Académique Documents

Professionnel Documents

Culture Documents

Contflow Solution

Transféré par

Wäśü RāđDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Contflow Solution

Transféré par

Wäśü RāđDroits d'auteur :

Formats disponibles

1.

Batch and continuous ow reactors (a) The productivity of continuous ow reactors, as dened in this problem, may be evaluated by solving the conversion expressions for Q. In plug ow, this gives: kV CA,out = exp CA,in Q Q= And for perfect mixing/CSTR: CA,out 1 = CA,in 1 + kV Q 1+ kV CA,in = Q CA,out kV

CA,in CA,out

kV ln

CA,out CA,in

Q=

(b) For the batch reactor with downtime td and residence time tR , the productivity is the volume divided by the total time V /(tR + td ). The residence time can be determined from the batch conversion equation: CA,out = ektR CA,in 1 CA,out tR = ln k CA,in The productivity is then: Q = V kV V = 1 CA,out = CA,out tR + td k ln CA,in + td ln CA,in + ktd

In the limit where td /tR goes to zero, the second term in the denominator vanishes and this approaches the productivity of the plug ow reactor. Another way to express this is: Q = V V tR kV tR = = CA,out tR + t d tR t R + td tR + t d ln

CA,in

This is ne, but since tR is a dependent variable, putting it on the right side does not allow direct calculation of the productivity from reactor characteristics as can be done with the expression above. (c) In this case with a target CA,out /CA,in = 0.05, the plug ow reactors productivity is: Q= And for perfect mixing/CSTR: Q=

1 0.05

kV kV = ln 0.05 3.0 kV kV = 19 1

For a batch reactor: Q = ln

kV

CA,out CA,in

+ ktd

kV 3.0 + ktd

1/3 The plug ow reactor is clearly 1/19 = 6.34 times more productive than the perfect mixing reactor. And since hD , A, V and td are all positive, the batch reactor will have slightly lower productivity than the plug ow reactor as well, with the ratio depending on the downtime.

(d) The perfect mixing reactor is likely to give the highest quality output for a couple of reasons: In the batch reactor, signicant concentration inhomogeneities can develop, particularly if k is temperature-dependent and the reaction gives o or consumes a signicant amount of heat (much more so in a heterogeneous/surface reactor). Reactions with the containment vessel can also introduce location-dependent variations in composition. For these reasons, its often desirable to stir a batch reactor. A plug ow reactor will always exhibit signicant concentration inhomogeneities logitudinally, and sometimes across the reactor for the same reason as the batch reactor. If ow conditions deviate at all from steady state, changes in ow patterns can result in inhomogeneity in the output. If the raw material in a plug ow reactor enters at varying concentration, that variation will carry through to the end of the reactor, and show up as inhomogeneous output. A perfect mixing reactor, on the other hand, will rapidly mix in any concentration departures in the raw material, smoothing out their inuence over time. (e) Batch reactors have several advantages over continuous ow reactors: They can be stopped between batches, so the production rate is exible and can be varied if economically desirable. If a continuous reactor is stopped, it takes time and wastes material to return it to consistent steady-state production. Batch reactors are also more exible, in that one can easily use dierent compositions in dierent batches to produce products with dierent specications. If the process degrades the reactor in some way, a batch reactor can be cleaned, relined, etc. between batches, where continuous reactors must run for a long time before that can be done. Because aws tend to be isolated to a given batch, one can track the quality more easily in a batch process. For example, when the cause of a plane is traced to a aw in a titanium part, it is common practice to ground all planes with parts made from the same vacuum arc remelt (VAR) titanium ingot, and other defective parts are often found in the subsequent inspections. If the reactants are stirred, a batch reactor can often achieve better quality than a plug ow reactor (which cannot be well-mixed in order to maintain plug ow), and better productivity than a continuous ow reactor (as seen above). Any of the above receives full credit.

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- 4 - 5.1 - Fluid Action On Surfaces (Plane Surface)Document16 pages4 - 5.1 - Fluid Action On Surfaces (Plane Surface)Jacky CagampanPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Ductle Iron Spec1Document8 pagesDuctle Iron Spec1윤병택Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- HVAC Water TreatmentDocument7 pagesHVAC Water TreatmentDuxToyPas encore d'évaluation

- 2 Combined Dci Standards 6 13 13Document7 pages2 Combined Dci Standards 6 13 13api-32776059Pas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- 27U RackDocument6 pages27U Racknitin lagejuPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Accounting Principles Ifrs Version Global 1st Edition Weygandt Solutions ManualDocument26 pagesAccounting Principles Ifrs Version Global 1st Edition Weygandt Solutions ManualKimberlyMendezyptr98% (40)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Alpha Testing Form LATESTDocument2 pagesAlpha Testing Form LATESTazizaharsad0% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Acquisition (Pagtamo) Meaning-Making (Pag-Unawa) Transfer (Paglilipat)Document2 pagesAcquisition (Pagtamo) Meaning-Making (Pag-Unawa) Transfer (Paglilipat)MAY BEVERLY MORALES100% (8)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

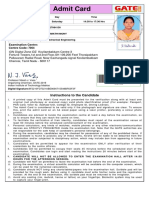

- Admit Card: Examination Centre: Centre CodeDocument1 pageAdmit Card: Examination Centre: Centre CodekrishnaPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Plotting in MatlabDocument7 pagesPlotting in Matlabpride3351Pas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Revised Runway Length Discussion (20171206) - 201712211212022318Document3 pagesRevised Runway Length Discussion (20171206) - 201712211212022318Ilham RaffiPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- 990 Vibration Transmitter Datasheet-141612mDocument14 pages990 Vibration Transmitter Datasheet-141612mloopkkPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- TEX20-NV: Technical and Maintenance ManualDocument110 pagesTEX20-NV: Technical and Maintenance Manualvasilikot50% (2)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- External Command in 10 Steps For Revit 2015Document2 pagesExternal Command in 10 Steps For Revit 2015JigneshPas encore d'évaluation

- QA/QC Filling INDEX: North Gas Compression Plants (NGCP) Pipelines Index File Name File #Document3 pagesQA/QC Filling INDEX: North Gas Compression Plants (NGCP) Pipelines Index File Name File #deva017Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Global Cardiac Catheters - 2012-2018Document4 pagesGlobal Cardiac Catheters - 2012-2018Axis Research MindPas encore d'évaluation

- Lec 1 - SuperelevationDocument24 pagesLec 1 - SuperelevationMohamedPas encore d'évaluation

- DBMS-LM Kavi With MinipjtDocument56 pagesDBMS-LM Kavi With Minipjtkavi_mithuPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- SWIMS Directory of LibrariesDocument17 pagesSWIMS Directory of LibrariessudakshinaroyPas encore d'évaluation

- Commercial Vehicles BrochureDocument20 pagesCommercial Vehicles Brochurebinhtb14Pas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- If Then ElseDocument10 pagesIf Then Elseapi-297910907Pas encore d'évaluation

- Split Panasonic Cspc18dkqDocument16 pagesSplit Panasonic Cspc18dkqMaria de VillalobosPas encore d'évaluation

- NessusDocument23 pagesNessusShivaprakash TimmapurPas encore d'évaluation

- Sap Accrual EngineDocument2 pagesSap Accrual Enginerohit12345aPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- District CoolingDocument16 pagesDistrict Coolingmazzam75Pas encore d'évaluation

- Ems2348x User Manual Id IdDocument104 pagesEms2348x User Manual Id IdGod GamerPas encore d'évaluation

- NR 10 Specification 75ADocument2 pagesNR 10 Specification 75AHsalmani1991Pas encore d'évaluation

- All The Wrong MovesDocument13 pagesAll The Wrong Movesabhishek2006100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Emmeskay MIL-SIL TutorialDocument52 pagesEmmeskay MIL-SIL TutorialNeacsu EugenPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)