Académique Documents

Professionnel Documents

Culture Documents

Geotextiles in Transportation Applications

Transféré par

tsuakDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Geotextiles in Transportation Applications

Transféré par

tsuakDroits d'auteur :

Formats disponibles

GEOTEXTLE8 N

TRAN8PORTATON

APPLCATON8

Paper presented at the Second Gulf Conference

On Roads, Abu Dhabi, March 2004,

BY

Khad a Mecca & Eyad a Hasan

Page 2

Authors:

Khalid Ahmed Meccai

Eyad Al Hasan

Khalid Meccai obtained his Masters degree in Technology with specialization in Geotextiles in 1984. With over 18 years

experience in geotextiles, he is currently heading the Marketing and Technical Services department at Alyaf.

Eyad Al Hasan obtained his Bachelor's degree in Civil Engineering from U.K. in 1982. He is currently working with

Alyaf as Sales Manager.

Summary:

Geotextiles play a significant part in modern pavement design and maintenance techniques. The

growth in their use worldwide for transportation applications in particular, has been nothing short of

phenomenal. The focus of this paper is on better understanding of this relatively new tool available

to the transportation engineer. The paper provides an overview of the current geotextile technologies

and highlights the functions geotextiles perform in enhancing the performance and extending the

service life of paved roads. Three key application areas of geotextiles, construction of pavements, in

asphalt concrete overlays and for drainage systems along with impetus on the current design

methodologies available in geotextile design and selection are addressed.

Keywords: Geotextile, pavement, drainage, reflective cracking, subgrade, functional properties.

1. Introduction

Geotextiles have proven to be among the most versatile and cost-effective ground modification

materials. Their use has expanded rapidly into nearly all areas of civil, geotechnical, environmental,

coastal, and hydraulic engineering. They form the major component of the field of geosynthetics, the

others being geogrids, geomembranes and geocomposites. The ASTM (1994)[1] defines geotextiles

as permeable textile materials used in contact with soil, rock, earth or any other geotechnical related

material as an integral part of civil engineering project, structure, or system.

Based on their structure and the manufacturing technique, geotextiles may be broadly classified into

woven and nonwoven. Woven geotextiles are manufactured by the interlacement of warp and weft

yarns, which may be of spun, multifilament, fibrillated or of slit film. Nonwoven geotextiles are

manufactured through a process of mechanical interlocking or thermal bonding of fibers/filaments.

Mechanical interlocking of the fibers/filaments is achieved through a process called needle

punching. Needle-punched nonwoven geotextiles are best suited for a wide variety of civil

engineering applications and are the most widely used type of geotextile in the world. Interlocking of

the fibers/filaments could also be achieved through thermal bonding. Heat-bonded geotextiles

should be used with caution, as they are not suitable for filtration applications or road stabilization

applications over soft soils [2].

2. Geotextile Functions:

The mode of operation of a geotextile in any application is defined by six discrete functions:

separation, filtration, drainage, reinforcement, sealing and protection. Depending on the application

GEOTEXTLE8 N TRAN8PORTATON APPLCATON8

Second Gulf Conference On Roads, Abu Dhabi, March 2004,

Page 3

GEOTEXTLE8 N TRAN8PORTATON

the geotextile performs one or more of these functions simultaneously. The protection function is not

discussed here as it is not related to transportation applications.

2.1. Separation:

Separation is defined as, The introduction of a flexible porous textile placed between dissimilar

materials so that the integrity and the functioning of both the materials can remain intact or be

improved (Koerner, 1993) [3]. In transportation applications separation refers to the geotextiles role

in preventing the intermixing of two adjacent soils. For example, by separating fine subgrade soil from

the aggregates of the base course, the geotextile preserves the drainage and the strength characteristics

of the aggregate material. The effect of separation is illustrated in figure 1.

Figure 1, Concept of separation Function

2.2. Filtration:

It is defined as the equilibrium geotextile-to-soil system that allows for adequate liquid flow with

limited soil loss across the plane of the geotextile over a service lifetime compatible with the

application under consideration (Koerner, 1993) [3]. To perform this function the geotextile needs to

satisfy two conflicting requirements: the filters pore size must be small enough to retain fine soil

particles while the geotextile should permit relatively unimpeded flow of water into the drainage

media. A common application illustrating the filtration function is the use of a geotextile in a

pavement edge drain, as shown in figure 2.

Figure 2 Filtration and Transmissivity Functions

Second Gulf Conference On Roads, Abu Dhabi, March 2004,

Page 4

DOCUME NT TTLE

2.3. Drainage (Transmissivity):

This refers to the ability of thick nonwoven geotextile whose three-dimensional structure provides

an avenue for flow of water through the plane of the geotextile. Figure 2 also illustrates the

Transmissivity function of geotextile. Here the geotextile promotes a lateral flow thereby

dissipating the kinetic energy of the capillary rise of ground water.

2.4. Reinforcement:

This is the synergistic improvement in the total system strength created by the introduction of a

geotextile into a soil and developed primarily through the following three mechanisms: One,

lateral restraint through interfacial friction between geotextile and soil/aggregate. Two, forcing the

potential bearing surface failure plane to develop at alternate higher shear strength surface. And

three, membrane type of support of the wheel loads.

2.5. Sealing Function:

A nonwoven geotextile performs this function when impregnated with asphalt or other polymeric

mixes rendering it relatively impermeable to both cross-plane and in-plane flow. The classic

application of a geotextile as a liquid barrier is paved road rehabilitation, as shown in Figure 3.

Here the nonwoven geotextile is placed on the existing pavement surface following the application

of an asphalt tack coat. The geotextile absorbs asphalt to become a waterproofing membrane

minimizing vertical flow of water into the pavement structure.

Figure 3 Sealing Function

3. Design Properties and Tests:

Standardized testing of geotextile properties has evolved over a very short time reflecting the

increasing rate with which these materials are used. Sufficient number of standardized tests both

ASTM [1] and EN [4] are available with which to assess the suitability of the geotextile to the

specific application. The design engineer incorporating geotextiles needs to understand these test

methods and specify only those properties that govern the functional needs of the end application.

By taking these steps, the engineer not only protects the clients interest in getting the right

product for the application but also invites the largest number of geotextile manufacturers

GEOTEXTLE8 N TRAN8PORTATON APPLCATON8

Second Gulf Conference On Roads, Abu Dhabi, March 2004,

Page 5

DOCUME NT TTLE

possible; thereby assuring that the cost of the construction materials is kept to a minimum. In

this paper only the functional properties that govern typical geotextile applications are

addressed.

3.1. Puncture Strength: ASTM D 4833.

This test is intended to measure the puncture resistance of geotextiles and geomembranes and

simulates the puncture strength of the geotextiles to static loads of aggregates. In this test the

geotextile is secured in a ring clamp. A steel rod with a conical tip is then forced through the

material and the resistance to puncture is measured in Newton.

3.2. Burst Strength: ASTM D 3786.

This test simulates the strength of the geotextile to a continuous hydraulic/mechanical load. In

this test the geotextile sample is secured over an inflatable membrane. As the membrane is

inflated, the geotextile deforms to a hemispherical shape. The force causing rupture of the

geotextile is recorded in units of pounds per square inch or kilo Pascal.

3.3. Dynamic Puncture: EN 918.

This test is intended to measure the strength of the geotextile to falling objects and simulates the

placement of aggregates over the geotextile during the installation stage. In this method the

geotextile is fixed in a ring clamp and a steel cone of 1000 grams is dropped from a height of

500 centimeters over the geotextile. The diameter of the hole created by the impact is measured

and expressed in millimeters. Note, the smaller the hole size the tougher the geotextile is to

dynamic loading.

3.4. Grab Tensile Strength and Elongation: ASTM D 4632.

This index test measures the tensile strength and elongation along the plane of the geotextile by

loading it continually. In this test the specimen sample of dimensions 100 by 200 millimeters is

secured in clamps of a tensile testing instrument and loaded with a constraint strain rate of 300

millimeters per second. The value of the breaking load is expressed in Newton and the

elongation at break in percent.

3.5. Permeability:

This test is intended to measure the rate at which liquids can pass through the geotextile. The test

method ASTM D 4491 measures the permittivity, which is related to permeability, by the

following equation.

= k / t - (1)

Where:

= geotextile permittivity (sec-1)

k = geotextile permeability (cm/sec)

t = geotextile thickness (cm)

GEOTEXTLE8 N TRAN8PORTATON APPLCATON8

Second Gulf Conference On Roads, Abu Dhabi, March 2004,

Page 6

DOCUME NT TTLE

Alternatively the test method BS 6906 Part 3 measures the permeability as flow rate and the

value expressed in liters per square meters per second.

3.6. Apparent Opening Size (AOS): ASTM D 4751

The apparent opening size reflects the approximate largest opening dimension available

through which the soil may pass. In this test method, the geotextile is secured between two

US Standard Sieves. Glass beads are then placed in the upper screen and sieved through the

geotextile. The AOS corresponds to the bead size for which no more than 5% pass through

the geotextile. The AOS is expressed as US Standard Sieve Number or in millimeters.

4. Areas of Application:

This paper addresses the following major application areas of geotextiles in transportation

engineering: Flexible paved road construction, Drainage Applications and Pavement overlays.

Other transportation related geotextile applications like erosion control of slopes both in

waterways and dry areas have not been covered in this paper.

4.1. Flexible Paved Road Construction

Geotextiles extend the service life of roads, increase their load-carrying capacity, and reduce

rutting. The effectiveness of geotextiles in stabilization and separation roles with flexible

pavements has been extensively researched at Virginia Tech. (Smith et al, 1995[5]; Lacina,

1997[6]; Valentine, 1994[7]). The researches found that for weak subgrades (CBR = 2%) the

geotextile extends the service life of a flexible pavement section by a factor of 2.5 to 3.0

compared to a non-stabilized section. Further the research found that a geotextile effectively

increased the pavement sections total AASHTO structural number by approximately 19 %.

Research on the effect of geotextile in pavement sections with moderate strengths (CBR = 4.2

to 4.5 %) found that the geotextile increased the service life of the pavement section by a

factor of 2.0 to 3.3 and the AASHTO structural number increased by 13 to 22%.

These significant improvements are obtained primarily through the separation function of the

geotextile placed at the interphase of the base course aggregate and subgrade soil. Without a

separator geotextile, the aggregate layer becomes contaminated with fines from the subgrade.

This contamination leads to the development of a new soil-aggregate layer at the interface

whose strength is less than that of the aggregate layer. The loss of strength occurs because

granular aggregates (gravel, sand, etc.,) obtain their shear strength primarily through the

point-to-point contact of adjacent particles. As the volume of fines increases, the shear

strength of the aggregate mixture increases because the fines help to distribute shear stress.

However as the fine soil content further increases the stress is distributed primarily through

the soil fines, which have considerable lower strength.

With geotextile acting as a separation / filtration layer at the interphase of the subgrade and

the drainage aggregate, the aggregate base course layer is completely insulated from the soil

fines, therefore the designed base course properties are maintained throughout the life of the

project. The system performance is also improved through the secondary functions of

drainage (the geotextile allowing excess pore pressures to dissipate through the

Transmissivity function) and the reinforcement function of the geotextile.

GEOTEXTLE8 N TRAN8PORTATON APPLCATON8

Second Gulf Conference On Roads, Abu Dhabi, March 2004,

Page 7

DOCUME NT TTLE

4.1.1. Pavement Section Design:

The design of pavement sections incorporating geotextiles can be performed using many of the

current design methodologies. The AASHTO (1986)[8] design method is modified to account

for the contribution of geotextile and can be found in the FHWA publication Geosynthetic

Design and Construction Guidelines (Holtz et al, 1995)[9].

Figure 4, Base Course Being Laid Over Geotextile

Geotextiles also play a major role in construction of paved roads over areas having high ground

water table. Drainage of water from pavements has always been an important consideration in

road design; however current methods of pavement design have resulted in base courses that do

not drain well. The problem has been compounded with the rise in the water table. Water rises

up into the base course through pore water pressures and through capillary function leading to

saturation of the base courses. Saturation of the base course changes the dynamics of vertical

stress distribution, and may allow transfer of traffic loads directly to subgrade soil, eliminating

the benefits of the structural layers leading to rapid pavement distress. A pavement layer, which

is saturated 10% of its time, will have its service life reduced by as much as 50% (Cedergreen

1974) [10]. Thus eliminating saturation of the base course is a prudent design objective.

AASHTO also recognizes the harmful effects of water in the pavement structure. In the

AASHTO design method, the effective structural number (SN

eff

) of pavement base and sub-

base materials, which drain well, is increased, whereas if materials drain poorly, the effective

structural number is decreased (AASHTO, 1993)[11]. While drainage factor for excellent

drainage can be 1.20, Drainage factor for poor drainage can be as low as 0.60. This means by

providing proper drainage the design strength of pavement base and sub-base materials can be

doubled.

To adequately address the ground water drainage the designer needs to consider providing

subsoil drainage systems as illustrated in figure 2 that not only lead the ground water away from

the pavement structural layers but also prevent the capillary rise of the ground water into the

structural layers. It is recommended that the structural drains be connected to shoulder edge

drains that lead the water away. The location of the trench drain can vary depending on actual

site conditions. Design of these subsurface drains is detailed subsequently in this paper.

GEOTEXTLE8 N TRAN8PORTATON APPLCATON8

Second Gulf Conference On Roads, Abu Dhabi, March 2004,

Page 8

DOCUME NT TTLE

4.1.2. Geotextile Requirement:

Selecting a geotextile for paved road depends upon the geotextile survivability. If a roadway

system is designed correctly, then the stress at the top of the subgrade due to the weight of the

aggregate and the traffic load is less than the bearing capacity of the subgrade plus a safety

factor. However the stresses applied to the subgrade and the geotextile during the construction

is much greater than that applied during service. Therefore, selection of the geotextile in

roadway applications is usually governed by the anticipated construction stresses. The

geotextile must survive the construction operations if it is to perform the intended function of

separation and filtration.

The geotextile requirements under moderate and severe conditions are provided in Table 1.

These survivability requirements are based on properties of geotextiles, which have performed

satisfactorily. Judgment and experience our required to select final specification values. For

large projects geotextile survivability should be verified by conducting field tests under site-

specific conditions. The selected geotextile must also retain underlying soil fines, while

allowing a relatively unimpeded flow of water. Hence the geotextile Opening size and

Permeability should be ascertained to match the site requirements.

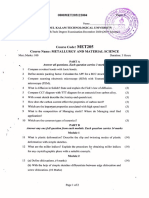

Table 1 Geotextile Requirements for Roadway Applications

4.2. Pavement Overlays

Asphalt concrete pavement overlays can benefit from the use of paving fabric interlayer. The

documented field experience indicates to a number of positive benefits including:

Waterproofing of the lower layers, thereby maintaining higher material strengths.

Retarding reflection cracking in the overlay by acting as a stress absorbing membrane

interlayer.

Increase in structural stability by providing for more stable subgrade moisture contents.

Paving fabrics can also be used in new pavements to provide the same benefits. If fabric is

added and the overlay thickness is not reduced from that determined by normal methods,

than an increase in performance can be obtained.

GEOTEXTLE8 N TRAN8PORTATON APPLCATON8

PROPERTY

TEST

METHOD

REQUIREMENTS

MODERATE HIGH

Puncture Strength ASTM D4833 N 400 700

Dynamic Puncture

(Minimum hole diameter)

ENISO

918

mm 18 12

Ultimate Elongation ASTM D4632 % >50 >50

Burst Strength ASTM D3786 kPa 2000 3000

Grab Strength ASTM D4632 N 700 800

Permeability ASTM D 4491 cm/sec > than the soil permeability

Apparent Opening Size ASTM D4751 mm < 0.15

UNIT

Second Gulf Conference On Roads, Abu Dhabi, March 2004,

Page 9

DOCUME NT TTLE

4.2.1. Capabilities Of Paving Fabrics:

The inclusion of a nonwoven paving fabric interlayer system significantly improves the

performance of asphalt concrete overlays. This performance improvement is a result of both the

waterproofing capabilities and the stress absorption capabilities of the paving fabric system.

(Maxim Technologies Report)[12].

Synthetic fabrics and stress-absorbing interlayer (SAMI) have been effective in controlling

low to medium severity alligator cracking. They may be also useful for controlling reflection of

temperature cracks when used in combination with crack filling. They generally do little,

however, to retard reflection of cracks subject to significant horizontal or vertical movement.

AASHTO Guide for Design of Pavement Structures 1993[11].

Figure 5 Paving Fabric Installation

Both laboratory and field pavement cores indicate that the presence of a properly installed

paving fabric interlayer reduces the permeability of a pavement by one to three orders of

magnitude. By reducing the infiltration of moisture the paving fabric maintains the strength of

the subgrade, subbase and base course, limiting damage due to saturated condition pore

pressures (Mark and Thomas, TRB circular 1999) [13].

4.2.2. Properties of Paving Fabric:

Paving fabrics are nonwoven fabrics from grades ranging from 135 gm/m2 to 200 gm/m2. The

lighter fabrics when impregnated with asphalt primarily function as moisture barrier. Use of

heavier, nonwoven geotextiles provides cushioning or stress-relieving membrane benefits in

addition to moisture-barrier functions. Minimum properties required for paving fabrics as per

AASHTO M 288-96, Standard specifications for geotextiles [14] are provided in Table 2.

4.2.3. Installation procedure:

The surface on which the paving fabric is to be placed should be free from dirt, water,

vegetation or other debris. Cracks are filled or repaired and tack coat typically ranging from 1 to

1.35 l/m2 of residual asphalt is applied evenly on the surface. The paving fabric is then laid on

GEOTEXTLE8 N TRAN8PORTATON APPLCATON8

Second Gulf Conference On Roads, Abu Dhabi, March 2004,

Page 10

DOCUME NT TTLE

the surface with minimum wrinkles, and placement of the hot mix overlay shall closely follow

the fabric lay down.

Table 2 Paving Fabric Requirements

4.3. Drainage:

The removal of water is important to the success of many civil engineering problems. In

transportation applications, if the base course does not drain rapidly enough, stress from the

traffic loadings is transferred to the subgrade with little or no reduction, resulting in accelerated

road failure. The removal of water must be performed in a controlled fashion. Otherwise, severe

erosion, piping, or settlement of soils may result in undermining adjacent structures. To

accomplish this task the drainage system should fulfill two criteria:

Have maintained permeability by providing relatively unimpeded flow of water.

Filtration of base soil by preventing the migration of soil fines into the drain.

These criteria can be met by using several layers of specially graded aggregates. This often

proves to be extremely expensive requirement to meet. The same result can be achieved at a

fraction of the cost by using selected geotextiles, which act as filters around the aggregate

drainage system. The introduction of geotextile lined drainage systems has enhanced the

technical benefits and economical application of blanket and trench drains under and adjacent to

pavement structures. The excellent filtration and separation characteristics associated with

geotextiles permits the use of a single layer of open graded aggregate base or trench aggregate

enveloped in a geotextile.

Figure 6 Pavement Edge Drains

GEOTEXTLE8 N TRAN8PORTATON APPLCATON8

PROPERTY TEST METHOD UNITS REQUIREMENTS

Grab Strength ASTM D4632 N 450

Mass per unit area ASTM D3776 gm/m

2

140

Ultimate Elongation ASTM D4632 % >50

Asphalt Retention Texas DOT 3099 l/m

2

1.1

Melting Point ASTM D276

0

C 150

Second Gulf Conference On Roads, Abu Dhabi, March 2004,

Page 11

DOCUME NT TTLE

4.4. Geotextile Filter Design:

Designing with geotextiles for filtration is essentially the same as designing with graded filters.

Based on the analogy to soil filter design criteria, the following design criteria for geotextiles is

stated:

The geotextile must retain the soil fines (retention criterion), while

Allowing a relatively unimpeded flow of water (permeability criterion), throughout the life

of the structure (clogging resistance criterion).

To perform effectively, the geotextile must survive the installation process (survivability

criterion).

The design procedure proposed is based on the above stated parameters and the design

procedure developed by Christopher and Holtz (1985) [9].

4.4.1. Retention Criteria Under Steady State Flow

The retention criterion is governed by the Apparent Opening Size (AOS) of the geotextile.

AOS or O

95 (geotextile)

< B D

85 (soil)

- (2)

Where:

AOS or O

95

= apparent opening size (mm);

O

95

= opening size in the geotextile for which 95% are smaller (mm);

B = a coefficient (dimensionless) ranging from 0.5 to 2 depending on the type of soil; and

D

85

= soil particle size for which 85% are smaller (mm).

4.4.2. Clogging Resistance:

The criterion for clogging resistance is: Geotextile porosity, n > 70%. For severe / critical

conditions where soils potential to clog are addressed it is recommended that soil-geotextile

clogging tests like the gradient ratio test [ASTM D 5102] [1] are conducted.

4.4.3. Permeability Criteria:

Permeability requirements:

For less critical applications:

k

geotextile

> k

soil

- (3)

For critical applications:

k

geotextile

> 10 k

soil

- (4)

Where:

k

soil

is the Darcys coefficient of permeability (m / sec.) of the soil to be filtered.

k

geotextile

is the permeability coefficient of the geotextile.

GEOTEXTLE8 N TRAN8PORTATON APPLCATON8

Second Gulf Conference On Roads, Abu Dhabi, March 2004,

Page 12

DOCUME NT TTLE

4.4.4. Survivability Criteria:

Survivability refers to the geotextiles ability to withstand the installation stresses and perform

as intended in the project design. Table 3 gives the minimum physical property requirements for

drainage applications. These minimum survivability requirements are based on the experience

on the properties of geotextiles, which have known to perform satisfactorily in these

applications.

Table 3 Physical Requirements for Drainage Applications

5. Conclusion:

Geotextiles are effective tools in the hands of the civil engineer that have proved to solve a

myriad of geotechnical problems. With the availability of variety of products with differing

characteristics, the design engineer needs to be aware of not only the application possibilities

but also more specifically the reason why he is using the geotextile and the governing geotextile

functional properties to satisfy these functions. Design and selection of geotextiles based on

sound engineering principles will serve the long-term interest of both the user and the industry.

6. References:

[1] ASTM (1994), Annual Books of ASTM Standards, American Society Testing and

Materials, Philadelphia, Pennsylvania. Volume 4.08 (1), Soil and Rock. Volume 4.08 (2),

Soil and Rock, Geosynthetics, Volume 7.01, Textiles.

[2] GREGORY RICHARDSON N., BARRY CHRISTOPHER R., Geotextiles in

Transportation Applications, Featured Short Course, 1998.

[3] KOERNER, R. M., Designing with Geosynthetics, Third edition, Prentice Hall, 1993.

GEOTEXTLE8 N TRAN8PORTATON APPLCATON8

Property

Test method Unit High Survivability Moderate Survivability

Puncture strength ASTM D4833 N 690 420 260

Dynamic puncture (hole

diameter)

EN 918 mm < 14 < 18 < 22

Burst strength ASTM D3786 psi 400 300 185

Elongation at break ASTM D4632 % 60 60 60

Notes:

1. High-survivability drainage applications for geotextiles are where installation stresses are more

severe than moderate applications, i.e., very coarse, sharp angular aggregate is used, a heavy degree of

compaction (>95%) is specified, or depth of trench is greater than 3m.

2. Moderate-survivability drainage applications are those where geotextiles are used with smooth-

graded surfaces having no sharp, angular projections, no sharp angular aggregates is used, compaction

requirements are light, (less than 95%), and trenches are less than 3m in depth.

Second Gulf Conference On Roads, Abu Dhabi, March 2004,

Page 13

DOCUME NT TTLE

[4] EUROPEAN COMMITTEE FOR STANDARDIZATION (CEN), Geotextiles and

geotextile related products, central Secretariat: rue de Stassart 36, B-1050, Brussels.

[5] SMITH T.E., BRANDON T.L., AL-QADI I.L., LACINA B.A., BHUTTA S.A.,

HOFFMAN S.E., 1995, "Laboratory Behavior of Geogrid and Geotextile Reinforced

Flexible Pavements; Final Report," Virginia Tech, Blacksburg, VA.

[6] AL-QADI I.L., BRANDON T.L., BHUTTA S.A., LACINA B.A. [1997]. "Geosyntically

Stabilized Flexible Pavements": Virginia Tech Study, Proceedings, Geosynthetics 1997

Conference, Long Beach.

[7] AL-QADI I.L., BRANDON T.L., VALENTINE R.J., LACINA B.A., SMITH T.E.,

[1997]."How Do Geosynthetics Improve Pavement Performance": Proceedings of

Infrastructure: New Materials and Methods for Repair, ASCE, San Deio, pp. 606-616.

[8] AASHTO Guide for the Design of Pavement Structures, American Association of State

Highway and Transport Officials, Washington DC, 1986.

[9] ROBERT HOLTZ D., BARRY CHRISTOPHER R., RYAN BERG R., Geosynthetic

Engineering, Bitech Publishers Ltd. Canada, 1997

[10] CEDERGREEN H. R., Drainage of Highway and Airfield Pavements, John Wiley and

Sons., New York, NY, 1994.

[11] AASHTO Guide for the Design of Pavement Structures, American Association of State

Highway and Transport Officials, Washington DC, 1993.

[12] MAXIM TECHNOLOGIES INC, Nonwoven Paving Fabrics Study Final R e p o r t ,

December 1997. <WWW@ gmanow.com/pages/desconcept.asp>

[13] MARK MARIENFIELD L., THOMAS BAKER L., Paving Fabrics Interlayer System

as a Pavement Moisture Barrier, Transportation Research Board, 1998.

[14] AASHTO (1996) Standard Specifications for Geotextiles - M288-96 Standard

Specifications for Transportation Materials and Methods of Sampling and Testing,

American Association of State Transportation and Highway Officials, Washington D.C.,

pp 689-692.

GEOTEXTLE8 N TRAN8PORTATON APPLCATON8

Second Gulf Conference On Roads, Abu Dhabi, March 2004,

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Study On Karai Mini-Hydro Power Project PDFDocument280 pagesStudy On Karai Mini-Hydro Power Project PDFtsuakPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- 2013 IPP Procedure PDFDocument10 pages2013 IPP Procedure PDFtsuakPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Independent Power Producers Face Risks Under New Power Purchase RegulationDocument7 pagesIndependent Power Producers Face Risks Under New Power Purchase RegulationtsuakPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Construction Specification Cs-Ut-243, Concrete Canal LiningDocument4 pagesConstruction Specification Cs-Ut-243, Concrete Canal LiningtsuakPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Construction Specification 52-Steel Pipe: 1. ScopeDocument6 pagesConstruction Specification 52-Steel Pipe: 1. ScopetsuakPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- FEM in Geotech EngineeringDocument21 pagesFEM in Geotech Engineeringtsuak100% (1)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- An Update On New and Future Earthworks Standards in The UK and EuropeDocument6 pagesAn Update On New and Future Earthworks Standards in The UK and EuropetsuakPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Digest: Geotechnical Baseline Reports - Their Use & Abuse in Hong Kong WelcomeDocument8 pagesDigest: Geotechnical Baseline Reports - Their Use & Abuse in Hong Kong WelcometsuakPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Sample Project 2016 Foundation ManualDocument102 pagesSample Project 2016 Foundation ManualJOSE OSCAR ZAMBRANO CANCHALAPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Medtech OriginalDocument12 pagesMedtech OriginaltsuakPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Civil Design Requirements For Developers Part A Integrated Stormwater Management Version 4Document30 pagesCivil Design Requirements For Developers Part A Integrated Stormwater Management Version 4tsuakPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Design N Consid Derations Sofmic Cro-Hydr Ro-Electr Ric Powe Er PlantDocument11 pagesDesign N Consid Derations Sofmic Cro-Hydr Ro-Electr Ric Powe Er PlanttsuakPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Evaluating The Seismic Coefficient For Slope Stability AnalysesDocument68 pagesEvaluating The Seismic Coefficient For Slope Stability AnalysestsuakPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- HydDocument502 pagesHydtsuakPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- 1409 HOBAS Gravity Pipe Systems WebDocument44 pages1409 HOBAS Gravity Pipe Systems WebtsuakPas encore d'évaluation

- Ambo University Hachalu Hundessa Campus: School of Civil and Environmental EngineeringDocument22 pagesAmbo University Hachalu Hundessa Campus: School of Civil and Environmental EngineeringTarekegnPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Ventiloconvectoare CITIZEN 2011Document6 pagesVentiloconvectoare CITIZEN 2011office8200Pas encore d'évaluation

- ProFloat Booklet NEWDocument16 pagesProFloat Booklet NEWnicopin60Pas encore d'évaluation

- 423.7 14 Specification For Unbonded Single Strand Tendon MaterialsDocument12 pages423.7 14 Specification For Unbonded Single Strand Tendon MaterialsJosh KoerberPas encore d'évaluation

- Rigid Pavement MethodologyDocument3 pagesRigid Pavement MethodologyVibekananda MohantyPas encore d'évaluation

- Ben Hielscher Portfolio TemplateDocument2 pagesBen Hielscher Portfolio TemplateChiefPas encore d'évaluation

- C8516-CLT-QMT-0002 Rev.02-Inspection Checklist For Precast Gully InstallationDocument1 pageC8516-CLT-QMT-0002 Rev.02-Inspection Checklist For Precast Gully InstallationJabinPas encore d'évaluation

- Shear and Torsion in Concrete StructuresDocument202 pagesShear and Torsion in Concrete StructuresRobert VochescuPas encore d'évaluation

- Forensic Geotechnical Engineering: V.V.S. Rao G.L. Sivakumar Babu EditorsDocument30 pagesForensic Geotechnical Engineering: V.V.S. Rao G.L. Sivakumar Babu EditorsKikieKirana AndMePas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- 2019 04 18 Understanding The Aisc Direct Analysis Method of Design HandoutDocument85 pages2019 04 18 Understanding The Aisc Direct Analysis Method of Design Handoutcons2engPas encore d'évaluation

- 2 4 Ce225 Research - Paper Group 4Document7 pages2 4 Ce225 Research - Paper Group 4JEAN KATHLEEN SORIANOPas encore d'évaluation

- Timber Connector2Document8 pagesTimber Connector2gerald jahoPas encore d'évaluation

- 4 Question 2 Worked ExampleDocument8 pages4 Question 2 Worked ExampleTomislav ŠimagPas encore d'évaluation

- 4806 en MiraDRAIN 9800 TDSDocument2 pages4806 en MiraDRAIN 9800 TDSabdalla el-saadaneyPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Cast in PlatesDocument18 pagesCast in Plates贾天伟Pas encore d'évaluation

- Scrutiny of Shamli-AmbalaDocument16 pagesScrutiny of Shamli-AmbalaAbhishek PathakPas encore d'évaluation

- 100 Morks 1 Bonds. 2 Structure. 3 4 5 6 7 8 9 l0: Metallurgy MaterialDocument2 pages100 Morks 1 Bonds. 2 Structure. 3 4 5 6 7 8 9 l0: Metallurgy MaterialManeesh TPas encore d'évaluation

- Experimental Investigation On Compressive Strength of PaverblockDocument35 pagesExperimental Investigation On Compressive Strength of PaverblockPachai ManiPas encore d'évaluation

- Civil Book List New 1Document64 pagesCivil Book List New 1Sulakshna TpPas encore d'évaluation

- Pipe & Tube SpecificationsDocument3 pagesPipe & Tube SpecificationsIbrahim Ali100% (1)

- Factors Influencing Hydrogen Induced CrackingDocument3 pagesFactors Influencing Hydrogen Induced CrackingNapoleon DasPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 2021 NSPC Matrix and Proposed Changes 7112019 PDFDocument241 pages2021 NSPC Matrix and Proposed Changes 7112019 PDFPatricia100% (1)

- Overview of LEED CertificationDocument19 pagesOverview of LEED CertificationAkter Ul Azim ParvezPas encore d'évaluation

- Superior Performance Fan CoilsDocument24 pagesSuperior Performance Fan CoilsJorge Cardona GilPas encore d'évaluation

- 7 Group Action of PileDocument31 pages7 Group Action of PileSamirsinh ParmarPas encore d'évaluation

- How To Build A Small Vertical Shaft Lime Kiln: An Example of A Continuous Production, Mixed Feed Kiln From ZimbabweDocument8 pagesHow To Build A Small Vertical Shaft Lime Kiln: An Example of A Continuous Production, Mixed Feed Kiln From ZimbabweMohammad Ali TaghdiriPas encore d'évaluation

- Analysis and Design of Multi Storey Building by Using STAAD Pro V8iDocument3 pagesAnalysis and Design of Multi Storey Building by Using STAAD Pro V8iInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Acoustic Treatment - Vibration Control: MEBS6008 Environmental Services IIDocument26 pagesAcoustic Treatment - Vibration Control: MEBS6008 Environmental Services IISandeep BhatiaPas encore d'évaluation

- AAMA-NPEA-NSA-2100-12 Specification For SunroomsDocument14 pagesAAMA-NPEA-NSA-2100-12 Specification For SunroomsRey Eduard Q. UmelPas encore d'évaluation

- THbI-04 InternalsDocument35 pagesTHbI-04 InternalsMarwan AhmedPas encore d'évaluation

- Hero Found: The Greatest POW Escape of the Vietnam WarD'EverandHero Found: The Greatest POW Escape of the Vietnam WarÉvaluation : 4 sur 5 étoiles4/5 (19)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureD'EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureÉvaluation : 5 sur 5 étoiles5/5 (125)