Académique Documents

Professionnel Documents

Culture Documents

SSP-M003 Thermal Isolation and Lagging

Transféré par

Binh DaoDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SSP-M003 Thermal Isolation and Lagging

Transféré par

Binh DaoDroits d'auteur :

Formats disponibles

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard

Specifications

Page i

PART IV - STANDARD SPECIFICATIONS M-003 THERMAL INSULATION AND LAGGING

TABLE OF CONTENTS 1 2 3 3.1 3.2 3.3 3.4 4 4.1 4.2 4.3 4.4 4.5 4.6 4.6.1 4.6.2 4.6.3 4.7 4.8 4.8.1 4.8.2 4.8.3 4.8.4 4.9 4.9.1 4.9.2 4.10 4.11 4.12 4.13 SCOPE OF WORK ........................................................................................................................................ 1 CODES AND STANDARDS ......................................................................................................................... 1 DESIGN AND OPERATING CONDITIONS............................................................................................. 1 GENERAL ........................................................................................................................................................ 1 TYPE OF INSULATION ................................................................................................................................. 1 DESIGN CRITERIA ........................................................................................................................................ 2 DESIGN LOADS ............................................................................................................................................. 2 DETAILED REQUIREMENTS ................................................................................................................... 2 GENERAL ........................................................................................................................................................ 2 MATERIALS.................................................................................................................................................... 3 INSULATION FASTENING ........................................................................................................................... 4 LAGGING ........................................................................................................................................................ 5 PIPING INSULATION .................................................................................................................................... 6 EQUIPMENT INSULATION .......................................................................................................................... 6 Vessels and Heat Exchangers ........................................................................................................................... 7 Pumps: ............................................................................................................................................................... 7 Equipment Lagging: ......................................................................................................................................... 7 VALVES AND FITTINGS INSULATION .................................................................................................... 7 SPECIAL REQUIREMENTS FOR BOILER ................................................................................................. 8 Technical Parameter ......................................................................................................................................... 8 Materials and Technical Requirements ............................................................................................................ 8 Materials: .......................................................................................................................................................... 9 Lagging: ............................................................................................................................................................ 9 SPECIAL REQUIREMENTS FOR TURBINE AND FEED HEATING TRAIN ......................................... 9 Technical Parameter ......................................................................................................................................... 9 Materials............................................................................................................................................................ 9 PERSONNEL PROTECTION INSULATION ............................................................................................. 10 ACOUSTIC INSULATION ........................................................................................................................... 10 ANTI-CONDENSATION INSULATION .................................................................................................... 11 VENTILATION AND AIR CONDITIONING INSULATION ................................................................... 11

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard Specifications

Page ii

4.13.1 4.13.2 4.13.3 4.13.4 4.13.5 5 6 7 8 9

Internal Duct Liner ......................................................................................................................................... 11 Indoor External Insulation for Rectangular Ducts ......................................................................................... 11 Indoor External Duct Insulation for Round Ducts ......................................................................................... 11 Outdoor External Duct Insulation and Finish ................................................................................................ 11 Flashing ........................................................................................................................................................... 12 DESIGN REVIEW AND SAMPLES ......................................................................................................... 12 PERFORMANCE TESTING AND FUNCTIONAL GUARANTEES .................................................. 12 QUALITY ASSURANCE / QUALITY CONTROL (QA/QC) ............................................................... 12 SPECIAL TOOLS ........................................................................................................................................ 13 STORAGE OF INSULATION MATERIAL ............................................................................................ 13

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard Specifications

Page 1

SCOPE OF WORK The work shall include the detailed design, manufacturing or procurement of materials, delivery to site and installation of all Thermal Insulation and Lagging within Contractor's scope of supply. The Contractor shall supply Thermal Insulation and Lagging in accordance with his scope of supply as defined and as further outlined in the individual Technical Specifications for the equipment and system. This Standard Specification defines the minimum requirements for the equipment under consideration. It does, however, not limit Contractor's responsibility to supply such equipment complete in any respect and in line with applicable codes and standards as well as overruling specific project requirements and good engineering practice.

CODES AND STANDARDS The Contractor shall comply with the individual Technical Specification requirements. The following Codes and Standards are specifically applicable to the design, manufacture and testing of the equipment covered by this specification. Alternative internationally recognised codes for the thermal insulation are acceptable provided that the Contractor specifies the appropriate codes in his Proposal and provides an English language translation of his proposed codes.

3 3.1

ASME ASTM NFPA UL TCVN

American Society of Mechanical Engineers. American Society for Testing and Materials. National Fire Protection Association. Underwriters' Laboratories Vietnamese Standards

DESIGN AND OPERATING CONDITIONS GENERAL Design and operating conditions for individual piping systems are specified under their plant systems of the individual Technical Specifications for equipment and system. If design and operating parameters are not explicitly stated therein it is the Contractor's responsibility to establish proper parameters in line with the overall plant system requirements, applicable codes and standards as well as good engineering practice. Operating and design conditions of all piping systems and equipment shall be specified by the Contractor in the "Pipe List" in accordance with Standard Specification M-001 and/or the equipment design specifications. Based on this data the Contractor shall derive the requirements for insulation and shall summarise the information on the "Pipe List" and/or the "Thermal Insulation and Lagging List". The layout of these lists shall be subject of approval by the Owners Consultant.

3.2

TYPE OF INSULATION "Thermal Insulation" comprises insulation applied to surfaces with a working temperature of 60 C or higher for the purpose of reduction of thermal losses due to radiation of useful heat. "Personnel Protection Insulation" refers to thermal insulation applied on hot surfaces above 60 C for the only for personnel protection "Anti-condensation insulation" is required for cold surfaces (chilled water piping, etc) to prevent moisture in the ambient air from condensation on the pipe/equipment surface.

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard Specifications

Page 2

"Acoustical insulation" refers to insulation applied on noise emitting surfaces to achieve a sound level reduction/attenuation

3.3

DESIGN CRITERIA "Thermal insulation" shall be applied to all exposed surfaces to maintain a surface temperature that is no more than 250C above the ambient temperature. Design ambient temperatures indoor and/or outdoor shall be 30 C for the purpose of insulation sizing. Normal steady state operating conditions in the whole load range, no exposure to sunshine and no wind shall be assumed. "Personal protection insulation" shall be sized such as to maintain the outer surface temperature of the insulation lagging in any case below or at 50 C. "Anti-condensation insulation" (anti-sweating insulation) shall be sized such as to ensure that the outer surface temperature of the insulation lagging is above the dew point of the ambient moist air. "Acoustical insulation" shall be sized such as to limit sound pressure levels to the allowable noise limits as specified.

3.4

DESIGN LOADS The outdoor insulation and lagging, including supporting members and fasteners, shall be designed to withstand the following wind loads and live loads in addition to dead loads and internal pressures without exceeding the maximum allowable unit stresses. Wind loads shall be taken as acting normal to the surfaces of aluminium lagging in both directions, toward the surfaces and away from the surfaces. The design wind loads shall be based on a wind velocity of 40 m/sec per ANSI A58.1, exposure type D or approved equivalent. Live loads equal to 195 kg/m2 shall be used as acting vertically down on the horizontal tops or horizontal projection of sloped tops of lagging structures.

4 4.1

DETAILED REQUIREMENTS GENERAL All insulating materials shall be new, of high quality and suitable for the purpose intended and shall be of such durability and capability of giving effective service for at least thirty years under normal operating conditions. All insulation shall be of high efficiency in respect of its designation (thermal, acoustical, etc) and shall be capable of withstanding the maximum specified working/design temperatures without deterioration. All insulation material shall be chemically neutral, stable under the prevailing ambient and operating conditions, non-flammable, imputrescible and resistant to vermin. The use of asbestos for insulating purpose is prohibited for this Project. Surfaces to be insulated shall be clean of dirt, scale, rust, grease, or moisture before any insulation is applied. Insulation materials shall be kept dry and shall not be applied when it is wet. If the materials become wet after application, they shall be allowed to dry before proceeding with the application of metal jacket or weatherproof compounds. Removable sections of insulation shall be provided over removable plates, lifting lugs, access doors, or areas on pressure vessels where code inspection data appear, and where otherwise specified. Insulation shall be applied in a manner, which will allow withdrawal of removable sections without damage to such sections, or to adjacent insulation.

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard Specifications

Page 3

Equipment nameplates mounted on brackets, extending from the body, shall be framed in with the insulation so as to leave them exposed for ready identification. Welded joints in pipes and equipment shall not be covered with insulation until hydrostatic tests have been satisfactorily performed on the pipes and equipment. The use of "Pop" type rivets as a means of securing or supporting insulation, lagging, and/or flashing is not permitted. The insulation and lagging shall be arranged with expansion joints or similar provisions, as far as required, so that all surfaces will be effectively insulated whether in the hot or cold position and to prevent cracking or distortion of the insulation due to thermal expansion of the equipment. Insulation on outdoor piping and equipment shall be fully weatherproof, waterproof and suitable for the specific Site conditions.

4.2

MATERIALS The materials to be supplied shall conform to the latest issues of the designated ASTM Standards. Equivalent internationally recognised standards may be accepted, subject to approval of the Owners Consultant. Thermal insulation, lagging materials, and hardware called for in subsequent sections of this specification shall conform to the following requirements:

Thermal insulation for hot equipment (temperatures up to 600oC): Long fibre mineral wool blankets per ASTM C612-class 3, 120-130 kg/m3 minimum density (except as otherwise specified), reinforced on both sides with galvanised hexagonal wire mesh. (see also clauses 4.7/4.8 for deviations) Thermal insulation for hot piping systems (temperatures up to 600oC): Pre-formed calcium silicate per ASTM C533 Anti-condensation insulation for cold equipment and piping: Pre-formed cellular (foam) glass per ASTM C552 with vapour barrier Metal lagging and jacket (for all insulated surfaces): Aluminium sheets as per ASTM B209 type 3004, with two coats of clear acrylic coating on exterior surface and two coats of catalysed epoxy coating on interior surface as a moisture barrier; ribs, corrugations, surface finish and thickness shall be as specified in subsequent sections of this specification Insulating and finishing cement: Mineral wool based as per ASTM C449, blended with hydraulic setting binders and corrosion inhibitors to provide smooth, hard, monolithic finish when dry Weatherproof Mastic : Weatherproof/vapour proof, fire-resistant, vinyl-acrylic emulsion type, with approved perm rating. Note that perm rating shall not exceed 0.1 perm. All mastics shall bear "UL" labels. Wire mesh: Hexagonal woven, minimum 1.6 mm thick, hot dip galvanised steel wire mesh (galvanising shall be performed after fabrication of the mesh) Lacing wire: 1.6 mm minimum diameter stainless steel wire Insulation and metal lagging bands: Type 304 stainless steel as follows: 13 mm wide, 0.4 mm thick for pipes DN 600 mm and smaller; 19 mm wide, 0.6 mm thick for larger size pipes and for all equipment Aluminium foil: minimum 0.6 mm thick Screws for metal lagging: Self-tapping stainless steel screws with neoprene washers.

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard Specifications

Page 4

Acoustic barrier: Lead sheet of minimum 5 kg/m2 specific weight

Insulation Review Insulation materials and thickness used for each purpose and methods of application will be subject to careful review and must be completely acceptable to the Owners Consultant. Contractor shall submit to the Owners Consultant for review, complete specifications covering materials and methods of application. Drawings showing the specific insulation materials, thickness and lagging for all insulated surface shall be acceptable to the Owners Consultant before the materials are purchased. Contractor shall indicate on his insulation drawings and specifications that all projecting ribs, flanges, lugs, supports etc. on all equipment and piping furnished by him are properly insulated to prevent excessive heat losses.

Multiple Layer Insulation All calcium silicate blocks and segmental and sectional insulation for all equipment 76 mm and over in total thickness (no including finish coat) shall be applied in two layers unless otherwise specifically approved. In the case of 2-layer insulation the inner layer thickness shall be half of the total specified thickness or 13 mm less then the thickness of the outer layer where this is not practical.

4.3

INSULATION FASTENING All surfaces to be insulated, except piping and tubes, shall have clips, welding studs, pins or other suitable means spaced on centres as hereinafter specified for attachment of insulation holding wire for impaling mineral wool blocks or blankets. All materials required for proper support and fastening of insulation to all surfaces shall be provided. Mineral wool block, board or blankets shall be applied by impaling on self-welded studs or pins and retaining the insulation with speed washers. Studs or pins shall be in a set pattern with spacing not in excess of 450 mm centres in both directions on the top and sides, and 300 mm centres in both directions on bottom of the insulated surfaces. The pin length shall be 25 mm greater than the thickness of insulation. After the insulation and speed washers are in place the pins shall be bent over and not cut. Calcium silicate block insulation shall be securely wired in place. Welding studs or drilled clips shall be welded to the surfaces in a set pattern with spacing not in excess of 450 mm centres in both directions on top and sides and 300 mm centres in both directions on bottom of insulated surfaces for attaching insulation tie lacing wires. Each layer of calcium silicate block insulation shall be firmly wired in place. All insulation fasteners used in areas where the temperature may exceed 395 oC shall be stainless steel. Joints in insulation shall be tightly butted so as to produce a monolithic continuous insulation. Edges of metal mesh covered blankets shall be tied together with wire.

Joints and Finish All spaces or joints between calcium silicate segmental, sectional and block forms of insulation shall be filled with insulating cement. Road mesh may be used to span stiffeners for surfaces that are to be insulated with calcium silicate block or metal mesh reinforced mineral wool blankets. General wool block or board insulation shall be installed employing either of the following methods:

Mineral wool insulation shall be applied directly against hot surfaces or surfaces with an intermediate layer of insulation. When the cool side of the insulation is not in contact with the

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard Specifications

Page 5

outer metal lagging, the insulation shall be covered with a metal mesh. Metal mesh facing must be suitably lapped and tied together. Mineral wool insulation shall be of sandwich construction, i.e., confined between inner and outer metal sheets.

Road mesh, where used to span stiffener members, shall be a minimum of 100 mm x 100 mm x 4/6 mm for horizontal surfaces, which may be walked upon, and 150 mm x 150 mm x 6/5 mm for other surfaces. Road mesh shall be tack welded to stiffeners or supports on not greater than 600 mm centres both ways. Insulation block and blankets shall be fastened to the road mesh with tie wires or pins and speed washers respectively, in such manner as to ensure firm attachment of the insulation to all surfaces. Wherever sandwich type insulation construction is used (or where tubes or pipes are insulated as a group), suitable barriers of plate and block or plastic insulation shall be installed in vertical runs on approximately 3 m intervals to eliminate any stack effect.

4.4

LAGGING In general all piping and equipment which is insulated shall be lagged or jacketed as specified for individual applications below. Lagging for flat surfaces shall be ribbed type aluminium alloy sheets 1.25 mm thick

for large shaped surfaces flat type aluminium alloy sheets 1.25mm thick for piping and fittings, smooth aluminium sheets.

Lagging shall be applied with all joints lapped. Longitudinal overlaps shall be 50 mm; circumferential overlaps shall be 75 mm. Lagging shall not be applied until insulating cement is dry. Lagging shall be applied with bands and screws as specified in Clause 4.2 above. All joints or screws shall be placed where they are least visible. The jacket shall be applied directly over the blanket insulation (unless otherwise specified) and neatly fitted into place. All joints shall be arranged so as to shed water. Suitable flashing or weatherproofing shall be provided at all nozzles, manholes, and other projections to prevent the entrance of water. For outdoor applications, the lagging shall be completely waterproof with proper flashing installed so that water cannot reach the insulation. The lagging shall be designed and installed to provide for complete water runoff with no pockets where water can collect. Insulation with factory attached metal lagging will not be acceptable (except where specified otherwise). Removable panels of doors shall be provided in the metal lagging to provide access to handholds, manholes, valves, fittings, etc. The method of fastening metal lagging shall be acceptable to the Owners Consultant. The spacing of fasteners shall be in a set pattern both vertically and horizontally and shall be such as to prevent ratting of the lagging due to vibration of equipment or piping. Dissimilar metal that may cause galvanic corrosion shall be properly isolated. Metal lagging fastening screws and washers shall be of the type as indicated in Clause 4.2 and shall not stain the lagging. Full-threaded stud set lock fastener and blind rivets are not acceptable methods of fastening lagging. The alloy temper shall be such that the material can be bent flat on itself without cracking. The use of canvas jacketing for insulation is not permitted.

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard Specifications

Page 6

Elbows with an insulated outside diameter less than 330 mm shall be covered with formed aluminium elbow jackets. Piping elbows with larger insulated outside diameter shall be covered using metered segment aluminium elbow jackets constructed with rolled interlocking edge joints. Metered segments shall have included angles not greater than 15 degrees. Insulated long radius bends shall be jacketed using spiral wrapped aluminium straps or individual mitred segments. The jacket shall be applied directly over the blanket insulation and neatly fitted into place. All joints shall be arranged so as to shed water; and suitable flashing or weatherproofing shall be provided at all nozzles, manholes, and other projections to prevent the entrance of water. Insulated flanges shall be lagged and the lagging shall be fabricated to fit neatly around the flange and shall be removable.

4.5

PIPING INSULATION For hot piping pre-formed segmental calcium silicate insulation as per Clause 4.2 shall be used. Piping insulation shall allow for radial expansion and contraction of the pipe, and shall permit the pipe to expand longitudinally. It shall accommodate all movements of the pipe during operation without opening up the joints between sections of insulation. Insulation for service below 400oC shall be applied in single layers with staggered longitudinal joints. Insulation for service at higher temperatures shall be applied in double layers with staggered circumferential and longitudinal joints. Insulation joints shall be tightly butted and gaps shall be filled with insulating cement. Insulation diameters under 500 mm size shall be fastened with wires, larger diameters with bands as specified in Clause 4.2. Wires or bands shall be placed on maximum 250 mm centres. The number and spacing of expansion joints shall be such that the expansion in any joint is limited to 20 mm. The design of the expansion joints in single layer insulation shall be of double-wall construction. On multi layer insulation, the locations of the expansion joints shall be staggered. The joints shall be filled with resilient material. Projections on cold piping such as pipe hangers shall be sealed with mastic where they join the pipe insulation to prevent vapour penetrating into the insulation material. All pipes shall have adequate support rings and/or attachments to prevent settling of insulation and to provide support for the lagging. These supports shall be composed of spacers and circumferential straps made of flat steel suitable for the prevailing temperature. On piping with minimum 120 mm insulation the spacing between supporting rings shall not exceed 2 m for horizontal and 3 m for vertical piping. Lagging shall be fabricated from flat sheets of smooth, embossed aluminium alloy as per Clause 4.2; the thickness shall be 0.8 mm for insulation outer diameters up to 320 mm, 1.0 mm up to 640 mm and 1.2 mm for larger diameters.

4.6

EQUIPMENT INSULATION Hot equipment shall be insulated with mineral wool blankets as specified in Clause 4.2. Lagging shall be in intimate contact with the insulation. In areas where it is not convenient to have the lagging in intimate contact with the insulation (air space between insulation and lagging), galvanised steel plaster lath shall be applied to the cold surface of the insulation for support. Insulation for service below 400 C shall be applied in a single layer. Insulation for service at higher temperatures shall be applied in double layers.

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard Specifications

Page 7

Insulation shall be fitted to the equipment and provided with an adequate number of expansion joints. All joints shall be staggered and tightly butted. Adjacent edges shall be laced with lacing wire. Gaps shall be filled with insulating cement and reinforced with wire mesh.

4.6.1

Vessels and Heat Exchangers

Insulation for vessels and heat exchangers shall be hung from insulation supports as special attachments. Insulation shall be secured using lacing wire and insulation bands on 300 mm centres. Expansion joints shall be provided as required. Insulation of vessel heads shall be cut to fit the curvature of the heads and secured with radial bands spaced on 300 mm centres at the perimeter of the heads. Nozzles on vessels and heat exchangers shall be insulated the same way as the adjoining pipes. Manholes, handholds, and blanked nozzles shall be insulated with removable type covers. The insulation thickness shall be the same as on the shell. Shell flanges on heat exchangers and on vessels shall be insulated with removable covers. The insulation thickness shall be the same as on the shell.

4.6.2

Pumps

Pump insulation shall be cut and fitted to the shape of the pump body. Pump body shall be coated with core coating before insulating. If straps cannot be used to secure insulation due to irregularities of the body, insulation shall be secured in place with insulation wire. Pump insulation may be formed into a box around the unit, in lieu of being formed to fit the shape of the pump body. All void spaces shall be filled with fibrous insulation. Core coating of the pump body is not required.

4.6.3

Equipment Lagging

The lagging shall be made of 1.0 mm thick, ribbed (100 mm centre-to-centre, 25 mm depth) aluminium sheets as specified in Clause 4.2. In case flat sheets are required, they shall be 1.2 mm thick. Elbows with an insulated outside diameter less than 320 mm shall be covered with formed aluminium elbow jackets. Piping elbows with larger insulated outside diameter shall be covered using mitred segment aluminium elbow jackets constructed with rolled interlocking edge joints. Mitred segments shall have included angles not greater than 15 degrees. Insulated long radius bends shall be jacketed using spiral wrapped aluminium straps or individual mitred segments.

4.7

VALVES AND FITTINGS INSULATION Valves and fittings in hot piping shall be insulated with segments of pipe insulation carefully cut to fit and then firmly wired in place. Moulded or shop-fabricated insulation of the same material as for piping shall be used with preference. Voids shall be filled with high temperature insulating cement. Two coats of finishing cement each 6 mm thick shall be finally applied, bringing the total insulation thickness on fittings to that of the adjacent pipe insulation. The finishing cement shall be reinforced on fittings of DN 200 mm nominal size and larger with wire mesh. Where pipe is provided with flanges, the pipe insulation shall be tapered adjacent to the flange to permit removal of the flange bolts without damaging the insulation. Valves and flanges shall be insulated in all lines as required for thermal insulation and/or personnel protection insulation.

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard Specifications

Page 8

Where flanges are un-insulated, the jacket shall end flush with the insulation and finish at 45 degree with insulating cement and weatherproof mastic. Where flanges are insulated, the jacket shall be fabricated to fit neatly around the flange insulation. Insulated valves and fittings, which require access for frequent maintenance and adjustment, such as the ring pin in safety valves, shall be provided with a metal sleeve through the insulation. Mineral wool insulating cement may be used to insulate valves and fittings in 50 mm and smaller piping to be insulated with 50 mm or less of insulation.

Lagging

The basic requirements for the lagging shall correspond to those of the related piping system (see 4.4. above). Insulated flanges shall be lagged. The lagging shall be fabricated to fit neatly around the flange and shall be removable.

4.8 4.8.1

SPECIAL REQUIREMENTS FOR BOILER Technical Parameter Thermal Insulation: Thermal insulation will be applied to all exposed heated surfaces as follows:

Under cover (roof) or enclosed

equipment:

to maintain 55 oC maximum surface temperature at ambient temperatures of 30 oC with air circulation speeds of 8 km/h. to maintain 55 oC maximum surface temperature at 30 C ambient temperature with air circulation speeds of 8 km/h. Noise insulation may be used as required together with other mean of noise control to meet work area or plant boundary condition noise standards.

Outdoor equipment:

Noise Insulation:

4.8.2

Materials and Technical Requirements Technical Requirements

The surfaces of cladding where not under cover will be water proof, and sealed in difficult areas such as access doors with flashing and/or sealing compounds. The cladding and its supports will be suitable to meet the wind velocity standards without damage, Where walkways are required for operation or maintenance on insulated surfaces these will be supported internally and indicated as suitable for walking or gratings provided over the top of the personal access. Insulation will be single layer for temperatures below 400 oC and double layer for higher temperatures. All holes and slits over 1.6 mm wide in each layer of insulation shall be filled with insulating cement (mineral wool base). Lagging shall be in intimate contact with the insulation. In areas where it is not convenient to have lagging in intimate contact with the insulation (in air space between insulation and lagging) galvanised steel plaster lath shall be applied to the cold surface of the insulation for support. Insulation and lagging shall be held in place by welded pins and fastened with special speed clips. All pins shall be field installed.

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard Specifications

Page 9

All flanges and expansion joints shall be suitably insulated to prevent heat leakage. Expansion joint insulation shall in no way reduce the effectiveness of the expansion joint and shall be designed to withstand thermal movements without failure.

4.8.3

Materials

For flat surfaces (boiler casing, ductwork, ESP) and large shaped surfaces (fans, air heaters): mineral wool blankets per ASTM C596, minimum density 48 kg/m3 reinforced with galvanised wire mesh will be provided. For piping, valves, fittings, drums and headers: pre-formed calcium silicate blocks per ASTM C533 will be applied.

Finishing Cement and Weather-Proofing Mastic

For valves, fittings and irregular surfaces: Finishing cement per ASTM C449; Mastic: vinylacrylic, fire resistant, will be provided.

4.8.4

Lagging

For flat surfaces: ribbed type coated steel sheeting (for corrosion resistance in marine climate), (i.e. type Robertson-Vesracor or equivalent), 1.2 mm minimum thickness, For large shaped surfaces same as above, except flat type, For piping, valves, fittings, drums and headers, flat surface coated steel sheeting, 0.4 minimum thickness for 600 mm diameter and smaller, 0.8 mm larger diameter and other equipment. All lagging shall be suitably braced for the wind loading specified for structural steel design. Insulated surfaces of air heaters, ducts, drum heads, and other insulated surfaces, except exposed pipes outside of the enclosure, shall be lagged with fabricated aluminium sheet, in embossed surface not thinner than 1.25 mm. Lagging on the top of the boilers, furnaces, auxiliary equipment, and ductwork shall be suitably reinforced to allow workmen walking on the top surfaces. The lagging of access doors and openings shall be suitably reinforced and provided with heavyduty hardware and latches.

4.9

SPECIAL REQUIREMENTS FOR TURBINE AND FEED HEATING TRAIN Thermal insulation and lagging materials to be supplied and installed on turbine units shall conform to the best standards of the equipment manufacturer. The Contractor shall provide complete details regarding proposed materials and installation methods.

4.9.1

Technical Parameter Thermal insulation will be applied to all exposed heated surfaces, as follows :

Indoor equipment : Outdoor equipment :

to maintain 55 C maximum surface temperatures to maintain 55 C maximum surface temperature at 30 C ambient temperature and wind speed of 8 km/h.

The insulation will be fire and water proof and compatible with the surface to which it is applied.

4.9.2

Materials Thermal Insulation For large shaped surface (deaerator, feed water tank, feed heaters):

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard Specifications

Page 10

Mineral wool blankets per ASTM C 592, minimum density 48 kg/m3, reinforced with galvanised wire mesh.

For turbine casings, turbine valve chests:

Sprayed-on, mineral wool type thermal insulation, suitable for temperatures up to 570 C, reinforced with wire mesh and held in place by means of anchor pins. A layer of at least 12 mm finishing cement will be applied.

For piping, valves, fittings, etc.:

Pre-formed calcium silicate blocks per ASTM C 533.

Insulation will be single layer for temperatures below 350 C and double layer for higher temperatures. Provisions will be made for easy removal, where required, for inspection and maintenance.

Finishing Cement and Weather Proofing Mastic For valves, fittings and irregular surfaces:

Finishing cement per ASTM C 449. Mastic: Vinyl-acrylic, fire resistant.

Lagging For large shaped surfaces:

Indoor installation: Flat type, embossed aluminium alloy sheets, ASTM B 209, with vapour barrier, 1.25 mm minimum thickness. Outdoor/semi-outdoor installation: Flat type coated steel sheeting (for corrosion resistance in maritime climate) i.e. Robertson - Vesracor or equivalent with vapour barrier, 1.25 mm minimum thickness

For piping, valves, fittings and headers:

Indoor installation: Smooth, embossed aluminium alloy sheets, 0.4 mm minimum thickness for larger diameters and equipment. Outdoor / semi outdoor: same as above, except flat surface coated steel sheets (for corrosion resistance in maritime climate (i.e. Robertson - Vesracor or equivalent).

Welded steel plate lagging structures will be provided for the high pressure and intermediate pressure turbine. The inside of the lagging will have a sound absorbing coating. Provisions will be made for easy removal for inspection and maintenance of the turbines.

4.10

PERSONNEL PROTECTION INSULATION Personnel protection insulation shall be provided for plant and equipment which is within 1 meter distance from an operating platform or other walking area and having a surface temperature exceeding the limit as specified in clause 3.2. The insulation shall be applied up to a height of 2 m above the respective ground. Plant and equipment which for technical reasons cannot be insulated shall be provided with personnel protection shields. The shield shall be fabricated from minimum 1.3 mm thick expanded galvanised steel. All sharp edges must be folded back on the material. Shields shall be of the removable type, employing screws and nuts for servicing the equipment shielded. Contractor shall submit typical drawings to the Owners Consultant for review prior to installation.

4.11

ACOUSTIC INSULATION Acoustic insulation shall be combined with other type of insulation to the utmost extent. i.e. normally with thermal insulation.

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard Specifications

Page 11

Suitable ways and means for specific applications shall be proposed by the Contractor and sufficient details of the design shall be provided to the Owners Consultant for review and approval.

4.12

ANTI-CONDENSATION INSULATION Anti-condensation (anti-sweat) insulation shall be applied to all cold equipment and piping which are susceptible to sweating under the prevailing ambient conditions. This is particularly applicable to chilled water piping. These classes of surfaces shall be systematically identified based on a hygrometric diagram and the plant ambient design conditions. The anti-condensation insulation shall consist of pre-formed, sectional cellular (foam) glass of sufficient thickness. Butt joints of insulation sections must be filled with bedding mastic. All blocks shall be held in place by stainless steel bands placed on suitable centres. The insulation shall finally be protected from water and humidity by a suitable coating reinforced by glass or nylon cloth as required. The permeability of the coating shall be subject to the Owners Consultant's approval.

4.13

VENTILATION AND AIR CONDITIONING INSULATION All air-conditioning ductwork shall be insulated as specified hereinafter.

4.13.1

Internal Duct Liner

Insulation shall be 25 mm thick, 48 kg/m3 minimum density, fibreglass board impregnated with NFPA approved fire retardant, having a vapour proof coating and a smooth surface on the side exposed to the air stream. Adhesive shall be vapour proof mastic and shall be compatible with the above insulation material as recommended by the insulation manufacturer.

4.13.2

Indoor External Insulation for Rectangular Ducts

4.13.3

Insulation shall be not less than 25 mm thick, and not less than 64 kg/m3 density fibreglass board with factory applied laminate of pre-sized, finely woven, glass cloth and foil, having a white finish suitable for painting. Sealing tape shall not be less than 76 mm wide and shall be the insulation manufacturer's recommended vapour proof pressure sealing tape. Colour shall match the insulation facing. Adhesive shall be white, vapour proof mastic and shall be compatible with the above insulation materials as recommended by the insulation manufacturer. The entire insulation system shall meet NFPA 90A Fire Hazard Classification.

Indoor External Duct Insulation for Round Ducts

4.13.4

Insulation shall be 25 mm thick, pre-formed fibreglass insulation with factory applied laminate of pre-sized, finely woven, glass cloth and foil, having a white surface suitable for painting. Fibreglass insulation shall have a density of not less than 64 kg/m3. Sealing tape shall be not less than 76 mm wide and shall be the insulation manufacturer's recommended vapour proof pressure sealing tape. Colour shall match the insulation facing. Adhesive shall be white, vapour proof mastic and shall be compatible with the above insulation materials as recommended by insulation manufacturer. The entire insulation system shall meet NFPA 90A Fire Hazard Classification.

Outdoor External Duct Insulation and Finish

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard Specifications

Page 12

Insulation shall be 25 mm foam plastic sheet insulation finished with two (2) coats of manufacturer's recommended finish for outdoor service.

4.13.5

Flashing

The Contractor shall provide hot-dip galvanised steel flashing as hereinafter specified. 1.3 mm thick flashing shall be provided where insulated or un-insulated ductwork penetrates a building wall. The Contractor shall submit a sketch to the Owners Consultant showing the flashing details for penetrations through walls.

DESIGN REVIEW AND SAMPLES Insulation material selection, sizing, methods of application will be subject to review and approval by the Owners Consultant. Contractor shall therefore submit complete specifications and drawings showing the required details. Thermal conductivity tables or curves shall be submitted to the Owners Consultant for information and review. The thermal conductivity figures and thereof derived Specific thermal loss figures (W/m2) shall be valid for the proposed insulation assembly including insulation, lagging and supports. A sample of each type of insulation together with material specifications shall be provided by the Contractor on request to the Owners Consultant.

PERFORMANCE TESTING AND FUNCTIONAL GUARANTEES The Contractor shall guarantee that the type, size and method of application of the insulating materials called for in this Specification are suitable for the specified service conditions. Therefore the Contractor shall warrant that the materials furnished by him are suitable for these specific applications and will maintain their thermal efficiency, physical properties and mechanical strength without deterioration under the planned operating conditions throughout the lifetime of the plant. The Contractor shall demonstrate that the specified performance data of the insulation are met, i.e. surface temperatures are within stated limits, noise level reduction is achieved, etc. The test procedures and scope of testing shall be proposed by the Contractor and be approved by the Owners Consultant.

QUALITY ASSURANCE / QUALITY CONTROL (QA/QC) The quality control including inspection and testing shall conform to the requirements of the individual Technical Specification (clause: Quality Assurance and Quality Control) The quality control procedures shall include but not be limited to the following:

procurement packaging and shipping testing cleaning non-destructive testing

The quality control documentation shall include but not be limited to the following: material certificates NDE reports all shop test reports all other documentation required by applicable codes and standards.

Vung Ang 1 Thermal Power Plant Water Treatment and Waste Water Treatment Plant Part IV Project Standard Specifications

Page 13

SPECIAL TOOLS All special tools and devices necessary to apply to all kinds of insulation, jacket, and lagging shall be supplied by the Contractor.

STORAGE OF INSULATION MATERIAL All insulation materials shall be supplied with adequate protection to withstand damage during transportation and storage. Where applicable, the materials shall be supplied in waterproof containers, which can be satisfactorily resealed after partial using of content.

Vous aimerez peut-être aussi

- ADWEA I&C InstallationDocument32 pagesADWEA I&C InstallationAyman Termanini100% (2)

- Noise Control Buildings-Seminar ReportDocument29 pagesNoise Control Buildings-Seminar ReportVîkÅš VìČký69% (13)

- Chevron Pre-Inspection ChecklistDocument2 pagesChevron Pre-Inspection ChecklistosersPas encore d'évaluation

- Specs-Stage 2& 3-TrackworksDocument76 pagesSpecs-Stage 2& 3-Trackworksismail tp100% (2)

- CUI: An In-Depth Analysis: Hira S. AhluwaliaDocument6 pagesCUI: An In-Depth Analysis: Hira S. AhluwaliaJithuJohnPas encore d'évaluation

- ENG STD 1602 Cold InsulDocument32 pagesENG STD 1602 Cold Insuldarrybr52Pas encore d'évaluation

- Guide to Bend Pipes for Insulated Pipe SystemsDocument2 pagesGuide to Bend Pipes for Insulated Pipe Systemsdmitos100% (1)

- Engineered Gasketing GARLOCKDocument56 pagesEngineered Gasketing GARLOCKMac Donal PerezPas encore d'évaluation

- Technical Inspection Report Due To Corrosion Ocured On LPC Pump G-2707Document2 pagesTechnical Inspection Report Due To Corrosion Ocured On LPC Pump G-2707Junie PranantaPas encore d'évaluation

- Boiler Tube FailureDocument7 pagesBoiler Tube FailureBhupendra GobadePas encore d'évaluation

- Boiler Types and Classifications - WikiDocument21 pagesBoiler Types and Classifications - WikiKarthik ChillaPas encore d'évaluation

- Cold Thermal Insulation SpecificationDocument13 pagesCold Thermal Insulation SpecificationCameliaPas encore d'évaluation

- GS P&D Archsd 2012Document127 pagesGS P&D Archsd 2012Andy Lee100% (1)

- Introduction to Process Control SystemsDocument36 pagesIntroduction to Process Control SystemsAneketh GurumurthiPas encore d'évaluation

- CSBP Underground PipingDocument27 pagesCSBP Underground PipingKatamaneni KoteswararaoPas encore d'évaluation

- Corrosion Under Insulation in Process IndustryDocument30 pagesCorrosion Under Insulation in Process IndustryWILLIAM100% (1)

- EGP3-01.16 Welding For Skids and Miscellaneous SteelDocument10 pagesEGP3-01.16 Welding For Skids and Miscellaneous SteelMathias OnosemuodePas encore d'évaluation

- Basics of Shell and Tube Heat Exchangers With PDFDocument12 pagesBasics of Shell and Tube Heat Exchangers With PDFtruong cong truc100% (1)

- EGE13B10Document46 pagesEGE13B10Jhonny Rafael Blanco CauraPas encore d'évaluation

- 353.FoamglassAssamblyDocument12 pages353.FoamglassAssamblyCeratita ClarkPas encore d'évaluation

- Mostostalex - Sprinkler TanksDocument8 pagesMostostalex - Sprinkler TanksVanja IvkovicPas encore d'évaluation

- Insulation RequirementsDocument6 pagesInsulation RequirementsNisarPas encore d'évaluation

- Piping Guide Pipe WorkDocument8 pagesPiping Guide Pipe WorkSiddiq RahimPas encore d'évaluation

- MQ SP I 7015 PDFDocument66 pagesMQ SP I 7015 PDFJaseelKanhirathinkalPas encore d'évaluation

- PipingDocument54 pagesPipingakhilsyam21Pas encore d'évaluation

- FuturePipe Installation Manual 18-7-05 PDFDocument25 pagesFuturePipe Installation Manual 18-7-05 PDFPaul WoworPas encore d'évaluation

- T 18Document10 pagesT 18khuramluck100% (2)

- Design of Welded Connections: Submitted To Prof. Berlanty Iskander byDocument17 pagesDesign of Welded Connections: Submitted To Prof. Berlanty Iskander byاحمد حمديPas encore d'évaluation

- Pages From API 571 2020Document1 pagePages From API 571 2020Mohammad FouladiPas encore d'évaluation

- A StandardsDocument5 pagesA StandardsSampath KumarPas encore d'évaluation

- Welcome To: Training Program On GUIDED TOUR OF ASME CodesDocument120 pagesWelcome To: Training Program On GUIDED TOUR OF ASME CodesAndri Konyoa KonyoaPas encore d'évaluation

- Corrosion PDFDocument22 pagesCorrosion PDFVishal ThakarePas encore d'évaluation

- Inspection of Heat ExchangerDocument83 pagesInspection of Heat ExchangerRaghavanPas encore d'évaluation

- Condenser Cladding InfoDocument37 pagesCondenser Cladding Infoabhishe_reenaPas encore d'évaluation

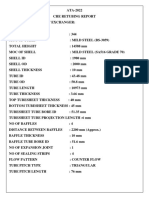

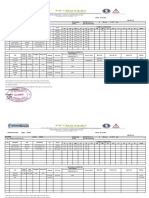

- CHE Retubing ReportDocument29 pagesCHE Retubing ReportRajesh KtrPas encore d'évaluation

- PIPING SYSTEM DESIGN GUIDEDocument6 pagesPIPING SYSTEM DESIGN GUIDEMananPas encore d'évaluation

- Vessel Module Sans RH GoodDocument24 pagesVessel Module Sans RH GoodThaksenPas encore d'évaluation

- To Rerate or Not To RerateDocument6 pagesTo Rerate or Not To ReratekblaxtonPas encore d'évaluation

- How To Install and Erect TrunkingDocument13 pagesHow To Install and Erect TrunkingDaniel Madulu CharlesPas encore d'évaluation

- Wet Pipe Sprinkler SystemDocument12 pagesWet Pipe Sprinkler SystemrockykrishPas encore d'évaluation

- 02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical ApplicationsDocument12 pages02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical ApplicationsivanmatijevicPas encore d'évaluation

- Tanks and Hold Corrosion Prevention DNVDocument9 pagesTanks and Hold Corrosion Prevention DNVblakasPas encore d'évaluation

- Stub Onin ConnectionsDocument4 pagesStub Onin ConnectionsMehman NasibovPas encore d'évaluation

- Interview Questions 1 TCSDocument3 pagesInterview Questions 1 TCSSrinivas TumpalaPas encore d'évaluation

- Alzamil Chiller - SeriesDocument13 pagesAlzamil Chiller - SeriesRAZA MEHDIPas encore d'évaluation

- Shell Corrosion Under InsulationDocument16 pagesShell Corrosion Under InsulationDavide CongiuPas encore d'évaluation

- Types of Welding DefectsDocument7 pagesTypes of Welding DefectsPradip Erande100% (1)

- InsulationDocument2 pagesInsulationNavneet MukeshPas encore d'évaluation

- Exxon Mobil Matls Lab A105N Vs A350LF2 GrainSize PDFDocument5 pagesExxon Mobil Matls Lab A105N Vs A350LF2 GrainSize PDFAnonymous nw5AXJqjdPas encore d'évaluation

- Design Fabrication and Testing of Shell and Tube Heat Exchanger For Heat Recovery From Hydraulic Oil IJERTV6IS070289Document8 pagesDesign Fabrication and Testing of Shell and Tube Heat Exchanger For Heat Recovery From Hydraulic Oil IJERTV6IS070289PAPPU KUMARPas encore d'évaluation

- Wrapping MethodDocument5 pagesWrapping Methodnnuek67% (3)

- Collar Bolts in Shell and Tube Heat ExchangersDocument3 pagesCollar Bolts in Shell and Tube Heat ExchangersBaher ElsheikhPas encore d'évaluation

- Basics of Piping and Instrumentation Diagrams (P&IDsDocument34 pagesBasics of Piping and Instrumentation Diagrams (P&IDssaravanan aathiPas encore d'évaluation

- Oman LNG Train 3 CUI Shutdown Method StatementDocument25 pagesOman LNG Train 3 CUI Shutdown Method StatementZainul Abid100% (1)

- Why A Shell and Tube Heat Exchanger?Document17 pagesWhy A Shell and Tube Heat Exchanger?Avishek KumarPas encore d'évaluation

- Pipeline Welding InspectionDocument4 pagesPipeline Welding InspectionRizky TrianandaPas encore d'évaluation

- Weld Built-Up ProcedureDocument1 pageWeld Built-Up ProcedureMohd Shafuaaz KassimPas encore d'évaluation

- CorrosionNotes Handout1 2017 v1 PDFDocument40 pagesCorrosionNotes Handout1 2017 v1 PDFAbdo MohdyPas encore d'évaluation

- Internal & External Inspection GuidelinesDocument5 pagesInternal & External Inspection Guidelinesgeverett2765Pas encore d'évaluation

- Corrosion Failures: Theory, Case Studies, and SolutionsD'EverandCorrosion Failures: Theory, Case Studies, and SolutionsPas encore d'évaluation

- Apco Surge Relief Valves Angle Sra 3000Document8 pagesApco Surge Relief Valves Angle Sra 3000JakePas encore d'évaluation

- Electrical Service Minimum RequirmentDocument97 pagesElectrical Service Minimum RequirmentachniajosiPas encore d'évaluation

- LES Cable Entry SystemsDocument26 pagesLES Cable Entry SystemsVasudev AgrawalPas encore d'évaluation

- ING HOUSE HQ SUSTAINABLE DESIGNDocument26 pagesING HOUSE HQ SUSTAINABLE DESIGNYunn TanPas encore d'évaluation

- Petrofast MTC 3.1 PO-400234 Anchor Bolts - Option FDocument2 pagesPetrofast MTC 3.1 PO-400234 Anchor Bolts - Option Fحسن صالح حسن المياحيPas encore d'évaluation

- Automatic-Recirculation-Check Valve SSV 40-48Document3 pagesAutomatic-Recirculation-Check Valve SSV 40-48Herberth SilitongaPas encore d'évaluation

- Black & Decker Advanced Home Wiring - Updated 3rd Edition - DC Circuits - Transfer Switches - Panel Upgrades PDFDocument349 pagesBlack & Decker Advanced Home Wiring - Updated 3rd Edition - DC Circuits - Transfer Switches - Panel Upgrades PDFHector100% (1)

- Stress Intensity Factor Crack Tip StressesDocument5 pagesStress Intensity Factor Crack Tip StressesOsmar DiasPas encore d'évaluation

- New COADocument15 pagesNew COAAhadNurParagPas encore d'évaluation

- Splinkler Asfr-1Document12 pagesSplinkler Asfr-1Jose HernandezPas encore d'évaluation

- 2018 Verity Brochure v1Document2 pages2018 Verity Brochure v1RatkoMRPas encore d'évaluation

- Model of Tender SpecificationDocument15 pagesModel of Tender SpecificationRishi KathirPas encore d'évaluation

- Project Management in ConstructionDocument9 pagesProject Management in Constructionvineeth reddyPas encore d'évaluation

- Steel Fibers For Fiber-Reinforced ConcreteDocument4 pagesSteel Fibers For Fiber-Reinforced ConcreteIvan TapiaPas encore d'évaluation

- CR (N) 2&4 D&RDocument14 pagesCR (N) 2&4 D&RRudo RockPas encore d'évaluation

- Maintenance Checklist Form: SL No Condition Inspection / Check Point MonthlyDocument1 pageMaintenance Checklist Form: SL No Condition Inspection / Check Point MonthlyAneesh ConstantinePas encore d'évaluation

- Giw LCCDocument8 pagesGiw LCCCesar Leonardo Mendoza LoyolaPas encore d'évaluation

- 612 B Fig702 Flanged y Type Strainer UlDocument2 pages612 B Fig702 Flanged y Type Strainer UlPradipta DwiPas encore d'évaluation

- Copy of Pending Pos MetalDocument112 pagesCopy of Pending Pos MetalVijay OfficialPas encore d'évaluation

- Nvent Erico IAPMO-UES-ER-0129-ENDocument29 pagesNvent Erico IAPMO-UES-ER-0129-ENEric GardnerPas encore d'évaluation

- QAP Format - QA 01 F 01Document1 pageQAP Format - QA 01 F 01Murukan PadmanabhanPas encore d'évaluation

- The Market Scape 01: Goals For "Integrated" Streets For DelhiDocument3 pagesThe Market Scape 01: Goals For "Integrated" Streets For DelhiVamsi Krishna ReddyPas encore d'évaluation

- Case Law - Project EmployeeDocument4 pagesCase Law - Project EmployeeZeniPas encore d'évaluation

- 45-144 - A505 - Elevator Details (Version)Document1 page45-144 - A505 - Elevator Details (Version)Parth DaxiniPas encore d'évaluation

- Mat UrbanismDocument11 pagesMat UrbanismBadr ZeinaPas encore d'évaluation

- How To Control The Warping of Parts in Thin SheetDocument6 pagesHow To Control The Warping of Parts in Thin SheetNeil WaynePas encore d'évaluation

- CK Jet Diffuser Technical SpecificationDocument4 pagesCK Jet Diffuser Technical SpecificationJf OngPas encore d'évaluation

- Series LFN45B-M1 Specification SheetDocument2 pagesSeries LFN45B-M1 Specification SheetWattsPas encore d'évaluation