Académique Documents

Professionnel Documents

Culture Documents

Calculation of effective section properties for a cold-formed lipped channel section in bending

Transféré par

Anca SimaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Calculation of effective section properties for a cold-formed lipped channel section in bending

Transféré par

Anca SimaDroits d'auteur :

Formats disponibles

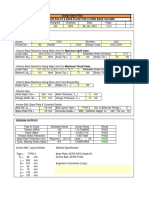

CALCULATION SHEET

Document Ref: Title

T3701a-DFE

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in bending EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

Example: Calculation of effective section properties for a cold-formed lipped channel section in bending

This example deals with the effective properties calculation of a coldformed lipped channel section subjected to bending about its major axis. Basic Data The dimensions of the cross-section and the material properties are: Total height h = 200 mm Total width of flange in compression Total width of flange in tension Total width of edge fold Internal radius Nominal thickness

Steel core thickness Basic yield strength Modulus of elasticity Poissons ratio

b1 = 74 mm b2 = 66 mm

c = 20,8 mm r = 3 mm

t nom = 2 mm

t = 1,96 mm

f yb = 350 N mm 2

EN1993-1-3 3.2.4(3)

E = 210000 N mm 2

= 0,3

Partial factor

M0 = 1,00

EN1993-1-3 2(3)

The dimensions of the section centre line are:

Web height

Width of flange in compression Width of flange in tension

hp = h t nom = 200 2 = 198 mm bp1 = b1 t nom = 74 2 = 72 mm

bp2 = b2 t nom = 66 2 = 64 mm cp = c t nom 2 = 20,8 2 2 = 19,8 mm

Width of edge fold

T3701a-DFE.doc

CALCULATION SHEET

Document Ref: Title

T3701a-DFE

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in bending EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

Checking of geometrical proportions

The design method of EN1993-1-3 can be applied if the following conditions EN1993-1-3 are satisfied: 5.2 b t 60 b1 t = 74 1,96 = 37,75 < 60 OK

c t 50

h t 500

c t = 20,8 1,96 = 10,61 < 50 OK

h t = 200 1,96 = 102,04 < 500 OK

In order to provide sufficient stiffness and to avoid primary buckling of the stiffener itself, the size of stiffener should be within the following range:

0,2 c b 0,6 c b1 = 20,8 74 = 0,28 c b2 = 20,8 66 = 0,32

0,2 < 0,28 < 0,6 OK

0,2 < 0,32 < 0,6 OK EN1993-1-3 5.1(3)

The influence of rounding of the corners is neglected if:

r t5 r t = 3 1,96 = 1,53 < 5 OK

r bp 0,10

r bp1 = 3 72 = 0,04 < 0,10 OK r bp 2 = 3 64 = 0,05 < 0,10 OK

Gross section properties

Abr = t (2cp + bp1 + bp2 + hp ) = 1,96 (2 19,8 + 72 + 64 + 198) = 732 mm 2 Position of the neutral axis with respect to the flange in compression:

z b1

[c (h =

p

2 2 cp 2 ) + bp2 hp + hp 2 + cp 2 t

Abr

= 96,88 mm

Effective section properties of the flange and lip in compression

The general (iterative) procedure is applied to calculate the effective EN1993-1-3 properties of the compressed flange and the lip (plane element with edge 5.5.3.2 stiffener). The calculation should be carried out in three steps:

Step 1:

Obtain an initial effective cross-section for the stiffener using effective widths EN1993-1-3 of the flange determined by assuming that the compressed flange is doubly 5.5.3.2(3) supported, the stiffener gives full restraint ( K = ) and that design strength is not reduced ( com,Ed = f yb / M 0 ).

T3701a-DFE.doc

CALCULATION SHEET

Document Ref: Title

T3701a-DFE

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in bending EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

Effective width of the compressed flange The stress ratio: = 1 (uniform compression), so the buckling factor is: k = 4 for internal compression element.

EN1993-1-3 5.5.2 and EN1993-1-5 4.4

= 235 f yb

The relative slenderness: bp1 t 28,4 k

p,b =

72 1,96 = 0,789 28,4 235 350 4

The width reduction factor is:

p,b 0,055(3 + ) 0,789 0,055 (3 + 1) = = 0,914 0,789 2 p,b 2

The effective width is:

beff = bp1 = 0 ,914 72 = 65,8 mm be1 = be2 = 0 ,5beff = 0 ,5 65,8 = 32 ,9 mm

Effective width of the edge fold The buckling factor is: if bp, c bp1 0,35 : if 0,35 < bp,c bp1 0,6 :

EN1993-1-3

k = 0,5

k = 0,5 + 0,83 3 (bp, c bp1 0,35)

2

5.5.3.2(5a)

bp, c bp1 = 19,8 72 = 0,275 < 0,35

The relative slenderness:

so

k = 0,5 EN1993-1-5 4.4

p,c =

cp t 28,4 k

19,8 1,96 = 0,614 28,4 235 350 0,5

The width reduction factor is:

p,c 0,188 0,614 0,188 = = 1,13 0,614 2 p,c 2

so

but 1

=1

T3701a-DFE.doc

CALCULATION SHEET

Document Ref: Title

T3701a-DFE

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in bending EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

The effective width is: ceff = cp = 1 19,8 = 19,8 mm Effective area of the edge stiffener: As = t be2 + ceff = 1,96 32,9 + 19,8 = 103,3 mm 2

Step 2:

EN1993-1-3 5.5.3.2(5a)

5.5.3.2(6)

Use the initial effective cross-section of the stiffener to determine the EN1993-1-3 reduction factor, allowing for the effects of the continuous spring restraint. 5.5.3.2(3) The elastic critical buckling stress for the edge stiffener is EN1993-1-3 5.5.3.2(7)

cr ,s =

where:

2 K E Is As

K is the spring stiffness per unit length: K= E t3 1 2 3 2 4(1 ) b1 hp + b1 + 0,5 b1 b2 hp kf

EN1993-1-3 5.5.3.1(5)

with:

b1 distance from the web to the centre of the effective area of the stiffener in compression (upper flange)

b1 = bp1

be2t be2 2 32,9 1,96 32,9 2 = 72 = 61,73 mm (be2 + ceff )t (32,9 + 19,8) 1,96

kf = 0 for bending about the y-y axis K = 0,439 N mm

I s is the effective second moment of area of the stiffener:

3 2 ceff 2 ceff be2 t 3 ceff t ceff Is = + + be2 t + ceff t 12 12 2(be2 + ceff ) 2 2(be2 + ceff ) 2 2

I s = 3663 mm 4

T3701a-DFE.doc

CALCULATION SHEET

Document Ref: Title

T3701a-DFE

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in bending EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

so, the elastic critical buckling stress for the edge stiffener is

cr,s =

2 0,439 210000 3663 = 355,78 N mm 2 103,3 EN1993-1-3 5.5.3.2(3) Figure 5.10d EN1993-1-3 5.5.3.1(7) EN1993-1-5

Thickness reduction factor d for the edge stiffener The relative slenderness:

d =

f yb cr,s = 350 355,78 = 0,992

The reduction factor will be: if d 0,65 if 0,65 < d < 1,38 if d 1,38

d = 1,0 d = 1,47 0,723 d d = 0,66 d

so

0,65 < d = 0,992 < 1,38

Step 3:

d = 1,47 0,723 0,992 = 0,753

4.4(2) EN1993-1-3

As the reduction factor for buckling of the stiffener is d < 1, iterate to refine 5.5.3.2(3) the value of the reduction factor for buckling of the stiffener. Figure 5.10e The iterations are carried out based on modified values of obtained using:

com,Ed,i = d f yb M0 and

p, red = p d

EN1993-1-3 5.5.3.2 (10)

The iteration stops when the reduction factor converges. Initial values (iteration 1): Final values (iteration n):

d = 0,753

be2 = 32,9 mm ceff = 19,8 mm

d = d, n = 0,737

be2 = be2, n = 35,9 mm ceff = ceff,n = 19,8 mm be2 = 35,9 mm ceff = 19,8 mm

Final values of effective properties for flange and lip in compression are:

d = 0,737

and be1 = 32,9 mm

T3701a-DFE.doc

CALCULATION SHEET

Document Ref: Title

T3701a-DFE

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in bending EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

t red = t d = 1,96 0,737 = 1,44 mm

EN1993-1-3 5.5.3.2(12)

Effective section properties of the web

The position of the neutral axis with regard to the flange in compression:

hc = cp (hp cp 2 ) + bp2 hp + hp 2 + ceff d 2

2 2

cp + bp2 + hp + be1 + (be2 + ceff ) d

hc = 101,6 mm

The stress ratio:

hc hp hc

101,6 198 = 0,949 101,6

The buckling factor: k = 7,81 6,29 + 9,78 2 The relative slenderness: hp t 28,4 k k = 22,58

EN1993-1-5 4.4 (Table 4.1)

p, h =

198 1,96 = 0,914 28,4 235 350 22,58

The width reduction factor is:

p, h 0,055(3 + ) 0,914 0,055 (3 0,949) = = 0,959 0,9142 p, h 2

T3701a-DFE.doc

CALCULATION SHEET

Document Ref: Title

T3701a-DFE

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in bending EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

The effective width of the zone in compression of the web is: heff = hc = 0,959 101,6 = 97,5 mm Near the flange in compression: he1 = 0,4heff = 0,4 97,5 = 39 mm Near the neutral axis: he2 = 0,6heff = 0,6 97,5 = 58,5 mm The effective width of the web is: Near the flange in compression: h1 = he1 = 39 mm Near the flange in tension: h2 = hp (hc he2 ) = 198 (101,6 58,5) = 154,9 mm

Effective section properties

Effective cross-section area:

Aeff = t[cp + bp 2 + h1 + h2 + be1 + (be 2 + ceff ) d ]

Aeff = 1,96 [19,8 + 64 + 39 + 154,9 + 32,9 + (35,9 + 19,8) 0,737] Aeff = 689,2 mm 2 Position of the neutral axis with regard to the flange in compression:

zc = t cp (hp cp 2 ) + bp2 hp + h2 (hp h2 2 ) + h1 2 + ceff d 2

2 2

Aeff

zc = 102,3 mm Position of the neutral axis with regard to the flange in tension: z t = hp zc = 198 102,3 = 95,7 mm

T3701a-DFE.doc

CALCULATION SHEET

Document Ref: Title

T3701a-DFE

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in bending EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

Second moment of area:

3 3 3 c t b t 3 b ( t )3 c 3 ( d t ) h1 t h2 t bp2t + + + p + e1 + e2 d + eff + I eff,y = 12 12 12 12 12 12 12 2 + cp t ( z t cp 2) 2 + bp 2tz t + h2t ( z t h2 2) 2 + h1t ( zc h1 2) 2 + 3

+ be1t zc + be2 ( d t ) zc + ceff ( d t )( zc ceff 2) 2

2 2

I eff,y = 4139861 mm 4

Effective section modulus: - with regard to the flange in compression Weff,y,c = I eff,y zc I eff,y zt = 4139861 = 40463 mm3 102,3

- with regard to the flange in tension Weff,y,t = = 4139861 = 43264 mm3 95,7

T3701a-DFE.doc

Example: Calculation of effective section properties for a cold-formed lipped channel section in bending T3701a-DFE.doc

Quality Record

RESOURCE TITLE Example: Calculation of effective section properties for a cold-formed lipped channel section in bending

Reference(s) ORIGINAL DOCUMENT Name Created by Technical content checked by Editorial content checked by Technical content endorsed by the following STEEL Partners: 1. UK 2. France 3. Sweden 4. Germany 5. Spain Resource approved by Technical Coordinator TRANSLATED DOCUMENT This Translation made and checked by: Translated resource approved by: SCI CTICM SBI RWTH Labein V. Ungureanu, A. Ruff D. Dubina Company BRITT Ltd. Timisoara, Romania BRITT Ltd. Timisoara, Romania Date 05/12/2005 08/12/2005

C:\Documents and Settings\viorel.ungureanu\Desktop\upload 2\T3701a-DFE.doc

Page 9

Example: Calculation of effective section properties for a cold-formed lipped channel section in bending T3701a-DFE.doc

Wrapper Information

Title* Series Description* Access Level* Identifiers* This example deals with the effective properties calculation of a cold-formed lipped channel section subjected to bending about its major axis. Expertise Filename C:\Documents and Settings\viorel.ungureanu\Desktop\STEEL_iteratia2\upload 2\T3701a.doc Microsoft Office Word; 10 Pages; 587kb; Resource Type Viewpoint Subject* Dates Application Area(s) Created Date Last Modified Date Checked Date Valid From Valid To Language(s)* Contacts Author English V. Ungureanu, A. Ruff, BRITT Ltd. Timisoara, Romania Worked example Engineer Residential buildings 23/02/2006 Example: Calculation of effective section properties for a cold-formed lipped channel section in bending

Format Category*

Checked By Approved by Editor Last Modified By Keywords* See Also

D. Dubina, BRITT Ltd. Timisoara, Romania

Effective section properties, bending, cold-formed, lipped channel section Eurocode Reference Worked Example(s) Commentary Discussion Other EN1993-1-3, EN1993-1-1, EN1993-1-5

Coverage Special Instructions

National Applicability

Europe

C:\Documents and Settings\viorel.ungureanu\Desktop\upload 2\T3701a-DFE.doc

Page 10

Vous aimerez peut-être aussi

- Forklift Truck Risk AssessmentDocument2 pagesForklift Truck Risk AssessmentAshis Das100% (1)

- The Grey Nomads Guide To AustraliaDocument3 pagesThe Grey Nomads Guide To AustraliaFreerangecamping60% (5)

- PC Assembly PlantDocument19 pagesPC Assembly Plantmuyenzo100% (1)

- Slab With OpeningDocument16 pagesSlab With OpeningTomislav Šimag100% (1)

- Access Steel - SX023a - Effective Section Properties of Steel Lipped Channel in CompressionDocument10 pagesAccess Steel - SX023a - Effective Section Properties of Steel Lipped Channel in Compressiongianniorlati1972Pas encore d'évaluation

- Example Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingDocument10 pagesExample Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in Bendingcbler100% (10)

- Personality Types and Character TraitsDocument5 pagesPersonality Types and Character TraitspensleepePas encore d'évaluation

- CH 10Document125 pagesCH 10Lisset Soraya Huamán QuispePas encore d'évaluation

- Structural Design - Post Tensioned Slab Design1Document12 pagesStructural Design - Post Tensioned Slab Design1Chamil MahagamagePas encore d'évaluation

- International Lateral LoadsDocument38 pagesInternational Lateral LoadsRamilArtates100% (1)

- SX037a-En-EU-Example-Fire Resistance of A Composite Slab To en 1994-1-2Document10 pagesSX037a-En-EU-Example-Fire Resistance of A Composite Slab To en 1994-1-2Benediktas DervinisPas encore d'évaluation

- 16 - Bruce Ireland - Joint DetailsDocument32 pages16 - Bruce Ireland - Joint DetailsTian NgPas encore d'évaluation

- Pinned Joint EC3Document180 pagesPinned Joint EC3Lipuvka0% (1)

- Yield Line Theory: Prepared byDocument22 pagesYield Line Theory: Prepared byKartikMandaniPas encore d'évaluation

- Platic AnalysisDocument29 pagesPlatic AnalysisSiddhanth S NairPas encore d'évaluation

- Proposed Students Hospital Wind Load CalculationsDocument24 pagesProposed Students Hospital Wind Load CalculationsJohn NjorogePas encore d'évaluation

- Engg/10/s4 Reinforced Concrete Design To Bs 8110: Contract RefDocument3 pagesEngg/10/s4 Reinforced Concrete Design To Bs 8110: Contract RefGodfrey James MachotaPas encore d'évaluation

- Design of Haunched Composite Connections For Long-Span Beam ConstructionDocument10 pagesDesign of Haunched Composite Connections For Long-Span Beam ConstructioncasanovavnPas encore d'évaluation

- Con 1302Document12 pagesCon 1302Sanket Arun More100% (1)

- Lecture 11-1 Bases by H.J. MtyanaDocument29 pagesLecture 11-1 Bases by H.J. MtyanaHarold Jackson Mtyana100% (1)

- Vertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisDocument10 pagesVertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisNeven Ahmed HassanPas encore d'évaluation

- Members With Combined Bending and Axial ForceDocument32 pagesMembers With Combined Bending and Axial ForceJohn RomanusPas encore d'évaluation

- Member Design - Prestressed Concrete Beam and Slab BS8110 (EC2), ACI318, AS3600 v2021.03 PDFDocument98 pagesMember Design - Prestressed Concrete Beam and Slab BS8110 (EC2), ACI318, AS3600 v2021.03 PDFlau lauPas encore d'évaluation

- 1 - Intro To RC Detailing - KDocument23 pages1 - Intro To RC Detailing - KAnonymous dlSmlsymHPas encore d'évaluation

- Excavation CalDocument28 pagesExcavation CalngPas encore d'évaluation

- Coupling Beam DesignDocument14 pagesCoupling Beam DesignkibzeamPas encore d'évaluation

- Designing structural steelwork to BS5950Document8 pagesDesigning structural steelwork to BS5950Reef20Pas encore d'évaluation

- DOS Web Cleat ConnectionDocument31 pagesDOS Web Cleat ConnectionArfat PatelPas encore d'évaluation

- Composite Steel DesignDocument33 pagesComposite Steel DesignALABIADESINA100% (1)

- Deep Beams and Special Structural ElementsDocument14 pagesDeep Beams and Special Structural Elementsomar100% (1)

- Ramset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringDocument10 pagesRamset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringjlolhnpPas encore d'évaluation

- Waffle slabs with integral beamsDocument2 pagesWaffle slabs with integral beamsKasun Geenath Vithanage100% (1)

- Reinforced Concrete Column by Zinab EC2Document15 pagesReinforced Concrete Column by Zinab EC2berto2008Pas encore d'évaluation

- Sway Frame Steel Column DesignDocument1 pageSway Frame Steel Column DesignChirianu MarianPas encore d'évaluation

- Column Design Design of Short Braced ColumnsDocument17 pagesColumn Design Design of Short Braced ColumnsPimpa MwiingaPas encore d'évaluation

- Axially Loaded Columns - Base Plate DesignDocument2 pagesAxially Loaded Columns - Base Plate DesignaomareltayebPas encore d'évaluation

- Welds of A Fin Plate ConnectionDocument2 pagesWelds of A Fin Plate Connectioncretz2Pas encore d'évaluation

- Ec3 Kolon HesabıDocument5 pagesEc3 Kolon HesabınaimalimliPas encore d'évaluation

- Design Model For Simple Column Bases - Axially Loaded I Section ColumnsDocument17 pagesDesign Model For Simple Column Bases - Axially Loaded I Section Columnshooky1100% (2)

- Opening in Slab and BeamDocument13 pagesOpening in Slab and BeamYohan LimPas encore d'évaluation

- Design of CorbelsDocument30 pagesDesign of CorbelsSafiurrehmanPas encore d'évaluation

- Mat Chapter 18Document29 pagesMat Chapter 18hemant_durgawalePas encore d'évaluation

- Software Verification: Example 17Document8 pagesSoftware Verification: Example 17sancloudPas encore d'évaluation

- Column Splices Not Requiring Full Continuity of StiffnessDocument6 pagesColumn Splices Not Requiring Full Continuity of StiffnessBobaru MariusPas encore d'évaluation

- MasterSeries Student Masonry Retaining EtcDocument21 pagesMasterSeries Student Masonry Retaining EtcekaPas encore d'évaluation

- BS 5950-2000 Example 001Document5 pagesBS 5950-2000 Example 001Anitha Hassan KabeerPas encore d'évaluation

- Bracing Design To Eurocode 3Document13 pagesBracing Design To Eurocode 3B.A H100% (1)

- Flat Slab DesignDocument2 pagesFlat Slab DesignKim ChanthanPas encore d'évaluation

- Beam ColumnsDocument21 pagesBeam ColumnsSherif Mohamed Ibrahim100% (1)

- Horizontal Reinforcement (Walls BS 8110)Document2 pagesHorizontal Reinforcement (Walls BS 8110)dhanya1995Pas encore d'évaluation

- Corbel DesignDocument12 pagesCorbel DesignURVESHKUMAR PATELPas encore d'évaluation

- Resistance Moment Calculations (Walls BS 8110) PDFDocument3 pagesResistance Moment Calculations (Walls BS 8110) PDFdhanya1995Pas encore d'évaluation

- 5-Slender Columns (1604)Document27 pages5-Slender Columns (1604)Peh Hoong PingPas encore d'évaluation

- Full Shear Notes and ExampleDocument6 pagesFull Shear Notes and ExampleSiti MaimunahPas encore d'évaluation

- Strengthening Design of Concrete Beams by Adition of Steel PlatesDocument10 pagesStrengthening Design of Concrete Beams by Adition of Steel PlatesgparratPas encore d'évaluation

- Simply Supported Primary Composite BeamDocument17 pagesSimply Supported Primary Composite BeamPaul Marceti100% (2)

- Composite floor slab design verificationDocument7 pagesComposite floor slab design verificationFong Pei TyngPas encore d'évaluation

- Reinforced Concrete Early Thermal Crack CheckDocument7 pagesReinforced Concrete Early Thermal Crack CheckklynchellePas encore d'évaluation

- Seismic Design To EC8 - L3Document18 pagesSeismic Design To EC8 - L3Chamil MahagamagePas encore d'évaluation

- Slab With and Without OpeningDocument17 pagesSlab With and Without Openingstructure123Pas encore d'évaluation

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionD'EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionPas encore d'évaluation

- Example: Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingDocument10 pagesExample: Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingVarga ZoranPas encore d'évaluation

- Design of anchor bolts and base plate for a fixed base columnDocument4 pagesDesign of anchor bolts and base plate for a fixed base columnSuryaSinghPas encore d'évaluation

- Calculation of The Moment Resistance of Z - and C-Shaped Cold-Formed Sections According To Eurocode 3Document18 pagesCalculation of The Moment Resistance of Z - and C-Shaped Cold-Formed Sections According To Eurocode 3Liviu Ion100% (1)

- Mathcad - Baseplate Design - 8Document6 pagesMathcad - Baseplate Design - 8Monotobo X MakinaPas encore d'évaluation

- Electrical Machines Multiple Choice Questions - Mcqs - QuizDocument10 pagesElectrical Machines Multiple Choice Questions - Mcqs - Quiztooba mukhtarPas encore d'évaluation

- Regenerative Medicine Manual ISSCA 2020 EnglishDocument21 pagesRegenerative Medicine Manual ISSCA 2020 EnglishDana MihutPas encore d'évaluation

- Pemanfaatan Limbah Spanduk Plastik (Flexy Banner) Menjadi Produk Dekorasi RuanganDocument6 pagesPemanfaatan Limbah Spanduk Plastik (Flexy Banner) Menjadi Produk Dekorasi RuanganErvan Maulana IlyasPas encore d'évaluation

- Nitocote WP DDocument4 pagesNitocote WP DdaragPas encore d'évaluation

- Thank You For Taking The Week 3: Assignment 3. Week 3: Assignment 3Document3 pagesThank You For Taking The Week 3: Assignment 3. Week 3: Assignment 3DhivyaPas encore d'évaluation

- History: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHDocument3 pagesHistory: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHPatrizio MassaroPas encore d'évaluation

- DerbyCityCouncil Wizquiz Presentation PDFDocument123 pagesDerbyCityCouncil Wizquiz Presentation PDFShubham NamdevPas encore d'évaluation

- 841 Specific GravityDocument1 page841 Specific GravityJam SkyPas encore d'évaluation

- HS-2172 Vs HS-5500 Test ComparisonDocument1 pageHS-2172 Vs HS-5500 Test ComparisonRicardo VillarPas encore d'évaluation

- Tennis BiomechanicsDocument14 pagesTennis BiomechanicsΒασίλης Παπατσάς100% (1)

- Sony HCD-GTX999 PDFDocument86 pagesSony HCD-GTX999 PDFMarcosAlves100% (1)

- Ethics Module 2 - NotesDocument1 pageEthics Module 2 - Notesanon_137579236Pas encore d'évaluation

- Nakshatra Exaltation DebilitationDocument3 pagesNakshatra Exaltation DebilitationBhanu Pinnamaneni100% (1)

- Textile Pretreatment and Finishing 2023Document205 pagesTextile Pretreatment and Finishing 2023Aweru gebremariamPas encore d'évaluation

- Ericsson Microwave Outlook 2021Document16 pagesEricsson Microwave Outlook 2021Ahmed HussainPas encore d'évaluation

- IruChem Co., Ltd-Introduction of CompanyDocument62 pagesIruChem Co., Ltd-Introduction of CompanyKhongBietPas encore d'évaluation

- Datta Das FET ExplanationDocument2 pagesDatta Das FET ExplanationJulie HaydenPas encore d'évaluation

- 500 Important Spoken Tamil Situations Into Spoken English Sentences SampleDocument7 pages500 Important Spoken Tamil Situations Into Spoken English Sentences SamplerameshdurairajPas encore d'évaluation

- MUCLecture 2021 10311889Document11 pagesMUCLecture 2021 10311889Ramon Angelo MendezPas encore d'évaluation

- Ca2Document8 pagesCa2ChandraPas encore d'évaluation

- Shanidham - In-Shanidham Pacify Lord ShaniDocument3 pagesShanidham - In-Shanidham Pacify Lord ShanisubramanyaPas encore d'évaluation

- Poultry Disease Prevention and ControlDocument64 pagesPoultry Disease Prevention and Controlsigra100% (3)

- Chapter 4 Cost MinimizationDocument6 pagesChapter 4 Cost MinimizationXavier Hetsel Ortega BarraganPas encore d'évaluation

- GERD – Definition, pathophysiology, epidemiology and diagnostic investigationsDocument132 pagesGERD – Definition, pathophysiology, epidemiology and diagnostic investigationsSorana VasilescuPas encore d'évaluation

- Mfz-Odv065r15j DS 1-0-0 PDFDocument1 pageMfz-Odv065r15j DS 1-0-0 PDFelxsoonPas encore d'évaluation