Cleaning of air intake manifold and inlet valves 1. Start the engine and let it warm up. Remove a flexible hose in the air intake system, situated between the turbocharger/ intercooler and the air intake manifold. 2. Let engine run at 2000 rpm. 3. With warm engine, spray the product into the air intake manifold. 4. Spray with short intervals to avoid uncontrolled rise of rpm and diesel knocking. 5. After each pulverisation, wait until original set rpm is regained. 6. If necessary accelerate to avoid engine stalling. 7. Continue until the 200 ml of product in the aerosol are consumed. 8. Let the engine run at idle during a few minutes. 9. After this idling period, accelerate the engine approximately 5 to 10 times. Do not exceed 3000 rpm. Or drive for 5 to 10 km with the car. 10. Before stopping the engine, let it run again for at least 1 minute. Put hose back in place. B. Cleaning of air intake system before turbocharger and compression part of turbocharger Act in the same way, but spray the product in before the turbocharger. Remove the air filter to reach this area. C. Preventive cleaning of EGR valve

C1. If the valve is close to the injection point of the product, act the same way as in A

Page 7 of Total 11 51805 / 51820/51850 WYNN'S HEAVY DUTY ENGINE COOLANT (PRE-MIX) Date of Issue April 2008

C2. If the valve is at remote distance to the injection point of the product, use an extension tube (available in option) to get closer to the valve, then act the same way as in A

D. Curative cleaning of very dirty EGR valve 1. Dismantle the EGR valve (housing). 2. Spray the product directly on the valve, housing and other components, until these parts are very wet. 3. Let the product act a few minutes. 4. Spray again on the parts until all the dirt has been removed. 5. It can help to remove the dirt with a piece of cloth or paper tissue. 6. Dry the parts with compressed air, cloth or paper tissue. Usage Method A, B and C Every maintenance (15 000-20 000 km) Method D At initial first treatment on car with high mileage Note: For direct and strong cleaning of the fuel system of diesel engines, the Wynns FuelServe with Diesel System Purge liquid can also be used. Due to the fuel system technology, this will only clean injectors and combustion chamber.

Page 8 of Total 11 51805 / 51820/51850 WYNN'S HEAVY DUTY ENGINE COOLANT (PRE-MIX) Date of Issue April 2008

4. TEST RESULTS

Clean up test VW Bora 1.9 TDI at the Belgian Technology Institute De Nayer (method A)

before 115,4 271,9 after 118,7 276,6 change 3,3 4,7

engine power in HP engine torque in Nm

Clean up test VW Vento 1.9 TD at Technology Institute De Nayer (method A)

Before

treatment

After treatment

Clean up test Citron C5 HDI at Wynns (method A)

one week after treatment 0,92

soot in m-1

before 2,89

after 0,88

change in % -69,6

change in % -68,2

Page 9 of Total 11 51805 / 51820/51850 WYNN'S HEAVY DUTY ENGINE COOLANT (PRE-MIX) Date of Issue April 2008

Clean up test Hyundai Elantra at Hyundai Belgium (method A)

Before treatment

soot in m-1 before 4,15 after 2,30

After treatment

change in % -44,6

Clean up test Mitsubishi Pajero 3.2 TDI (method D) at Wynns Direct EGR cleaning:

Before treatment

After treatment

Clean up test Nissan Micra 1.5 dCi 68 HP (method C) at Nissan workshop

Before treatment

After treatment

Page 10 of Total 11 51805 / 51820/51850 WYNN'S HEAVY DUTY ENGINE COOLANT (PRE-MIX) Date of Issue April 2008

Clean up test Nissan Micra 1.5 dCi 68 HP (method D) at Nissan workshop

Before treatment

change in % after C -63,2

After treatment

one week after treatment 2,50 change in % after D -73,7

soot in m

-1

before 9,50

after 3,50

Clean up test Nissan Patrol 3.0 TD (method D) at Nissan workshop

Before treatment

After treatment

Clean up test Opel Zafira 2.0 Turbo DI 16V (method A) in Italy

change in % after C -67,34

soot in m

-1

before 3,46

after 1,13

Page 11 of Total 11 51805 / 51820/51850 WYNN'S HEAVY DUTY ENGINE COOLANT (PRE-MIX) Date of Issue April 2008

5. CONCLUSION

1. Wynn's Exhaust Gas Recirculation 3 can de used to clean the air intake system of ALL diesel engines: Indirect injection Direct injection In-line injection pumps Rotary injection pumps Mechanical or electronic steering Common rail Pump injectors

2. It cleans and keeps clean the "dry part" of the diesel fuel system without dismantling.

3. It can be used to clean dismantled parts thoroughly such as EGR valve and turbocharger.

4. In combination with Diesel Power 3 or High Pressure 3 it provides a complete cleaning of the diesel fuel system.

5. The treatment preserves a good operation of the fuel system with Stable idle Good accelerations High power and torque Low fuel consumption Low exhaust emissions 6. An additional spray nozzle helps to reach parts to be cleaned.

Vous aimerez peut-être aussi

- Power Pack View PDFDocument1 pagePower Pack View PDFflorin1975apriliePas encore d'évaluation

- Catalogo Inglese 01 2017 Internet PDFDocument76 pagesCatalogo Inglese 01 2017 Internet PDFflorin1975apriliePas encore d'évaluation

- AHT Trouble Shooting PDFDocument6 pagesAHT Trouble Shooting PDFflorin1975apriliePas encore d'évaluation

- 3123, 4117 Produktovy List 1 PDFDocument2 pages3123, 4117 Produktovy List 1 PDFflorin1975apriliePas encore d'évaluation

- Mann Hummel Air Cleaners enDocument132 pagesMann Hummel Air Cleaners enflorin1975apriliePas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Lister LPW Marine Spec SheetDocument2 pagesLister LPW Marine Spec SheetMartyn PitmanPas encore d'évaluation

- CM2 Spareparts CatalogueDocument60 pagesCM2 Spareparts CataloguepapatangocomercialPas encore d'évaluation

- QSK60-G6 Epa Tier 2Document3 pagesQSK60-G6 Epa Tier 2ivan1989104Pas encore d'évaluation

- Engine Components For Cummins Series QSB 6.7QSB 4.5ISB - 58467 PDFDocument1 pageEngine Components For Cummins Series QSB 6.7QSB 4.5ISB - 58467 PDFFernando LejarazoPas encore d'évaluation

- Reciprocating EnginesDocument3 pagesReciprocating EnginesvivaboyPas encore d'évaluation

- R32.engine - Manual Ca18i, Rb20e, Rb20de, Rb20det, Rb25de & Rb26dettDocument580 pagesR32.engine - Manual Ca18i, Rb20e, Rb20de, Rb20det, Rb25de & Rb26dettNick Viccajee100% (1)

- Common Rail Diesel Diagnostics in Shropshire & Mid Wales: CR Diesel Engine RepairDocument8 pagesCommon Rail Diesel Diagnostics in Shropshire & Mid Wales: CR Diesel Engine RepairMügïshá ÆlfiePas encore d'évaluation

- Intake and Exhaust Manifold DesignDocument28 pagesIntake and Exhaust Manifold DesignDarius Toth100% (3)

- Marine Propulsion Engine: 1678 BKW (2250 BHP) at 1800 RPMDocument2 pagesMarine Propulsion Engine: 1678 BKW (2250 BHP) at 1800 RPMResul UygunPas encore d'évaluation

- Cylinder Head Relief ValveDocument3 pagesCylinder Head Relief ValveHrishikesh MorePas encore d'évaluation

- Hilux 1KD y 2KDDocument11 pagesHilux 1KD y 2KDJotaz V. Suarez0% (1)

- 2015 KTM 250 Exc-F XC-W Six Days ManualDocument329 pages2015 KTM 250 Exc-F XC-W Six Days ManualRodrigo JuniorPas encore d'évaluation

- Tad1642ve PartsDocument444 pagesTad1642ve PartsEmanuel Nicolas VillarruelPas encore d'évaluation

- How Does Turbo Intercooler WorkDocument1 pageHow Does Turbo Intercooler WorkPerfect Love BouquetPas encore d'évaluation

- Volkswagen W8 EngineDocument2 pagesVolkswagen W8 EngineAve FenixPas encore d'évaluation

- SSP 455 2.0l TDI Engines in The T5 2010Document48 pagesSSP 455 2.0l TDI Engines in The T5 2010pedpabagu100% (1)

- Agricultural Engine Construction-Wei ShengliDocument43 pagesAgricultural Engine Construction-Wei ShengliTakudzwa TamirepiPas encore d'évaluation

- Qual Fast Performance Catalog 10-2022-NEDocument24 pagesQual Fast Performance Catalog 10-2022-NEAlanCarpioPas encore d'évaluation

- Man B&W WarningDocument284 pagesMan B&W WarningMarcin SrokaPas encore d'évaluation

- Workshop Manual Datsun 1300 1600Document104 pagesWorkshop Manual Datsun 1300 1600Aldher Sama100% (1)

- Carburetion System PDFDocument8 pagesCarburetion System PDFMahmud SaikatPas encore d'évaluation

- Yamaha DT 250 Microfiche - 1976Document58 pagesYamaha DT 250 Microfiche - 1976rabu64Pas encore d'évaluation

- 2017 EPA Tier3 Exhaust Emission - C60Document1 page2017 EPA Tier3 Exhaust Emission - C60Carlos AlbertoPas encore d'évaluation

- DCT CodeDocument9 pagesDCT Codemrx200Pas encore d'évaluation

- Valve Timing DiagramDocument17 pagesValve Timing DiagramAnush R AminPas encore d'évaluation

- Engine Lubrication: Click On The Applicable Bookmark To Selected The Required Model YearDocument14 pagesEngine Lubrication: Click On The Applicable Bookmark To Selected The Required Model YearRogério MorenoPas encore d'évaluation

- TD90 Straddle Mount PDFDocument747 pagesTD90 Straddle Mount PDFAndreas AndryPas encore d'évaluation

- Mechanical MCQsDocument76 pagesMechanical MCQsAnonymous aTK5Le49dRPas encore d'évaluation

- L6 Introduction To Cycle Analysis Second Law of Thermodynamics 6 Hrs. To Be Distributed - NewDocument25 pagesL6 Introduction To Cycle Analysis Second Law of Thermodynamics 6 Hrs. To Be Distributed - NewJohn Paul AbanPas encore d'évaluation

- Fuel Injectors: Denny Schroeter Injectors / Removal / Fitting 25/01/23Document14 pagesFuel Injectors: Denny Schroeter Injectors / Removal / Fitting 25/01/23Евгений МуллаяновPas encore d'évaluation