Académique Documents

Professionnel Documents

Culture Documents

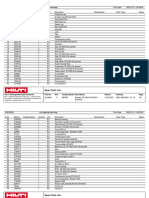

Lock Nut1

Transféré par

kumarswami2012Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lock Nut1

Transféré par

kumarswami2012Droits d'auteur :

Formats disponibles

Low Carbon Steel

JLNS

No.10~20 303 Stainless Steel

No.25~50 304 Stainless Steel

Stainless

JLNSK

304 Stainless Steel

HLB

HLBM

HLBC

HLBS

(2) (1)

(1)

Parker

1018 Carbon Steel

Equivalent

Electroless Nickel Plating

Parker

HLBU 1045 Carbon Steel Thermal Refined 22~28HRC

304 Stainless Steel

D1

Designed Offset (a) is provided between No.2 Nut

boss.

e1

For Thin Type (HLBU), please mount the second nut (upper nut) first, followed by the first one.

Part Number

(M10~50)

HLBM

(M12~50)

HLBC

25

(M10~50)

HLBS

30

(M12~50)

<Thin Type>

HLBU

(M25~50)

D1

Type

((1)+(2)) set

(Steel)

JLNK

(Stainless Steel)

JLNSK

(1) Only

*Popular sizes now stocked locally

and ship next day! P.91

(Stainless Steel)

JLNS

6H (Class 2)

(1) Nut for Bearing

Reference Weight (g)

Unit Price ((1)+(2) set)

Unit Price ((1) only)

MxPitch

per set ((1)+(2)) per 1 pcs. ((1) Only)

JLNK

JLNSK

JLN

JLNS

D1 D2 B d S T

(Fine Thread)

JLNK JLNSK JLN JLNS Qty. 1~49 Sets 50 Sets~ Qty. 1~49 Sets 50 Sets~ Qty. 1~49. 50 pcs.~ Qty. 1~49. 50 pcs.~

10x0.75 18 13

14

5.0

5.3

3.7

4.1

3.20

2.90 12.70 11.40

2.70

2.40 10.20

9.20

4

3

12x1.0 22 17

18

8.3

8.2

6.4

6.6

3.30

3.00 12.70 11.40

2.80

2.50 10.20

9.20

15x1.0 25 21

21

12.5

12.7

10

10.3

3.50

3.20 12.70 11.40

3.00

2.70 10.20

9.20

5

17x1.0 28 24

24 4

15.5

16.3

12.4

13

3.80

3.40 12.70 11.40

3.30

3.00 10.20

9.20

2

20x1.0 32 26 6 28

21.5

22.8

19

19.5

4.20

3.80 15.00 13.50

3.70

3.30 12.30 11.10

25x1.5 38 32

34

31.4

36.6

25

31.2

4.80

4.30 21.10 19.00

4.30

3.90 18.20 16.40

7

30x1.5 45 38

41 5

47.8

48.3

40

41.1

5.70

5.10 22.80 20.50

5.20

4.70 19.00 17.10

35x1.5 52 44 8 48

63.4

73.7

53

64.3

6.90

6.20 29.00 26.10

6.40

5.80 23.80 21.40

40x1.5 58 50 9 53

97.3

97.7

85

86.5

8.00

7.20 32.40 29.20

7.40

6.70 26.70 24.00

45x1.5 65 56 10 60 6 2.5 134.2 135

119

121

9.50

8.60 38.40 34.60

8.80

7.90 32.20 29.00

50x1.5 70 61 11 65

162.5 161.5 146.5 147 10.80

9.70 45.50 41.00 10.10

9.10 38.50 34.70

10

12

15

17

20

25

30

35

40

45

50

50~

10%

Unit Price Qty. 1~19

HLBM

HLBC

HLBS

8.70

7.50

7.70

26.80

7.80

8.00

27.80

6.60

6.80

28.80

6.40

6.60

29.80

7.50

7.70

39.50

11.40

11.60

44.50

15.10

15.30

52.30

16.60

16.80

52.80

19.30

19.50

63.70

23.60

23.80

80.50

HLB

6.20

4.80

4.90

5.00

5.10

5.10

5.60

6.80

7.70

9.50

11.70

Cautions for Use

Machine chamfering (C = 1 pitch or equivalent) on the tip of

male thread, whose precision grade is JIS 6g (Class 2).

Structure and Function of Hard Lock Nut

For larger quantity orders "Days to Ship" may

differ from published catalog term.P.91

Screw Center of Bolt

and Nut

Fig. -1

2nd Nut Boss Eccentric

Center

HLBU

Comparison with Conventional Products

Strong wedge action takes

effect in this part.

P1

a

a b

(1)

Fig. -2

Wedge action does not change when nuts are installed

upside down of the figure on left.

P1

Fig.-1 When upper nut tightened, stress is automatically applied in P1 arrow direction. Horizontal stress continues to increase with tightening until upper Nut closely contacts lower Nut as shown in Fig.-2.

The nuts are perfectly locked by the wedge effect.

Fig.-2 After nuts are tightened, internal stress remains distributed as

composite stress of P1 + P2 + P3 to resist external impact.

Unlike the regular bearing nut set, key grooves on

toothed washers and shafts are not required.

(2)

9.90

14.70

18.80

21.30

24.90

30.40

P3

P2

Fine U Nuts

d 0.5

S 0.2

Body

Friction Ring

Type

FUNT

1018 Carbon Steel

FUNTC

1045 Carbon Steel

Thermal Refined

(22~28HRC)

301 Stainless Steel

H

h

Clamp

0 .5

-0

JLN

10

12

15

17

20

25

30

35

40

45

50

4.2

(Steel)

No.

4.2

FUNTS 304 Stainless Steel

Part Number

B0211

8

9

10

11

Volume Discount Rate

M

JIS

11

12

13

14

(2) No.2 Nut (Upper Nut)

Common for No.1 and 2 Setting Height Perpendic. Weight (g)

of End Face per Set

B

e1

b

Standard

Thin

S

T

Standard Thin Standard Thin Standard Thin

Min Max Min Max (Max) Standard Thin

15

6

3.5

3

9.5 10.5

17

23

2.5

7

4.5

11.5 12.5

4

29

2.0

8

5.5

13.5 14.5

43

0.05 72

45

10

7

4

6

3

16.0 17.5 10 11.5

103 63

5

11

8

7

4

18.0 19.5 12 13.5

150 100

4.0

9

9

5

5

17.0 18.5 14 15.5

170 140

4.0

6

2.5 19.0 20.5 16 17.5

10

10

6

6

240 201

11

11

7

7

21.0 22.5 18 19.5

285 250

3*

Quantity 1~19 20~49

Rate Price List 5%

Screw Precision

44

50

56

61

HLB35

D3

D4

D2

d1

52

58

65

70

18

22

25

28

32

38

45

52

58

65

70

Part Number

S2

(Fine)

10x0.75

12x1.0

15x1.0

17x1.0

20x1.0

25x1.5

30x1.5

35x1.5

40x1.5

45x1.5

50x1.5

D1

0

1 0.5

S1

10

12

15

17

20

25

30

35

40

45

50

(2) Tooth Lock Washer for Bearing

B

<Standard Type>

D1

Screw Precision JIS B0211 6H (Class 2)

(1) Nut for Bearing

HLB

(1)No.1 Nut (Lower Nut)

B

e

D2

Standard Thin Standard Thin

18

13

6

22

17

25

21

2.7

7

28

24

32

26

8

38

32

10

7

3.7

45

38

MxPitch

Type

Friction Ring

30

For larger quantity orders "Days to Ship" may differ from published catalog term.P.91

10

12

15

17

20

25

30

35

40

45

50

d1

10

12

15

17

20

25

30

35

40

45

50

(2) Tooth Lock Washer for Bearing

k

S1 S2

t

V

D3

D4

8.5

21

13

3 3

2

10.5

25

17

13.5

28

21

1.0

15.5

32

24

4 4

18.5

36

26

23

42

32

5

2.5

27.5

49

38

5

32.5

57

44

1.2

37.5

62

50

6

6

42.5

69

56

47.5

74

61

Part Number

((1)+(2)) set

JLNK

(1) Only

JLN

765

Dim. of Tooth Lock Washer Mounting Groove (reference)

No. of Teeth Slot Width a Groove Depth b

9

Part Number

Type

a

b

No.

4

2

FUNT

FUNTC

FUNTS

5

13

2.5

15

17

1018 Carbon Steel

(2)

Type

Standard Type Thin Type

JLN

JLNK

Hard Locking Bearing Nuts

D2

D1

(2) Tooth Lock Washer for Bearing

D1

Steel

(1) Nut for Bearing

Type

((1)+(2)) set (1) Only

Type

Hard Locking Bearing Nuts/Fine U Nuts

Nuts for Bearings, Tooth Lock Washers for Bearings

M

8

10

12

15

17

20

25

30

35

40

45

50

MxPitch

(Fine Thread)

8x0.75

10x0.75

12x1.0

15x1.0

17x1.0

20x1.0

25x1.5

30x1.5

35x1.5

40x1.5

45x1.5

50x1.5

Nut and Tooth Lock Washer for Bearing

These 2 items are common tools for fixing

bearings.

Nut loosening can be prevented by machining a

vertical groove (Key Groove) on the thread part of

a rotary shaft, and by tightening the nut and the

shaft with the tooth lock washer.

Part Number

[Mounting Procedure]

(1) Assemble a bearing into a rotary shaft.

(2) Fit the tooth lock washer tab (S2) in the groove

of the rotary shaft (a).

(3) Tight the bearing nut.

(4) Fold the tooth lock washer tab (S1) to fit the

groove of the rotary shaft (S).

Hard Lock Structure

As shown in the figure, stress P occurs caused by

the spring effect when Friction Ring contacts the

screw thread of the bolt. In addition, strong load

is applied to the screw thread of the bolt by P

and reaction forces, which creates friction torque

(preventing torque) to prevent any free motion.

D1

16

18

22

25

28

32

38

45

52

58

65

70

12

13.5

17

21

24

26

32

38

44

50

56

61

13

14.4

18.4

21.4

24.2

28.4

34

41

48

53

60

65

1.5

1.8

1.8

1.8

1.9

1.8

2

2

2

2.5

2.5

2.5

3

3

3

4

4

4

5

5

5

6

6

6

3*

FUNT10

*Popular sizes now stocked locally

and ship next day! P.91

P

P

Fine U Nut is a registered trademark of FUJISEIMITSU CO., LTD.

H

5.3

5.2

5.4

6.5

6.4

7.7

9.1

9.1

10.2

11.2

12.5

13.5

0.3

0.5

0.8

1.0

Perpendic. of End Face

(Max)

4.3

4

4

5

5

6

7

7

8

9

10

11

0.05

Screw Precision JIS 6H (Class 2)

Unit Price Qty. 1~4

FUNT

FUNTC

FUNTS

7.40

3.20

3.90

14.50

3.30

3.90

14.50

3.50

3.90

14.50

3.80

4.20

16.50

4.20

4.60

17.70

4.80

5.70

20.60

5.70

7.00

25.50

6.90

9.50

37.00

8.00

11.90

41.40

9.50

14.80

48.80

10.80

17.70

56.10

Volume Discount Rate

Quantity

1~4

5~9

10~19

20~

Rate

Price List

5%

10%

15%

For larger quantity orders "Days to Ship" may differ from published catalog term.P.91

Cautions for Use

Machine chamfering (C = 1 pitch or equivalent) on the tip of male thread, whose precision grade is JIS 6g (Class 2).

Use lubricant when twisting in and out the thread.

(Use extra high performance lubricant when shaft hardness is low.)

For optimal performance, ensure that the complete thread portion is to extrude by 2 pitches or more from function ring side.

The perpendicularity of the plane end in the above table is effective only when tightened with twice or more the preventing torque.

Not usable with impact wrenches of high-speed revolution.

Not usable on machined thread portion of shafts (key grooves, etc.)

Screwing in from the friction ring side is impossible.

Do not use when the deflection of Friction Rings or Clamp Part occurs.

766

Vous aimerez peut-être aussi

- ELINE Ball Screw AssembliesDocument24 pagesELINE Ball Screw AssembliesAnonymous PIqdeNp8Pas encore d'évaluation

- Work Document T 34.2 Tightening Torques For Screw Connections Used For SILUMIN Parts VC General AssemblyDocument2 pagesWork Document T 34.2 Tightening Torques For Screw Connections Used For SILUMIN Parts VC General AssemblyLetacio OliveiraPas encore d'évaluation

- Te 1000 AvrDocument19 pagesTe 1000 AvrJoseLuisCarrilloMena100% (1)

- Body Flange Design-Appx-2Document4 pagesBody Flange Design-Appx-2Matthieu100% (1)

- Parts List DR112M-132MCDocument3 pagesParts List DR112M-132MCAmanPas encore d'évaluation

- Plummer Blocks: Tightening Bolt Oil Fill PlugDocument30 pagesPlummer Blocks: Tightening Bolt Oil Fill Plugmanoj983@gmail.comPas encore d'évaluation

- Plummer en 03-32Document30 pagesPlummer en 03-32refeiPas encore d'évaluation

- SBM 1050vt ServiceDocument3 pagesSBM 1050vt Servicealteromr mrPas encore d'évaluation

- Indexing Plungers With Rest PositionDocument2 pagesIndexing Plungers With Rest PositionEngenharia FlexleanPas encore d'évaluation

- NTTF Press Tool Standards Ebook GeneralDocument207 pagesNTTF Press Tool Standards Ebook GeneralRagunathan GPas encore d'évaluation

- SBM 810vt ServiceDocument3 pagesSBM 810vt Servicealteromr mrPas encore d'évaluation

- Bezares Part List 1000 BZDocument19 pagesBezares Part List 1000 BZreincidentesk8Pas encore d'évaluation

- Stand-Offs: Some Distance AheadDocument6 pagesStand-Offs: Some Distance AheadCorrado MototrePas encore d'évaluation

- Parts List 08 616 07 02: AC Motor Dft/Dfte90 Gear Unit VersionDocument2 pagesParts List 08 616 07 02: AC Motor Dft/Dfte90 Gear Unit Versionluis terronesPas encore d'évaluation

- PN16 Backing RingDocument1 pagePN16 Backing Ringalmandhari33Pas encore d'évaluation

- Mares Ruby 2002Document15 pagesMares Ruby 2002EUROTANK MARITIMEPas encore d'évaluation

- Shed Detail Bom For Solar Combiner Panel-1 - R01Document1 pageShed Detail Bom For Solar Combiner Panel-1 - R01YashwantRajVermaPas encore d'évaluation

- CBD20J-Li2 Part ListDocument11 pagesCBD20J-Li2 Part Listmvv-sspPas encore d'évaluation

- Rectificador Milwaukee Modelo 5192 Part ListDocument1 pageRectificador Milwaukee Modelo 5192 Part ListJesus RamirezPas encore d'évaluation

- Te1000 Gen 2 Parts ListDocument8 pagesTe1000 Gen 2 Parts ListDomPas encore d'évaluation

- Cylinder Head: Shutdown SIS Previous ScreenDocument5 pagesCylinder Head: Shutdown SIS Previous ScreenEric LedesmaPas encore d'évaluation

- Pizzato Elettrica Position Switches FR Series - Catalog 2011-2012Document12 pagesPizzato Elettrica Position Switches FR Series - Catalog 2011-2012IBJSC.comPas encore d'évaluation

- Threading Tools (SST Series)Document8 pagesThreading Tools (SST Series)Gilberto ManhattanPas encore d'évaluation

- Chapter 2 Gear Drive-3Document41 pagesChapter 2 Gear Drive-3Abaziz Mousa OutlawZzPas encore d'évaluation

- Mat Bich 2 (Flanged Bulkhead Pieces)Document2 pagesMat Bich 2 (Flanged Bulkhead Pieces)vyvy83Pas encore d'évaluation

- TE - 3000-AVR 3, PeçaspdfDocument7 pagesTE - 3000-AVR 3, PeçaspdfGabriel Pedroso BispoPas encore d'évaluation

- Spare Parts: Walking Beam 7T Brake Drum 355X150 - S/SaDocument5 pagesSpare Parts: Walking Beam 7T Brake Drum 355X150 - S/SaOlegPas encore d'évaluation

- DD 150Document17 pagesDD 150blinkesku67% (3)

- Plummer Block DskatkasndfmDocument30 pagesPlummer Block DskatkasndfmVivek AradhyaPas encore d'évaluation

- Coupling - Hoist Cam Switch PDFDocument14 pagesCoupling - Hoist Cam Switch PDFvozefjadavPas encore d'évaluation

- Hilti 905 1Document16 pagesHilti 905 1Bokiiiiiiiiiiiii100% (1)

- Plummer Block Housings: FeaturesDocument3 pagesPlummer Block Housings: FeaturesrefeiPas encore d'évaluation

- hs3200 Issue 12 H Parts List CustomerDocument13 pageshs3200 Issue 12 H Parts List Customermk saravananPas encore d'évaluation

- 8000 Series Bezares PtoDocument4 pages8000 Series Bezares Ptobigsmilth420Pas encore d'évaluation

- Spare Part List: PMV 919 (W-XW-TW)Document51 pagesSpare Part List: PMV 919 (W-XW-TW)m100% (1)

- Parts List Dr112m-132mc FGDocument3 pagesParts List Dr112m-132mc FGAman50% (2)

- Steel Supply Sub-Grades To EC3Document22 pagesSteel Supply Sub-Grades To EC3Anonymous iS33V5Pas encore d'évaluation

- 2343 - 2074 - AT17319 Swivel Joint PC200-8M IsiDocument2 pages2343 - 2074 - AT17319 Swivel Joint PC200-8M Isiali wardanaPas encore d'évaluation

- B300 Plummer BlocksDocument12 pagesB300 Plummer BlocksBudy AndikaPas encore d'évaluation

- Ycf SM F150 - 2019Document26 pagesYcf SM F150 - 2019artem.samanovskiyPas encore d'évaluation

- PM919 Spare Parts en Rev.12Document59 pagesPM919 Spare Parts en Rev.12aalinares1100% (2)

- GC-0302-0302CX Sewing Machine Parts CatalogDocument17 pagesGC-0302-0302CX Sewing Machine Parts CatalogDeneteusPas encore d'évaluation

- 03d001a BDocument4 pages03d001a BRasha AbdullahPas encore d'évaluation

- Bushings For Locating Pins Bushings For Locating PinsDocument1 pageBushings For Locating Pins Bushings For Locating PinslamnhoPas encore d'évaluation

- 2 Speed TransmissionDocument57 pages2 Speed TransmissionNatalie WyattPas encore d'évaluation

- Despiece ZLUDocument49 pagesDespiece ZLUAgustin Losada EcheverriaPas encore d'évaluation

- Din 11851 Edited VersionDocument22 pagesDin 11851 Edited VersionSenthilKumarShanmughamPas encore d'évaluation

- Compression SpringsDocument9 pagesCompression Springssmhea123Pas encore d'évaluation

- Trio TV85B VSI Parts Manual AbelDocument34 pagesTrio TV85B VSI Parts Manual AbelvictorpalaciossPas encore d'évaluation

- Parts List - KRS2-B61Document4 pagesParts List - KRS2-B61crispyyy baconPas encore d'évaluation

- AK6-80+GV80 AK6-80: Old RangeDocument6 pagesAK6-80+GV80 AK6-80: Old RangeCiprian MaiorPas encore d'évaluation

- Assembly List 2T2S SS From 02-05-2019Document4 pagesAssembly List 2T2S SS From 02-05-2019ronak shahPas encore d'évaluation

- Front IdlerDocument2 pagesFront IdlerfranPas encore d'évaluation

- GC201 - 202 Sewing Machine Parts CatalogDocument16 pagesGC201 - 202 Sewing Machine Parts CatalogDeneteusPas encore d'évaluation

- 30 FrontordfhDocument1 page30 FrontordfhEbied YoussefPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Lock Nut1Document1 pageLock Nut1kumarswami2012Pas encore d'évaluation

- Energy Conservation and Equipment Reliability With UltrasoundDocument48 pagesEnergy Conservation and Equipment Reliability With Ultrasoundkumarswami2012Pas encore d'évaluation

- T PM 100 Study GuideDocument21 pagesT PM 100 Study Guidesiddis316100% (1)

- Plummer BlockDocument66 pagesPlummer BlockmmkattaPas encore d'évaluation