Académique Documents

Professionnel Documents

Culture Documents

Car Sensor Hardware Manual Rev 1r0

Transféré par

Haroon Jalil BaigDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Car Sensor Hardware Manual Rev 1r0

Transféré par

Haroon Jalil BaigDroits d'auteur :

Formats disponibles

e-Gizmo Magnetic Car Sensor

2009 e-Gizmo Mechatronix Central

Page 1 of 5 pages

e-Gizmo mag-

netic car sensor

detects presence or

passing of cars by measur-

ing the disturbance caused by

the car with the earth's magnetic

feld. Only large and heavy metal

objects (e.g. car engine) can cause feld

disturbances that are detectable by this sen-

sor. Hence, the sensor is largely unaffected by

e-Gizmo

Magnetic Car Sensor

Hardware Manual

Rev 1r0

people, animals, non metals, and even small metal objects when

more than 12 away from the sensor.

Although the Magnetic Car sensor is made to detect cars, its

sensitivity to the earth's magnetic feld (hence, position), makes is

usable for other purposes as well. For example, you can use it as

a security detection device that sets off an alarm when something

it is protecting is moved. t can be used to detect fow of current in

a wire. t is not hard to fnd other potential uses for this sensor.

Specications:

Sensor Type: HMC1021Z Magneto Resistive Sensor

Supply Voltage: 8V - 12VDC

Supply Current: 25mA Typical with LED OFF

Car Detection Range : 1 M typical (Mounted Overhead)

Dimensions: 42 x 45 x 13 mm (WLH)

e-Gizmo Magnetic Car Sensor

2009 e-Gizmo Mechatronix Central

Page 2 of 5 pages

+

R1

JP1

+8-12V

GND

2K2

R

HOST

NPUT

HOST

Vcc

HOST

CONTROLLER CIRCUIT

WIRING

The sensor has a single bit open collector digital output that acti-

vates whenever a car passes within sensing range. Open collec-

tor output allows the sensor to be interfaced with a wide variety

of host controller (of differing logic levels), with just the addition of

one pull-up resistor terminating on the host controller Vcc rail. t is

even possible to use the sensor with 24VDC logic that is a stan-

dard for industrial controllers.

Figure 1 shows a general wiring scheme for the car sensor. A

8V to 12V DC must be supplied either by the host controller or a

separate power supply. The 2.2K pull up resistor will work with 3V

to 12V logic level.

Figure 1. Magnetic Car Sensor wiring diagram.

e-Gizmo Magnetic Car Sensor

2009 e-Gizmo Mechatronix Central

Page 3 of 5 pages

INSTALLATION AND ADJUSTMENT

Enclosure

While protecting the sensor board with an enclosure is a good

idea, you have to make sure you use one made from non metallic

materials. Water resistant plastic enclosures are highly preferred,

especially if the sensor is to be installed in locations where rain

and fooding is likely to occur.

nstallation

The Magnetic Car Sensor does not like to work near objects and

places where there is too much stray magnetic feld abound. t

must be installed away from electric motors, transformers, AC

lines, generators, and the like. Magnets, being a strong source

of magnetic feld, will confuse the sensor. Even a small magnet a

foot or so away will prevent the sensor from doing its job, so keep

these objects away.

The Magnetic Car Sensor is most sensitive in the direction per-

pendicular to the sensor face (Figure 2). You must always take this

into account when planning for your installations.

Figure 2. The Magnetic Car Sensor works best when mounted with the

pcb lined up with the horizontal plane. It is most sensitive in the direc-

tions shown by the arrows.

e-Gizmo Magnetic Car Sensor

2009 e-Gizmo Mechatronix Central

Page 4 of 5 pages

CAR SENSOR KIT

CAR SENSOR KIT

Figure 3. The Magnetic Car Sensor can be installed (a) hanging above

head or at (b) pavement level. With careful adjustment, detection dis-

tance of up to a meter is possible. Make sure the sensor is mounted

away from large metal objects. See text for more details.

Fig. 3A

Fig. 3B

e-Gizmo Magnetic Car Sensor

2009 e-Gizmo Mechatronix Central

Page 5 of 5 pages

ADJUSTMENT

Once the sensor is installed and secured, the sensor can be

adjusted for operation. Because of the small PCB size, the ad-

justment pot R1 cannot be located far enough from the sensor

element, and any metallic object (i.e. screwdriver) used to adjust

R1 can disturb the magnetic feld around the sensor, making the

adjustment somewhat more diffcult. Adjustment will be easy when

using a non metallic screw driver. f a non metallic screwdriver is

not available, use the smallest you can get, and make sure the

screwdriver is not magnetized!

Adjust R1 while observing the LED sensing indicator. You will

notice that as you rotate R1, there is a point where the LED fick-

ers. Slowly rotate back to that point until the LED completely turns

OFF. Mark or remember the R1 knob position. Continue rotating

R1 along the same direction until the LED turns ON again. Slowly

turn R1 knob back until the LED turns OFF again. Note the new

knob position, and then fnally adjust the knob until it sits midway

between the two OFF position. The LED should stay OFF once

the adjustment is completed.

Test the sensor by bringing a small iron object close to the sensing

element. The sensor indicator should turn ON as the metal close

in within a few centimeters, and turn OFF again when the metal is

withdrawn.

+

R1

MAGNETO-RESISTIVE

SENSOR (SOLDERED

ON COPPER SIDE)

SENSING

INDICATOR

JP1

VCC

GND

OUT

SET ADJUSTMENT

Figure 4. R1 set adjustment and sensing LED indicator location.

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

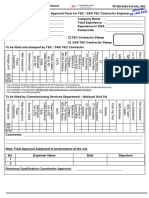

- TP-NG-6450-010-003 Pre-Qualification Approval Form For T&C SAS - T&C Contractor Engineer Rev02Document1 pageTP-NG-6450-010-003 Pre-Qualification Approval Form For T&C SAS - T&C Contractor Engineer Rev02karthikPas encore d'évaluation

- 04-68350A Manual CCN DM01-DI01 PDFDocument47 pages04-68350A Manual CCN DM01-DI01 PDFtaha50% (2)

- Intellix BMT 330: Grid SolutionsDocument4 pagesIntellix BMT 330: Grid SolutionsMarcus SiaPas encore d'évaluation

- Field Communication Unit, Fcu 2160: Tankradar RexDocument4 pagesField Communication Unit, Fcu 2160: Tankradar RexJohnny CastilloPas encore d'évaluation

- Pricing MatrixDocument1 pagePricing Matrixoldschool8Pas encore d'évaluation

- Micronote #101Document2 pagesMicronote #101eng,amPas encore d'évaluation

- VEG2000 - Manual - ENG - V4.6Document49 pagesVEG2000 - Manual - ENG - V4.6ahmed morsyPas encore d'évaluation

- April2003 TechbriefDocument1 pageApril2003 Techbriefroberto carlos ortizPas encore d'évaluation

- Electrical / Electronic Equipment: From WM No. 5044 OnwardsDocument18 pagesElectrical / Electronic Equipment: From WM No. 5044 OnwardsMohammedasifPas encore d'évaluation

- Mini Project 1 - 1Document9 pagesMini Project 1 - 1Sameer BaraPas encore d'évaluation

- Q400 CommunicationsDocument54 pagesQ400 CommunicationsMoshiurRahmanPas encore d'évaluation

- How To Use An Oscilloscope Effectively - EditedDocument13 pagesHow To Use An Oscilloscope Effectively - EditedOmwana NyabokePas encore d'évaluation

- DSF Secondary Power Supply Uninterruptible Power SuppliesDocument4 pagesDSF Secondary Power Supply Uninterruptible Power SuppliesVinay PallivalppilPas encore d'évaluation

- COA NotesDocument36 pagesCOA NotessunnybaggaPas encore d'évaluation

- Side ToneDocument3 pagesSide Tonewkkchamara100% (1)

- Control AccessoriesDocument66 pagesControl AccessoriesAnonymous SDeSP1Pas encore d'évaluation

- LPKF Protomat S64Document124 pagesLPKF Protomat S64Rodrigo de Carvalho VieiraPas encore d'évaluation

- Forklift OM-694Document92 pagesForklift OM-694World AmusementPas encore d'évaluation

- Contact Resistance Micro-Ohm Meter - Contact Resistance Tester Manufacturer From PuneDocument7 pagesContact Resistance Micro-Ohm Meter - Contact Resistance Tester Manufacturer From PuneAtanu PanPas encore d'évaluation

- 13-2-117 Service BulletinDocument6 pages13-2-117 Service BulletinRidwanPas encore d'évaluation

- 03 - TransmissaoDocument15 pages03 - TransmissaojohnnyPas encore d'évaluation

- Atmel 2508 Zero Cross Detector ApplicationNote AVR182Document11 pagesAtmel 2508 Zero Cross Detector ApplicationNote AVR182armando nolasco rodriguezPas encore d'évaluation

- BOQ - Hearts & Arrows Office 04sep2023Document15 pagesBOQ - Hearts & Arrows Office 04sep2023ChristianPas encore d'évaluation

- Intellinet - 561273Document4 pagesIntellinet - 561273bader eddine khezamiPas encore d'évaluation

- ESG2002 ControllerDocument15 pagesESG2002 ControllerPedro Perez La Rosa100% (1)

- 501-12 Instrument Panel and Console PICKUP JMCDocument5 pages501-12 Instrument Panel and Console PICKUP JMCRusonegroPas encore d'évaluation

- Single Phase Semi ConverterDocument18 pagesSingle Phase Semi Convertermohamed enanyPas encore d'évaluation

- C30 Service ManualDocument46 pagesC30 Service ManualLawrence100% (1)

- Polaris 180 Repair ManualDocument40 pagesPolaris 180 Repair ManualPool Supply Sales100% (2)

- Alliedeaglesupplies-Issa Facility Cleaning ChecklistDocument2 pagesAlliedeaglesupplies-Issa Facility Cleaning ChecklistLos TrevilocosPas encore d'évaluation