Académique Documents

Professionnel Documents

Culture Documents

Flow Boss Manager - Emerson

Transféré par

JRadeon_3Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Flow Boss Manager - Emerson

Transféré par

JRadeon_3Droits d'auteur :

Formats disponibles

FloBoss 107

TM

FloBoss 107 Flow Manager.

TM

The FloBoss 107 Flow Manager introduces a new technology platform to the FloBoss family of flow computers that raises the bar for modularity, versatility, performance, and ease of use. Whether you need a single or multi-run flow computer or few or many I/O points, the new FloBoss 107 can accommodate your needs. The FloBoss 107 is the ideal measurement solution for many natural gas applications. These include, but are not limited to: Custody Transfer Wellhead Measurement and Control Well Injection Pressure Compressor Fuel Gas Industrial Gas Usage Commercial Gas Usage The new FloBoss 107 offers you benefits that research has shown flow computer users request. You also get all of the tried and true features of previous FloBoss units such as accurate AGA calculations, data archival, broad communications support, low power consumption, PID loop control, FST control, and operation over extreme temperatures. API/AGA/ISO Compliant Flow Measurement. The FloBoss 107 maintains API Chapter 21.1 compliant historical archives for measured and calculated values, as well as events and alarms. The firmware has the capability to perform AGA3 orifice flow calculations or AGA7 pulse flow calculations using AGA8 compressibility. It also performs ISO 5167 flow calculations. Other gas flow or properties calculations can be implemented using User C programs. One to Four Meter Runs. The FloBoss 107 features a built-in dual-variable sensor (DVS) port and RTD input for handling a single meter run. For multiple runs, an optional multi-variable sensor (MVS) module supports up to four remote MVS units. Scalable and Configurable I/O. You can add a configurable I/O board to the CPU module and up to three configurable I/O modules to the base FloBoss 107. For even more capacity, add an expansion rack to house up to three additional I/O modules.

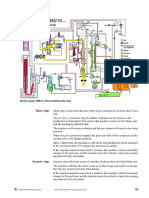

FloBoss 107 Base Unit

Local or Host Operation. The FloBoss 107 is configured and operated on-site using our Windows based ROCLINK 800 Configuration Software. The FloBoss 107 can also be configured and operated from a computer running popular host software packages. Modbus ASCII and RTU slave or host protocols, as well as native ROC protocol, are supported. More Communication Choices. The FloBoss 107 comes standard with 3 ports: local operator interface, RS-232, and RS-485. One additional port is supported using an expansion communication module. Built-in Control Capability. The FloBoss 107 can perform PID control on 8 loops using analog or discrete outputs. A wide range of control problems can be solved easily and quickly with outstanding results. It can also perform logic and sequencing control by means of Function Sequence Tables (FSTs).

Remote Automation Solutions

Phone (641) 754-3449 Toll Free (800) 807-0730 (US & Canada only) FAX (641) 754-3630 Website: www.EmersonProcess.com/flow

Base unit (left) provides the backplane, module slots, ports, and electrical interconnections for the FloBoss 107. Dimensions are 204 mm H by 153 mm W by 140 mm D (8 in. H by 6 in. W by 5.5 in. D). Expansion rack (right) plugs into base unit and provides backplane and slots for additional modules. (Same dimensions as base unit).

Local operator interface port (RS-232) communicates to a laptop or similar PC device for local configuration and data retreival.

1 2 3 4 5

I/O card is available for the CPU module. Five of the six I/O points are configurable by type (AI/ DI, AI/DI, AO/DO, DI/PI, DI/PI) and the sixth is a DO. CPU module contains the main processing unit, memory, operational firmware, RS-232 port, RS-485 port, and RTD input. Communication modules are available for a second RS-232 port or RS-485 port.

I/O modules provide six I/O points (same as I/O card). Up to six I/O modules can be plugged into the FloBoss 107. 24 Vdc loop power is provided.

Module slots accommodate I/O and communication modules and are protected by removable covers when not used.

7 8 9

Covered wiring tray neatly routes field wiring to and from modules. Battery compartment uses lIthium battery to backup RAM in the CPU. Input power range for the FloBoss 107 and I/O is 8 to 30 Vdc. DVS port provides a serial data link to a dualvariable sensor (DVS) unit.

MVS module supports up to six multi-variable sensor units for differential pressure flow measurement. One MVS module can be used in either slot 4 of the base unit or expansion rack.

10 11 12

Display port connects a keypad / display unit to the FloBoss 107. Supports ROC and Modbus slave protocols.

ISO 9001:2000 2006 Fisher Controls International, LLC. FloBoss and ROCLINK are marks of one of the Emerson Process Management companies. All other marks are the property of their respective owners. This publication is presented for informational purposes only, and while every effort has been made to ensure its accuracy, its content is not to be construed as a warranty or guarantee, expressed or implied, regarding the products described herein or their use or applicability. D351406X012 / Printed in USA / 5M / 12-06

Certificate No. 004372 Certificate No. 005912

Vous aimerez peut-être aussi

- Floboss 107 SeriesoverviewDocument39 pagesFloboss 107 SeriesoverviewRodrigo ValérioPas encore d'évaluation

- The Floboss 104 Flow Manager: Remote Automation SolutionsDocument4 pagesThe Floboss 104 Flow Manager: Remote Automation SolutionsAdveric NishizawaPas encore d'évaluation

- Flow Boss 107 Flow MangerDocument9 pagesFlow Boss 107 Flow Mangervaibhavdate10Pas encore d'évaluation

- Computador de Vazão - Emerson - Floboss 107 Flow ManagerDocument8 pagesComputador de Vazão - Emerson - Floboss 107 Flow ManagerRafael IbelliPas encore d'évaluation

- 33 Floboss Fb407 Product DocumentDocument2 pages33 Floboss Fb407 Product DocumentAnonymous 2nwhJoM8HPas encore d'évaluation

- Computador de Vazão - Emerson - Floboss 407 Flow ManagerDocument2 pagesComputador de Vazão - Emerson - Floboss 407 Flow ManagerRafael IbelliPas encore d'évaluation

- Roc 407Document2 pagesRoc 407docrafiPas encore d'évaluation

- Product Data Sheet Floboss 107 Flow Manager Fb107 en 132260Document9 pagesProduct Data Sheet Floboss 107 Flow Manager Fb107 en 132260Edvier MapayePas encore d'évaluation

- Floboss 103 Flow Manager (Atex and Iecex Versions) : Specification SheetDocument4 pagesFloboss 103 Flow Manager (Atex and Iecex Versions) : Specification SheetcartarPas encore d'évaluation

- The FloBoss 104 Flow ManagerDocument4 pagesThe FloBoss 104 Flow ManagersalemPas encore d'évaluation

- HPOpencall Ocadd DatasheetDocument4 pagesHPOpencall Ocadd DatasheetUpendra PradhanPas encore d'évaluation

- d301233x012 PDFDocument9 pagesd301233x012 PDFMario AstroñaPas encore d'évaluation

- FloBoss 407 Flow Manager - Specification SheetDocument4 pagesFloBoss 407 Flow Manager - Specification SheetAllan Martins SandyPas encore d'évaluation

- Series: Programmable Logic ControllerDocument28 pagesSeries: Programmable Logic ControllerhegonmilesPas encore d'évaluation

- Floboss 407 Flow Manager: Field Automation SystemsDocument4 pagesFloboss 407 Flow Manager: Field Automation SystemsAlexander Charry GiraldoPas encore d'évaluation

- FBs Brochure 2008Document27 pagesFBs Brochure 2008Nasr AlabdaliPas encore d'évaluation

- MVI56 104S DatasheetDocument2 pagesMVI56 104S DatasheetDeysi PeñaPas encore d'évaluation

- ABB FreelanceOverviewDocument12 pagesABB FreelanceOverviewMuhammad IrfanPas encore d'évaluation

- Honeywell Acm 72Document8 pagesHoneywell Acm 72Delbert RicardoPas encore d'évaluation

- En 13 04 Eng (A4) f4 MSC A MultipakDocument8 pagesEn 13 04 Eng (A4) f4 MSC A MultipakJavier Alejandro QuingaPas encore d'évaluation

- Flow ComputerDocument16 pagesFlow ComputerAbabPas encore d'évaluation

- q_dn_core_110f_appguide_multi-core_conferencingDocument8 pagesq_dn_core_110f_appguide_multi-core_conferencingJmac303Pas encore d'évaluation

- CENTUM VP System IntroductionDocument8 pagesCENTUM VP System IntroductionKevin NgoPas encore d'évaluation

- Acom EVO IP Console SAystemDocument4 pagesAcom EVO IP Console SAystemcrispix2000Pas encore d'évaluation

- 3bse004512r501 - en Advant Controller 450 Version 2.3 1 Brochure PDFDocument4 pages3bse004512r501 - en Advant Controller 450 Version 2.3 1 Brochure PDFabdussamad_electricPas encore d'évaluation

- E PLC400 Spec ProvisionalDocument8 pagesE PLC400 Spec ProvisionalNishant JhaPas encore d'évaluation

- Disocont Tersus (DT-9) Legacy: Stock Feeder Controller UpgradeDocument2 pagesDisocont Tersus (DT-9) Legacy: Stock Feeder Controller UpgradeRajesh SirsathPas encore d'évaluation

- FlypcbusDocument8 pagesFlypcbusjiya_jhawarPas encore d'évaluation

- Control Wave RTUDocument22 pagesControl Wave RTUAnonymous awwd0cnPas encore d'évaluation

- MIL-STD-1553 Aircraft Data BusDocument3 pagesMIL-STD-1553 Aircraft Data BusVasthadu Vasu KannahPas encore d'évaluation

- FATEK enDocument28 pagesFATEK enLe Professionist100% (1)

- Docu9424 Brocade Fabric OS Control Processor Blade (CP8) Replacement ProcedureDocument16 pagesDocu9424 Brocade Fabric OS Control Processor Blade (CP8) Replacement ProcedureDemodx DemodxzPas encore d'évaluation

- Andover Controls Diver ListDriver ListDocument12 pagesAndover Controls Diver ListDriver Listjbhall55Pas encore d'évaluation

- 1001 - EDPCML - Section #1 - StorageCenter FundamentalsDocument51 pages1001 - EDPCML - Section #1 - StorageCenter FundamentalsHugo CGPas encore d'évaluation

- An x2 Ab Dhrio+DatasheetDocument3 pagesAn x2 Ab Dhrio+DatasheetricardorobsonPas encore d'évaluation

- Ciu Plus & Ciu PrimeDocument8 pagesCiu Plus & Ciu Prime91665111Pas encore d'évaluation

- Mplab 1Document75 pagesMplab 1lingalashanthipriya_Pas encore d'évaluation

- 3BDD013090 H en Freelance Version 2013 - Distributed Control System For Process Applications PDFDocument16 pages3BDD013090 H en Freelance Version 2013 - Distributed Control System For Process Applications PDFAdelmoKarigPas encore d'évaluation

- CFDS 747 777Document2 pagesCFDS 747 777Isac Andrei RobertPas encore d'évaluation

- DL205 - Great For Simple Data Acquisition And ControlDocument1 pageDL205 - Great For Simple Data Acquisition And ControlEngr Nayyer Nayyab MalikPas encore d'évaluation

- The Basics of Fieldbus: Technical Data SheetDocument4 pagesThe Basics of Fieldbus: Technical Data Sheetcharro1623Pas encore d'évaluation

- FloBoss S600+Document10 pagesFloBoss S600+Syed Haris Bin AkhterPas encore d'évaluation

- The Most Powerful PLCDocument16 pagesThe Most Powerful PLCpandhuPas encore d'évaluation

- FloBoss S600Document11 pagesFloBoss S600ing_76Pas encore d'évaluation

- 3BDD013090 en M Freelance Version 2019 - Distributed Control System For Process ApplicationsDocument16 pages3BDD013090 en M Freelance Version 2019 - Distributed Control System For Process ApplicationsckatiPas encore d'évaluation

- Controllogix: Selection GuideDocument92 pagesControllogix: Selection GuideneoflashPas encore d'évaluation

- 450222Document826 pages450222dilligas1234Pas encore d'évaluation

- Flow Computers: Measurement Data from Well to AwarenessDocument12 pagesFlow Computers: Measurement Data from Well to AwarenessSardar PerdawoodPas encore d'évaluation

- Terminal Exerciser Datasheet WebDocument2 pagesTerminal Exerciser Datasheet WebcoralonsoPas encore d'évaluation

- Abb Dcs ArchitectureDocument21 pagesAbb Dcs ArchitectureAitzaz Hussain100% (1)

- Advantech ADAM-5510/TCP and ADAM-5510E/TCP Ethernet-enabled 4-slot and 8-slot PC-based ControllersDocument2 pagesAdvantech ADAM-5510/TCP and ADAM-5510E/TCP Ethernet-enabled 4-slot and 8-slot PC-based ControllersPhạm Ngọc HòaPas encore d'évaluation

- FB 600Document2 pagesFB 600Irwan PambudiPas encore d'évaluation

- Computer Organization and Design: The Hardware / Software InterfaceD'EverandComputer Organization and Design: The Hardware / Software InterfaceÉvaluation : 4 sur 5 étoiles4/5 (12)

- Embedded Controller Forth For The 8051 FamilyD'EverandEmbedded Controller Forth For The 8051 FamilyÉvaluation : 4 sur 5 étoiles4/5 (1)

- Operating Systems Interview Questions You'll Most Likely Be Asked: Job Interview Questions SeriesD'EverandOperating Systems Interview Questions You'll Most Likely Be Asked: Job Interview Questions SeriesPas encore d'évaluation

- BalostrosDocument2 pagesBalostrosJRadeon_3Pas encore d'évaluation

- Nema Standards For FreeDocument1 pageNema Standards For FreeDinesh KumarPas encore d'évaluation

- Petrolux PETLDocument8 pagesPetrolux PETLJRadeon_3Pas encore d'évaluation

- HGST CinemaStar 5K320 DSDocument2 pagesHGST CinemaStar 5K320 DSJRadeon_3Pas encore d'évaluation

- A GAMS TutorialDocument30 pagesA GAMS TutorialSivadon Chaisiri100% (1)

- GAL22V10Document21 pagesGAL22V10jackkairiPas encore d'évaluation

- C-TEC - XFP Programming ToolsDocument48 pagesC-TEC - XFP Programming ToolsJose Carmo100% (1)

- Windows Operating System ArchitectureDocument6 pagesWindows Operating System ArchitectureBasharat Ali100% (3)

- Fundamentals and Programming ComponentsDocument2 pagesFundamentals and Programming ComponentsjaninePas encore d'évaluation

- MOSCAD L Owners Manual PDFDocument126 pagesMOSCAD L Owners Manual PDFJesús Valdés100% (1)

- MNL Avalon SpecDocument59 pagesMNL Avalon SpecAlexis Jonathan Bautista BaqueroPas encore d'évaluation

- SacoDocument44 pagesSacorasheed3130% (1)

- An728 Iopll Phase ShiftDocument17 pagesAn728 Iopll Phase ShiftYair LinnPas encore d'évaluation

- Chapter 6Document124 pagesChapter 6Saichandar Reddy LethakulaPas encore d'évaluation

- Basics of Computer SystemsDocument37 pagesBasics of Computer SystemsANANDA RAO DEVARAKONDAPas encore d'évaluation

- Módulos de Entrada e Saída XI-OCDocument122 pagesMódulos de Entrada e Saída XI-OCBruno OliveiraPas encore d'évaluation

- MITSUBISHI - CR750CR751 Controller Instruction Manual Troubleshooting PDFDocument60 pagesMITSUBISHI - CR750CR751 Controller Instruction Manual Troubleshooting PDFayxworks eurobotsPas encore d'évaluation

- Lecture 1 IntroductionDocument91 pagesLecture 1 IntroductiondronPas encore d'évaluation

- Ch - - 3 (١)Document24 pagesCh - - 3 (١)هياف هيافPas encore d'évaluation

- Alr 121 S50Document8 pagesAlr 121 S50Sulis TiyoPas encore d'évaluation

- User Manual: HMC6000A/E (HMC6000A/HMC6000EG/HMC6000ED) Diesel Engine ControllerDocument37 pagesUser Manual: HMC6000A/E (HMC6000A/HMC6000EG/HMC6000ED) Diesel Engine ControllerAli100% (1)

- Computer Parts and Components ExplainedDocument21 pagesComputer Parts and Components ExplainedMuqadas HussainPas encore d'évaluation

- HCI-QuickGuideDocument25 pagesHCI-QuickGuideRanjeet Singh100% (1)

- IJCAS v3 n3 pp.493-501Document9 pagesIJCAS v3 n3 pp.493-501Muhammad ZanuarPas encore d'évaluation

- Brosur SMA EDMM-10 - HDPDocument3 pagesBrosur SMA EDMM-10 - HDPLendi MeyshaPas encore d'évaluation

- ADM-FR EngDocument98 pagesADM-FR Engvitor santosPas encore d'évaluation

- K01 000 10Document190 pagesK01 000 10arfeemPas encore d'évaluation

- Accuload IV Manual de Operador Mn06200Document192 pagesAccuload IV Manual de Operador Mn06200Gregory RodríguezPas encore d'évaluation

- Computer Awareness - Computer Awareness-1Document12 pagesComputer Awareness - Computer Awareness-1samskruti speaksPas encore d'évaluation

- BioStamp 2RDocument3 pagesBioStamp 2RHrishikesh Sinha0% (1)

- ALTERA - In-System Programmability GuidelinesDocument18 pagesALTERA - In-System Programmability GuidelinesRobert GuzmanPas encore d'évaluation

- Inspiron-11-3147-Laptop - Owner's Manual - En-UsDocument79 pagesInspiron-11-3147-Laptop - Owner's Manual - En-UsLeopoldo Godinez HernandezPas encore d'évaluation

- Symbol Function ExampleDocument3 pagesSymbol Function ExampleElmer Castañeda EstuistaPas encore d'évaluation

- LilyPad3 GAMING EDITIONDocument3 pagesLilyPad3 GAMING EDITIONEthan TampusPas encore d'évaluation

- Computer Architecture and OrganizationDocument8 pagesComputer Architecture and Organizationrovejama caayaPas encore d'évaluation