Académique Documents

Professionnel Documents

Culture Documents

Mid 1 Study 05

Transféré par

Julianto Tobing0 évaluation0% ont trouvé ce document utile (0 vote)

12 vues4 pages1st Midterm Study Guide Lectures 1-7 including lecture 7 which is very important Here is the study guide for the first exam. For those of you who haven't taken a class from me I will typically ask questions based on what is asked in this document. For this class, I will also look back at the questions from the homework so it is important that you also look at these.

Description originale:

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

DOC, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce document1st Midterm Study Guide Lectures 1-7 including lecture 7 which is very important Here is the study guide for the first exam. For those of you who haven't taken a class from me I will typically ask questions based on what is asked in this document. For this class, I will also look back at the questions from the homework so it is important that you also look at these.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

12 vues4 pagesMid 1 Study 05

Transféré par

Julianto Tobing1st Midterm Study Guide Lectures 1-7 including lecture 7 which is very important Here is the study guide for the first exam. For those of you who haven't taken a class from me I will typically ask questions based on what is asked in this document. For this class, I will also look back at the questions from the homework so it is important that you also look at these.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

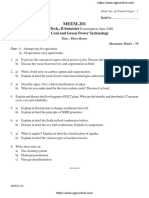

PSE 476

1st Midterm

January 17, 2007

Study Guide Lectures 1-7 including Lecture 7 which is very important

Here is the study guide for the first exam. For those of you who havent taken a class from me I will typically ask questions based on what is asked in this document. For this class, I will also look back at the questions from the homework so it is important that you also look at these.

Introduction and Raw Material (Lecture 1)

1) I hope you learned a little bit about the history of papermaking in the first part of this lecture. Here are a couple of questions regarding what I hoped you learned in this section. a) Before paper was made from wood, what was it made from? b) When were the first chemical pulping processes developed? 2) There are large differences in raw material use for pulp production in the United States based on geographic location. I expect that you would know the following: a) Are hardwoods or softwoods most used in the West? How about roundwood versus residual? b) Are hardwoods or softwoods most used in the Southeast and South Central? How about roundwood versus residual? c) Are hardwoods or softwoods most used in the Northeast and North Central? How about roundwood versus residual? d) Why are there these differences in use patterns? 3) When material (wood/chips/whatever) comes into a mill there are a number of things which happen such as debarking, chipping, washing, screening, testing etc. Why are these important? 4) Physical Measurements a) Moisture content: Do you know the equations for moisture content green and oven dry? Which one is used in the pulp and paper business b) Density: Why is density important? c) Why is chip size important? d) What problems do debris cause? 5) Wood degradation: Why is this process a problem for pulp manufacture? a) There are a variety of variables that affect the decay processes that go on in a chip pile. Why are the following i) Time in the pile ii) Moisture iii) Temperature iv) Shape of the pile

Mechanical Pulping: (Lecture 2)

1) What is different between the raw materials used for stone groundwood and for refiner pulps? a) What is important about the raw materials used in both processes in terms of age, species, cleanliness, etc? 2) Can you list in general terms the properties of mechanical pulps? 3) Can you describe the operation of a stone groundwood operation? a) Why are there burrs on the stone? b) How often are these burrs sharpened? c) Why is water used in this process? 4) Can you explain the mechanism of the removal of fibers? a) What effect does heat or chemicals have on this process? b) What portion of the cell wall does separation occur? c) What is the effect of getting the fibers too hot? Where does separation occur under these conditions? What effect does this have on the resulting fibers? 5) Can you name the different type of refiner processes? 6) Can you draw a basic flowsheet for a refiner plant? a) Why are chips washed before refinning? b) Why is there more than one refiner in series in the process flow sheet?

PSE 476

1st Midterm

January 17, 2007

Study Guide Lectures 1-7 including Lecture 7 which is very important

c) What is the purpose of a latency tank? 7) Can you describe a refiner plate? 8) Can you name the conditions used for each refining process (RMP/TMP/CTMP/CMP) in terms of: i) Is there a preheating time? At what temperature? ii) Are there chemicals used? What are they? How long a treatment? At what temperature do they chemically treat? iii) Why does the CTMP produce a product superior to RMP and TMP? 8) How is endpoint determined in mechanical pulping?

Mechanical Pulp Bleaching (Lecture 3)

1) Can you explain why mechanical pulp is not as bright as chemical pulp? a) Why does mechanical pulp turn yellow on exposure to light? i) What types of chemical structures are responsible for this yellowing and for the reduced brightness? 2) What are the 2 systems used to bleach mechanical pulps? 3) Can you provide a basic discussion of how each of these systems work chemically? 4) Can you provide a description of the system variables used in both these systems and how they affect the final product? a) What chemicals are used and why? b) What other variables are important? c) Which system is more likely to suffer through color reversion? d) Why are chelating agents added to the oxidative system? 5) Which of these 2 systems is the most efficient?

Introduction to Chemical Pulping (Lecture 4)

1. Chip quality issues: there are a lot of issues related to chip quality mentioned in my lectures. Here are some issues that I find important. a) Chip Thickness: Why is chip thickness such an important variable? b) Why is chip moisture content important for pulping? c) How does wood density affect production, and pulp qualities? Are hardwoods or softwoods typically denser? d) Why is it not a good idea to pulp forest thinnings with chips from mature trees? e) What problems does heartwood pose for pulping and for pulp properties? f) Reaction wood: How does compression wood and tension wood affect pulp? g) How does the use of decayed wood affect pulp properties? Batch reactors a) Typically how large are these reactors? b) Typically how many batch digesters does a typical kraft mill have? Can you describe the methods used to pack a digester? a) Which methods work best? b) Why do you want improved packing? Why would you want to presteam? Can you describe the methods used to heat a digester? a) Can you name the benefits of both? Chip impregnation a) What is the difference between penetration and diffusion of liquor? In general terms what variables affect each process? General Kraft Pulping Process: a) Why is the heating time usually longer than time at temperature? b) Why is there gas relief? What gasses are vented?

2. 3. 4. 5. 6. 7.

PSE 476

1st Midterm

January 17, 2007

Study Guide Lectures 1-7 including Lecture 7 which is very important

c) Can you describe the process of blowing down the digester? i) Why do the chips turn into fibers at this point? (2 reasons) d) What is displacement pulping? Why is this done?

Continuous Reactors (Lecture 5)

This was a pretty short lecture. There are several facts I wanted you to understand. 1. There is more chemical pulp produced using continuous reactors than batch reactors. 2. Chips move continuously through these reactors; all the same steps that occur in a batch system occur in a continuous reactor. a) Can you name the different zones in a continuous reactor? b) Can you provide a rough temperature profile of a reactor? c) Why is there different direction of flow of liquor in different sections? d) Roughly how long is the retention time in each section? e) Do you know the steps involved in getting chips into a continuous digester? i) Why presteam? ii) How are the chips charged into the reactor? a) Why is excess white liquor used? f) Why is black liquor used to wash the chips if what the washing system is supposed to do is remove black liquor? (Question thanks to Paul and Joe) 3. Important: Can you compare the benefits of both the batch and continuous systems?

Kraft Pulping Chemicals (Lecture 6) and (Lecture 7)

1. 2. White liquor versus black liquor: In simple terms, can you describe what these are? You need to be able to name (and know the chemical structure) of the 6 components of white liquor a) Can you identify their source (origin)? b) Can you identify which ones are active reactants? c) Roughly how much NaOH and Na2S are found in black liquor d) Which has more dissolve organic material, black or white liquor? White liquor equations a) You will need to know the equations for: i) Total Alkali ii) Effective Alkali iii) Active Alkali iv) Sulfidity v) Reduction Efficiency vi) Causticizing Efficiency The Na2O issue a) You need to be able to convert any sodium species in the world to a Na2O basis. This is something you need to be able to do in your sleep. You need to know reaction equation for when Na2S is added to water? In class problems Dr. Gustafson explained a variety of calculations. You need to understand how the answers to these questions were obtained. You also need to be able to work these types of problems without a lot of thinking time. There will be questions like these on the exam and in real life. a) Can you work with moisture contents to determine how much dry wood you have? b) Do you understand the concept of liquor to wood ratio? c) Can you convert from g/liter to charge (% on wood) d) Can you convert from g/l Na2O to moles/liter of the actual chemical e) Do you understand the concept that the amount of OH- in solution is dependent upon NaOH and Sulfide

3.

4. 5. 6.

PSE 476

1st Midterm

January 17, 2007

Study Guide Lectures 1-7 including Lecture 7 which is very important

f) Basically make sure you understand the questions from Lecture #7..dont just look at the questions; understand what you are doing.

Vous aimerez peut-être aussi

- Integral FisicoQuimicaDocument5 pagesIntegral FisicoQuimicaMarco LegnamePas encore d'évaluation

- 2) Solar Energy (Photovoltaic Energy)Document25 pages2) Solar Energy (Photovoltaic Energy)Eric RapirapPas encore d'évaluation

- 11.01.2021 EnglishDocument5 pages11.01.2021 EnglishJeevikaPas encore d'évaluation

- Test From Lakhmmir Singh Class 8th Book of ch1,2,3,4,8,11,12,13,18 and You Can Access The Book From This Website Https - Online - Fliphtml5.com - CCWXT - KLVX - #P 1Document2 pagesTest From Lakhmmir Singh Class 8th Book of ch1,2,3,4,8,11,12,13,18 and You Can Access The Book From This Website Https - Online - Fliphtml5.com - CCWXT - KLVX - #P 1Sunny RajPas encore d'évaluation

- The Break Out (Scientific Method)Document10 pagesThe Break Out (Scientific Method)gabriella sanonPas encore d'évaluation

- Cbse Question Papers For Class 8 Science FA 1 PDFDocument2 pagesCbse Question Papers For Class 8 Science FA 1 PDFdineshPas encore d'évaluation

- CBSE Sample Papers For Class 6 Science FA 2Document4 pagesCBSE Sample Papers For Class 6 Science FA 2Anirban SahaPas encore d'évaluation

- IESOL B2 Practice Paper 4Document19 pagesIESOL B2 Practice Paper 4Kinga Szász100% (1)

- Thin Film Winter Sem 2022Document2 pagesThin Film Winter Sem 2022Baja TechinPas encore d'évaluation

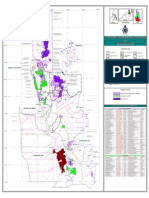

- Meem 201 Clean Coal and Green Power Technology Jun 2020Document1 pageMeem 201 Clean Coal and Green Power Technology Jun 2020ramprakashpatelPas encore d'évaluation

- Civil Questions and Answers-Other-Major-TopicsDocument39 pagesCivil Questions and Answers-Other-Major-TopicsAkd Deshmukh100% (1)

- 1Document3 pages1Dhiman DeyPas encore d'évaluation

- Class 7 ch-1 To 5 WorksheetDocument5 pagesClass 7 ch-1 To 5 WorksheetRakesh KumarPas encore d'évaluation

- St. Xavier's Senior Secondary School Bahrampur, Ram Nagar Ambedkar Nagar (U.P.)Document5 pagesSt. Xavier's Senior Secondary School Bahrampur, Ram Nagar Ambedkar Nagar (U.P.)Satyam BhargavPas encore d'évaluation

- Unit 2 Processes and Procedures: General ObjectivesDocument26 pagesUnit 2 Processes and Procedures: General ObjectivesMohammad MubarakPas encore d'évaluation

- X IT WorksheetsDocument32 pagesX IT WorksheetsChinna SamyPas encore d'évaluation

- Class 8 THDocument9 pagesClass 8 THSuman SainiPas encore d'évaluation

- Mastery Level - C2: International ESOL English For Speakers of Other Languages Practice Paper 3Document19 pagesMastery Level - C2: International ESOL English For Speakers of Other Languages Practice Paper 3Raheem BrownPas encore d'évaluation

- Research On Sawdust and Coconut Peat As Particle BoardDocument11 pagesResearch On Sawdust and Coconut Peat As Particle BoardAecee Quibod OlivarPas encore d'évaluation

- Cbse Sample Papers For Class 8 Science FA 2Document6 pagesCbse Sample Papers For Class 8 Science FA 2ABHISHEK UPADHYAYPas encore d'évaluation

- Screenshot 2023-10-30 at 2.27.18 PMDocument8 pagesScreenshot 2023-10-30 at 2.27.18 PMrana.azab30Pas encore d'évaluation

- Guide 2nd PeriodDocument11 pagesGuide 2nd PeriodrdPas encore d'évaluation

- Week 5 TOEFL LISTENING 2 MahasiswaDocument4 pagesWeek 5 TOEFL LISTENING 2 MahasiswaZorro HikariPas encore d'évaluation

- Terms Grade 8 ChemDocument6 pagesTerms Grade 8 ChemshadanihanPas encore d'évaluation

- 6.dealing With WasteDocument4 pages6.dealing With Wastealvaroyd1Pas encore d'évaluation

- Pce Che 20-07-2023Document1 pagePce Che 20-07-2023mehdi.mehdi15121472Pas encore d'évaluation

- ESL Brains E Waste Recycling SV 6128Document3 pagesESL Brains E Waste Recycling SV 6128antonina.1989Pas encore d'évaluation

- Unit BreakdownDocument3 pagesUnit Breakdownapi-212901753Pas encore d'évaluation

- Class 9 Cbse Sample Paper Science Sa2 DownlaodDocument16 pagesClass 9 Cbse Sample Paper Science Sa2 DownlaodParas SukhijaPas encore d'évaluation

- Worksheet A. Match The Questions To The Answers About Climate ChangeDocument6 pagesWorksheet A. Match The Questions To The Answers About Climate ChangeByamba Erdene Nyam OsorPas encore d'évaluation

- CBSE Class 8 Science Sample Paper Set 5: Each Question Carriers 1 Mark: Choose The Correct Answers: (5 X 1 5 Marks)Document3 pagesCBSE Class 8 Science Sample Paper Set 5: Each Question Carriers 1 Mark: Choose The Correct Answers: (5 X 1 5 Marks)shweta kothariPas encore d'évaluation

- Mini Test 3 ListeningDocument3 pagesMini Test 3 ListeningColegio 1212 Nuestra Señora de LujanPas encore d'évaluation

- Natural Gas: Task 1Document9 pagesNatural Gas: Task 1Syahrie AnggaraPas encore d'évaluation

- SUMMATIVE ASSESSMENT-II - (2014-2015) Subject: SCIENCE Class: VIII Time 2: 30 Hrs. + 30 Mins For OTBA M.M. 60 General InstructionsDocument3 pagesSUMMATIVE ASSESSMENT-II - (2014-2015) Subject: SCIENCE Class: VIII Time 2: 30 Hrs. + 30 Mins For OTBA M.M. 60 General InstructionsMd ImranPas encore d'évaluation

- Jss 1 IctDocument9 pagesJss 1 IctalmightyfavouritePas encore d'évaluation

- 2020 Biology Unit 12Document37 pages2020 Biology Unit 12Ralph Rezin MoorePas encore d'évaluation

- Chem TopicsDocument4 pagesChem TopicsThaarvena RetinaPas encore d'évaluation

- Sample Test Items Rev 08-07-19Document15 pagesSample Test Items Rev 08-07-19KomishinPas encore d'évaluation

- Grade 4 Revision Paper Half Yearly Exam-1Document3 pagesGrade 4 Revision Paper Half Yearly Exam-1raj27385Pas encore d'évaluation

- 10 Sci Question PaperDocument4 pages10 Sci Question Papersunil patnePas encore d'évaluation

- Urban Sewage TreatmentDocument6 pagesUrban Sewage TreatmentCristianAlexGrijalbaMuñozPas encore d'évaluation

- 2023-2024 SNC1W Exam Review (No Textbook)Document8 pages2023-2024 SNC1W Exam Review (No Textbook)noodlenuggetplaysPas encore d'évaluation

- CH 5Document17 pagesCH 5AUM patelPas encore d'évaluation

- CLASS - 7t1 (1) 2Document3 pagesCLASS - 7t1 (1) 2daundfacultiesPas encore d'évaluation

- Question Paper Code:: Reg. No.Document2 pagesQuestion Paper Code:: Reg. No.Ameer Hakeem Primus100% (4)

- GCSE Chemistry Triple Revision Questions - Topic 10 Using ResourcesDocument8 pagesGCSE Chemistry Triple Revision Questions - Topic 10 Using ResourcesBenjamin WatsonPas encore d'évaluation

- Chapter Wise Questions On Solid Waste QuestionsDocument1 pageChapter Wise Questions On Solid Waste Questionsgautamshankar0% (1)

- Question Bank 2 - Unit Wise MCQ SWMDocument51 pagesQuestion Bank 2 - Unit Wise MCQ SWMROYAL ENFIELD89% (19)

- ok-EAS Manpro Gasal 2020-2021Document2 pagesok-EAS Manpro Gasal 2020-2021Samuel ArelianoPas encore d'évaluation

- ScienceDocument3 pagesSciencevgautambarcPas encore d'évaluation

- Test Structure and Sample Questions: Testing ServicesDocument5 pagesTest Structure and Sample Questions: Testing ServicesPräbhüPas encore d'évaluation

- DR Mtallib's ASSIGNMENT 2 ON CIV9301Document14 pagesDR Mtallib's ASSIGNMENT 2 ON CIV9301Smith Abutu Simon JohnPas encore d'évaluation

- CBSE Sample Paper For Class 6 ScienceDocument7 pagesCBSE Sample Paper For Class 6 ScienceBhavana ShindePas encore d'évaluation

- Class 6 Winter Break 2022 2Document21 pagesClass 6 Winter Break 2022 2DishaPas encore d'évaluation

- PROBLEMS - Module 5 - Solids DisposalDocument4 pagesPROBLEMS - Module 5 - Solids DisposalankursonicivilPas encore d'évaluation

- Chapter 1-IntroductionDocument5 pagesChapter 1-IntroductionKalaivani KanasingPas encore d'évaluation

- NAR209Document2 pagesNAR209Harshita MittalPas encore d'évaluation

- Intervention Session TeacherDocument10 pagesIntervention Session TeacherN husnaPas encore d'évaluation

- L&T Interview QuestionsDocument5 pagesL&T Interview QuestionsRanjani J DeepakPas encore d'évaluation

- Kajian Emisi PT. X (Edit Bab 4)Document39 pagesKajian Emisi PT. X (Edit Bab 4)Julianto Tobing100% (1)

- Lampiran I Salinan PP Nomor 5 Tahun 2021 Sektor PerindustrianDocument652 pagesLampiran I Salinan PP Nomor 5 Tahun 2021 Sektor PerindustrianumaediPas encore d'évaluation

- H2 Production ProcessDocument3 pagesH2 Production ProcessJulianto TobingPas encore d'évaluation

- H2 Production ProcessDocument3 pagesH2 Production ProcessJulianto TobingPas encore d'évaluation

- Die Casting - Wikipedia, The Free EncyclopediaDocument10 pagesDie Casting - Wikipedia, The Free EncyclopediaSantanu MondalPas encore d'évaluation

- Ebtm 3102Document18 pagesEbtm 3102Ija Mirza100% (1)

- HydrostaticDocument7 pagesHydrostatichafzanborhanPas encore d'évaluation

- E WasteDocument21 pagesE WasteFArez Asmi100% (1)

- What Does Regenerative Air Pre-Heater Means, Why They Named SoDocument10 pagesWhat Does Regenerative Air Pre-Heater Means, Why They Named SoAbdulyunus AmirPas encore d'évaluation

- Slab-On-Grade Reinforcing DesignDocument9 pagesSlab-On-Grade Reinforcing DesignAdam GreenlawPas encore d'évaluation

- Sikadur 52 - PDSDocument2 pagesSikadur 52 - PDS231340Pas encore d'évaluation

- ISO 3269 SamplingDocument4 pagesISO 3269 Samplingscribd14341Pas encore d'évaluation

- Ucrete WR AseanDocument2 pagesUcrete WR AseanDoby YuniardiPas encore d'évaluation

- DMGT551 Retail Business Environment PDFDocument301 pagesDMGT551 Retail Business Environment PDFdexterPas encore d'évaluation

- Polyurethane Purenit enDocument12 pagesPolyurethane Purenit enAndreiModrescuPas encore d'évaluation

- Is 3431Document16 pagesIs 3431Rajesh ChoudharyPas encore d'évaluation

- Literature Resources For Chemical Process Industries (Advances in Chemistry Series 010)Document578 pagesLiterature Resources For Chemical Process Industries (Advances in Chemistry Series 010)Rian PuspitasariPas encore d'évaluation

- ANNALS of Faculty Engineering HunedoaraDocument6 pagesANNALS of Faculty Engineering HunedoaraDragana RajicPas encore d'évaluation

- Report On Cost of ProductionDocument34 pagesReport On Cost of ProductionUnique OmarPas encore d'évaluation

- R&D Chemist Materials Engineer in United States Resume Glenn HowlandDocument2 pagesR&D Chemist Materials Engineer in United States Resume Glenn HowlandGlennHowland1Pas encore d'évaluation

- Uniqlo - When SC Goes GloballyDocument16 pagesUniqlo - When SC Goes GloballyVũ NguyễnPas encore d'évaluation

- SSAB Domex 420MC: General Product DescriptionDocument2 pagesSSAB Domex 420MC: General Product DescriptionpeterPas encore d'évaluation

- Integrating Earned Value Management With CC ExecutionDocument12 pagesIntegrating Earned Value Management With CC ExecutionAntonio CalcinaPas encore d'évaluation

- Cover Letter: Mob. No.: 9801105207Document6 pagesCover Letter: Mob. No.: 9801105207vinodsnPas encore d'évaluation

- ACC 327 Test IIDocument5 pagesACC 327 Test IIthangdongquay1520% (1)

- Toyota Supply ChainDocument21 pagesToyota Supply ChainArmo LuangPas encore d'évaluation

- Technical Specification Hydrogen Generation PlantDocument404 pagesTechnical Specification Hydrogen Generation PlantSHIVAJI CHOUDHURY100% (1)

- Kahramaa Architectural SpecificationsDocument471 pagesKahramaa Architectural SpecificationsLepanto SakyodPas encore d'évaluation

- Welding of Nickel AlloysDocument4 pagesWelding of Nickel AlloysMuhammed SulfeekPas encore d'évaluation

- Aprroved MPS EPDocument1 pageAprroved MPS EPAlverastine AnPas encore d'évaluation

- 03 Validation Documentation PDFDocument57 pages03 Validation Documentation PDFAhmed MagdyPas encore d'évaluation

- Cable Tray SystemsDocument45 pagesCable Tray SystemsAmin Hasan AminPas encore d'évaluation

- Chapter 9 - Inventory Costing and Capacity AnalysisDocument40 pagesChapter 9 - Inventory Costing and Capacity AnalysisBrian SantsPas encore d'évaluation

- Wi Insp 02 Heat ExchangerDocument6 pagesWi Insp 02 Heat ExchangerSamir Chaudhary100% (1)

- Hero Found: The Greatest POW Escape of the Vietnam WarD'EverandHero Found: The Greatest POW Escape of the Vietnam WarÉvaluation : 4 sur 5 étoiles4/5 (19)

- The Fabric of Civilization: How Textiles Made the WorldD'EverandThe Fabric of Civilization: How Textiles Made the WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (58)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestD'EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestÉvaluation : 4 sur 5 étoiles4/5 (28)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaD'EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaPas encore d'évaluation

- The End of Craving: Recovering the Lost Wisdom of Eating WellD'EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellÉvaluation : 4.5 sur 5 étoiles4.5/5 (81)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindD'EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindPas encore d'évaluation

- Sully: The Untold Story Behind the Miracle on the HudsonD'EverandSully: The Untold Story Behind the Miracle on the HudsonÉvaluation : 4 sur 5 étoiles4/5 (103)

- Highest Duty: My Search for What Really MattersD'EverandHighest Duty: My Search for What Really MattersPas encore d'évaluation

- Pale Blue Dot: A Vision of the Human Future in SpaceD'EverandPale Blue Dot: A Vision of the Human Future in SpaceÉvaluation : 4.5 sur 5 étoiles4.5/5 (588)

- System Error: Where Big Tech Went Wrong and How We Can RebootD'EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootPas encore d'évaluation

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationD'EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationÉvaluation : 4.5 sur 5 étoiles4.5/5 (46)

- A Place of My Own: The Architecture of DaydreamsD'EverandA Place of My Own: The Architecture of DaydreamsÉvaluation : 4 sur 5 étoiles4/5 (242)

- Reality+: Virtual Worlds and the Problems of PhilosophyD'EverandReality+: Virtual Worlds and the Problems of PhilosophyÉvaluation : 4 sur 5 étoiles4/5 (24)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerD'EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerÉvaluation : 4.5 sur 5 étoiles4.5/5 (122)

- The Future of Geography: How the Competition in Space Will Change Our WorldD'EverandThe Future of Geography: How the Competition in Space Will Change Our WorldÉvaluation : 4 sur 5 étoiles4/5 (5)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyD'EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyPas encore d'évaluation

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterD'EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterPas encore d'évaluation

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansD'EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansPas encore d'évaluation

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerD'EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerÉvaluation : 4.5 sur 5 étoiles4.5/5 (54)

- Transformed: Moving to the Product Operating ModelD'EverandTransformed: Moving to the Product Operating ModelÉvaluation : 4 sur 5 étoiles4/5 (1)

- The Weather Machine: A Journey Inside the ForecastD'EverandThe Weather Machine: A Journey Inside the ForecastÉvaluation : 3.5 sur 5 étoiles3.5/5 (31)

- Mini Farming: Self-Sufficiency on 1/4 AcreD'EverandMini Farming: Self-Sufficiency on 1/4 AcreÉvaluation : 4 sur 5 étoiles4/5 (76)

- Packing for Mars: The Curious Science of Life in the VoidD'EverandPacking for Mars: The Curious Science of Life in the VoidÉvaluation : 4 sur 5 étoiles4/5 (1395)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureD'EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureÉvaluation : 5 sur 5 étoiles5/5 (125)

- When the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachD'EverandWhen the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachÉvaluation : 4.5 sur 5 étoiles4.5/5 (27)