Académique Documents

Professionnel Documents

Culture Documents

Color Filter Array

Transféré par

Moji PiyapongDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Color Filter Array

Transféré par

Moji PiyapongDroits d'auteur :

Formats disponibles

Color filter array

The Bayer color filter mosaic. Each two-by-two submosaic contains 2 green, 1 blue and 1 red filter, each covering one pixel sensor. In photography, a color filter array (CFA), or color filter mosaic (CFM), is a mosaic of tiny color filters placed over the pixel sensors of an image sensor to capture color information. Color filters are needed because the typical photosensors detect light intensity with little or no wavelength specificity, and therefore cannot separate color information.[1] Since sensors are made of semiconductors they obey solid-state physics. The color filters filter the light by wavelength range, such that the separate filtered intensities include information about the color of light. For example, the Bayer filter (shown to the right) gives information about the intensity of light in red, green, and blue (RGB) wavelength regions. The raw image data captured by the image sensor is then converted to a full-color image (with intensities of all three primary colors represented at each pixel) by a demosaicing algorithm which is tailored for each type of color filter. The spectral transmittance of the CFA elements along with the demosaicing algorithm jointly determine the color rendition.[2] The sensor's passband quantum efficiency and span of the CFA's spectral responses are typically wider than the visible spectrum, thus all visible colors can be distinguished. The responses of the filters do not generally correspond to the CIE color matching functions,[3] so a color translation is required to convert the tristimulus values into a common, absolute color space.[4] The Foveon X3 sensor uses a different structure such that a pixel utilizes properties of multi-junctions to stack blue, green, and red sensors on top of each other. This arrangement does not require a demosaicing algorithm because each pixel has information about each color. Dick Merrill of Foveon distinguishes the approaches as "vertical color filter" for the Foveon X3 versus "lateral color filter" for the CFA.[5][6]

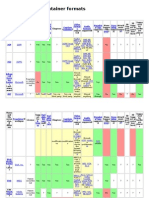

List of color filter arrays

Imag Name e Bayer filter RGBE filter CYYM filter CYGM filter RGBW Bayer RGBW #1 RGBW #2 RGBW #3 Three example RGBW filters from Kodak, with 50% white. (See Bayer filter#Alternatives) Description Pattern size (pixels)

Very common RGB filter. With one blue, one 22 red, and two green. Bayer-like with one of the green filters modified to "emerald"; used in a few Sony cameras. One cyan, two yellow, and one magenta; used in a few cameras of Kodak. One cyan, one yellow, one green, and one magenta; used in a few cameras. 22 22 22

Traditional RGBW similar to Bayer and RGBE 22 patterns.

44

24

Bayer CFA

A 2005 patent application depicting an arrangement of red, green, blue, and "white" sensor filters referred to there as "RGBW color filters having the Bayer pattern". The Bayer CFA is named for its inventor, Dr. Bryce E. Bayer from Eastman Kodak. It is realized by application of color filters over the photodiodes used in sensors, cameras, videocameras, and scanners, for creation of the color image.

RGBW sensor

An RGBW matrix (from Red, Green, Blue, White) is a CFA that includes "white" or transparent filter elements that allow the photodiode to respond to all colors of light; that is, some cells are "panchromatic", and more of the light is detected, rather than absorbed, compared to the Bayer matrix. Kodak announced several RGBW CFA patterns in 2007, all of which have the property that when the panchromatic cells are ignored,

the remaining color filtered cells are arranged such that their data can be processed with a standard Bayer demosaicing algorithm.

CYGM sensor

A CYGM matrix (Cyan, Yellow, Green, Magenta) is a CFA that uses mostly secondary colors, again to allow more of the incident light to be detected rather than absorbed. Other variants include CMY and CMYW matrices.

Manufacture of the CFA

Diazonaphthoquinone (DNQ)-novolac photoresist is one material used as the carrier for making color filters from color dyes. There is some interference between the dyes and the ultraviolet light needed to properly expose the polymer, though solutions have been found for this problem. Color photoresists sometimes used include those with chemical monikers CMCR101R, CMCR101G, CMCR101B, CMCR106R, CMCR106G, and CMCR106B. A few sources discuss other specific chemical substances, attending optical properties, and optimal manufacturing processes of color filter arrays. For instance, Nakamura said that materials for on-chip color filter arrays fall into two categories: pigment and dye. Pigment based CFAs have become the dominant option because they offer higher heat resistance and light resistance compared to dye based CFAs. In either case, thicknesses ranging up to 1 micrometre are readily available. Theuwissen says "Previously, the color filter was fabricated on a separate glass plate and glued to the CCD (Ishikawa 1981), but nowadays, all single-chip color cameras are provided with an imager which has a color filter on-chip processed (Dillon, 1978) and not as a hybrid." He provides a bibliography focusing on the number, types, aliasing effects, moire patterns, and spatial frequencies of the absorptive filters. Some sources indicate that the CFA can be manufactured separately and affixed after the sensor has been manufactured, while other sensors have the CFA manufactured directly on the surface of the imager. Theuwissen makes no mention of the materials utilized in CFA manufacture. At least one early example of an on-chip design utilized gelatin filters (Aoki et al., 1982). The gelatin is sectionalized, via photoliothography, and subsequently dyed. Aoki reveals that a CYWG arrangement was used, with the G filter being an overlap of the Y and C filters. Filter materials are manufacturer specific. Adams et al. state "Several factors influence the CFA's design. First, the individual CFA filters are

usually layers of transmissive (absorptive) organic or pigment dyes. Ensuring that the dyes have the right mechanical propertiessuch as ease of application, durability, and resistance to humidity and other atmospheric stressesis a challenging task. This makes it difficult, at best, to fine-tune the spectral responsivities.". Given that the CFAs are deposited on the image sensor surface at the BEOL (back end of line, the later stages of the integrated circuit manufacturing line), where a low-temperature regime must be rigidly observed (due to the low melting temperature of the aluminum metalized "wires" and the substrate mobility of the dopants implanted within the bulk silicon), organics would be preferred over glass. On the other hand, some CVD silicon oxide processes are low temperature processes. Ocean Optics has indicated that their patented dichroic filter CFA process (alternating thin films of ZnS and Cryolite) can be applied to spectroscopic CCDs. Gersteltec sells photoresists that possesses color filter properties.

Some pigment and dye molecules used in CFAs

In U.S.P.# 4,808,501, Carl Chiulli cites the use of 5 chemicals, three of which are C.I. #12715, AKA Solvent Red 8; Solvent Yellow 88; and C.I. # 61551, Solvent Blue 36. In U.S.P. # 5,096,801 Koya et al., of Fuji Photo Film company, list some 150-200 chemical structures, mainly azo dyes and pyrazolone-diazenyl, but fail to provide chemical names, CAS Registry numbers, or Colour Index numbers.

Optically efficient CFA implementation

Nakamura provides a schematic and bibliographic items illustrating the importance of microlenses, their f-number, and the interplay with the CFA and CCD array. Further, a short discussion of anti-reflection films is offered, though Janesick's work appears is more concerned with photon silicon interaction. Early work on microlenses and on the three-CCD/prism cameras stress the importance of a fully integrated design solution for CFAs. The camera system, as a whole, benefits from careful consideration of CFA technologies and their interplay with other sensor properties.

Vous aimerez peut-être aussi

- A Novel Method For Enhancing Satellite & Land Survey Images Using Color Filter Array Interpolation Technique (CFA)Document5 pagesA Novel Method For Enhancing Satellite & Land Survey Images Using Color Filter Array Interpolation Technique (CFA)International Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Debayering DemystifiedDocument5 pagesDebayering Demystifiedtech_dfPas encore d'évaluation

- Bayer FilterDocument4 pagesBayer FilterMoji PiyapongPas encore d'évaluation

- Ijtra 140747Document5 pagesIjtra 140747Akshay Kumar PandeyPas encore d'évaluation

- Digital Photography and Video EditingDocument8 pagesDigital Photography and Video EditingEdwin MugoPas encore d'évaluation

- 4.2.1. Overview of JPEG: What Is ?Document13 pages4.2.1. Overview of JPEG: What Is ?rekhassePas encore d'évaluation

- Image CompressionDocument42 pagesImage CompressionNasir AliPas encore d'évaluation

- Content Based Image Retrieval Using Color, Multi Dimensional Texture and Edge OrientationDocument6 pagesContent Based Image Retrieval Using Color, Multi Dimensional Texture and Edge OrientationIJSTEPas encore d'évaluation

- NEOPAN 100 ACROS Black-and-White Film GuideDocument6 pagesNEOPAN 100 ACROS Black-and-White Film GuideMadalina CriveanuPas encore d'évaluation

- Lightmeter en PDFDocument2 pagesLightmeter en PDFfirefox2005Pas encore d'évaluation

- MSDS Pelicula AA 400 Film-DataDocument4 pagesMSDS Pelicula AA 400 Film-DataPercy Junior Berrios Muñoz100% (1)

- Agfa Range of Films: Technical DataDocument12 pagesAgfa Range of Films: Technical DataCHERPIN100% (1)

- FUJIFILM Superia X-TRA 400 color negative film guideDocument6 pagesFUJIFILM Superia X-TRA 400 color negative film guideFelipe EduardoPas encore d'évaluation

- Anomalous Object Detection With Deep LearningDocument8 pagesAnomalous Object Detection With Deep LearningIJRASETPublicationsPas encore d'évaluation

- JPEG Compression: CSC361/661 Spring 2002 Burg/WongDocument16 pagesJPEG Compression: CSC361/661 Spring 2002 Burg/Wongmahajan777Pas encore d'évaluation

- Fujicolor Pro 160 S Professional: Emulsion Number Size and Package ConfigurationDocument8 pagesFujicolor Pro 160 S Professional: Emulsion Number Size and Package ConfigurationBA (Hons) Photography, Contemporary PracticePas encore d'évaluation

- Fujicolour Superia 200 Data SheetDocument4 pagesFujicolour Superia 200 Data SheetDF100% (1)

- Wallner CA526 Color AnalyzerDocument13 pagesWallner CA526 Color Analyzerrga1n2324Pas encore d'évaluation

- Superia Xtra400 DatasheetDocument6 pagesSuperia Xtra400 Datasheetdust_royPas encore d'évaluation

- Fujicolor Superia 100Document4 pagesFujicolor Superia 100tester1972Pas encore d'évaluation

- Kodak Professional Plus-X 125 Film / 125PX: Technical Data / Black-And-White FilmDocument10 pagesKodak Professional Plus-X 125 Film / 125PX: Technical Data / Black-And-White FilmGreg MartPas encore d'évaluation

- Vivid Color Reversal Film GuideDocument8 pagesVivid Color Reversal Film GuideKino Tel LokPas encore d'évaluation

- Video Compression 1 H 261Document15 pagesVideo Compression 1 H 261Rockstar_rohithPas encore d'évaluation

- An Introduction To MPEG Video CompressionDocument24 pagesAn Introduction To MPEG Video Compressionthuhienptit2003Pas encore d'évaluation

- High Speed B&W Film GuideDocument7 pagesHigh Speed B&W Film GuideFernando GiorgioPas encore d'évaluation

- Jpeg PDFDocument9 pagesJpeg PDFAvinashKumarPas encore d'évaluation

- DELTA 100 Professional: Technical InformationDocument6 pagesDELTA 100 Professional: Technical Informationgiovanni.castelletti2004Pas encore d'évaluation

- Compression JPEGDocument33 pagesCompression JPEGBalachanderKandasamyPas encore d'évaluation

- The Discrete Cosine TransformDocument15 pagesThe Discrete Cosine TransformShilpaMohananPas encore d'évaluation

- ILFORD PHOTO To Kodak EquivalentsDocument2 pagesILFORD PHOTO To Kodak EquivalentsMichael ZhangPas encore d'évaluation

- Image Segmentation using Nearest Neighbor Classifier in MatlabDocument16 pagesImage Segmentation using Nearest Neighbor Classifier in MatlabRashi AgarwalPas encore d'évaluation

- Agfa Professional FilmsDocument12 pagesAgfa Professional FilmsdprakelPas encore d'évaluation

- Mpeg 1.nisDocument18 pagesMpeg 1.nisnisanth123Pas encore d'évaluation

- KodachromeDocument8 pagesKodachromeapi-3759623Pas encore d'évaluation

- Fp4 Plus: Technical InformationDocument6 pagesFp4 Plus: Technical Informationgiovanni.castelletti2004Pas encore d'évaluation

- Presented By: Priya Raina 13-516Document68 pagesPresented By: Priya Raina 13-516Priya RainaPas encore d'évaluation

- Foma Fomapan 200 DatenblattDocument2 pagesFoma Fomapan 200 DatenblattMarkusMayerPas encore d'évaluation

- Arriflex D-21Document12 pagesArriflex D-21momento moriPas encore d'évaluation

- Image Compression Using DFT Through Fast Fourier Transform TechniqueDocument5 pagesImage Compression Using DFT Through Fast Fourier Transform TechniqueInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Fomapan 200Document3 pagesFomapan 200Jovan Mac TirePas encore d'évaluation

- Inverted Research Microscope ECLIPSE TiDocument32 pagesInverted Research Microscope ECLIPSE TiHamdi SeverPas encore d'évaluation

- Fomapan-400 Info FilmDocument2 pagesFomapan-400 Info FilmRoberto RutkauskasPas encore d'évaluation

- Tamron SP - 350mm f5.6 06b - 500mm f8 55b - Manual PDFDocument20 pagesTamron SP - 350mm f5.6 06b - 500mm f8 55b - Manual PDFHank MarvinPas encore d'évaluation

- Kapitel - 7 - en - QXD - Administrator PDFDocument10 pagesKapitel - 7 - en - QXD - Administrator PDFTechPas encore d'évaluation

- Darkroom TimerDocument7 pagesDarkroom TimerHuy NguyễnPas encore d'évaluation

- Kodak Verichrome PanDocument4 pagesKodak Verichrome Panfoster747Pas encore d'évaluation

- Fomapan 200Document2 pagesFomapan 200Theo DelCampo100% (1)

- To Ensure Correct Usage, Read Manuals Carefully Before Using Your Equipment. Some Documentation Is Supplied On Cd-Rom Only. WarningDocument16 pagesTo Ensure Correct Usage, Read Manuals Carefully Before Using Your Equipment. Some Documentation Is Supplied On Cd-Rom Only. WarningApichet KiatworakunPas encore d'évaluation

- Contrast Control For ILFORD MULTIGRADEDocument4 pagesContrast Control For ILFORD MULTIGRADEJuan Fco MartínPas encore d'évaluation

- The World's Smallest, Lightest Body Based On RICOH IMAGING ResearchDocument28 pagesThe World's Smallest, Lightest Body Based On RICOH IMAGING ResearchSayar Aung Naing ThuPas encore d'évaluation

- Biological Sample Preparation For TemDocument29 pagesBiological Sample Preparation For TemRahulsalunkhePas encore d'évaluation

- Discover New Perspectives: Stunningly Sharp Pictures. Full HD Video. Creative FreedomDocument8 pagesDiscover New Perspectives: Stunningly Sharp Pictures. Full HD Video. Creative FreedomEHisaingenisPas encore d'évaluation

- Color Rendering Index White Paper Ron Kubara NoritsuDocument7 pagesColor Rendering Index White Paper Ron Kubara NoritsuelsokukabaPas encore d'évaluation

- EOS M6 Mark II BrochureDocument4 pagesEOS M6 Mark II BrochureMichael Zhang50% (2)

- JPEG Image Compression and Decompression by Huffman CodingDocument7 pagesJPEG Image Compression and Decompression by Huffman CodingInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Digital Camera Review: Canon EOS D30Document12 pagesDigital Camera Review: Canon EOS D30grmi1Pas encore d'évaluation

- Bayer FilterDocument7 pagesBayer FilterRitesh DoshiPas encore d'évaluation

- Color Filter Array - WikipediaDocument38 pagesColor Filter Array - Wikipediaamir farahi nezhadPas encore d'évaluation

- DemosaicingDocument4 pagesDemosaicingpeterPas encore d'évaluation

- Standard and Super-Resolution Bioimaging Data Analysis: A PrimerD'EverandStandard and Super-Resolution Bioimaging Data Analysis: A PrimerPas encore d'évaluation

- FujinonAngleOfViewComparison3Perf Micro4 3Document1 pageFujinonAngleOfViewComparison3Perf Micro4 3Moji PiyapongPas encore d'évaluation

- Foveon X3 SensorDocument5 pagesFoveon X3 SensorMoji PiyapongPas encore d'évaluation

- FFmpegDocument4 pagesFFmpegMoji PiyapongPas encore d'évaluation

- Digital NegativeDocument10 pagesDigital NegativeMoji PiyapongPas encore d'évaluation

- Digital CinematographyDocument8 pagesDigital CinematographyMoji PiyapongPas encore d'évaluation

- Exposure ValueDocument12 pagesExposure ValueMoji PiyapongPas encore d'évaluation

- DNXHD OverviewDocument2 pagesDNXHD OverviewMoji PiyapongPas encore d'évaluation

- Digital Picture ExchangeDocument2 pagesDigital Picture ExchangeMoji PiyapongPas encore d'évaluation

- Display PortDocument12 pagesDisplay PortMoji PiyapongPas encore d'évaluation

- Digital Vs FilmDocument8 pagesDigital Vs FilmMoji PiyapongPas encore d'évaluation

- Digital Container FormatDocument3 pagesDigital Container FormatMoji PiyapongPas encore d'évaluation

- Digital IntermediateDocument3 pagesDigital IntermediateMoji PiyapongPas encore d'évaluation

- Comparison of Graphics File FormatsDocument21 pagesComparison of Graphics File FormatsMoji PiyapongPas encore d'évaluation

- D Cinema FQAsDocument4 pagesD Cinema FQAsMoji PiyapongPas encore d'évaluation

- Digital CinemaDocument12 pagesDigital CinemaMoji Piyapong100% (1)

- CIE 1931 Color SpaceDocument15 pagesCIE 1931 Color SpaceMoji PiyapongPas encore d'évaluation

- Digital Cinema PackageDocument8 pagesDigital Cinema PackageMoji PiyapongPas encore d'évaluation

- Data CompressionDocument10 pagesData CompressionMoji PiyapongPas encore d'évaluation

- Color DepthDocument6 pagesColor Depth17sheenaPas encore d'évaluation

- Comparison of H.264 and VC-1Document2 pagesComparison of H.264 and VC-1Moji PiyapongPas encore d'évaluation

- Comparison of Container FormatsDocument8 pagesComparison of Container FormatsMoji PiyapongPas encore d'évaluation

- Comparison of Video CodecsDocument15 pagesComparison of Video CodecsMoji PiyapongPas encore d'évaluation

- Color VisionDocument14 pagesColor VisionMoji PiyapongPas encore d'évaluation

- Active Pixel Sensor / CMOS: HistoryDocument7 pagesActive Pixel Sensor / CMOS: HistoryMoji PiyapongPas encore d'évaluation

- Color TheoryDocument10 pagesColor TheoryMoji PiyapongPas encore d'évaluation

- CCD CmosDocument3 pagesCCD CmosMoji PiyapongPas encore d'évaluation

- Color SpaceDocument6 pagesColor SpaceMoji Piyapong0% (1)

- CCDDocument14 pagesCCDMoji PiyapongPas encore d'évaluation

- Bit RateDocument8 pagesBit RateMoji PiyapongPas encore d'évaluation

- Weather ElementsDocument6 pagesWeather ElementsFrenzie Mae Vasquez RiveraPas encore d'évaluation

- Product Note PD30 en RevA 2011 Anti-Sway Control ProgramDocument2 pagesProduct Note PD30 en RevA 2011 Anti-Sway Control ProgramkumarPas encore d'évaluation

- Programming ExercisesDocument2 pagesProgramming ExercisesDaryl Ivan Empuerto HisolaPas encore d'évaluation

- $binder 1Document156 pages$binder 1fchem11Pas encore d'évaluation

- Computer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentDocument43 pagesComputer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentSreedhar PugalendhiPas encore d'évaluation

- MSDS Lipotronik Reagen KitDocument6 pagesMSDS Lipotronik Reagen Kitlaboratorium rsst klaten100% (1)

- Power Transmission: Components Used To Transmit Power: Gears, Belt, Clutch and BrakesDocument17 pagesPower Transmission: Components Used To Transmit Power: Gears, Belt, Clutch and Brakesrip111176Pas encore d'évaluation

- IS 1570 Part 5Document18 pagesIS 1570 Part 5Sheetal JindalPas encore d'évaluation

- Homework 1Document6 pagesHomework 1Ahmet Kemal ÇetinPas encore d'évaluation

- Sustainability Report Ingeteam 2018 - ENDocument51 pagesSustainability Report Ingeteam 2018 - ENRana Awais KhanPas encore d'évaluation

- Chapter 6 - Cementing - Part 1 PDFDocument32 pagesChapter 6 - Cementing - Part 1 PDFfadz607Pas encore d'évaluation

- Quincy Qrds Series Single-Stage, Oil-Less Reciprocating Air Compressors 2-30 HPDocument8 pagesQuincy Qrds Series Single-Stage, Oil-Less Reciprocating Air Compressors 2-30 HPCoral IcmPas encore d'évaluation

- EM I Unit 1Document18 pagesEM I Unit 1Srimathi tjPas encore d'évaluation

- Calcined Clays For Sustainable Concrete Karen Scrivener, AurÇlie Favier, 2015Document552 pagesCalcined Clays For Sustainable Concrete Karen Scrivener, AurÇlie Favier, 2015Débora BretasPas encore d'évaluation

- Introduction To Random MatricesDocument508 pagesIntroduction To Random Matricesjorelex100% (1)

- Linear equations worksheet solutionsDocument4 pagesLinear equations worksheet solutionsHari Kiran M PPas encore d'évaluation

- Armfield F1 Fluid Mechanics Series Brochure V2a Download 1Document30 pagesArmfield F1 Fluid Mechanics Series Brochure V2a Download 1paul contrerasPas encore d'évaluation

- Orifice SizingDocument2 pagesOrifice SizingAvinav Kumar100% (1)

- Analysis of Buckling of Piles Fully Embedded in Ground According To Finite Element MethodDocument5 pagesAnalysis of Buckling of Piles Fully Embedded in Ground According To Finite Element Methodctlim88Pas encore d'évaluation

- En010 104 Engineering MechanicsDocument1 pageEn010 104 Engineering MechanicsArun SaiPas encore d'évaluation

- 2018 Book FractographyAndFailureAnalysis PDFDocument172 pages2018 Book FractographyAndFailureAnalysis PDFDavid Casarrubias A100% (4)

- Cover PrintDocument4 pagesCover PrintFidel ArroyoPas encore d'évaluation

- Engineering Calculation Sheet Consulting EngineersDocument17 pagesEngineering Calculation Sheet Consulting EngineersParthiban ArivazhaganPas encore d'évaluation

- Learning Objectives-2: Uniform MotionDocument7 pagesLearning Objectives-2: Uniform MotionBryanHarold BrooPas encore d'évaluation

- WhatReallyisUHPC TowardsaGlobalDefinition UHPC2018FuzhouChina July292018Document14 pagesWhatReallyisUHPC TowardsaGlobalDefinition UHPC2018FuzhouChina July292018Данило ГадайчукPas encore d'évaluation

- CUP IBChemistry c06 It Rates of ReactionsDocument33 pagesCUP IBChemistry c06 It Rates of ReactionsAdnan ChowdhuryPas encore d'évaluation

- 0625 s07 Ms 3Document7 pages0625 s07 Ms 3Hubbak Khan50% (2)

- Teaching Quantum Mechanics On An Introductory Level PDFDocument10 pagesTeaching Quantum Mechanics On An Introductory Level PDF24263537Pas encore d'évaluation

- Chap3 (D) MillDocument22 pagesChap3 (D) MilljojoPas encore d'évaluation

- 11 HW ChemistryDocument6 pages11 HW ChemistryJ BalanPas encore d'évaluation