Académique Documents

Professionnel Documents

Culture Documents

Sheet 4

Transféré par

Abdalla Mohamed AbdallaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sheet 4

Transféré par

Abdalla Mohamed AbdallaDroits d'auteur :

Formats disponibles

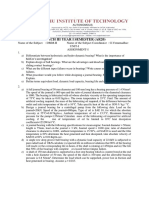

BENHA UNIVERSITY BANHA FACULTY OF ENGINEERING MECHANICAL ENGINEERING DEPARTMENT

M471 MACHINE DESIGN 4 YEAR MECHANICAL ENGINEERING DR. AL-ASSAL | ENG. AMRO | ENG. ABDALLA

TH

SHEET4: DESIGN OF CHAIN DRIVES

1.

KNOWLEDGE & UNDERSTANDING QUESTIONS

1. Classify chains based on: a) Geometry. b) Strands number. c) Application and uses. d) Material of composition. Discuss what is meant by a) Service factor b) Sprocket teeth factor c) Chordal action List some of basic advantages, disadvantages, and applications for using chain drives. Clarify how sprockets are different than gears. Show how the arrangement of the chain drive affects the transmission efficiency. State the best arrangement in the case of no idler is used. Specify the roller chain nomenclature as shown in the figure below (a-e).

2.

3. 4. 5. 6.

2.

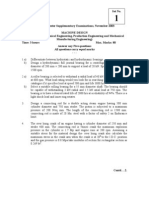

DESIGN PROBLEMS

Solve the following problems, assume any missing data, and use the tables for selecting standard Roller Chain dimensions (according to DIN standards): 1. A chain drive is required for a gear pump operating at 470 rpm driven by a 3 kW electric motor running at 1485 rpm. The centre distance between the motor and the pump is approximately 300mm. a) Calculate the reduction ratio b) Determine the application factor c) Calculate the tooth factor d) Determine the selection power e) Identify a suitable drive from the DIN8188 selection chart f) Calculate the approximate chain length g) Determine the number of pitches in the chain h) Calculate the exact centre distance 2. A compressor needs to be driven by a one step reduction system based on a chain drive. The torque required to rotate the compressor against the load is equal to 30 N.m, and the compressor rotational speed is required to be 63 rad/s. The chain drive is required to perform a reduction ratio of 3. a) Select the suitable chain number. b) Design each sprocket. c) Select the chain length for a center distance of 42 pitches. d) Specify the exact center distance. 3. An ordinary textile machine is driven by an electric motor using a single transmission system. It is preferable to use a chain drive system. The factory has a lot of sprocket pinions with 19 T. The transmission housing requirement is to choose the pinion diameter less than 100 mm. Design the chain drive system if the motor power is 2 kW, and its speed is 100 rpm (integrated with a worm gear system). The speed of the driven sprocket is 50 rpm. 4. Design a chain drive system to transmit a nominal power of 4.2 kW from an internal combustion engine (integrated with hydraulic drive) to a pulverizer. The input speed is 10.47 rad/s and the transmission ratio is 1:2.5. It is required to do an optimal design based on size only. 5. A roller chain is to transmit 90 hp from a 17-tooth sprocket to a 34-tooth sprocket at a speed of 300 rev/min. The load characteristics are moderate shock with abnormal service conditions (poor lubrication, cold temperatures, and dirty surroundings). Specify the length and size of chain required for a center distance of about 35 pitches. 6. A 720 rev/min 10-hp squirrel-cage motor is to drive a two-cylinder reciprocating pump which is to be located out-of-doors under a shed. The pump speed is 144 rev/min. Select suitable chain and sprocket sizes.

3.

ANALYTICAL PROBLEMS

1. A double-strand No. 12 A roller chain is used to transmit power between a 13-tooth driving sprocket rotating at 300 rev/min and a 52-tooth driven sprocket. Find the rated horsepower of this drive, and determine the approximate center distance if the chain length is 82 pitches. Calculate also the torque on the driving shaft produced by this chain. A triple-strand No. 16 A roller chain transmits power from a 21-tooth driving sprocket which turns at 1000 rev/min. The velocity ratio is 4:1. a) Calculate the rated horsepower of this drive. b) Find the tension in the chain. c) What should be the chain length if the center distance is to be about 20 in? A double-strand No. 60 roller chain is used to transmit power between a 13-tooth driving sprocket rotating at 300 rev/min and a 52-tooth driven sprocket. Find the rated horsepower of this drive, and determine the approximate center distance if the chain length is 82 pitches. Calculate also the torque on the driving shaft produced by this chain. A triple-strand No. 40 roller chain transmits power from a 21-tooth driving sprocket which turns at 1200 rev/min. The velocity ratio is 4:1. a) Calculate the rated horsepower of this drive. b) Find the tension in the chain. c) What should be the chain length if the center distance is to be about 20 in? A roller chain is to transmit 90 hp from a 17-tooth sprocket to a 34-tooth sprocket at a speed of 300 rev/min. The load characteristics are moderate shock with abnormal service conditions (poor lubrication, cold temperatures, and dirty surroundings). Specify the length and size of chain required for a center distance of about 25 pitches. A 720 rev/min 10-hp squirrel-cage motor is to drive a two-cylinder reciprocating pump which is to be located out-of-doors under a shed. The pump speed is 144 rev/min. Select suitable chain and sprocket sizes.

2.

3.

4.

5.

6.

DUE DATE: NEXT WEEK | 1,2 DAYS AFTER D.D.: -5% | 3,6: -10% | 7,21: -20% | >21: 0 PLAGIARISM = 0 | A4 PAPERS | NAME, SECTION & SUB.; CLEAR ON THE 1ST PAPER ONLY

Vous aimerez peut-être aussi

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationD'EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationPas encore d'évaluation

- Machine Design Elements and AssembliesD'EverandMachine Design Elements and AssembliesÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Concrete Simplified Flat Slabs Tables BS 8110 EngineeringSoftwareGuideComDocument24 pagesConcrete Simplified Flat Slabs Tables BS 8110 EngineeringSoftwareGuideComManuel SueroPas encore d'évaluation

- Prompting Science and Engineering Students in Practical TrigonometryD'EverandPrompting Science and Engineering Students in Practical TrigonometryPas encore d'évaluation

- Fluid Mechanics Yunus Cengel 4th Solution Manual PDFDocument5 pagesFluid Mechanics Yunus Cengel 4th Solution Manual PDFJuan Carlos Suescun Garcia0% (3)

- Japan VIsa Application SampleDocument2 pagesJapan VIsa Application SampleBudi Utami Wibawani80% (5)

- ICT Structured Cabling GuidelinesDocument37 pagesICT Structured Cabling GuidelinesSylvester Muzendah100% (1)

- Chain Drive CalculationsDocument42 pagesChain Drive CalculationsAchin67% (3)

- Scrap Specification PDFDocument62 pagesScrap Specification PDFr mohadiker0% (1)

- Pipelines and Buried PipesDocument22 pagesPipelines and Buried PipesjwochPas encore d'évaluation

- Industrial Hydraulic CircuitsDocument16 pagesIndustrial Hydraulic CircuitskingkakingPas encore d'évaluation

- Civil Engineering ProjectDocument87 pagesCivil Engineering ProjectNeeraj Porwal100% (6)

- Technical Analysis of BakerDocument27 pagesTechnical Analysis of BakerManu KhodPas encore d'évaluation

- Mechanical Design Handbook BookDocument3 pagesMechanical Design Handbook Bookpintu singh0% (5)

- Chain Drive Problems 2 PDFDocument3 pagesChain Drive Problems 2 PDFHannah Phamela de GuzmanPas encore d'évaluation

- Chain Drives: Why Use A Chain Drive?Document6 pagesChain Drives: Why Use A Chain Drive?Syed Raheel AdeelPas encore d'évaluation

- Study of a reluctance magnetic gearbox for energy storage system applicationD'EverandStudy of a reluctance magnetic gearbox for energy storage system applicationÉvaluation : 1 sur 5 étoiles1/5 (1)

- Hyderabad Database BackupDocument48 pagesHyderabad Database BackupVikramPas encore d'évaluation

- Chain Drive Design Problems Mechanical Engineering Department Benha UniversityDocument1 pageChain Drive Design Problems Mechanical Engineering Department Benha UniversityAmrAliPas encore d'évaluation

- Md2 Plates No 3 Chains and SprocketsDocument1 pageMd2 Plates No 3 Chains and SprocketsDaniel Tanus MararangPas encore d'évaluation

- Design of Transmission Systems - Important QuestonsDocument5 pagesDesign of Transmission Systems - Important QuestonsPost BoxPas encore d'évaluation

- Sathyabama University: Register NumberDocument3 pagesSathyabama University: Register NumberSecret SecretPas encore d'évaluation

- Design of Transmission SystemsDocument3 pagesDesign of Transmission SystemsSaravanan KumarPas encore d'évaluation

- Design of Transmission SystemsDocument6 pagesDesign of Transmission SystemsSelva KumarPas encore d'évaluation

- ME2352 Design of Transmission Question BankDocument4 pagesME2352 Design of Transmission Question BankKarthik SubramaniPas encore d'évaluation

- Design of Transmission System Question BankDocument18 pagesDesign of Transmission System Question BankAravind50% (2)

- Me 2352 - DTS Q BankDocument5 pagesMe 2352 - DTS Q Bankpaul_jaikumarm27530% (1)

- BELT Lecture 01Document56 pagesBELT Lecture 01mahaveer dasPas encore d'évaluation

- Dts Important Ques 2 16 MarksDocument5 pagesDts Important Ques 2 16 MarksBas RamuPas encore d'évaluation

- 12 Me 5dcdm2Document3 pages12 Me 5dcdm2Abhyudaya SinghPas encore d'évaluation

- Designn of Tranmission SystemDocument4 pagesDesignn of Tranmission Systemsathiskumar411Pas encore d'évaluation

- DMM-2 3 1 Q&aDocument6 pagesDMM-2 3 1 Q&aAnand vinayPas encore d'évaluation

- A Machine Tool GearboxDocument2 pagesA Machine Tool GearboxSanket ShahPas encore d'évaluation

- Dmm-II Assignment TestDocument2 pagesDmm-II Assignment TestSai Srinivas BodapatiPas encore d'évaluation

- Gear BoxDocument2 pagesGear BoxSp PatelPas encore d'évaluation

- ME6601 Transmission Design QuestionsDocument11 pagesME6601 Transmission Design QuestionsMURUGANPas encore d'évaluation

- MD II Machine Design AssignmentsDocument5 pagesMD II Machine Design Assignmentsrishabhk28995Pas encore d'évaluation

- Design of Transmission System-QbDocument5 pagesDesign of Transmission System-QbGanapathi SekaranPas encore d'évaluation

- Yu Xiangs Sugar Cane Machine ReportDocument53 pagesYu Xiangs Sugar Cane Machine ReportadstrativeclownPas encore d'évaluation

- ACFrOgA5tUgRDZJXHXmL8 Tw5dcxYJxiOIwOU5Eo4HonpVpoFZFJo3FpR3jkEpxVlzSr4SlTPfwEhXU2oUrUpctlLPK5aDrEIjX Z49543n2D8VZdCWCJYobCVtHeuFv-2Hje7s8XnE4FiVLAx-HDocument3 pagesACFrOgA5tUgRDZJXHXmL8 Tw5dcxYJxiOIwOU5Eo4HonpVpoFZFJo3FpR3jkEpxVlzSr4SlTPfwEhXU2oUrUpctlLPK5aDrEIjX Z49543n2D8VZdCWCJYobCVtHeuFv-2Hje7s8XnE4FiVLAx-HDept of MechanicalPas encore d'évaluation

- Design Report MCE 412 VDocument19 pagesDesign Report MCE 412 VGebra TogunPas encore d'évaluation

- NR 320301 Machine DesignDocument8 pagesNR 320301 Machine DesignSrinivasa Rao GPas encore d'évaluation

- Me 1352Document6 pagesMe 1352arunramakrishnanPas encore d'évaluation

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringDocument3 pages1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishPas encore d'évaluation

- Design of Transmission Systems Model ExamDocument3 pagesDesign of Transmission Systems Model ExamrajkumardotcomPas encore d'évaluation

- ME6601.16 MarksDocument6 pagesME6601.16 Markssathiskumar411Pas encore d'évaluation

- cp0053 25-Jul-2011 rm01Document2 pagescp0053 25-Jul-2011 rm01stalinkbcPas encore d'évaluation

- Design of Transmission ElementDocument42 pagesDesign of Transmission ElementVenkatesh MohanPas encore d'évaluation

- Me 7 Sem Subject Design of Mechanical Drives Jun 2017Document2 pagesMe 7 Sem Subject Design of Mechanical Drives Jun 2017djniksthehearteditorPas encore d'évaluation

- Me-1352 Design of Transmission SystemDocument7 pagesMe-1352 Design of Transmission Systemshujai cruise100% (1)

- Tutorial 7 (Gears) DMCD 3523 PDFDocument3 pagesTutorial 7 (Gears) DMCD 3523 PDFIzzat HaikalPas encore d'évaluation

- Design of Belt, Chain, and Flat-Belt Drives for MachineryDocument1 pageDesign of Belt, Chain, and Flat-Belt Drives for MachineryBrijpal PatlePas encore d'évaluation

- AT8611 Lab QuestionsDocument9 pagesAT8611 Lab QuestionsChirpiPas encore d'évaluation

- Me 7 Sem Design of Mechanical Drives Winter 2017Document2 pagesMe 7 Sem Design of Mechanical Drives Winter 2017djniksthehearteditorPas encore d'évaluation

- Me0405 7 SemDocument2 pagesMe0405 7 SemSurya BalamuruganPas encore d'évaluation

- 181505-181902-MD - IiDocument2 pages181505-181902-MD - IiSiddharth PanchalPas encore d'évaluation

- Jeppiaar Institute of Technology: Kunnam, Sunguvarchatram, Sriperumbudur, Chennai - 631 604Document3 pagesJeppiaar Institute of Technology: Kunnam, Sunguvarchatram, Sriperumbudur, Chennai - 631 604Balu phoenixPas encore d'évaluation

- Design of Transmission Systems examDocument3 pagesDesign of Transmission Systems examCyril JasonPas encore d'évaluation

- ME2352-DTS Question BankDocument8 pagesME2352-DTS Question BankNaresh015Pas encore d'évaluation

- Design spur gears transmit powerDocument3 pagesDesign spur gears transmit powerMohammed YunusPas encore d'évaluation

- Me 7 Sem Design of Mechanical Drives 3560 Summer 2019Document2 pagesMe 7 Sem Design of Mechanical Drives 3560 Summer 2019djniksthehearteditorPas encore d'évaluation

- Roller Chain and Sprocket Chapter OverviewDocument29 pagesRoller Chain and Sprocket Chapter Overviewzakibrant23Pas encore d'évaluation

- Design of Transmission Systems Question BankDocument10 pagesDesign of Transmission Systems Question BankDesejo SozinandoPas encore d'évaluation

- A1. Examples: Belt Drives Examples and WorksheetDocument3 pagesA1. Examples: Belt Drives Examples and WorksheetAb_AlizadehPas encore d'évaluation

- DMDDocument4 pagesDMDSantosh AlonePas encore d'évaluation

- Te 2008Document273 pagesTe 2008Smith KashidPas encore d'évaluation

- Design of Transmission Systems 3Document2 pagesDesign of Transmission Systems 3srajapratyPas encore d'évaluation

- Machine Design-II Question BankDocument32 pagesMachine Design-II Question BankAbhishek SakatPas encore d'évaluation

- Lathe DesignDocument11 pagesLathe DesignShiyas Basheer0% (1)

- Optimization of Polysulfone / Graphene Oxide / Polyethylene Glycol / Triaminopyrimidine by Using Response Surface MethodologyDocument8 pagesOptimization of Polysulfone / Graphene Oxide / Polyethylene Glycol / Triaminopyrimidine by Using Response Surface MethodologyAbdalla Mohamed AbdallaPas encore d'évaluation

- Course SpecificationDocument93 pagesCourse SpecificationAbdalla Mohamed AbdallaPas encore d'évaluation

- OAFISjLOEeiP Qrke KVoA Setting A Sales Goal AOSDocument1 pageOAFISjLOEeiP Qrke KVoA Setting A Sales Goal AOSAbdalla Mohamed AbdallaPas encore d'évaluation

- Engineering From Home: White PaperDocument7 pagesEngineering From Home: White PaperAbdalla Mohamed AbdallaPas encore d'évaluation

- JHVJHVDocument5 pagesJHVJHVAbdalla Mohamed AbdallaPas encore d'évaluation

- #Aimenjobs: R&D Senior Researcher in Advanced Materials: Polymer and CompositesDocument2 pages#Aimenjobs: R&D Senior Researcher in Advanced Materials: Polymer and CompositesAbdalla Mohamed AbdallaPas encore d'évaluation

- Dd422i Specification Sheet EnglishDocument4 pagesDd422i Specification Sheet EnglishAbdalla Mohamed AbdallaPas encore d'évaluation

- Investigation On Tensile Properties of Epoxy/graphene Nano-Platelets/ Carboxylated Nitrile Butadiene Rubber Ternary Nanocomposites Using Response Surface MethodologyDocument12 pagesInvestigation On Tensile Properties of Epoxy/graphene Nano-Platelets/ Carboxylated Nitrile Butadiene Rubber Ternary Nanocomposites Using Response Surface MethodologyAbdalla Mohamed AbdallaPas encore d'évaluation

- Optimization of UHMWPE/graphene Nanocomposite Preparation by Single Supported Ziegler Natta Catalytic System Via RSMDocument6 pagesOptimization of UHMWPE/graphene Nanocomposite Preparation by Single Supported Ziegler Natta Catalytic System Via RSMAbdalla Mohamed AbdallaPas encore d'évaluation

- Trade MapDocument1 pageTrade MapAbdalla Mohamed AbdallaPas encore d'évaluation

- W 4 Yte 54 SyDocument2 pagesW 4 Yte 54 SyAbdalla Mohamed AbdallaPas encore d'évaluation

- Hydraulics and Conveyor Systems: TrainingDocument3 pagesHydraulics and Conveyor Systems: TrainingAbdalla Mohamed AbdallaPas encore d'évaluation

- Research Grant Donors: ItidaDocument5 pagesResearch Grant Donors: ItidaAbdalla Mohamed AbdallaPas encore d'évaluation

- PublicationDocument1 pagePublicationAbdalla Mohamed AbdallaPas encore d'évaluation

- Baba Yevsky 1973Document22 pagesBaba Yevsky 1973Abdalla Mohamed AbdallaPas encore d'évaluation

- RSC Advances: PaperDocument5 pagesRSC Advances: PaperAbdalla Mohamed AbdallaPas encore d'évaluation

- Creating Effective Scientific Figures For PublicationDocument24 pagesCreating Effective Scientific Figures For PublicationAbdalla Mohamed AbdallaPas encore d'évaluation

- TKT 2003Document2 pagesTKT 2003Abdalla Mohamed AbdallaPas encore d'évaluation

- ErwgrwgwDocument5 pagesErwgrwgwAbdalla Mohamed AbdallaPas encore d'évaluation

- Teaching Statement: Roberto Silveira Silva FilhoDocument2 pagesTeaching Statement: Roberto Silveira Silva FilhoAbdalla Mohamed AbdallaPas encore d'évaluation

- مركز لخدمات الكمبيوترDocument11 pagesمركز لخدمات الكمبيوترmax_slamPas encore d'évaluation

- Jin 2013Document9 pagesJin 2013Abdalla Mohamed AbdallaPas encore d'évaluation

- ﻝﺎﻤﻟﺍ ﺓﺪﻳﺮﺟ ﺭﺎﺒﺧﺃ ﻢﻫﺃ (Alltopstories - 1.Aspx/) : ﻙﻮـــﻨﺑ (Section/12/1/بنـــوك/)Document9 pagesﻝﺎﻤﻟﺍ ﺓﺪﻳﺮﺟ ﺭﺎﺒﺧﺃ ﻢﻫﺃ (Alltopstories - 1.Aspx/) : ﻙﻮـــﻨﺑ (Section/12/1/بنـــوك/)Abdalla Mohamed AbdallaPas encore d'évaluation

- Kurapati 2012Document3 pagesKurapati 2012Abdalla Mohamed AbdallaPas encore d'évaluation

- Uspesna PrezentacijaDocument13 pagesUspesna Prezentacijaboban72Pas encore d'évaluation

- Rwgtrygr 5Document5 pagesRwgtrygr 5Abdalla Mohamed AbdallaPas encore d'évaluation

- Schedule of Student Affairs Required Documents - Minutes #1Document2 pagesSchedule of Student Affairs Required Documents - Minutes #1Abdalla Mohamed AbdallaPas encore d'évaluation

- Interns - Shortlist - NIT SilcharDocument12 pagesInterns - Shortlist - NIT SilcharPraneet KumarPas encore d'évaluation

- 2017 Postgraduate Convocation ListDocument11 pages2017 Postgraduate Convocation ListCheckPas encore d'évaluation

- EC - Design of Steel Buildings 6 - Worked Examples PDFDocument15 pagesEC - Design of Steel Buildings 6 - Worked Examples PDFAnonymous AV90SAXa5V100% (1)

- Career Opportunities: Bridge Engineer, For COWI in New York, North America (38420)Document2 pagesCareer Opportunities: Bridge Engineer, For COWI in New York, North America (38420)Indra MishraPas encore d'évaluation

- 1125 - 04 Automation WriteupDocument16 pages1125 - 04 Automation WriteupDestinifyd MydestinyPas encore d'évaluation

- ContractDocument12 pagesContractNor Syazwani SharudinPas encore d'évaluation

- ASCENTIADocument4 pagesASCENTIAEdgar Jr MaglasangPas encore d'évaluation

- Mechanisation and Automation Evolution of Automation Goals and Applications of AutomationDocument7 pagesMechanisation and Automation Evolution of Automation Goals and Applications of AutomationRifat RashidPas encore d'évaluation

- Seminar Deep Foundation Unpar PDFDocument2 pagesSeminar Deep Foundation Unpar PDFryan rakhmat setiadi0% (1)

- Pramesh Electrical Draughtsman Electrical 4yrsDocument3 pagesPramesh Electrical Draughtsman Electrical 4yrsMunniPas encore d'évaluation

- Engineering Structures: Eduardo Cavaco, Ilton Pacheco, José CamaraDocument14 pagesEngineering Structures: Eduardo Cavaco, Ilton Pacheco, José CamaraElber Cuya PillacaPas encore d'évaluation

- Limitless Innovation With Limited Space: Parking Simpli EdDocument7 pagesLimitless Innovation With Limited Space: Parking Simpli EdAbudo PaixaoPas encore d'évaluation

- Earthquake Resistant BuildingsDocument16 pagesEarthquake Resistant BuildingsArnold TunduliPas encore d'évaluation

- Basic Mechanical and HVAC SystemsDocument29 pagesBasic Mechanical and HVAC Systemsวรศิษฐ์ อ๋องPas encore d'évaluation

- RCC & Steel Building DEA ProposalDocument10 pagesRCC & Steel Building DEA ProposalABDUL JABBERPas encore d'évaluation

- Duke SyllabusDocument18 pagesDuke SyllabusAhsaan RizviPas encore d'évaluation

- Basic Engineering Circuit Analysis 10thDocument185 pagesBasic Engineering Circuit Analysis 10thGustavoPas encore d'évaluation

- 2018 SeismicwindforcesDocument622 pages2018 SeismicwindforcesTerry TriestPas encore d'évaluation

- Eurocode ListDocument2 pagesEurocode ListBobby WongPas encore d'évaluation

- Compressive Concrete Cylinder LogDocument3 pagesCompressive Concrete Cylinder LogMohammed JaveedPas encore d'évaluation

- Inspection & Test Certificate Serial No: ....Document4 pagesInspection & Test Certificate Serial No: ....Somidu ChandimalPas encore d'évaluation