Académique Documents

Professionnel Documents

Culture Documents

Effect of Temperature, Moisture, and Carbon

Transféré par

asep muhamadDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Effect of Temperature, Moisture, and Carbon

Transféré par

asep muhamadDroits d'auteur :

Formats disponibles

Copyright 2004 by Humana Press Inc. SSF of Soy Cake by P. simplicissimum All rights of any nature whatsoever reserved.

. 0273-2289/04/113/01730180/$25.00

173

Effect of Temperature, Moisture, and Carbon Supplementation on Lipase Production by Solid-State Fermentation of Soy Cake by Penicillium simplicissimum

MARCO DI LUCCIO,*,1 FERNANDO CAPRA,1 NAJARA P. RIBEIRO,1 GEAN D. L. P. VARGAS,1 DENISE M. G. FREIRE,2 AND DBORA DE OLIVEIRA1

Department of Food Engineering, URICampus de Erechim, Av. Sete de Setembro 1621, Erechim, 99700-000, RS, Brazil, E-mail: diluccio@uricer.edu.br; and 2 Department of BiochemistryIQ/UFRJ, Centro de Tecnologia, Bl. A, Sala 549-2, Rio de Janeiro, 21945-900, RJ, Brazil

1

Abstract

The production of lipases by Penicillium simplicissimum using solid-state fermentation and soy cake as substrate was investigated. The effects of temperature, cake moisture, and carbon supplementation on lipase production were studied using a two-level experimental plan. Moisture, pH, and lipase activity were followed during fermentation. Statistical analysis of the results was performed to evaluate the effect of the studied variables on the maximum lipase activity. Incubation temperature was the variable that most affected enzyme activity, showing a negative effect. Moisture and carbon supplementation presented a positive effect on activity. It was possible to obtain lipase activity as high as 21 U/g of dry cake in the studied range of process variables. Index Entries: Solid-state fermentation; lipase; Penicillium, soy cake; olive oil; moisture.

Introduction

The use of lipases in wastewater treatment in the food industry has been proposed to improve process efficiency (1,2). However, economical feasibility depends on low-cost enzyme preparations. Lipase production

*Author to whom all correspondence and reprint requests should be addressed.

Applied Biochemistry and Biotechnology

173

Vol. 113116, 2004

174

Di Luccio et al.

by solid-state fermentation (SSF) may be suitable because this kind of fermentation process presents many advantages over the submerged process, including higher productivity, higher product concentrations, and the use of simpler equipment and low-cost substrate such as agroindustry wastes. In addition, industrial plants for production of enzymes by SSF require low investment and operation costs (3,4). In a recent study, Castilho et al. (3) presented an economical evaluation of lipase production by Penicillium restrictum using both submerged fermentation and SSF. They demonstrated that the total investment required for a plant based on submerged fermentation was 78% higher than the investment necessary for installation of an SSF plant. The final enzyme cost in the submerged fermentation process was 68% higher than the cost of a commercial lipase (3). SSF proved to be a highly attractive alternative from an economical point of view. The use of a low-cost raw material (babassu oil extraction waste) coupled with a low investment decreased the final enzyme cost up to 47% lower than the cost of the commercial enzyme (3). The return of the investment was only 1.5 yr and the return rate was 62%, considering a 5-yr lifetime for the project. These aspects, make the production of lipase by SSF extremely promising. In this context, the aim of the present work was to study the effect of some cultivation parameters on lipase production by Penicillium simplicissimum using soy cake as substrate for application in wastewater treatment in the food industry.

Materials and Methods

Microorganism

The microorganism used was P. simplicissimum, previously isolated by Freire (5,6), using samples of babassu nuts, which were naturally fermented at a babassu oil plant.

Production of Inoculum

The medium used for inoculum production consisted of soluble starch (2% [w/v]), olive oil (1% [w/v]), yeast extract (0.1% [w/v]), MgSO47H2O (0.025% [w/v]), KH2PO4 (0.05% [w/v]), CaCO3 (0.5% [w/v]), and agar (1.5% [w/v]). The constituents of the medium were dissolved in deionized water, transferred to a 500-mL Erlenmeyer flask, and then sterilized at 111C for 30 min. The medium was inoculated with a spore suspension obtained previously from a stock agar slant and incubated at 30C for 7 d. Spores were collected by adding 10 mL of an aqueous solution of Tween80 (0.1% vol) and glass beads to the Erlenmeyer flask containing the fermented medium.

Cultivation Medium

The substrate used in all experiments consisted of soy cake, which is the byproduct of soybean oil extraction. The cake was milled and classified (Tyler 35-60) and then stored at 10C in vacuum packs. Fermentation was

Applied Biochemistry and Biotechnology Vol. 113116, 2004

SSF of Soy Cake by P. simplicissimum

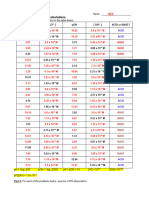

Table 1 Experimental Design and Results of Maximum Lipase Activity

Experiment Temperature (C) Olive oil Initial moisture (%) (%)

175

Maximum activity Time (U/g dry cake) (h) a

1 2 3 4 5 6 7 8 9

a

27 27 27 27 33 33 33 33 30

0 4 0 4 0 4 0 4 2

50 50 70 70 70 70 50 50 60

11.1 1.7 16.3 2.4 16.3 2.4 21.5 3.2 9.6 1.4 13.9 2.1 10.9 1.6 10.9 1.6 12.7 1.9

64.2 59.3 93.4 94.0 43.7 168.0 85.4 45.8 49.9

Time necessary to reach maximum lipase activity.

carried out in 600-mL polypropylene beakers covered with sheets of acrylic fabric. Each experimental point consisted of one beaker with 10 g of cake (dry basis) supplemented with the amount of olive oil and water following a two-level full factorial experimental design (Table 1). The water added with the inoculum was also considered in moisture correction. The beakers with the substrate were sterilized at 111C for 30 min. The medium was inoculated with the stock spore suspension collected as already described. The final spore concentration in the cake was 108 spores/g of dry cake. Spore concentrations were determined using a hematocytometer after appropriate dilution. The beakers were incubated for 7 d in a climatic chamber at different temperatures, with humid air injection. Relative humidity of the air inside the chamber was kept at about 99%. Samples were taken periodically to monitor pH, cake moisture, and lipase activity.

Experimental Procedure

The effect of incubation temperature, initial cake moisture, and olive oil supplementation on lipase production was evaluated following a twolevel experimental plan. The range of study of the variables was chosen based on previous results of the our group (2,7,10).

Analytical Methods

Two 0.5-g samples were taken from each beaker for moisture and pH determination. Moisture content was measured by gravimetry, and pH was measured after adding 5 mL of deionized water to the sample, using a pH meter. The enzyme was extracted from the remaining fermented cake by adding 45 mL of sodium phosphate buffer (100 mmol/L, pH 7.0) following incubation at 35C and 200 rpm for 30 min. After filtration the liquid phase was used for determination of lipase activity.

Applied Biochemistry and Biotechnology Vol. 113116, 2004

176

Di Luccio et al.

Lipase activity was determined by adding 2 mL of the extract to an emulsion of olive oil (10% olive oil, 5% Arabic gum in 100 mmol/L of phosphate buffer, pH 7.0.) and incubating at 37C and 200 rpm for 15 min. The reaction was stopped with the addition of a solution of ethanol and acetone (1:1). The fatty acids released in the hydrolysis were titrated with a solution of 0.04 N NaOH (5). Blank tests were performed by titration of a sample of emulsion without incubation, adding the enzyme extract sample just before the beginning of titration. One unit of lipase activity corresponds to the amount of enzyme that produces 1 mol of fatty acids/min in the reaction conditions just described. The total nitrogen of the substrate was determined following the standard Kjeldahl method (8). The oil content of the cake was determined by gravimetry after extraction of the samples with n-hexane using a Soxhlet extraction apparatus (8).

Results and Discussion

The mean content of oil and grease and of nitrogen of the cake, after milling and classification, was 13.0 and 5.4 wt%, respectively. The C/N ratio of the cake was estimated using the average triglyceride content of the soybean and olive oil (9), considering that the microorganism consumes preferentially the carbon of the oil, which is promptly available in the medium. The estimated C/N ratios for the nonsupplemented and for the 2 and 4 wt% supplemented cake were 1.87, 2.15, and 2.44, respectively. The results show that the cake is rich in oil. This explains the good lipase yields obtained even when the substrate is not supplemented with oil. The mean moisture of the cake was 7.6 wt%. This value was considered for moisture correction of the substrate. An experimental plan was designed with nine experiments, which were performed in duplicate to estimate experimental errors. The plan is presented in Table 1, as well as the results of maximum lipase activity and necessary fermentation time to reach the maximum activity in each experiment. It is known that the moisture content in the substrate is essential for good development of the microorganism in SSF (4). Therefore, the moisture of the cake during the fermentation was monitored in all experiments. In most of the studied conditions, the moisture was quite constant with time until 100 h of fermentation, considering an experimental error of 6%. The only exception to this behavior occurred at low initial moisture conditions. In such experiments, there was a strong decrease in moisture of the cake during the course of fermentation. The increase in incubation temperature caused a stronger decrease in cake moisture, probably owing to the higher water uptake rate by the microorganism and the increase in water vapor pressure in the system at higher temperatures. Figure 1 presents the kinetics of lipase activity for the different studied conditions. In all cases, a maximum in lipase activity could be observed,

Applied Biochemistry and Biotechnology Vol. 113116, 2004

SSF of Soy Cake by P. simplicissimum

177

Fig. 1. Lipase production at different conditions of moisture and supplementation: (A) 27C and (B) 33C.

often followed by a new increase by the end of fermentation. The decrease in lipase activity may be related to the effect of pH; temperature; or, still, the protease production by the microorganism, as shown by Gombert et al. (10) and Palma et al. (11) in previous studies with P. restrictum. The presence of proteases in the medium may cause deactivation of the lipase and even the complete loss of lipase activity. The increase in lipase activity at the end of fermentation may be related to the production of a new lipase or decrease in the protease activity. However, new experiments, in which protease activity should be determined, are necessary for confirmation of such a hypothesis. The mean experimental error of lipase activity, calculated based on duplicates, was 14%. In a preliminary analysis, we noted that the production of lipase was higher at lower temperature (27C). This result was later confirmed by statistical analysis, which is discussed in the next section. The negative effect of temperature may be related to the increase in the protease activity at higher temperatures.

Applied Biochemistry and Biotechnology Vol. 113116, 2004

178

Di Luccio et al.

Fig. 2. Evolution of pH during fermentation at different conditions of moisture and supplementation: (A) 27C and (B) 33C.

Supplementation of the substrate with oil led to an increase in lipase activity and a reduction in the time required to reach the maximum activity. This might be owing to acceleration of the metabolism of the microorganism. However, the time to reach the maximum must be analyzed carefully, since factors such as inoculum age and physiologic state may directly affect this result. Figure 2 shows pH evolution during fermentations. The mean experimental error of pH was 2.2%. pH increased after 24 h of fermentation, and in some experiments it reached 8.5 after 70 h of fermentation. In all experiments the increase in pH may be correlated to the decrease in lipase activity. This behavior is probably owing to the proteolysis, which yields ammonia to the culture medium, increasing pH (6). A decreasing pH trend could also be noted after 100 h of fermentation, matching the new increase in lipase activity. This behavior suggests a reduction in the protease activity in the medium.

Applied Biochemistry and Biotechnology Vol. 113116, 2004

SSF of Soy Cake by P. simplicissimum

Table 2 Best Fit for Maximum Lipase Activity in Function of Temperature, Moisture, and Olive Oil Content a Model: AT = a0 + a1 T + a2 OO + a3 M + a4 T M + a5 T OO Dependent variable: AT Loss function: ([OBS-PRED]2)/S2experim Final value of loss function: 0.117 R2: 0.97 Parameter b Estimate SE a0 2.76 0.07 a1 0.487 0.065 a2 0.371 0.079 a3 0.338 0.076 a4 0.256 0.078

179

a5 0.156 0.080

a AT, maximum lipase activity; T, temperature; M, moisture; OO, % olive oil; a0, a1, a2, a3, a4, and a5, model parameters; S2experim, experimental variance. b Confidence level >95%.

Statistical Analysis

Statistical analysis of the results was performed using the software Statistica 5.5 (Stat Soft). Maximum lipase activities and time to reach the maximum were calculated through fitting of kinetic curves. The maximum was estimated by derivation of the fits. Empirical models were built to fit maximum lipase activity in the function of incubation temperature (T), moisture of the cake (%M), and supplementation (%OO). The experimental error estimated from the duplicates was considered in the parameter estimation. The choice of the best model to describe the influence of the variables on lipase activity was based on the correlation coefficient (r2) and on the 2 test. The model that best fits the experimental data is presented in Table 2. Note that the three variables present quite the same effect on maximum lipase activity. Nevertheless, temperature presented a negative effect, which was unexpected, since the metabolism of mesophyllic microorganisms tends to increase with temperature in the range investigated. In this situation, the negative influence might be related to the strong correlation between temperature and substrate moisture. The increase in temperature may lead to the decrease in cake moisture, owing to the increase in vapor pressure of the water. An indication of such an effect may be observed by the strong correlation between moisture and temperature effects (parameter a4). This correlation also negatively influences the activity to the same degree as the other isolated variables. Other possibilities may be related to a higher level of denaturation of the produced lipase induced by the increase in temperature or to the increase in the proteolytic activity, so that the balance for lipase favors deactivation rather than production. The concentration of olive oil and moisture content showed positive effects in the range investigated. The increase in olive oil content may favor lipase production by the microorganism owing to accelerated metabolism.

Applied Biochemistry and Biotechnology Vol. 113116, 2004

180

Di Luccio et al.

The increase in water content in the medium also increased the metabolic activity of the mold, resulting in a higher lipase production. These results were also observed by Gombert et al. (10) for lipase production using P. restrictum in babassu cake. The time to reach the maximum lipase activity did not show any satisfactory correlation with the studied variables. This behavior is probably owing to the high error associated with this variable or with other factors, such as inoculum age and concentration, which were not considered in the statistical analysis and may be influencing this response, although inoculum standardization procedures were used in all the experiments. Fermentation time was not found to be a determinant factor. However, this may be important on an industrial scale, since it can directly compromise enzyme productivity and production costs.

Conclusions

Our study showed that incubation temperature is the variable that most influences lipase production by P. simplicissimum using soy cake as substrate, even though it shows a negative effect. To maximize lipase production, fermentation should be carried out at low temperature levels, high moisture in the substrate, and higher concentration of oil. However, good results may also be obtained at lower temperatures without cake supplementation, owing to its high oil content. The use of soy cake is a promising substrate for lipase production. Even without optimization it is possible to achieve lipase activity as high as 21 U/g of dry cake, comparable with lipase activity obtained with other microorganisms and substrates.

References

1. Jung, F., Cammarota, M. C., and Freire, D. M. G. (2002), Biotechnol. Lett. 24, 17971802. 1 2. Cammarota, M. C., Teixeira, G. A., and Freire, D. M. G. (2001), Biotechnol. Lett. 23, 2 15911595. 3. Castilho, L. R, Polato, C. M. S., Baruque, E. A., and SantAnna, G. L., Jr. (2000), Biochem. 3 Eng. J. 4, 239247. 4. Del Bianchi, V. L., Moraes, I. O., and Capalbo, D. M. F. (2001), in Biotecnologia Industrial: Engenharia Bioqumica, vol. 3, Schmidell, W., Lima, U.A., Aquarone, E., and Borzani, W., eds., Edgard Blcher, So Paulo, Brazil. 5. Freire, D. M. G. (1996), PhD thesis, PEQ/COPPE/UFRJ, Rio de Janeiro, Brazil. 5 6. Freire, D. M. G., Gomes, P. M., Bon, E. P. S., and SantAnna, G. L., Jr. (1997), Revista Microbiologia 28(1), 612. 7. Leal, M. C. M. R., (2000), MS thesis, PEQ/COPPE/UFRJ, Rio de Janeiro, Brazil. 8. Pregnolatto, W., Pregnolatto, N. P. (coord.), and Rebocho, D. D. E. (ed.) (1985), Normas analticas do Instituto Adolfo Lutz: vol.1. Mtodos qumicos e fsicos para anlise de alimentos, 3rd Ed., Instituto Adolfo Lutz, So Paulo, Brazil. 9. MCT, Ministrio da Cincia e Tecnologia (Ministry of Science and Technology) (1985), Technical Report on Vegetable Oils, MCT. 10. 10 Gombert, A. K., Pinto, A. L., Castilho, L. R., and Freire, D. M. G. (1999), Process Biochem. 35, 8590. 11. Palma, M. B., Pinto, A. L., Gombert, A. K., Seitz, K. H., Kivatinitz, S. C., Castilho, L. R., and Freire, D. M. G. (2000), Appl. Biochem. Biotechnol. 8486, 11371145.

Applied Biochemistry and Biotechnology Vol. 113116, 2004

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 2 2+Power+NotesDocument1 page2 2+Power+Noteskparsons938512Pas encore d'évaluation

- Chapter 12 - Surface Water TreatmentDocument36 pagesChapter 12 - Surface Water TreatmentDwi Yerlis RahmiPas encore d'évaluation

- Lab 7 Soil PH and Salinity ObjectiveDocument5 pagesLab 7 Soil PH and Salinity ObjectiveViola Voon Li WeiPas encore d'évaluation

- Methods Controlling Depolymerization Polymer CompositionsDocument25 pagesMethods Controlling Depolymerization Polymer CompositionslgilPas encore d'évaluation

- The Chemistry of CleanDocument7 pagesThe Chemistry of Cleandfantastic_KKPas encore d'évaluation

- IN-B800 Blood Gas & Electrolyte Analyzer - ICENDocument3 pagesIN-B800 Blood Gas & Electrolyte Analyzer - ICENHari KarkiPas encore d'évaluation

- Silver Recovery From Photographic FilmDocument9 pagesSilver Recovery From Photographic FilmMohammad YoussefiPas encore d'évaluation

- Review of Related Literature Align WithDocument4 pagesReview of Related Literature Align WithJoshua VidalPas encore d'évaluation

- CHM271 - Chapter 3 - Ionic EquilibriumDocument49 pagesCHM271 - Chapter 3 - Ionic Equilibriumnur artikaPas encore d'évaluation

- Ab-082 4 enDocument12 pagesAb-082 4 enMARIANA SOFIA RODRIGUEZ VIVESPas encore d'évaluation

- PhotodegradationDocument8 pagesPhotodegradationLuminita AndronicPas encore d'évaluation

- ChemistryDocument1 pageChemistryDennoh OlengoPas encore d'évaluation

- Half Yearly Examination SESSION 2015 - 16 Class Xi Subject - ChemistryDocument4 pagesHalf Yearly Examination SESSION 2015 - 16 Class Xi Subject - ChemistrySuman SouravPas encore d'évaluation

- GrandeCIG Ultra WPI Case Study PDFDocument3 pagesGrandeCIG Ultra WPI Case Study PDFRam SantoshPas encore d'évaluation

- Ionic Equillibrium PDFDocument26 pagesIonic Equillibrium PDFHaltz t00nPas encore d'évaluation

- Ionization of WaterDocument18 pagesIonization of WaterrodneyperuPas encore d'évaluation

- 05 Determining The Molar Volume of A GasDocument8 pages05 Determining The Molar Volume of A Gaslouise50% (4)

- Protolytic ReactionDocument8 pagesProtolytic ReactionRobo KnapPas encore d'évaluation

- How To Calibrate and Use A PH Meter - 14 Steps (With Pictures)Document4 pagesHow To Calibrate and Use A PH Meter - 14 Steps (With Pictures)Shumraiz MPas encore d'évaluation

- Dye Removal Batch ProcessDocument15 pagesDye Removal Batch ProcessKedhareesh KPas encore d'évaluation

- Biochemistry-1 BCHT 201 Lab ManualDocument33 pagesBiochemistry-1 BCHT 201 Lab ManualBander Al BloyPas encore d'évaluation

- Record 12A: Measuring PH To Validate Your Acidification ProcessDocument2 pagesRecord 12A: Measuring PH To Validate Your Acidification ProcessJyot SoodPas encore d'évaluation

- Assignment 1Document2 pagesAssignment 1shuvobosu262Pas encore d'évaluation

- Ash Well 1957Document33 pagesAsh Well 1957Eko Isro RiyantoPas encore d'évaluation

- Acids and Bases Used Natural Indicators (Hibiscus Flowers)Document5 pagesAcids and Bases Used Natural Indicators (Hibiscus Flowers)Winda SglgPas encore d'évaluation

- DR - MPR - ElectrochemistryDocument25 pagesDR - MPR - ElectrochemistryRishan KundetyPas encore d'évaluation

- Sample Galvanizing Procedure +ITPDocument14 pagesSample Galvanizing Procedure +ITPsubash sivalingam67% (3)

- Fertilization and Irrigation Theory and Best Practices. Table of ContentsDocument5 pagesFertilization and Irrigation Theory and Best Practices. Table of Contentsvadira.baesuPas encore d'évaluation

- Env Lect w4Document19 pagesEnv Lect w4Sohail TariqPas encore d'évaluation

- PH Worksheet SolutionsDocument3 pagesPH Worksheet Solutionsxdiep10Pas encore d'évaluation