Académique Documents

Professionnel Documents

Culture Documents

Capacitors

Transféré par

hiremathvijayDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Capacitors

Transféré par

hiremathvijayDroits d'auteur :

Formats disponibles

Power Capacitors: Power Capacitor is a power saving product.

Hence, unlike any other electrical equipment, this product has a pay back period. This pay back period varies between 4 months to 1 year depending upon the economics of the electrical system and is generally worked out on the basis of the following formula: [Total Investment on Capacitor Purchase] = (Reduction rate per ) (Saving on A/c. of (in demand x per demand ) + (penalty for P.F. . ) )

This apart there are hidden advantages of capacitor installation such as: a) Reduction in demand thereby more utilization of power. No necessity to apply for more power. b) Reduction in current. Reduces the stress on the current carrying part of the system and hence increasing its life. c) Improvement of voltage profile of the system. Usually, after installation of capacitor the voltage improves by around 3% to 4%. d) Decrease in cable losses. Having seen above, the basic benefits of installing capacitor, there is no doubt that this is a product which is absolutely essential for any industry. Moreover, all State Electricity Boards and Utilities have imposed strict measures on their consumers to maintain a minimum power factor. The stipulation of minimum power factor varies between 0.85 to 0.90 depending upon the respective SEB or Utility. Although today the awareness of the advantages of capacitor is high, still there is a need to educate many industries about its importance. Type of Capacitors Basically the type of capacitor can be differentiated be into three types i.e. 1) HT Capacitors. 2) LT Capacitors. 3) Furnace Duty Capacitors. LT Capacitors:The most commonly used capacitors are LT capacitors and most of the industries are its users. Also, traders and dealers usually deal with LT capacitor as one of the standard electrical item like motors, switch gears, pumps etc. The competition for this market is immense and a rough estimation of around 120 or more manufactures is prevalent all over the country. But out of these, there may just a little over a dozen of companies who could be actually termed as established and reputed concerns.

1|Page

The types of LT capacitors that are today being sold extensively in the market are: i). AC condensers. Usually identified with its mfd ratings. These are used in fans, washing machines etc. ii). Electrolytic Capacitors: Used in Electronic applications. iii). MPP capacitors. (Metallised Polypropylene capacitors). The construction consists of metallisation done on Plastic Film which acts as a conductor and film as the dielectric. The metallisation has a thickness of 0.03/0.02 microns. This is very small thickness enables the metallisation to evaporate quickly under fault condition (break down of dielectric) and clear the fault immediately. This property is called self healing and is supposed to be the distinct feature of MPP type capacitors. Also due to its constructional advantages, it is the most economical capacitor. However, the thin layer of metallisation has also been proved to be the most notorious factor for large scale failure of MPP capacitors. Generally, electrical systems in India are far from the standards maintained in the advanced nations. The variation and fluctuations of the electrical system parameters here is quite high. Also the awareness to have clean electrical system, free from harmonics, is yet to take firm roots in our country. In Western countries harmonic filtration is a statutory requirement to have a pollution free electrical system. In our country this is so far not a priority area. Although some industries today are installing harmonic filter, this is yet to be made statutory like in case of improvement of power factor. The reason for highlighting the above is since MPP capacitors are vulnerable to failure when they are subjected to undue stress caused due to the harmonics present in the system. The failure is primarily caused due to evaporation of the metallisation layer of 0.02 to 0.03 microns under arduous system condition. Hence as a manufacturer or a dealer one should be judicious while offering MPP type capacitors. Based on experience it is observed that MPP capacitors should not be recommended in Industries like, steel, cement, fertilizer, textile & paper. Also where there is a high percentage of welding load as well frequent multi switching operations like in case of automatic switching operations like in case of automatic switching operation, use of MPP capacitor should be avoided. Ratings available for MPP Capacitor. 1, 2, 3, 4, 5, 7.5, 10, 12.5, 15, 20 & 25 KVAR units at 415 / 440 Volts. For above 25 KVAR Capacitor banks should be offered.

2|Page

iv). Mixed Dielectric: This type of capacitor is considered to be one of the oldest & established designs. The construction comprises a separate layer (unlike MPP capacitor) of conducting medium in the form Electrolytic grade Aluminium foil of 5 micron thickness (around 160 times more than metallisation deposit of MPP Capacitor). By this virtue the capacitor has a high withstand ability to overload conditions, although self healing operations are not possible. The dielectric medium consists a combination of tissue of paper and plastic film. This strong dielectric medium is precisely the reason for the longevity of this type of capacitor. As a compensation to self healing operations, as in case of MPP capacitor, in Mixed Dielectric Capacitor the design consists of number of elements connected in parallel with each element having its own element fuse. In event of break down of PP film only the particular element gets shorted and thereby blows the corresponding fuse. Thus the failure of one element leads to only a marginal drop in the rated capacitance value of the unit. Admittedly this drop in capacitance value is not as insignificant as in case of one self healing operation in MPP capacitors. The excellent dielectric properly of tissue paper + plastic film is further enhanced with the impregnation of PXE oil which also has excellent dielectric properties. This oil is filled under vacuum such that every part of the capacitor dielectric will have oil attached to it. Perhaps the only shortcoming of MD capacitor is its losses which are to the extent of 2.5 watts / KVAR. These high losses are mainly contributed by the tissue paper which generates heat more than PP Film. This most rugged construction has an average life of 10 / 15 Years and naturally is also the most expensive design. Ratings available for MD Capacitor 10, 15, 20, 2.5, 30, 40 & 50 KVAR is 415 / 440 V. For above 50 KVAR capacitor banks are to be offered. v). All Polypropylene Capacitor (2 Layer) Not much explanation is required for this type of capacitors since this is part of a revolution in capacitor technology, an advancement compared to MD capacitor. The construction is exactly similar to MD capacitor with just one crucial in dielectric medium. Tissue paper was dispensed and replaced with another layer of plastic film. By this the losses reduced drastically from 2.5 watts to 0.8 watts / KVAR. However, this technology had to undergo the initial teething problems mainly since plastic film does not have an equivalent oil absorption property of tissue paper. But with the introduction of modernized hazy film (having rough surface) the oil remains attached to the film and hence improves the dielectric strength. This apart, the capacitor is similar to MD capacitor in terms of construction as well as rating availability. .

3|Page

The technology being over 15 Years old India is today equally establishment as MD capacitor and has a proven track record for satisfactory performance even in the most complex electrical system. Hence today it is as reliable as MD capacitor and has average life of 10 / 15 years vi). ALL Polypropylene (Single Layer) A further innovation to All Polypropylene (2 Layer) design was achieved when the dielectric systems was further changed by having just one layer of plastic film (12 micron) as against 2 layers of 6 microns each. This brought down the price by around 20 25 %. Since the thickness of dielectric is equal to the overall construction and manufacturing process is same as that of MD & APP (2 Layers) type capacitors. Here, of course puncture to the plastic film lead to total failure of one element since there is no back up support of a second layer as in case of 2 layer design capacitor. This makes the design just a marginally less reliable than 2 layer. The technology was introduced around 4/5 years back and so far no major adverse complaints are received. But a long life reliability like in case of MD & All PP (2 layer) capacitors are yet to be proved. Single layer capacitor has also proved to be ideal substitute for MPP capacitors since it can work satisfactory even under complex system parameters where the variations are high and harmonics present. While the cost of MPP capacitors ranges around Rs. 125/per KVAR, single layers Capacitors are available in the range of around Rs. 235/- per KVAR. In Comparison for MD/ALL PP 2 layer capacitors price ranges around Rs. 320/- per KVAR. To summarise the type of LT capacitors are 1) 2) 3) 4) 5) 6) AC Condensers Electrolytic Capacitors MPP Capacitors MD Capacitors All PP (2 layer) Capacitors All PP (1 layer) Capacitors

Except for 1 & 2 we manufacture all types of capacitor and are one of the few manufactures to have such a wide range.

4|Page

HT Capacitors: This is a nonstandard product and it does not have standard ratings like in case of LT capacitors. The construction of HT capacitor has a separate layer of aluminium foil and PP film consisting of a number of layers depending upon design. The capacitors are of All PP design. The thickness of PP film and the number of layer of film depends upon required voltage rating. Capacitors are manufactured right from 3.3 KV and above up to 145 KV. For 3.3 KV & 6.6 KV the capacitors manufactured are of three phase internally star connected with maximum unit ratings of 150 KVAR. Above 150 KVAR capacitor banks are to be offered. For 11 KV and above the configuration is externally star connected or externally double star connected capacitor banks. In this case, single phase units are manufactured and they are connected in external star.

In most case, the capacitor units are provided with individual element fuses. However, in some cases capacitors are offered without internal fuses in which case external fuses of expulsion type have to be provided for unit protection. In case of HT capacitor banks the complete capacitor system are offered which consists various equipments like Circuit Breaker, Series Reactor, RVT, CT, Isolator, Lightning Arrestor, Control Panel etc. Furnace Capacitor This is special type of capacitor provided for furnace duty application of main frequencies. This is a totally tailor made item and manufactured exactly as per rating parameter provided by the furnace manufacturer. We have been one of the oldest manufacturers of furnace duty capacitor. Our first collaboration was with Otto Junker GmbH., West Germany who was basically furnace manufacturer. Due to this we have a specialisation in the manufacture of this type of capacitor and have supplied to all the major furnace manufacturer as well as furnace users. Normally, the voltages are of 500 Volts or 1000 Volts and most of foundry companies as well as Automobile industry have requirement of furnace duty capacitors.

Harmonic Filter Harmonic Filter is basically a device, which filters the harmonic present in the system. Harmonics are of various orders and it is a nuisance if it is present in the system. The presence of harmonics in the system causes undue abnormalities such as over voltage, over current etc. Also the protection system is distributed, if high orders on harmonics are present in the system. Hence, it is advisable that harmonics are filtered to keep the system clean and pure.

5|Page

Basically harmonic filter is a combination of capacitor and series reactor. Depending upon the harmonic that has to be filtered the ratings of capacitors as well as series reactors are derived so as to filter a particular order of harmonic. However, while designing this particular rating one has to carefully consider the over load withstand capacity of the capacitor bank and the series reactor. Hence, this is a very specialised engineering concept. We as a manufacturer of capacitors have also achieved specialisation in design of harmonic filters. We undertake carrying out a harmonic analysis of the system and also designing the rating of harmonic filter. Although the concept so far has not become very much popular in India, it will become one of the most important requirements In the near future. The awareness to keep system clean is being now emphasized to most of consumer and probably a day is not far when this could become a statutory requirement.

Conclusion. We are one of the leading manufacturers of HT and LT capacitors having set up in 1976. Today, we are one of the few manufacturers, who have entire range of products related to capacitors. All the types of capacitors mentioned above except for Mixed Dielectric capacitors and condensers and electrolytic capacitors are being manufactured by us. We have established a strong brand image and our brand is synonyms with capacitors in the whole industry. We have constantly up grade our facilities and have been in constant search to innovate our products by taking various Collaborations and Technical know hows. ************

6|Page

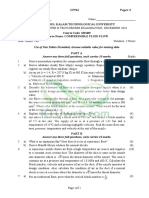

TECHNOLOGY COMPARSION FOR LT CAPACITORS

TYPE FEATURES Active element Dielectric Thickness of Active Element Impregnant MIXED DIELECTRIC Aluminium foil, PP film, oil. Combination of paper & PP film 5 micron Non PCB non hazardous Phenyl Xylyl Ethane (PXC) oil 110% of Vrated / 130% of Irated / 130% of output Not provided if require the same will be provided IS: 1385 1.5 Watt/KVAR 0.2 Watt/KVAR 0.14 Watt/KVAR ----------0.27 Watt/KVAR 2.11 Watt/KVAR 10, 15, 20, 25, 30, 40, 50 KVAR DOUBLE LAYER ALL PP Aluminium foil, PP film, oil Double Layer of PP film 5 micron Non PCB non hazardous Phenyl Xylyl Ethane (PXC) oil 110% of Vrated / 130% of Irated / 130% of output Not provided if require the same will be provided IS: 1385 0.2 Watt / KVAR 0.2 Watt / KVAR 0.14 Watt/KVAR ------------0.27 Watt/ KVAR 0.81 Watt/KVAR 10, 15, 20, 25, 30, 40, 50 KVAR SINGLE LAYER ALL PP Aluminium foil, PP film, oil Single layer of PP film 5 micron Non PCB non hazardous Phenyl Xylyl Ethane (PXC) oil 110% of Vrated / 130% of Irated / 130% of output Not provided if require the same will be provided IS: 1385 0.2 Watt / KVAR 0.2 Watt / KVAR 0.14 Watt/KVAR ------------0.27 Watt/ KVAR 0.81 Watt/KVAR 10, 15, 20, 25, 30, 40, 50 KVAR MPP Zn-Al Alloy Metallisation on PP film Single layer of PP film 0.02 to 0.03 micron Non PCB, non hazardous electrical grade castor oil

Permissible overloads

110% of Vrated / 130% of Irated / 130% of output Suitable rating of induction coil will be provided to limit the inrush current IS: 13340 0.2 Watt / KVAR 0.2 Watt / KVAR ------------------------------0.15 Watt/ KVAR 0.55 Watt/KVAR 1, 2, 3, 4, 5, 10, 15, 20, 25 KVAR Not suitable

Induction coil

Applicable standard Losses a) Dielectric b) Discharge resistance c) Internal element fuse d) Inductor coil. Leads etc. e) Leads etc. Total Unit standard ratings Applications a) Polluted system

Suitable for current Suitable for current Suitable for current harmonic upto 10% harmonic upto 10% harmonic upto 5% & voltage harmonic upto & voltage harmonic upto & voltage harmonic upto 5% 5% 2.5% Suitable Any type of load such as rolling mills (paper, steel) are furnaces, Thyristor, textiles, industry, cement industry Suitable Any type of load such as rolling mills (paper, steel) are furnaces, Thyristor, textiles, industry, cement industry Suitable Any type of load such as rolling mills (paper, steel) are furnaces, Thyristor, textiles, industry, cement industry

b) Freq. switching Example

Not suitable Loads which do not contain harmonics & frequent switching like agriculture load.

7|Page

Vous aimerez peut-être aussi

- Relay Coordination GuideDocument96 pagesRelay Coordination GuideShrimant Shanbhag80% (5)

- Ie Rules-1956Document191 pagesIe Rules-1956Murali MohanPas encore d'évaluation

- Electric Motor Controls TutorialDocument24 pagesElectric Motor Controls Tutorialvijai daniel100% (4)

- Aditya Hrudayam in KannadaDocument4 pagesAditya Hrudayam in Kannadahiremathvijay83% (6)

- 601 Um 1MDU07230-YN ENaDocument92 pages601 Um 1MDU07230-YN ENaHiral SolankiPas encore d'évaluation

- Adhhar Application FarmDocument2 pagesAdhhar Application FarmjaigodaraPas encore d'évaluation

- PLC or DCS PDFDocument12 pagesPLC or DCS PDFsafvanshaikhPas encore d'évaluation

- How To Read Control Panel Wiring Diagrams PDFDocument10 pagesHow To Read Control Panel Wiring Diagrams PDFhiremathvijay67% (3)

- The Art and Science of Measuring The Winding Resistance of Power Transformers Oleh W.Iwansiw, P.EngDocument6 pagesThe Art and Science of Measuring The Winding Resistance of Power Transformers Oleh W.Iwansiw, P.EngMeghavahinaPas encore d'évaluation

- Vedic MathsDocument220 pagesVedic Mathstargettutorials5740100% (7)

- 60Document9 pages60hiremathvijayPas encore d'évaluation

- Symmetrical ComponentsDocument2 pagesSymmetrical ComponentsHamayoun Murtaza100% (1)

- Eerecon EnggDocument26 pagesEerecon EngghiremathvijayPas encore d'évaluation

- Dok HB Mra4e - NewDocument664 pagesDok HB Mra4e - NewhiremathvijayPas encore d'évaluation

- Ac Motors EbookDocument74 pagesAc Motors EbookHammad MalikPas encore d'évaluation

- DG Set System: Syllabus Diesel Generating System: Factors Affecting Selection, Energy Performance Assessment ofDocument14 pagesDG Set System: Syllabus Diesel Generating System: Factors Affecting Selection, Energy Performance Assessment ofJitendra PatilPas encore d'évaluation

- Handbook Protection and Control DevicesDocument157 pagesHandbook Protection and Control Devicesadam1100100% (2)

- Bat Sizing UpsDocument8 pagesBat Sizing UpshiremathvijayPas encore d'évaluation

- Installation and Commissioning DMT PDFDocument124 pagesInstallation and Commissioning DMT PDFJaka Sembung GolokPas encore d'évaluation

- 103-4e Motor O& MDocument12 pages103-4e Motor O& MhiremathvijayPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Calorimetry ProblemsDocument3 pagesCalorimetry ProblemsLeticia CarandangPas encore d'évaluation

- Dialogs On Gravity Kinesthetics: From Christopher Veck and Adjo ZornDocument5 pagesDialogs On Gravity Kinesthetics: From Christopher Veck and Adjo ZornleoPas encore d'évaluation

- Subject Code/name: EE 2306-Flexible AC Transmission Systems: Facts 8 Kce/Eee/Qb/Ivyr/FactsDocument26 pagesSubject Code/name: EE 2306-Flexible AC Transmission Systems: Facts 8 Kce/Eee/Qb/Ivyr/FactssivakumarsarvananPas encore d'évaluation

- Use of Gas Tables Permitted, Assume Suitable Value For Missing DataDocument2 pagesUse of Gas Tables Permitted, Assume Suitable Value For Missing DataVenkitaraj K PPas encore d'évaluation

- Homework Assignment #2 AC Winding Losses: A 2:4 TransformerDocument3 pagesHomework Assignment #2 AC Winding Losses: A 2:4 Transformerganesh raoPas encore d'évaluation

- Mov-14Dxxxk Series - Metal Oxide Varistor: Features ApplicationsDocument4 pagesMov-14Dxxxk Series - Metal Oxide Varistor: Features ApplicationsFrancisco HernandezPas encore d'évaluation

- Day 3 - HW Test Review SOL G.14 Practice 3 - Similar SolidsDocument3 pagesDay 3 - HW Test Review SOL G.14 Practice 3 - Similar SolidsRyan AndersonPas encore d'évaluation

- Heating coil-100MTDocument31 pagesHeating coil-100MTHeong Siew LinPas encore d'évaluation

- Virtual Work Analysis of Mechanical Systems in EquilibriumDocument20 pagesVirtual Work Analysis of Mechanical Systems in EquilibriumarslansaeedarslanPas encore d'évaluation

- Fluid Machinery - PumpsDocument32 pagesFluid Machinery - PumpsIvan Jeremy AbilaPas encore d'évaluation

- IEC - 60243 Electric Strength of Insulating Materials - Test Methods - Part 2: Additional Requirements For Tests Using Direct VoltageDocument22 pagesIEC - 60243 Electric Strength of Insulating Materials - Test Methods - Part 2: Additional Requirements For Tests Using Direct VoltageAglieglie BrazorPas encore d'évaluation

- Physrevd.13.191 Hawking RadDocument7 pagesPhysrevd.13.191 Hawking RadSteven ChapmanPas encore d'évaluation

- Saginomiya CatalogS - Automatic ControlsDocument128 pagesSaginomiya CatalogS - Automatic Controlskepe81Pas encore d'évaluation

- Introduction to Non-Ideal TransformersDocument24 pagesIntroduction to Non-Ideal TransformersKANDEGAMA H.R. (BET18077)Pas encore d'évaluation

- Current Status of FPV and TrendsDocument10 pagesCurrent Status of FPV and TrendsKaushik DasPas encore d'évaluation

- Gsc-Sped Integrated School: For Item 2,3, 4 and 5 Refer To The Illustration AboveDocument3 pagesGsc-Sped Integrated School: For Item 2,3, 4 and 5 Refer To The Illustration AboveGlenda Baliad SecretariaPas encore d'évaluation

- VLT Brake Resistor MCE 101Document188 pagesVLT Brake Resistor MCE 101Bella SmithPas encore d'évaluation

- Protection Relays General Electrical Tests ChecklistDocument6 pagesProtection Relays General Electrical Tests ChecklistMohamed NasrPas encore d'évaluation

- Piezoelectric Actuators and Sensors LectureDocument32 pagesPiezoelectric Actuators and Sensors LecturetitiminetPas encore d'évaluation

- Chem011 Labrep2Document6 pagesChem011 Labrep2Glennmar OtillaPas encore d'évaluation

- Module 1 PhysicsDocument12 pagesModule 1 PhysicsCasimero CabungcalPas encore d'évaluation

- Unit 3.2: Unit 3.2 Mass-Energy RelationshipDocument33 pagesUnit 3.2: Unit 3.2 Mass-Energy RelationshipGabriel FungPas encore d'évaluation

- ABB T Max Breaker Certificate BV T1-T7 20125 - B0 BVDocument6 pagesABB T Max Breaker Certificate BV T1-T7 20125 - B0 BVM. ShaatPas encore d'évaluation

- Vectors Notes (Answers)Document24 pagesVectors Notes (Answers)ScionPas encore d'évaluation

- MCQ Res1Document6 pagesMCQ Res1Durairaj M.Pas encore d'évaluation

- Otto Cycle ProblemsDocument4 pagesOtto Cycle ProblemsBipulBrahmaPas encore d'évaluation

- Differential Liberation PVT Fluid TestDocument11 pagesDifferential Liberation PVT Fluid TestAhmed M. Saad0% (1)

- Dtu, Department of Energy Engineering S in (KJ/ (KG K) ) - V in (M 3/Kg) - T in (ºc) M.J. Skovrup & H.J.H Knudsen. 19-01-21 Ref:Dupont Suva Mp39Document1 pageDtu, Department of Energy Engineering S in (KJ/ (KG K) ) - V in (M 3/Kg) - T in (ºc) M.J. Skovrup & H.J.H Knudsen. 19-01-21 Ref:Dupont Suva Mp39sebastianPas encore d'évaluation

- AP Chem 2013S Mod C Notes - AnsDocument44 pagesAP Chem 2013S Mod C Notes - AnsWTSEPas encore d'évaluation

- Astm D445-17Document16 pagesAstm D445-17ridermatePas encore d'évaluation