Académique Documents

Professionnel Documents

Culture Documents

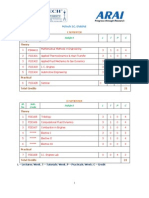

IV Semester: (AUTONOMOUS) 2008 - 09 Sl. No. Sub-Code Subject Dept/Board Hours/week Credits

Transféré par

Irfan AhmadDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

IV Semester: (AUTONOMOUS) 2008 - 09 Sl. No. Sub-Code Subject Dept/Board Hours/week Credits

Transféré par

Irfan AhmadDroits d'auteur :

Formats disponibles

IV Semester (AUTONOMOUS) 2008 - 09

Sl. No. 1 2 3 4 5 6 7 8 Sub-Code

MA221 ME221 ME222 ME223 ME224 ME225 ME226 ME227

Subject Mathematics IV

Mechanical Metrology Measurements &

Dept/Board Mathematics Mechanical Engg. Mechanical Engg. Mechanical Engg. Mechanical Engg. Mechanical Engg. Mechanical Engg. Mechanical Engg.

Hours/week Credits 4 (T) 4 (T) 4 (T) 4 (T) 4 (T) 4 (T) 3 (L) 3 (L) 30 4 4 4 4 4 4 1.5 1.5 27

Applied Thermodynamics Theory of Machines I Manufacturing Process II Fluid Mechanics

Metrology & Measurements Laboratory

Machine Shop Practice Total

MECHANICAL MEASUREMENTS AND METROLOGY (4-0-0) 4 Sub Code Hrs / Week SEE Hrs : ME 221 : 04 : 3 Hrs PART A Unit 1 Standards of measurement: Definition and Objectives of metrology, subdivision of standards, line and end standard. Slip gauges, wringing phenomena, numerical problems on building of slip gauges. Angular measurements, Interferometry: Bevel Protractor, Sine Principle and. use of Sine bars, Sine center, angle gauges, Clinometers. Principle of interferometry, autocollimator. 8 Hrs Unit - 2 System of limits, Fits, Tolerances and gauging: Definition of tolerance, specification in assembly, principle of inter changeability and selective assembly. Concept of limits of size and tolerances, compound tolerances, accumulation of tolerances. Definition of fits, types of fits. Geometrical tolerance and positional tolerances. Hole basis system and shaft basis system. Classification of gauges, brief concept of design of gauges (Taylor's principles), wear allowance on gauges. Types of gauges -plain plug gauge, ring gauge, snap gauge, gauge materials. 8 Hrs Unit 3 Comparators: Introduction to Comparators, characteristics and classification of comparators. Mechanical comparators, Sigma Comparators, Optical Comparators -principles, Zeiss ultra optimeter, Electric and Electronic Comparators , LVDT, Pneumatic Comparators, Solex Comparator. Screw thread gear measurement: Terminology of screw threads, measurement of major diameter, minor diameter, pitch, angles and effective diameter of screw threads by 2-wire and 3-wire methods, best size wire. Toolmakers microscope, gear terminology, use of gear tooth Vernier caliper and gear tooth micrometer. 10 Hrs PART B Unit 4 Measurements and Measurement systems: Definition, significance of measurement, generalized measurement system, definitions and concept of accuracy, precision, calibration, threshold, sensitivity, hysterisis, repeatability, linearity, loading effect, system response-times delay. Errors in Measurements, classification of Errors. Transducers: Transfer efficiency, Primary and Secondary transducers, classification of transducers with examples. Advantages of each type transducers. Intermediate modifying and terminating devices: Mechanical systems, inherent problems, Electrical intermediate modifying devices, input circuitry, electronic amplifiers. Terminating devices: Mechanical, Cathode Ray Oscilloscope, Oscillographs, X-Y Plotters. 10 Hrs Unit 5 Measurement of Force and Torque: Basic principles, analytical balance, proving ring, Torque measurement, Pony brake, hydraulic dynamometer. Temperature measurement: Resistance thermometers, thermocouple, law of thermocouple, materials used for construction, pyrometers, Optical Pyrometer. 8 Hrs Unit 6 Pressure Measurements: Basic principles, use of elastic members, Bridgeman gauge, Mc Leod gauge, Pirani gauge. Strain Measurements: Strain gauges, preparation and mounting of strain gauges, gauge factor, methods of strain measurement. 8 Hrs CIE : 50% SEE : 50 % Max. Marks: 100

Text Books: 1. Mechanical measurements by Beckwith Marangoni and Lienhard, Pearson Education, 6th Ed., 2006 2. Engineering Metrology by R.K.Jain, Khanna Publishers Reference Books: 1. Engineering Metrology by I.C.Gupta, Dhanpat Rai Publications, Delhi 2. Mechanical measurements by R.K.Jain 3. Industrial Instrumentation Alsutko, Jerry. D.Faulk, Thompson Asia Pvt. Ltd.2002 4. Mechanical measurements, by Sirohi and Radakrishna. 5. Mechanical measurements, by Doblin, McGraw Hill Publications

APPLIED THERMODYNAMICS (4-0-0) 4 Sub Code Hrs / Week SEE Hrs : ME 222 : 04 : 3 Hrs PART-A Unit 1 Combustion Thermodynamics: Theoretical (Stoichiometric) air for combustion of fuels, Excess air, mass balance, actual combustion. Exhaust gas analysis, A/F ratio. Energy balance for a chemical reaction, enthalpy of formation, enthalpy and internal energy of combustion, Combustion efficiency. Air standard cycles: Carnot, Otto, Diesel cycles, p-v and T-s diagrams, description, efficiencies and mean effective pressures comparison of Otto & Diesel cycles. 09 hrs Unit 2 Dual and Sterling cycles, p-v and T-s diagrams, description, efficiencies and mean effective pressures. Comparison of Otto, Diesel and Dual cycles. Gas turbine cycles: Brayton cycle for a gas turbine power plant, methods to improve the performance of Brayton cycle using regeneration, reheating and intercooling, deviations of practical gas turbine cycles from ideal cycles. 09 Hrs Unit 3 Vapour Power Cycles: Carnot vapour power cycle, drawbacks, simple Rankine cycle, description, T-s diagram, analysis for performance, Comparison of Carnot and Rankine cycles. Effects of pressure and temperature on Rankine cycle performance. Actual vapour power cycles. Ideal and practical regenerative Rankine cycles, open and closed feed water heaters. Reheat- regenerative- Rankine cycle. 8 Hrs PART-B Unit 4 Reciprocating Compressors: Operation of a single stage reciprocating compressors, work input using p-v diagram and steady state flow analysis, effect of clearance and volumetric efficiency, adiabatic, isothermal and mechanical efficiencies, multistage compressors, saving in work, optimum intermediate pressure, intercooling, minimum work for compression. 8 Hrs Unit - 5 Refrigeration: Vapour compression refrigeration system, description, analysis, refrigerating effect, capacity, power required, units of refrigeration, COP, Refrigerants and their desirable properties. Air cycle refrigeration, reversed Carnot; cycle, reversed Brayton Cycle, Vapour absorption refrigeration system, Steam jet refrigeration. Psychrometrics: Atmospheric air and psychometric properties, Dry bulb temperature, wet bulb temperature, dew point temperature, partial pressures, specific and relative humidity and the relation between them, enthalpy and adiabatic saturation temperature, Construction and use of psychrometric chart. 09 Hrs Unit - 6 Analysis of various Psychrometric processes such as heating, cooling, humidifying, dehumidifying and adiabatic mixing of stream of moist air. Summer and winter air conditioning. I.C. Engines: Testing of two-stroke and four stroke SI and CI engines for performance, related numerical problems, heat balance, methods to determine the frictional power, Morse test, MPFI engines, CRDe engines. 09 Hrs CIE : 50 % SEE : 50 % Max. Marks: 100

TEXT BOOKS: 1. Basic and Applied Thermodynamics by P.K,.Nag, Tata McGraw Hill Pub. Co., 2002 2. Engineering Thermodynamics by Dr.R.K.Rajput, Laxmi Publications , 2006 3. Internal Combustion Engines by M.L.Mathur and R.P.Sharma, Dhanpat Rai Pub. 2000. Reference Books: 1.Thermodynamics An engineering approach by Yunus A. Cenegal and Michael A., Boies, Tata McGraw Hill pub. Co.,2002 2 Applied Thermodynamics by T.D.EAstop & A.Mcconkey, Person Education Asia, 2002. 3.Applications of Thermodynamics by Bernard D.Wood, Addision Wesley, 2nd Ed. 1974. 4.Thermodynamics By B.S.Sarkar.

ME223 THEORY OF MACHINES-I(4-0-0)4 Sub Code Hrs / Week SEE Hrs : ME 223 : 04 : 3 Hrs CIE : 50 % SEE : 50 % Max. Marks: 100

PART A Unit 1 INTRODUCTION: Rigid & Resistant bodies, kinematics pairs, degrees of freedom, Grublers criterion Kinematic chain, Mechanism, structure, Mobility of Mechanism, Inversion, Machine. Inversions of Four bar chain: Single slider crank chain and Double slider crank chain. MECHANISMS: Quick return motion mechanisms-Drag link mechanism, Whitworth mechanism, Crank and slotted lever Mechanism, straight line motion mechanisms Peaucelliers mechanism and Roberts mechanism. 9 Hrs Unit 2 Intermittent Motion mechanisms Geneva mechanism and Ratchet and Pawl mechanism. Toggle mechanism, Pantograph, Ackerman steering gear mechanism, Davis steering gear mechanism. VELOCITY ANALYSIS OF MECHANISMS: Introduction, Absolute and relative motions, vectors, Addition and subtraction of vectors, Motion of a link, four-link mechanism, angular velocity of links, velocity of rubbing, slider-crank mechanism, crank and slotted lever mechanism, instantaneous centre, notation, number of I-centres, Kennedys theorem, locating I-centres, angular velocity by I-centre method, centroid. 9 Hrs Unit 3 ACCELERATION ANALYIS OF MECHANISMS: Acceleration, four-link mechanism, Angular acceleration of links, Acceleration of intermediate and offset points, Slider-crank mechanism, Coriolis acceleration component, Crank and slotted lever mechanism, Kliens construction, velocity and acceleration from displacement-time curve. 8 Hrs PART B Unit 4 GEARS: Classification & application of different types of gears, Gear terminology, law of gearing, gear tooth profiles, Path of contact, Arc of contact, Contact ratio, Interference in involute gears and under cutting. Methods of avoiding interference, Back lash, Comparison of involute and cycloidal tooth profiles. GEAR TRAINS: Simple gear trains, Compound gear trains, Epicyclic gear trains, Algebraic and tabular methods of finding velocity ratio of epicyclic gear trains. Tooth load and torque calculations in epicyclic gear trains. 10 Hrs Unit 5 Belt, Rope & Chain Drives: Belt drives: Introduction, classification, velocity ratio, slip, creep, law of belting, length of belt, ratio of belt tensions, effect of centrifugal tension, power transmitted-Belt: Expression for ratio of tensions & power transmitted. Rope & chain drive: Classification, expression for speed ratio, applications. 8 Hrs Unit 6 CAMS: Types of cams, Types of followers, Displacement, Velocity and Acceleration time curves for cam profiles. Disc cam with reciprocating follower having knife-edge, roller and flat-faced follower, Disc cam with oscillating roller follower, Follower motions including SHM, Uniform velocity, uniform acceleration and retardation and Cycloidal motion. 8 Hrs Text Books: 1. Rattan S.S, Theory of Machines Tata McGraw-Hill Publishing Company Ltd., New Delhi and 2nd edition 2005. 2. Sadhu Singh, Theory of Machines, Pearson Education (Singapore) Pvt. Ltd., Indian Branch, New Delhi, 2ND Edi. 2006.

Reference books: 1. Shigley. J. V. and Uickers, J.J., Theory of Machines & Mechanisms OXFORD University press.2004 2. Theory of Machines -I, by Thomas Bevan, CBS Publications, New Delhi.

MANUFACTURING PROCESS II (4-0-0) 4 Sub Code Hrs / Week SEE Hrs : ME 224 : 04 : 3 Hrs PART A Unit 1 Theory of Metal Cutting: Single point cutting tool nomenclature, geometry, orthogonal and oblique cutting, mechanism of chip formation, types of chips, Merchants circle diagram and analysis, Ernst Merchants solution, shear angle relationship, problems of Merchants analysis. 9 Hrs Unit 2 Cutting Tool & Tool Materials: tool wear and tool failure, effects of cutting parameters on tool life, tool failure criteria, Taylors tool life equation, problems on tool life evaluation. Heat generation in metal cutting, factors affecting heat generation, measurement of tool tip temperature. Desired properties, types of cutting tool materials HSS, carbides, coated carbides CBN, PCD and ceramics. Cutting fluids, desired properties, types and selection. Machinability and factors affecting machinability. 8 Hrs. Unit 3 Production lathes: Introduction, principle and working, part of centre lathe specification different operations, definitions of speed, feed and depth of cut, cutting time calculation, Calculation of change of gears in thread cutting, constructional features of turret and capstan lathes, tool layout. Shaping and Planning Machines: : Classification, specification, constructional features, driving mechanisms. Shaping and planning operations. Problems on calculation of machining time. 9 Hrs. PART B Unit 4 Drilling machines: Classification, Specification, constructional features, drilling & related operations, types of drill & drill bit nomenclature, machining time. . Milling Machines: Classification, constructional features, milling cutters nomenclature, milling operations, up milling and down milling concepts. Indexing: Simple, compound, differential indexing calculations. Simple problems on simple and compound indexing. 9 Hrs. Unit 5 Grinding Machines: Types of abrasives, bonding process, classification, constructional features of cylindrical and surface grinding machines, tool and cutter grinder, specification of grinding wheel, selection of grinding wheel, balancing of grinding wheel. Super Finishing Operations : Lapping, honing and super finishing operations. 9 Hrs. Unit 6 Non Traditional Machining : Introduction, classification, processes like EDM, LBM, EBM, USM, working principles Advantages & Disadvantages. 8 Hrs CIE : 50 % SEE : 50 % Max. Marks: 100

Text Books: 1. Workshop Technology by Hazara Choudhry, Vol-II, Media Promoters & Publishers Pvt. Ltd. 2004 2. Production Technology by R.K.Jain, Khanna Publications, 2003. 3. Production technology by HMT, Tata McGraw Hill, 2001. 4. Modern manufacturing process by Adithan. Tata McGraw Hill, 2002 edn Reference Books: 1. Manufacturing Science by Amitabha Ghosh and Mallik, affiliated East West Press, 2003. 2. Fundamentals of Metal Machining and Machine Tools by G. Boothroyd, McGraw Hill, 2000. 3. Theory of Metal cutting & practice by A. Bhatta charya.

FLUID MECHANICS (4-0-0) 4 Sub Code Hrs / Week SEE Hrs : ME 225 : 04 : 3 Hrs PART- A Unit 1 Properties of Fluids: Introduction, properties of fluids, viscosity, thermodynamics properties., surface tension and capillarity, vapour pressure. 10 Hrs Unit 2 Fluid Statistics: Fluid pressure at a point, Pascals law , pressure variation in a static fluid, absolute, gauge , atmospheric & vacuum pressures, simple manometers, differential manometers, Total pressure, & centre of pressure, vertical plane surfaces , inclined plane surfaces and curved surfaces submerged in liquid , Buoyancy , centre of buoyancy, metacentre and metacentric height, conditions of equilibrium of floating and submerged bodies. 9 Hrs Unit 3 Fluid Kinematics: Types of Fluid flow, Introduction, continuity equation, continuity equation in three dimensions (Cartesian co-ordinate system only) and velocity and acceleration, velocity potential function and stream function, flow net. Dimensional Analysis: Introduction, derived quantities, Dimensions of physical quantities, dimensional homogeneity-Buckinghams theorem, the Rayleighs method, important dimensionless numbers and similitude studies. 9 Hrs PART-B Unit 4 Fluid Dynamics: Introduction, Equation of motion, Eulers equation of motion, Bernoullis equation derived from fundamental & Eulers equation, Bernoullis equation for real fluids. Fluid Flow measurements: Venturimeter, Orifice meter and Pitot tube, Flow through pipes: Frictional losses in pipe flow, Darcy and Chezy equations for loss of head due to friction in pipes, hydraulic gradient & total energy line. 10 Hrs Unit 5 Laminar flow and viscous effects: Reynolds number, critical reynolds number , laminar flow through a round pipe- Hagen poisuilles equation, laminar flow between parallel stationery plates. Flow past immersed Bodies: Drag, lift, expression for lift and drag, pressure drag and friction drag, boundary layer concept, displacement thickness, momentum thickness and energy thickness. 9 Hrs Unit 6 Introduction to compressible flow: Velocity of sound in a fluid , Mach number, propagation of pressure waves in a compressible fluid. Introduction to CFD: General principles and approaches for solving fluid dynamic problems using computers , introduction to CFD software packages. 7 Hrs CIE : 50 % SEE : 50 % Max. Marks: 100

TEXT BOOKS: 1. Fluid Mechanics by Streeter Mc Graw Hill, 7th ed., 1979 2. Fluid Mechanics and Hydraulics by DR. Jagadish Lal, Metropolitan Book Co. pvt. Ltd, New Delhi. 1995.

Reference Books: 1. A Text Book of fluid mechanics and hydraulic machines by Dr. R.K.Bansal Laxmi publications (p)Ltd., New Delhi. 2000. 2. Fluid Mechanics by Agarwal, Tata McGraw Hill edition. 3. Engineering Fluid Mechanics by Dr.K.L.Kumar,Eurosia Publishing House (P),Ltd, 2005 4. Engineering Fluid Mechanics by Dr.R.J.Garde and Dr.A.J.Mirajgaonkar, Scitech Publications(India)Chennai,2003. 5. Fluid Mechanics by John F.Douglas, Janul and M.Gasiosek and John A. Swaffild,Pearson education Asia ,4th edn ,2002. 6. Fluid Mechanics by White,5th edn ,Tata Mcgraw Hill,2003.

METROLOGY & MEASUREMENTS LABORATORY (0-0-3) 1.5 Sub Code Max. Marks : ME 226 : 50 Hrs / Week : 03

PART - A Calibration of Pressure Gauge Calibration of Thermocouple Calibration of LVDT Calibration of Load cell Determination of modulus of elasticity of a mild steel specimen using strain gauges.

PART - B

Measurements using Optical Projector / Tool maker Microscope. Measurements of angle using Since Center / Sine bar / bevel Protector. Measurements of alignment using Autocollimator / roller set. Measurements of cutting tool forces using a) Lathe tool Dynamometer. B) Drill tool Dynamometer Measurements of Screw thread Parameters using two wire or three wire method. Measurements of Surface roughness using Talysurf / Mechanical Comparator. Measurements of gear tooth profile using gear tooth vernier / gear tooth micrometer. Calibration of a micrometer using slip gauges. Measurement using Optical flats.

MACHINE SHOP PRACTICE (0-0-3) 1.5 Sub Code Max. Marks : ME 227 : 50 Hrs / Week : 03

Plain Turning, Taper Turning, Step Turning, Thread Cutting, Facing, Knurling, Eccentric Turning using lathe. Cutting of gear teeth using Milling Machine. Cutting of V-groove / Dovetail / rectangular groove using Shaping Machine. Demonstration of Surface Grinding.

Vous aimerez peut-être aussi

- Engine Testing: Electrical, Hybrid, IC Engine and Power Storage Testing and Test FacilitiesD'EverandEngine Testing: Electrical, Hybrid, IC Engine and Power Storage Testing and Test FacilitiesPas encore d'évaluation

- Fuente Segura Hose 10 Edicion InglesDocument470 pagesFuente Segura Hose 10 Edicion InglesAnonymous voPTZ0r00100% (2)

- Mechanical Engineering Science: In SI UnitsD'EverandMechanical Engineering Science: In SI UnitsÉvaluation : 5 sur 5 étoiles5/5 (4)

- Measurement and Instrumentation: Theory and ApplicationD'EverandMeasurement and Instrumentation: Theory and ApplicationÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- CAT Excavator 330L 9ML ManualsDocument9 pagesCAT Excavator 330L 9ML ManualsCristhian Cardenas88% (8)

- Genie GS-3268 RT Service ManualDocument183 pagesGenie GS-3268 RT Service ManualBosko100% (3)

- 7 Semester Mechanical Engineering: Course No. Course Name Credits L T PDocument8 pages7 Semester Mechanical Engineering: Course No. Course Name Credits L T PAJPas encore d'évaluation

- Mech Vii & Viii Sem NMAMIT SYLLABUSDocument52 pagesMech Vii & Viii Sem NMAMIT SYLLABUSHn NayakPas encore d'évaluation

- B.Tech. Second Year (Mechanical Engineering) : (Batch 2009)Document11 pagesB.Tech. Second Year (Mechanical Engineering) : (Batch 2009)Faiz AkhtarPas encore d'évaluation

- Course DiaryDocument66 pagesCourse DiaryAishwarya RaviPas encore d'évaluation

- Theory of MachinesDocument14 pagesTheory of MachinesGourav KotriwarPas encore d'évaluation

- Sub Code: 15IM/IP 32 IA Marks: 25 Hrs/week: 04 Exam Hours: 03 Total Lecture HRS: 50 Exam Marks: 100Document14 pagesSub Code: 15IM/IP 32 IA Marks: 25 Hrs/week: 04 Exam Hours: 03 Total Lecture HRS: 50 Exam Marks: 100Biswajeet MohantyPas encore d'évaluation

- Mechanical Au 3-1Document10 pagesMechanical Au 3-1Venkata Sai Kumar NunnaPas encore d'évaluation

- 3rd Sem Aero Syllabus For VTUDocument8 pages3rd Sem Aero Syllabus For VTUaeroromeosPas encore d'évaluation

- 5TH 6TH Final As Per Bos Adjuen Meetin On 21-08-21 210824 164803Document28 pages5TH 6TH Final As Per Bos Adjuen Meetin On 21-08-21 210824 164803DigvijayPas encore d'évaluation

- 5sem Med NewDocument10 pages5sem Med NewRohitYadavPas encore d'évaluation

- Third Year Second Semester: Department of Mechanical Engineering - Course CatalogueDocument8 pagesThird Year Second Semester: Department of Mechanical Engineering - Course CatalogueSudeep GamerPas encore d'évaluation

- Mech AutoDocument36 pagesMech Autoapi-236544093Pas encore d'évaluation

- B.Tech. (Mechanical Engineering) Semester IVDocument11 pagesB.Tech. (Mechanical Engineering) Semester IVmahavircPas encore d'évaluation

- Third Year Mechanical Engineering SyllabusDocument54 pagesThird Year Mechanical Engineering SyllabusTonya WhitneyPas encore d'évaluation

- 7th Semester UET TaxilaDocument4 pages7th Semester UET TaxilaRameez AnwarPas encore d'évaluation

- Open ElectiveDocument7 pagesOpen ElectivevibhaPas encore d'évaluation

- Mech Sem6Document17 pagesMech Sem6Nidhi GandhiPas encore d'évaluation

- Vtu 6th Sem SyllabusDocument33 pagesVtu 6th Sem Syllabusshamanth022Pas encore d'évaluation

- SyllabusDocument6 pagesSyllabusAbhishek KumarPas encore d'évaluation

- IpsyllDocument134 pagesIpsyllsatish5269115Pas encore d'évaluation

- AutosyllDocument91 pagesAutosyllRashmi Gowda DPas encore d'évaluation

- IEM Full SyllabusDocument130 pagesIEM Full Syllabusavishekagarwal_09Pas encore d'évaluation

- Mechanical Engineering 2006 Sem VIDocument7 pagesMechanical Engineering 2006 Sem VIRahul Raveendran PillaiPas encore d'évaluation

- Elements of Mechanical EngineeringDocument2 pagesElements of Mechanical EngineeringMayur CharanPas encore d'évaluation

- M.E. Mechatronics SyllabusDocument38 pagesM.E. Mechatronics SyllabusJoswa CaxtonPas encore d'évaluation

- Nepal AirlinesDocument4 pagesNepal AirlinesAadarsh bhandariPas encore d'évaluation

- 15 Mechanical EngineeringDocument62 pages15 Mechanical Engineeringslv_prasaadPas encore d'évaluation

- General Ability Test (Common For All Streams EC, ME, Ee, Ce) Part A: General English: TheDocument18 pagesGeneral Ability Test (Common For All Streams EC, ME, Ee, Ce) Part A: General English: ThevqxknpnkPas encore d'évaluation

- Cc104 - Elements of Mechanical EngineeringDocument2 pagesCc104 - Elements of Mechanical Engineeringamit2691988Pas encore d'évaluation

- Apollo Engineering College Chennai: Yr "A"sec MechDocument4 pagesApollo Engineering College Chennai: Yr "A"sec MechSiva ShankarPas encore d'évaluation

- Text Books:: 2. Ansel Ugural, "Mechanical Design - An Integral Approach", 1 Edition, Tata Mcgraw-Hill Book Co, 2003Document6 pagesText Books:: 2. Ansel Ugural, "Mechanical Design - An Integral Approach", 1 Edition, Tata Mcgraw-Hill Book Co, 2003Liaqat ahmedPas encore d'évaluation

- Details of Courses For Fall 2018 TechnologyDocument14 pagesDetails of Courses For Fall 2018 Technologykihalid hayatPas encore d'évaluation

- ME Vol 2 FMDocument364 pagesME Vol 2 FMDeepak Gupta100% (4)

- Syllabus For VIII Semester (IV Year) B. Tech. (Mechanical Engineering)Document3 pagesSyllabus For VIII Semester (IV Year) B. Tech. (Mechanical Engineering)XtremeInfosoftAlwarPas encore d'évaluation

- National Institute of Technology, Hamirpur (HP) - 177 005 B.Tech. Mechanical Engineering, Third Year (5 Semester)Document13 pagesNational Institute of Technology, Hamirpur (HP) - 177 005 B.Tech. Mechanical Engineering, Third Year (5 Semester)Ranbir SinghPas encore d'évaluation

- 8th SemDocument5 pages8th SemjeyganishPas encore d'évaluation

- Mechanical Engineering 2006 Sem VDocument8 pagesMechanical Engineering 2006 Sem VMansanth BosePas encore d'évaluation

- IC EngineDocument52 pagesIC EngineShreepal ChilaPas encore d'évaluation

- Sem 3 SyallabusDocument12 pagesSem 3 SyallabusVishwadeep PaulPas encore d'évaluation

- B. Tech. Final Year InstruDocument32 pagesB. Tech. Final Year InstruRoman RoomannPas encore d'évaluation

- Mmi Final Copy DN PDFDocument127 pagesMmi Final Copy DN PDFAkhilprasad SadigePas encore d'évaluation

- Mech Final Syl Btech NitaDocument47 pagesMech Final Syl Btech NitaAngad SinghPas encore d'évaluation

- Semester VDocument14 pagesSemester VAbhishek GuptaPas encore d'évaluation

- 3rd SemesterDocument13 pages3rd SemesterRed-KanPas encore d'évaluation

- BE Syllabus of Mumbai Uni5Document10 pagesBE Syllabus of Mumbai Uni5Rajendra B PawarPas encore d'évaluation

- KANNUR UNIVERSITY BTech.S8 ME. SyllabusDocument13 pagesKANNUR UNIVERSITY BTech.S8 ME. SyllabusManu K MPas encore d'évaluation

- Ganpat University: U.V.Patel College of EngineeringDocument13 pagesGanpat University: U.V.Patel College of EngineeringMalith MadushanPas encore d'évaluation

- Mechanical Engineering Subject Duration - Maximum Marks Section I-Objective PapersDocument4 pagesMechanical Engineering Subject Duration - Maximum Marks Section I-Objective Paperssudheer92Pas encore d'évaluation

- Simulation and Optimization in Process Engineering: The Benefit of Mathematical Methods in Applications of the Chemical IndustryD'EverandSimulation and Optimization in Process Engineering: The Benefit of Mathematical Methods in Applications of the Chemical IndustryMichael BortzPas encore d'évaluation

- Introduction to Bond Graphs and their ApplicationsD'EverandIntroduction to Bond Graphs and their ApplicationsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Embedded Mechatronic Systems 2: Analysis of Failures, Modeling, Simulation and OptimizationD'EverandEmbedded Mechatronic Systems 2: Analysis of Failures, Modeling, Simulation and OptimizationPas encore d'évaluation

- Applied Metrology for Manufacturing EngineeringD'EverandApplied Metrology for Manufacturing EngineeringÉvaluation : 5 sur 5 étoiles5/5 (1)

- Modern Anti-windup Synthesis: Control Augmentation for Actuator SaturationD'EverandModern Anti-windup Synthesis: Control Augmentation for Actuator SaturationÉvaluation : 5 sur 5 étoiles5/5 (1)

- DrawingDocument1 pageDrawingM Tommy AdamsPas encore d'évaluation

- Power Team Manual Valves - CatalogDocument1 pagePower Team Manual Valves - CatalogTitanplyPas encore d'évaluation

- Fault Codes: STO U AndriivDocument39 pagesFault Codes: STO U AndriivAtochkavPas encore d'évaluation

- CWCH4IN Instal Manual WebDocument39 pagesCWCH4IN Instal Manual WebEnrique ScibiliaPas encore d'évaluation

- UNIT-3 Part-A 1. Write Short Notes On Mixture Requirements of SI EnginesDocument27 pagesUNIT-3 Part-A 1. Write Short Notes On Mixture Requirements of SI EnginesJVCPas encore d'évaluation

- Facts Volume 1Document92 pagesFacts Volume 1Maniak Muligambia100% (1)

- Elevador Rotary LiftDocument120 pagesElevador Rotary LiftMiguel Eliezer SequeiraPas encore d'évaluation

- Transport PhenomenaDocument8 pagesTransport PhenomenawaqaskhanPas encore d'évaluation

- Südmo DSV Complete Mix Proof: Valve Id KeyDocument2 pagesSüdmo DSV Complete Mix Proof: Valve Id KeyMike MurdaughPas encore d'évaluation

- Lecture-: Amr - Ahmed@eng - Asu.edu - EgDocument28 pagesLecture-: Amr - Ahmed@eng - Asu.edu - EgahmedaboshadyPas encore d'évaluation

- BOMBAS PRIMARIAS - Data - Sheet - TOP-S - 40 - 10 - 3 - PN - 6 - 10Document1 pageBOMBAS PRIMARIAS - Data - Sheet - TOP-S - 40 - 10 - 3 - PN - 6 - 10Sebastian FuentesPas encore d'évaluation

- G3520E Data SheetDocument3 pagesG3520E Data SheetIwaiter100% (2)

- 20115272209Document45 pages20115272209Cristian TeodorescuPas encore d'évaluation

- EN10255 Pipe SizeDocument3 pagesEN10255 Pipe SizeStefan CristescuPas encore d'évaluation

- Industrial Report at Incepta Pharmaceuticals Ltd.Document36 pagesIndustrial Report at Incepta Pharmaceuticals Ltd.Naimul Hoque Shuvo100% (1)

- Population Balance Modelling To Describe The Particle Aggregation Process: A ReviewDocument18 pagesPopulation Balance Modelling To Describe The Particle Aggregation Process: A ReviewAlexander FierroPas encore d'évaluation

- PSC AE QuestionsDocument9 pagesPSC AE QuestionsDipayan MisraPas encore d'évaluation

- Asme Y14.32.1m - 1994Document17 pagesAsme Y14.32.1m - 1994achmadnureddin8228Pas encore d'évaluation

- Hydraulic Jet PumpDocument3 pagesHydraulic Jet Pumpvictor javier nuñezPas encore d'évaluation

- Stability-Calculation For PipelineDocument2 pagesStability-Calculation For PipelineGeorge100% (1)

- Changanyikeni Apartments PadFtgDocument25 pagesChanganyikeni Apartments PadFtgAnonymous Xb3zHioPas encore d'évaluation

- Atif Baig (22467), Lal Chand (21591) Abdul Hannan (21618 Alveena (21651)Document1 pageAtif Baig (22467), Lal Chand (21591) Abdul Hannan (21618 Alveena (21651)Lal ChandPas encore d'évaluation

- 330B Excavator Hydraulic Variable Gauge Undercarriage Hydraulic Systems - AttachmentDocument2 pages330B Excavator Hydraulic Variable Gauge Undercarriage Hydraulic Systems - Attachmentnilton acPas encore d'évaluation

- 4.classification of Tensometry MethodsDocument3 pages4.classification of Tensometry MethodsМурад ГусейнзадеPas encore d'évaluation

- Delo Protection For Agricultural Equipment: Engine Crankcase Hydraulic SystemDocument1 pageDelo Protection For Agricultural Equipment: Engine Crankcase Hydraulic SystemflyinzeskyPas encore d'évaluation

- Product: WK Series Industrial BurnersDocument40 pagesProduct: WK Series Industrial Burnersbenlly alvarezPas encore d'évaluation

- MANUAL 08443-10A Rev 0 APPROVAL DOCUMENTS XL 110Document79 pagesMANUAL 08443-10A Rev 0 APPROVAL DOCUMENTS XL 110Black ScorpionPas encore d'évaluation