Académique Documents

Professionnel Documents

Culture Documents

HMT 113401 Anna Univ

Transféré par

sathiya_ramCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

HMT 113401 Anna Univ

Transféré par

sathiya_ramDroits d'auteur :

Formats disponibles

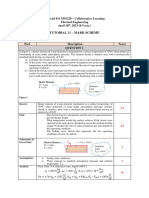

PART A 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21.

UNIT III (Part B Quest ions) 22. A tube of 2 m length and 25 mm outer diameter is to be used to condense saturated steam at 100C What is a Heat Exchanger? How heat exchangers are Classified? Give examples of non mixing type heat exchangers. Sketch temperature distribution graph for condensers & evaporators. What is overall heat transfer coefficient in a heat exchanger? What is LMTD? What is effectiveness of a heat exchanger? Discuss the advantage of NTU method over the LMTD method. What are the assumptions made during LMTD analysis? What are the factors are involved in designing a heat exchangers? In what way Boiling & Condensation differs from other types of heat exchange? What is Excess temperature in boiling? What is meant by sub cooled or local boiling? What is Nucleate boiling? Give expression for heat transfer coefficient in Nucleate boiling. What is flow boiling? What is meant by condensation? Draw heat flux curve for various regions of flow boiling. Define Film wise condensation. Define Drop wise condensation. How is the Reynolds number in condensation defined?

while the tube surface is maintained at 92C. Estimate the average heat transfer coefficient and the rate of condensation of steam if the tube is kept horizontal. The steam condenses on the outside of the tube. (16) Steam condenses at atmospheric pressure on the external surface of the tubes of a steam condenser. The tubes are 12 in number and each is 30 mm in diameter and 10 m long. The inlet and outlet temperatures of cooling water flowing inside the tubes are 25C and 60C respectively. If the flow rate is 1.1 kg/s, calculate 23. (i) (ii) The rate of condensation of steam The number of transfer units

(iii) The effectiveness of the condenser. (16) It is desired to boil water at atmospheric pressure on a copper surface which electrically heated. Estimate the heat flux from the surface to the water, if the surface is maintained at 100C and also the peak heat flux. (8) A tube of 2 m length and 25 mm OD is to be used to condense saturated steam at 100C while the tube surface is maintained at 92C. Estimate the average heat transfer coefficient and the rate of condensation of steam if the tube is kept horizontal. The steam condenses on the outside of the tube. (8) Give the classification of heat exchangers. (4)

24.

(i)

(ii)

25.

(i)

(ii)

26

(i)

It is desired to use a double pipe counter flow heat exchanger to cool 3 kg/s of oil (Cp = 2.1 kJ/kgK) from 120C. Cooling water at 20C enters the heat exchanger at a rate of 10 kg/s. The overall heat transfer coefficient of the heat exchanger is 600 W/m2Kand the heat transfer area is 6 m2. Calculate the exit temperatures of oil and water. (12) Discuss the general arrangement of parallel flow, counter flow and cross flow heat exchangers. (6) In a Double pipe counter flow heat exchanger 10000 kg/h of an oil having a specific heat of 2095 J/kgK is cooled from 80C to 50C by 8000 kg/h of water entering at 25C. Determine the heat exchanger area for an overall heat transfer coefficient of 300 W/m2K. Take Cp for water as 4180 J/kgK. (10) Discuss the various regimes of pool boiling heat transfer. (8) Dry saturated steam at a pressure of 2.45 bar condenses on the surface of a vertical tube of height 1 m. The tube surface temperature is kept at 117C. Estimate the thickness of the condensate film and the local heat transfer coefficient at a distance of 0.2m from the upper end of the tube. (8) With a neat and labeled sketch explain the various regimes in boiling heat transfer.

(ii)

27.

(i)

(ii)

28.

(i)

(ii)

29.

(i)

(ii)

(8) A vertical plate 0.5 m2 in area at temperature of 92C is exposed to steam at atmospheric pressure. If the steam is dry and saturated estimate the heat transfer rate and condensate mass per hour. The vertical length of the plate is 0.5m. Properties of water at film temperatures of 96C can be obtained from tables. (8) Compare LMTD and NTU method of heat exchanger analysis. (6) Hot exhaust gases which enters a finned tube cross flow heat exchanger at 300C and leave at 100C, are used to heat pressurized water at a flow rate of 1 kg/s from 35 to 125C. The exhaust gas specific heat is approximately 1000 J/kgK, and the overall heat transfer co-efficient based on the gas side surface area is Uh= 100W/m2K. Determine the required gas side surface area Ah using the NTU method. Take Cpc at Tc = 80C is 4197 J/kg.K and Cph = 1000 J/kg.K . (10)

30.

31.

Water is to be boiled at atmospheric pressure in a mechanically polished stainless steel pan placed on top of a heating unit. The inner surface of the bottom of the pan is maintained at 108C. The diameter of the bottom of the pan is 30 cm. Assuming Csf = 0.0130. calculate (i) the rate of heat transfer to the water and (ii) the rate of evaporation of water. (16) Define effectiveness of a heat exchanger. Derive

an expression for the effectiveness of a double pipe parallel flow heat exchanger. State the assumptions made. (16) Water enters a cross flow Heat exchanger (both fluids unmixed) at 5C and flows at the rate of 4600 kg/h to cool 4000 kg/h of air that is initially at 40C. Assume the overall heat transfer 32 Coefficient value to be 150 W/m2K For an exchanger surface area of 25m2, Calculate the exit temperature of air and water. (16) (i) Describe the principle of parallel flow and counter flow heat exchangers showing the axial temperature distribution. (8) A parallel flow heat exchanger has hot and cold water stream running through it, the flow rates are 10 and 25 kg/min respectively. Inlet temperatures are 75 C and 25 C on hot and cold sides. The exit temperature on the hot side should not exceed 50 C. Assume hi=h0= 600W/m2K. Calculate the area of heat exchanger using NTU approach. (8)

33

(i)

(ii)

Read more: ME2251- HEAT AND MASS TRANSFER - Anna University Engineering Question Bank 4 U http://questionbank4u.in/questionanswer.php?course=9&semester=32&subject=53&listid=499#i xzz1nMONMveH Under Creative Commons License: Attribution Enter to win a free tech book 101 Free Tech Books

Vous aimerez peut-être aussi

- Tutorial 5 TFP260S PDFDocument2 pagesTutorial 5 TFP260S PDFHundzukani Ngobeni100% (1)

- ME 307: Heat Transfer Equipment Design: (Arpachi-Ex-7.9)Document5 pagesME 307: Heat Transfer Equipment Design: (Arpachi-Ex-7.9)mz_haqPas encore d'évaluation

- Heat Exchanger MathDocument8 pagesHeat Exchanger MathMasum ParvezPas encore d'évaluation

- MEHB323 Example Question On Heat ExchangerDocument2 pagesMEHB323 Example Question On Heat ExchangerAkmal RosliPas encore d'évaluation

- Heat Exchanger Tutorial Sheet 5Document4 pagesHeat Exchanger Tutorial Sheet 5Charlotte BPas encore d'évaluation

- Heat Exchanger Tutorial Sheet 5Document4 pagesHeat Exchanger Tutorial Sheet 5Charlotte BPas encore d'évaluation

- Assignment - IVDocument4 pagesAssignment - IVdivyanshu.221ch018Pas encore d'évaluation

- Me8693 Heat and Mass Transfer - QBDocument5 pagesMe8693 Heat and Mass Transfer - QBmeckup123Pas encore d'évaluation

- Icam (Lille) - Heat Exchanger Course Icam 2 - Autumn 2003 Heat Exchanger Examples - Sheet 2Document3 pagesIcam (Lille) - Heat Exchanger Course Icam 2 - Autumn 2003 Heat Exchanger Examples - Sheet 2FahmiRamdanPas encore d'évaluation

- Heatex 02 AwDocument3 pagesHeatex 02 AwyvethendoPas encore d'évaluation

- Question Bank - HMTDocument5 pagesQuestion Bank - HMTSUNDARAMAHALINGAM APas encore d'évaluation

- Tutorial Heat ExchangerDocument2 pagesTutorial Heat ExchangerAhmad Nor Fahmi WalidPas encore d'évaluation

- Tutorial Questions On Heat Ex ChangersDocument3 pagesTutorial Questions On Heat Ex ChangersPuneet Garg100% (1)

- Ihte Que BankDocument2 pagesIhte Que BankNikunj PatelPas encore d'évaluation

- TUTORIAL 6 Heat ExchangerDocument4 pagesTUTORIAL 6 Heat ExchangerFikri Rahim50% (2)

- Tarea 4 CalorDocument2 pagesTarea 4 CalorDenisse M. ZamoraPas encore d'évaluation

- Tut 4 Heat ExchangersDocument2 pagesTut 4 Heat ExchangersGomolemo BaarxxPas encore d'évaluation

- Basic Design MethodologyDocument4 pagesBasic Design MethodologySatya SuryaPas encore d'évaluation

- Heat Transfer: Anna University Question BankDocument6 pagesHeat Transfer: Anna University Question BankaeroacademicPas encore d'évaluation

- Use of Heat and Mass Transfer Data Books, Steam Tables Are PermittedDocument4 pagesUse of Heat and Mass Transfer Data Books, Steam Tables Are Permitted3rajaPas encore d'évaluation

- Glasgow College of Nautical Studies Engineering DepartmentDocument2 pagesGlasgow College of Nautical Studies Engineering DepartmentMullah FassudinPas encore d'évaluation

- HMT Tut1Document2 pagesHMT Tut1Meet ShahPas encore d'évaluation

- Tutorial 3 - Revised SolutionDocument11 pagesTutorial 3 - Revised Solutionngoc.nguyenlamPas encore d'évaluation

- Chemical Engineering Job QuestionsDocument9 pagesChemical Engineering Job QuestionsMunia AkterPas encore d'évaluation

- Sheet (3.1) Heat Exchangers Analysis Using LMTD MethodDocument2 pagesSheet (3.1) Heat Exchangers Analysis Using LMTD MethodAya Bekhet 1253Pas encore d'évaluation

- Tutorial Heat Exchanger Sem 1 2019 2020 PDFDocument3 pagesTutorial Heat Exchanger Sem 1 2019 2020 PDFmimie azideePas encore d'évaluation

- Department of Mechanical Engineering: B. V. Raju Institute of Technology (Autonomous)Document2 pagesDepartment of Mechanical Engineering: B. V. Raju Institute of Technology (Autonomous)Murali KrishnaPas encore d'évaluation

- 3 Avaliacao Grupo1 PDFDocument3 pages3 Avaliacao Grupo1 PDFPedro Henrique Fauro De AraujoPas encore d'évaluation

- Tutorial 8Document3 pagesTutorial 8CHANDAN RAJPas encore d'évaluation

- Heat Transfer Assignment QuestionsDocument2 pagesHeat Transfer Assignment QuestionsMurali KrishnaPas encore d'évaluation

- Tutorial 3 SolutionDocument5 pagesTutorial 3 Solutionngoc.nguyennhuPas encore d'évaluation

- HMT IMP Questions NewDocument3 pagesHMT IMP Questions NewRavi PatilPas encore d'évaluation

- Assignment 2Document2 pagesAssignment 2PNPas encore d'évaluation

- Heat Transfer AssignmentDocument4 pagesHeat Transfer AssignmentHreaan SighaniaPas encore d'évaluation

- Prob Sheet Heat ExchangerDocument2 pagesProb Sheet Heat ExchangerAnonymous mXicTi8hB0% (1)

- Cycle Test 1 Set1Document6 pagesCycle Test 1 Set1logeshboy007Pas encore d'évaluation

- Heat Exchanger Tutorial 1 PDFDocument2 pagesHeat Exchanger Tutorial 1 PDFNitin BuZz100% (1)

- Heatex 01Document2 pagesHeatex 01sumitPas encore d'évaluation

- A Centrifugal Pump Is Drawing Water From An Overhead Tank - Autosaved - AutosavedDocument16 pagesA Centrifugal Pump Is Drawing Water From An Overhead Tank - Autosaved - AutosavedAkshat KhandelwalPas encore d'évaluation

- Question Bank On Unit 6Document5 pagesQuestion Bank On Unit 6dongaPas encore d'évaluation

- Bbbdnitm, Lko Mechanical Department Subject-Heat and Mass Transfer UNIT-5 Assignment-5 Section-A Short Questions: (2 Marks)Document2 pagesBbbdnitm, Lko Mechanical Department Subject-Heat and Mass Transfer UNIT-5 Assignment-5 Section-A Short Questions: (2 Marks)Hoài ThươngPas encore d'évaluation

- 4 25293 730Document12 pages4 25293 730elsa fitrianti pratiwiPas encore d'évaluation

- TD QP UPTO Nov 2012 18092012Document31 pagesTD QP UPTO Nov 2012 18092012Narayanan Srinivasan100% (1)

- Tutorial 6Document3 pagesTutorial 6Hoài ThươngPas encore d'évaluation

- MEHB323 Tutorial Assignment Ch11Document2 pagesMEHB323 Tutorial Assignment Ch11Lufy HahaPas encore d'évaluation

- QP-2 HMTDocument3 pagesQP-2 HMTtagoreboopathyPas encore d'évaluation

- R07 Set No. 2Document8 pagesR07 Set No. 2bhaskar5377Pas encore d'évaluation

- Question Paper Code:: Reg. No.Document4 pagesQuestion Paper Code:: Reg. No.Guru PrakashPas encore d'évaluation

- 7157902Document62 pages7157902Red RedPas encore d'évaluation

- KCT 2010-2011 HTDocument4 pagesKCT 2010-2011 HTask4krishnanPas encore d'évaluation

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityBala DuttPas encore d'évaluation

- BN 1395749865 Heat TransferDocument5 pagesBN 1395749865 Heat TransferFrancis LopezPas encore d'évaluation

- MEPME 132 - Assignment 3Document1 pageMEPME 132 - Assignment 3Belly John CarbonellPas encore d'évaluation

- Me8391 - EtdDocument3 pagesMe8391 - Etdsyed1188Pas encore d'évaluation

- HT Assignment 2Document2 pagesHT Assignment 2RambabuDaraPas encore d'évaluation

- Ejercicios Topico 3 Moreta HenryDocument6 pagesEjercicios Topico 3 Moreta HenrystearimofyPas encore d'évaluation

- Ay1011sem1 Me3122eDocument3 pagesAy1011sem1 Me3122eCammy MiunoPas encore d'évaluation

- HMT 113401 Anna UnivDocument3 pagesHMT 113401 Anna Univsathiya_ramPas encore d'évaluation

- HMT 113401 Anna UnivDocument4 pagesHMT 113401 Anna Univsathiya_ramPas encore d'évaluation

- HMT 113401 Anna UnivDocument3 pagesHMT 113401 Anna Univsathiya_ramPas encore d'évaluation

- HMT 113401 Anna UnivDocument4 pagesHMT 113401 Anna Univsathiya_ramPas encore d'évaluation

- Autombile EnggDocument8 pagesAutombile Enggsathiya_ramPas encore d'évaluation

- Bme Unit 4Document31 pagesBme Unit 4sathiya_ramPas encore d'évaluation

- Heat Transfer: Instructor: Associate Professor Department of Chemical Engineering, BUET, Dhaka-1000Document42 pagesHeat Transfer: Instructor: Associate Professor Department of Chemical Engineering, BUET, Dhaka-1000Mahmudur Rahman RiadPas encore d'évaluation

- Unit-4 2Document8 pagesUnit-4 2karan sihagPas encore d'évaluation

- Unit 3 - Boiling and CondensationDocument19 pagesUnit 3 - Boiling and CondensationThembiseni ShikwambaniPas encore d'évaluation

- Critical Heat Flux ApparatusDocument6 pagesCritical Heat Flux Apparatusأشرف عليPas encore d'évaluation

- Tutorial 11 - MS3220 Rekayasa Termal (Mark Scheme)Document6 pagesTutorial 11 - MS3220 Rekayasa Termal (Mark Scheme)i need documentsPas encore d'évaluation

- Reboiler Case StudyDocument6 pagesReboiler Case StudyamlhrdsPas encore d'évaluation

- Final Year Project On Solar Water HeaterDocument66 pagesFinal Year Project On Solar Water HeaterHailemariam Weldegebral100% (1)

- nUCLEAR ENG BASICSDocument77 pagesnUCLEAR ENG BASICSAsad SaeedPas encore d'évaluation

- Boiling and CondensationDocument15 pagesBoiling and CondensationAbhijit NathPas encore d'évaluation

- Boiling and CondensationDocument39 pagesBoiling and Condensationaranna lalPas encore d'évaluation

- Saturation Nucleate Pool Boiling - A Simple CorrelationDocument9 pagesSaturation Nucleate Pool Boiling - A Simple CorrelationForcus on100% (1)

- Leidenfrost EffectDocument10 pagesLeidenfrost EffectSnowswimmerPas encore d'évaluation

- Scan 6 Jul 2020Document10 pagesScan 6 Jul 2020memoPas encore d'évaluation

- 23 Condensers & EvaporatorsDocument26 pages23 Condensers & EvaporatorsPRASAD326100% (5)

- Design Practices-ReboilerDocument7 pagesDesign Practices-Reboileragarwalashwin32100% (1)

- J Ijheatmasstransfer 2018 12 048Document15 pagesJ Ijheatmasstransfer 2018 12 048Behrang SajadiPas encore d'évaluation

- Performance Analysis of Plate Heat Exchangers Used As Refrigerant EvaporatorsDocument295 pagesPerformance Analysis of Plate Heat Exchangers Used As Refrigerant EvaporatorskarthikeyanPas encore d'évaluation

- 1961 Kutateladze S.S. Kutateladze S.S. Int. J. Heat Mass TransfDocument15 pages1961 Kutateladze S.S. Kutateladze S.S. Int. J. Heat Mass TransfMutant_DNAPas encore d'évaluation

- Grup Two PresentiestionDocument23 pagesGrup Two PresentiestionFira tubePas encore d'évaluation

- Class Exercise 5 - SolutionsDocument6 pagesClass Exercise 5 - SolutionsFidelphin Mampeme SitaPas encore d'évaluation

- CFX Multiphase 14.5 L07 Interphase Mass TransferDocument116 pagesCFX Multiphase 14.5 L07 Interphase Mass Transferedersalcedocastro100% (1)

- API571 Part4Document129 pagesAPI571 Part4Charlie Chong100% (6)

- 6-Heat Transfer by S K Mondal (1) .UnlockedDocument72 pages6-Heat Transfer by S K Mondal (1) .UnlockedAbhishek TiwariPas encore d'évaluation

- Full Download Book Boiling Research and Advances PDFDocument41 pagesFull Download Book Boiling Research and Advances PDFdeborah.simpson533100% (16)

- Corr Topic2 Ch10incroperaDocument4 pagesCorr Topic2 Ch10incroperaMohammed AlghamdiPas encore d'évaluation

- Vegetable Oil Quenchants: Calculation and Comparison of The Cooling Properties of A Series of Vegetable OilsDocument12 pagesVegetable Oil Quenchants: Calculation and Comparison of The Cooling Properties of A Series of Vegetable OilsAndreea CristinaPas encore d'évaluation

- Prediction of The Minimum Film Boiling Temperature Using Artificial Neural NetworkDocument11 pagesPrediction of The Minimum Film Boiling Temperature Using Artificial Neural Networkvane-16Pas encore d'évaluation

- Comparison of Cryogenic Flow Boiling in Liquid Nitrogen and Liquid Hydrogen Chilldown ExperimentsDocument12 pagesComparison of Cryogenic Flow Boiling in Liquid Nitrogen and Liquid Hydrogen Chilldown Experimentsnewrajasingh100% (1)

- CH-9 Boiler Draught & Circulation SystemDocument30 pagesCH-9 Boiler Draught & Circulation SystemRavi ShankarPas encore d'évaluation