Académique Documents

Professionnel Documents

Culture Documents

TB.23 HVFA For Concrete Structures

Transféré par

Mahesh RamtekeDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TB.23 HVFA For Concrete Structures

Transféré par

Mahesh RamtekeDroits d'auteur :

Formats disponibles

BULLETIN

NUMBER

23

HVFA For Concrete Structures

HVFA concrete can be used in a variety of structural applications. It has been proven as a technology that can accommodate sustainable development and improve the lifespan and performance of structures

n 1981, long before using high volume fly ash (HVFA) concrete in structural applications was an accepted practice, EHDD architects used concrete with 40% fly ash in the seawater holding tanks in the Monterrey Bay Aquarium for durability considerations. Since then, concrete throughout the country has regularly utilized 20% to 35% fly ash. The desire from the environmentally conscious community to mitigate greenhouse gas emissions has resulted in a movement to allow higher fly ash contents than would have been thought possible a few short years ago. In fact, specifiers are now regularly asking for higher fly ash content for performance and environmental reasons. This movement is forcing the concrete industry to research the nature and performance of local materials that allow HVFA concrete to perform as needed. Performance of HVFA concrete is directly related to performance of local materials. Because of this, proportions of HVFA concrete vary from location to location. As with all concrete utilized in construction, field verification testing and trial placements should be used to make sure HVFA concrete performance meets project needs. HVFA Concrete Timeline Initially, HVFA projects utilized concrete with very low water contents achieved by the use of high dosages of high-range water reducing admixtures. A few of the early projects are listed below:

1987 1988 1990 1992 Satellite Communication Facility Ottawa, Canada Park Lane Hotel/Office Complex Halifax, Canada Purdys Warf Development Halifax, Canada Slope Protection Project Nova Scotia, Canada 50% fly ash concrete used in high durability concrete 55% fly ash concrete used in columns, beams, and floor slabs 55% fly ash concrete used in 62 large caissons 60% ash used in shotcrete slope protection

1999

GAP Headquarters Building San Francisco, CA

50% fly ash concrete in pile caps and slab-on- grade work; 30% used in column and slab-on- metal deck work

2000

Island Wood Environmental Learning Center Whidbey Island, WA 50% fly ash concrete in footings, stem-walls, and slab-on-grade Liu Centre for Global Studies Vancouver, Canada Artist Live/Work Studios Vancouver, Canada University of California Berkeley Berkeley, CA 50% ash for foundation and structural elements 50% fly ash concrete for architectural color and finish considerations 50% fly ash concrete used in Wurster Hall and Barker Hall seismic retrofits

2000 2001 2001

Many other structures are either underway or in planning as the sustainable building movement develops. Admixtures Aggregate proportioning techniques that take advantage of the workability offered by HVFA generate a least voids condition in concrete, which complements the water reducing action of fly ash. Concurrent with the demand for higher fly ash contents, mid-range and high-range chemical admixtures have been developed to further enhance water-reducing action without causing an unacceptable delay in setting time. Non-chloride set accelerating admixtures have proven useful for controlling set time within contractor requirements for finishing time. Much of the set time retardation experienced with older HVFA mixtures resulted from past practices using high dosages of older Type A water reducing admixtures on total cementitious materials. Type A admixtures can still be used in moderate dosages based on cement content, but set time can be improved if Type A admixtures are used in conjunction with mid-range and high-range chemical admixtures. Appropriate Applications HVFA concrete can be used in a variety of structural applications. Fly ash has not only been used regularly in massive concrete applications, but has been used in columns, shear walls, and floor slabs as well. Even though technology has improved HVFA concrete performance, some mixtures may be inappropriate for certain applications requiring very early age performance. Mixtures with 25% to 55% fly ash may be acceptable, depending upon conditions, for mass concrete and foundation applications. Where higher percentages of ash are used, the age of strength acceptance may need to be extended to 56 or 90 days. Column and shearwall work can generally accept 30% to 35% fly ash, especially when time of form-stripping is of concern. Higher cement content (20% to 30% depending on circumstances) may be required to provide appropriate finishing time for slab on metal deck exposed to cool temperatures and for achieving strength of 3000 psi at three days of age for post-tensioned concrete applications.

Further research into proportioning HVFA concrete mixtures revealed that higher water content could be used while maintaining acceptable performance. This opened the door for the use of mid-range water reducing admixtures and more user-friendly concrete. The following HVFA concrete products were built with the new mix ideology.

For more information or answers to specific questions about HVFA for concrete structures, contact your nearest Headwaters Resources technical sales representative, call 1-888-236-6236, or visit us online at www.flyash.com.

Rev. 3/05

Vous aimerez peut-être aussi

- Lifting MethodsDocument10 pagesLifting Methodsselva1965Pas encore d'évaluation

- Same s80 EngDocument432 pagesSame s80 EngSabadsag DariusPas encore d'évaluation

- Applied Soil Mechanics With ABAQUS ApplicationsDocument398 pagesApplied Soil Mechanics With ABAQUS ApplicationsSoumya Bhattacharyya100% (2)

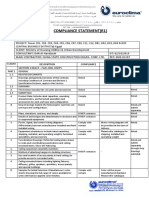

- Fan-Coil Units Compliance Statement for Egypt Tower ProjectsDocument9 pagesFan-Coil Units Compliance Statement for Egypt Tower ProjectsLi Liu100% (1)

- Multiple Choice Questions on Geotechnical EngineeringDocument16 pagesMultiple Choice Questions on Geotechnical EngineeringMahesh RamtekePas encore d'évaluation

- Surveying by Dr. RamachandraDocument338 pagesSurveying by Dr. Ramachandravrsec-rao84% (19)

- Road Safety PresentationDocument22 pagesRoad Safety PresentationMahesh Ramteke100% (4)

- Hanselmann-House Case StudyDocument17 pagesHanselmann-House Case StudyYordanos AbebawPas encore d'évaluation

- Underground Tank Design and Reinforcement DetailsDocument2 pagesUnderground Tank Design and Reinforcement Detailsaaditya chopadePas encore d'évaluation

- Framework For Durable ConcreteDocument8 pagesFramework For Durable ConcreteDai ThanhPas encore d'évaluation

- Characteristics of Concrete With Admixtures PDFDocument6 pagesCharacteristics of Concrete With Admixtures PDFTran Huynh NamPas encore d'évaluation

- Short Notes For Soil MechanicsDocument26 pagesShort Notes For Soil MechanicsColdWinterKid50% (2)

- Hydraulic FracturingDocument6 pagesHydraulic Fracturingner68100% (1)

- Plumbing SpecialitiesDocument4 pagesPlumbing SpecialitiesphilipyapPas encore d'évaluation

- ACI 304R Guide For Meas., Mix., Transp., & Placing ConcDocument41 pagesACI 304R Guide For Meas., Mix., Transp., & Placing ConcVasanth KumarPas encore d'évaluation

- Burj Khalifa Concrete ChallengeDocument8 pagesBurj Khalifa Concrete Challengemarineindia25100% (1)

- Harbour Dock and Tunnel Engineering by R SrinivasaDocument161 pagesHarbour Dock and Tunnel Engineering by R SrinivasadhivyadharshiniPas encore d'évaluation

- Unit-IV Railway EngineeringDocument177 pagesUnit-IV Railway Engineeringmshanraj100% (1)

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceD'EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssurancePas encore d'évaluation

- Volucon+White+Paper+21062018r-5+ 1Document10 pagesVolucon+White+Paper+21062018r-5+ 1Giacgiomb100% (1)

- COL3208695Document35 pagesCOL3208695Iulian SpatareluPas encore d'évaluation

- Reports On Usage of Fly Ash in Cement Concrete Mixes PDFDocument39 pagesReports On Usage of Fly Ash in Cement Concrete Mixes PDFanon_14764006Pas encore d'évaluation

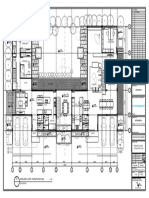

- Aic Management: Ground Floor Furniture Plan 01Document1 pageAic Management: Ground Floor Furniture Plan 01Hung NguyenthePas encore d'évaluation

- High Volume Fly Ash ConcreteDocument16 pagesHigh Volume Fly Ash ConcreteManoj palwePas encore d'évaluation

- Sustainability in Construction: Using Fly Ash As A Cement ReplacementDocument7 pagesSustainability in Construction: Using Fly Ash As A Cement ReplacementMuhamet AhmetiPas encore d'évaluation

- Trabajo Sólidos Sobre Nuevos MaterialesDocument3 pagesTrabajo Sólidos Sobre Nuevos MaterialesNicolas PeñaPas encore d'évaluation

- HvfacDocument18 pagesHvfacponchurrPas encore d'évaluation

- Developt of UHPCDocument11 pagesDevelopt of UHPCChristian Almaraz Gamez100% (2)

- Antiwashout AdmixturesDocument7 pagesAntiwashout AdmixturesKiran KoshyPas encore d'évaluation

- Center For By-Products Utilization: CBU-2002-19 REP-472 October 2002Document20 pagesCenter For By-Products Utilization: CBU-2002-19 REP-472 October 2002Kshitij MathurPas encore d'évaluation

- SuperplasticizersDocument5 pagesSuperplasticizersRaj RatnamPas encore d'évaluation

- Jurnal LN 1Document33 pagesJurnal LN 1Nanda FauziahPas encore d'évaluation

- AdmixtureDocument7 pagesAdmixturevinay rodePas encore d'évaluation

- Hydrophobic Concrete Using Waste Paper Sludge AshDocument12 pagesHydrophobic Concrete Using Waste Paper Sludge AshNiroshanPas encore d'évaluation

- Improving Strength and Durability of High-Volume Fly Ash Concretes with Ultrafine Fly AshDocument14 pagesImproving Strength and Durability of High-Volume Fly Ash Concretes with Ultrafine Fly AshKaraline MarcesPas encore d'évaluation

- Making Pervious Concrete Placement Easy: Using A Novel Admixture SystemDocument5 pagesMaking Pervious Concrete Placement Easy: Using A Novel Admixture SystemCassandra Valmadrid0% (1)

- Concrete AssignmentDocument24 pagesConcrete AssignmentPushpesh RanjanPas encore d'évaluation

- 1.1 High-Strength Concrete (HSC) and High-Performance Concrete (HPC) - BackgroundDocument60 pages1.1 High-Strength Concrete (HSC) and High-Performance Concrete (HPC) - BackgroundThilina Udara de SilvaPas encore d'évaluation

- Burj Khalifa - A New High For High-Performance Concrete: Proceedings of IceDocument8 pagesBurj Khalifa - A New High For High-Performance Concrete: Proceedings of Iceshuperduperman1Pas encore d'évaluation

- High Volume Fly-Ash ConcreteDocument21 pagesHigh Volume Fly-Ash ConcreteWorkless 0207Pas encore d'évaluation

- Sika Viscocrete: TechnologyDocument13 pagesSika Viscocrete: TechnologyacarthurPas encore d'évaluation

- Dinakar - 2008 - Durability of Flyash SCCDocument7 pagesDinakar - 2008 - Durability of Flyash SCCandri.kusbiantoro9761Pas encore d'évaluation

- Minor ProjectDocument44 pagesMinor ProjectMOHAMMAD DANISHPas encore d'évaluation

- High Volume Fly Ash Concrete: L.K. Crouch, Ryan Hewitt, Ben ByardDocument14 pagesHigh Volume Fly Ash Concrete: L.K. Crouch, Ryan Hewitt, Ben ByardMauricio Escobar LabraPas encore d'évaluation

- BUITELAAR High Performance Concrete OverlayDocument10 pagesBUITELAAR High Performance Concrete Overlayindra smiPas encore d'évaluation

- 2013-9-Industrial Application SF Technote 4 PG 5-09Document4 pages2013-9-Industrial Application SF Technote 4 PG 5-09rfvz6sPas encore d'évaluation

- IJCE - A Review On High Performance Concrete - Anoop - K. Jacob - OPaid IasetDocument8 pagesIJCE - A Review On High Performance Concrete - Anoop - K. Jacob - OPaid Iasetiaset123100% (1)

- Review of Partial Cement Replacement by Fly Ash and Effect of Steel FibersDocument4 pagesReview of Partial Cement Replacement by Fly Ash and Effect of Steel FibersRaj KirarPas encore d'évaluation

- New Construction Materials Types and UsesDocument17 pagesNew Construction Materials Types and UsesRavindra MRPas encore d'évaluation

- Influence of Sand Grain Size Distribution and Supplementary Cementitious Materials On The Compressive Strength of Ultrahigh-Performance ConcreteDocument9 pagesInfluence of Sand Grain Size Distribution and Supplementary Cementitious Materials On The Compressive Strength of Ultrahigh-Performance ConcreteShaker QaidiPas encore d'évaluation

- Thesis On Rice Husk Ash ConcreteDocument5 pagesThesis On Rice Husk Ash Concretefjf8xxz4100% (2)

- High Performance ConcreteDocument27 pagesHigh Performance ConcretePratik MandlikPas encore d'évaluation

- Review of Related Literature and Studies: Default - AspxDocument2 pagesReview of Related Literature and Studies: Default - AspxHallel John G. TangonanPas encore d'évaluation

- THOMASDocument22 pagesTHOMASEsposito EspositoPas encore d'évaluation

- Carro Lopez 2015Document11 pagesCarro Lopez 2015nesy610Pas encore d'évaluation

- Visco CreteDocument13 pagesVisco CreteMahmoud ShakerPas encore d'évaluation

- Pce Compression TestsDocument23 pagesPce Compression TestsKanishkPas encore d'évaluation

- Case Studies in Construction MaterialsDocument12 pagesCase Studies in Construction MaterialsABDULLAHSHARJEEL KHANPas encore d'évaluation

- AndrewsPhaedonas Bridge 2000 PDFDocument14 pagesAndrewsPhaedonas Bridge 2000 PDFjeffPas encore d'évaluation

- High-Performance, High-Volume Fly Ash Concrete For Sustainable DevelopmentDocument12 pagesHigh-Performance, High-Volume Fly Ash Concrete For Sustainable DevelopmentDeep SidPas encore d'évaluation

- Literature ReviewDocument3 pagesLiterature Reviewjoanaajuna01Pas encore d'évaluation

- 2015 O Comportamento Da Força de Adesão de Argamassas Modificadas Com Polímeros Durante Um Processo de Molhagem e SecagemDocument8 pages2015 O Comportamento Da Força de Adesão de Argamassas Modificadas Com Polímeros Durante Um Processo de Molhagem e SecagemAntonio RinaldoPas encore d'évaluation

- Progress in Concrete Technology Self-Consolidating ConcreteDocument5 pagesProgress in Concrete Technology Self-Consolidating ConcreteRawan ShalaldehPas encore d'évaluation

- UHPFRC-AE & IE Perspective by Shri S K PuriDocument18 pagesUHPFRC-AE & IE Perspective by Shri S K PuriSreekanth SattirajuPas encore d'évaluation

- Emerging Technologies in The Concrete IndustryDocument5 pagesEmerging Technologies in The Concrete IndustrymasteriragaPas encore d'évaluation

- ICforHVFAinprintCCC2012 PDFDocument8 pagesICforHVFAinprintCCC2012 PDFSaiteja PanyamPas encore d'évaluation

- Admixtures and Shotcrete DurabilityDocument7 pagesAdmixtures and Shotcrete DurabilityMulyawan WIdiasmanPas encore d'évaluation

- Article Rotorua NZversionfinaleDocument19 pagesArticle Rotorua NZversionfinaleyihenew assefaPas encore d'évaluation

- Hobas FTBDocument78 pagesHobas FTBdarkroomzc100% (1)

- Concreto Autocompactado Una Tecnologia UtilLUISDANIELDocument27 pagesConcreto Autocompactado Una Tecnologia UtilLUISDANIELLuis Daniel OjedaPas encore d'évaluation

- Concrete Pavement Advancements for Long-Term DurabilityDocument16 pagesConcrete Pavement Advancements for Long-Term DurabilityRob DamhuisPas encore d'évaluation

- Construction and Building MaterialsDocument11 pagesConstruction and Building MaterialsMarden Rengifo RuizPas encore d'évaluation

- Mechanical properties of concrete with very high fly ash contentDocument8 pagesMechanical properties of concrete with very high fly ash contentNeeraj Paulose RajPas encore d'évaluation

- Civil Engineering Materials Assignment 2 Uzhan Younis 21l-5517 Bs CV (A)Document4 pagesCivil Engineering Materials Assignment 2 Uzhan Younis 21l-5517 Bs CV (A)noorPas encore d'évaluation

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsD'EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsPas encore d'évaluation

- Fluid Mechanics - I Experiments Index Expt. No. Name of The ExperimentDocument37 pagesFluid Mechanics - I Experiments Index Expt. No. Name of The ExperimentAnand DattPas encore d'évaluation

- Venturi MeterDocument8 pagesVenturi MeterSwati SachanPas encore d'évaluation

- 103030001Document86 pages103030001Ayeshanabila0018 NabilaPas encore d'évaluation

- SUrevying and LevellingDocument80 pagesSUrevying and LevellingsarimfayyazPas encore d'évaluation

- Surveying-II: B.E. (Civil Engineering) Sixth Semester (C.B.S.)Document4 pagesSurveying-II: B.E. (Civil Engineering) Sixth Semester (C.B.S.)Mahesh RamtekePas encore d'évaluation

- 1 ST PDFDocument86 pages1 ST PDFSukesh MehtaPas encore d'évaluation

- Geotechnical Engineering 1 - RemovedDocument84 pagesGeotechnical Engineering 1 - RemovedMahesh RamtekePas encore d'évaluation

- Geotechnical Engineering Notes FullDocument84 pagesGeotechnical Engineering Notes FullMahesh RamtekePas encore d'évaluation

- 5 6337034553722405134 PDFDocument120 pages5 6337034553722405134 PDFMahesh RamtekePas encore d'évaluation

- 5 6336851171503767672 PDFDocument4 pages5 6336851171503767672 PDFMahesh RamtekePas encore d'évaluation

- Railway EngineeringDocument26 pagesRailway Engineeringanant100% (1)

- 5 6337034553722405133Document120 pages5 6337034553722405133Mahesh RamtekePas encore d'évaluation

- Arihant GK-Manohar Pandey (WWW - Sarkaripost.in)Document80 pagesArihant GK-Manohar Pandey (WWW - Sarkaripost.in)Saurav SarkarPas encore d'évaluation

- Soil Mechanics and Foundation Engineering by DR K.R PDFDocument903 pagesSoil Mechanics and Foundation Engineering by DR K.R PDFMahesh RamtekePas encore d'évaluation

- 5 6337034553722405133Document120 pages5 6337034553722405133Mahesh RamtekePas encore d'évaluation

- SR SR Chap3 PDFDocument64 pagesSR SR Chap3 PDFersachinpachoriPas encore d'évaluation

- CivilDocument730 pagesCivilEngr.Towhidul IslamPas encore d'évaluation

- Em 1Document18 pagesEm 1Mahesh RamtekePas encore d'évaluation

- TE II Question BankDocument5 pagesTE II Question BankMahesh RamtekePas encore d'évaluation

- Chapter 1Document23 pagesChapter 1Arun NesamPas encore d'évaluation

- V. Hari Krishna, R111794, Civil Engineering 4 Year, RGUKT, RK Valley, IdupulapayaDocument24 pagesV. Hari Krishna, R111794, Civil Engineering 4 Year, RGUKT, RK Valley, IdupulapayaMahesh RamtekePas encore d'évaluation

- V. Hari Krishna, R111794, Civil Engineering 4 Year, RGUKT, RK Valley, IdupulapayaDocument24 pagesV. Hari Krishna, R111794, Civil Engineering 4 Year, RGUKT, RK Valley, IdupulapayaMahesh RamtekePas encore d'évaluation

- Functions of A Marshalling YardDocument9 pagesFunctions of A Marshalling YardVishVishnuVMenonPas encore d'évaluation

- ACE GuidanceDocument53 pagesACE Guidancemohamed_gameel_3Pas encore d'évaluation

- Individual Qeustions 1springsDocument17 pagesIndividual Qeustions 1springsslv_prasaadPas encore d'évaluation

- Flange SupportDocument1 pageFlange SupportvijayanmksPas encore d'évaluation

- Hydraulic SystmDocument4 pagesHydraulic SystmArchana Choudhary100% (1)

- AdmixturesDocument27 pagesAdmixturesShubham ParmarPas encore d'évaluation

- The Concepts and Specification of Maintainance Ramp For Military VehicleDocument5 pagesThe Concepts and Specification of Maintainance Ramp For Military VehicleRestu PutraPas encore d'évaluation

- Unit Estimate of Circular Manhole of 1800 MM Dia Size and Depth of 7.5 MDocument9 pagesUnit Estimate of Circular Manhole of 1800 MM Dia Size and Depth of 7.5 MArvind BajpaiPas encore d'évaluation

- ASTMC Actual S-Curve Erwin 01-20-15Document69 pagesASTMC Actual S-Curve Erwin 01-20-15Dick Anthony MabaoPas encore d'évaluation

- C101 Electrolytic Tough Pitch CopperDocument2 pagesC101 Electrolytic Tough Pitch CopperMADDI MADHAV.Pas encore d'évaluation

- Chapt 10Document22 pagesChapt 10yaori700% (1)

- Cable Suspended Roof Structures Design & Construction GuideDocument12 pagesCable Suspended Roof Structures Design & Construction GuideYousif MustafaPas encore d'évaluation

- GTStrudl PushoverAnalysisDocument71 pagesGTStrudl PushoverAnalysisGeorge KaridisPas encore d'évaluation

- SB Oct07 DisclaimerDocument16 pagesSB Oct07 DisclaimerNgo Dieu Thuy TrangPas encore d'évaluation

- Progress Report 27.06.23 PT - Taro Rakaya Tasyra (Boiler)Document2 pagesProgress Report 27.06.23 PT - Taro Rakaya Tasyra (Boiler)Teknik Informatika VINA AZIZAHPas encore d'évaluation

- PLUMBINGDocument9 pagesPLUMBINGjustingollosossuPas encore d'évaluation

- Largest Brick Structure in The World JetavanaramayaDocument7 pagesLargest Brick Structure in The World JetavanaramayaTharindu Edirisinghe100% (1)

- Engineering Instructions - FTTH House WiringDocument18 pagesEngineering Instructions - FTTH House WiringReena SharmaPas encore d'évaluation

- Bill of Quantities: 1 Provisional SumDocument3 pagesBill of Quantities: 1 Provisional Sumnitish JhaPas encore d'évaluation

- Repairing and Rebuilding Houses Affected by The Canterbury EarthquakesDocument425 pagesRepairing and Rebuilding Houses Affected by The Canterbury EarthquakesJavier MtPas encore d'évaluation

- Jabal Al Zaytoon ClubDocument8 pagesJabal Al Zaytoon ClubPraveen KumarPas encore d'évaluation

- Prestress Beam DesignDocument11 pagesPrestress Beam DesignlfamelPas encore d'évaluation