Académique Documents

Professionnel Documents

Culture Documents

Eifeler Coating Application - Chart

Transféré par

ykc38Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Eifeler Coating Application - Chart

Transféré par

ykc38Droits d'auteur :

Formats disponibles

PVD-Coatings of the EIFELER-GROUP - Properties and Applications

TiN TiCN ZrN CrN CrCN Chromium Nitride, Carbo-Nitride CrN CrCN Arc 2000 200 2300 200 0.3 - 0.4 0.2 - 0.3 2-6 600C 1100F silver - gray low stress / good adhesion, high toughness and corrosion resistance EXXTRAL ros Aluminium Titanium Carbo-Nitride AlTiCN (stacked) Arc 3000 300 EXXTRAL EXXTRAL plus Aluminium Titanium Nitride AlTiN (monolayer) AITiN (stacked) Arc 3300 300 SISTRAL Aluminium Titanium Nitride (with addiditons) AlTiN (nanostructured) Arc 3500 500 VARIANTA SUPRAL Titanium Aluminium Carbo-Nitride TiAICN (ML) Arc 3500 500 0.7 <0.5 2-4 800C 1470F anthracite black high hardness, very good oxidation resistance low friction coating for a wide range of carbide, cermet and high speed steel tooling machining of cast iron and nickel based high temperature alloys VARIANTIC nano VARIANTIC Titanium Aluminium Carbo-Nitride TiAlCN (ML) Arc 3500 500 WC/C

Coating Material

Titanium Nitride TiN

Titanium Carbo-Nitride TiCN (ML) Arc 3500 500

Zirconium Nitride ZrN Arc 2800 300

Tungsten Carbide Carbon a-C : Me Arc 1000 - 2200

Technology Microhardness HV0.05 Friction Coefficient Against Steel (Dry) Coating Thickness [m]

1)

Arc 2300 300

0.6

0.2

0.5

0.2

0.7

0.7

0.2

0.2 - 0.25

2-4 500C 900F gold standard, all-purpose coating, biocompatible

2-4 400C 750F blue gray (anthracite) high hardness, good wear resistance, enhanced toughness machining of difficult-to-machine alloy steels high performance cutting where moderate temperatures are generated at the cutting edge

1-4 600C 1100F pale yellow decorative color, good wear and corrosion resistance, biocompatible

2-4 800C 1470F old rose high hardness and elasticity, low friction, high oxidation resistance excellent for stainless steel and nickel-based high temperature alloys hard and copy milling

1-3 800C 1470F anthracite high hardness, very good oxidation resistance

1-3 900C 1650F anthracite extreme wear resistant at high temperature, excellent oxidation resistance

2-4 800C 1470F old rose low friction, high oxidation resistance

1-2 400C 750F anthracite high lubricity, low tendency for adhesive wear

Thermal Threshold Colour of the Coating

Key Characteristics

Primary Applications

machining / cutting of iron based materials metal forming plastic moulding

cast aluminium and machining copper generally non-ferrous and other nonferrous materials materials machining metal forming machining of fibreglass, nylon and plastic moulding (improved most polymer demoulding) materials aluminium and magnesium die casting

best choice for machining of hardened steel work cutting under extreme conditions pieces (hard , abrasive for use on carbide materials, high speed, dry cutting) end mills

coating for a wide range of carbide, cermet and high speed steel tooling

precision components

machining of high speed interrupted cutting operations, semi-dry hardened steel (> 54 HRc) or dry machining operations, metal cutting tasks inconel machining lubricated, semidry or dry machining where other coatings reach their limits of roughing (stocking) thermal and mechanical load with specially adapted EXXTRAL ros coating (up to 7m)

punching & forming, minimal lubrication or machining of all dry types of steel under dry as well as wet plastic injection machining conditions & moulding

depends on size of tools, micro tools also smaller thicknesses necessary

1)

for

forming and excellent for metal punching - reduced cold rewelding forming (stainless steel) medical applications - biocompatible & corrosion resistant decorative industry

excellent for drilling moving parts, dry high speed operations, semi-dry in steel or dry machining drawing, stamp excellent for drilling ing, punching, operations in steel forming tools for (up to 45 HRC) processing of high and low alloy steel

Eifeler Coatings + Technology

For further information and contact details please check our web-site: www.eifeler-lafer.com

Eifeler-Lafer, Inc. 3800 Commerce Drive St. Charles, IL 60174 ph: +1-630+587-1220 E-Mail: sales@eifeler-lafer.com

Eifeler coatings overview - German and English ak

Vous aimerez peut-être aussi

- 拋光等級Document1 page拋光等級ykc3850% (2)

- The Five Basic Steps For Fixture DesignDocument6 pagesThe Five Basic Steps For Fixture Designykc38Pas encore d'évaluation

- FixtureDocument20 pagesFixturesrinivaskurmapu9101Pas encore d'évaluation

- Lecture 05 - C Programming Basics - 06Document34 pagesLecture 05 - C Programming Basics - 06api-3745065100% (1)

- Surface FinishDocument27 pagesSurface Finishykc38Pas encore d'évaluation

- 09 Surfacetensiontheory Atc 100125100011 Phpapp01Document26 pages09 Surfacetensiontheory Atc 100125100011 Phpapp01ykc38Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Proman - IntroductionDocument9 pagesProman - IntroductionHarshala ChoudharyPas encore d'évaluation

- Answer: A Answer: DDocument16 pagesAnswer: A Answer: DAriel Mark Pilotin100% (1)

- Tolerance Stackup AnalysisDocument1 pageTolerance Stackup AnalysisSumeet Saini100% (1)

- Milling Machines: - Column-And-Knee Milling Machines - Bed Type Milling Machines - Machining CentersDocument10 pagesMilling Machines: - Column-And-Knee Milling Machines - Bed Type Milling Machines - Machining Centersrk_kamatchi3483Pas encore d'évaluation

- HK 91, SR9,93,94, SP89Document3 pagesHK 91, SR9,93,94, SP89elvergonzalez1Pas encore d'évaluation

- Listado de Limpiadores de FajasDocument27 pagesListado de Limpiadores de FajasJoseph Arturo Solis100% (1)

- Turbine Rotor Runout Checks (Gek72270)Document4 pagesTurbine Rotor Runout Checks (Gek72270)hasan09950% (2)

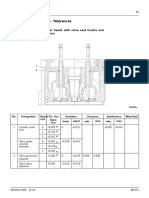

- 3.1.8 Cylinder Head - TolerancesDocument12 pages3.1.8 Cylinder Head - TolerancesSe BaPas encore d'évaluation

- GUHRING Deep Hole DrillsDocument12 pagesGUHRING Deep Hole Drillsbatman2054Pas encore d'évaluation

- GD&TDocument14 pagesGD&TsrajubasavaPas encore d'évaluation

- 11 New PEO TurningDocument7 pages11 New PEO TurningmichalPas encore d'évaluation

- Extrusion Machine and LineDocument12 pagesExtrusion Machine and Linesamurai7_77Pas encore d'évaluation

- Tap N DieDocument29 pagesTap N DieMd Rasid SamsuriPas encore d'évaluation

- Project SynopsisDocument10 pagesProject SynopsisMunishKumar100% (2)

- Crew Served WeaponsDocument11 pagesCrew Served WeaponsKyle Fagin100% (1)

- Bending Tools For Press BrakesDocument2 pagesBending Tools For Press BrakespressbraketoolsPas encore d'évaluation

- AWJMDocument43 pagesAWJMgajendra2010Pas encore d'évaluation

- CIRP Annals - Manufacturing Technology: J. Hesselbach (2), H.-W. Hoffmeister, B.-C. Schuller, K. LoeisDocument4 pagesCIRP Annals - Manufacturing Technology: J. Hesselbach (2), H.-W. Hoffmeister, B.-C. Schuller, K. LoeisKunal SharmaPas encore d'évaluation

- Kent USA Kls1840n - 2660N ElectricalDocument39 pagesKent USA Kls1840n - 2660N Electricalchidambaram kasiPas encore d'évaluation

- Tape & Label Cutting MachineDocument8 pagesTape & Label Cutting MachineLess DealPas encore d'évaluation

- BS 5352Document30 pagesBS 5352vb_pol@yahooPas encore d'évaluation

- Guhring AlargadorDocument210 pagesGuhring AlargadorFernandoPas encore d'évaluation

- Chapter 5 - Threads and FastenersDocument128 pagesChapter 5 - Threads and FastenersPradeep Kumar MehtaPas encore d'évaluation

- TRAINING Manufacturing of Camshaft & Valve TappetPRESENTATIONDocument18 pagesTRAINING Manufacturing of Camshaft & Valve TappetPRESENTATIONManisha TomarPas encore d'évaluation

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument9 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureJovanni RodriguezPas encore d'évaluation

- Elements in Machine Design (J.T.) Module 15Document6 pagesElements in Machine Design (J.T.) Module 15allovidPas encore d'évaluation

- Welders BizHouse - UkDocument3 pagesWelders BizHouse - UkAlex BekePas encore d'évaluation

- MillingDocument47 pagesMillingAvinash KankipatiPas encore d'évaluation

- Sino MachDocument6 pagesSino MachaerudzikriPas encore d'évaluation

- 9.75"/8.8"/7.5" Ring Gear and Pinion Sets: Mustang/ranger/f-150 8.8"Document1 page9.75"/8.8"/7.5" Ring Gear and Pinion Sets: Mustang/ranger/f-150 8.8"Lilian BarcaPas encore d'évaluation