Académique Documents

Professionnel Documents

Culture Documents

Processing and Quality Analysis of Milk

Transféré par

Ataul HakimDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Processing and Quality Analysis of Milk

Transféré par

Ataul HakimDroits d'auteur :

Formats disponibles

WELCOME MULTI HELP LINE

A PROJECT REPORT ON

PROCESSING AND QUALITY ANALYSIS OF MILK

SUBMITTED TO : Department of Food Science

SUBMITTED BY : . B.Sc. III (Food Science) Roll No. :

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

ACKNOWLEDGEMENT

It is my proud privilege to my deep sense of gratitude to , teacher of Food Science Department of .. College, for expert guidance and encouragement to sustain in this report. I would like to be thankful to my classmates for useful discussion and for their constant help and co-ordination and for successful completion of this project.

. B.Sc.III, Food Science.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

CERTIFICATE

This is to certify that this project report entitled Processing and Quality Analysis of Milk submitted for the course of B.Sc. Food Science is written by .. with the help of accessible literature under the guidance of ..

Department of Food Science . College, ..

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

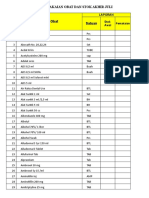

INDEX

Sr. No. 1

Contents PFA Definition and Chemical Composition of Milk

2 3 4 5 6 7 8 9 10 Annexure I II III IV

Introduction Procurement of Milk Reception of Milk Processing of Milk Quality Control Tests for Milk Butter Manufacturing Quality Control Tests for Butter Ghee Manufacturing Quality Control Tests for Ghee

Graph of Milk Receipt Graph of Table Butter Production Graph of Milk Sale Graph of Ghee Production

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

PFA DEFINITION OF MILK AND CHEMICAL COMPOSITION OF MILK

Milk may be defined as the whole, fresh, clean, lacteal secretion obtained by complete milking of one or more healthy milch animals, excluding that obtained within 15 days before or 5 days after calving or such periods as may be necessary to render the milk practically colostrums free and containing the minimum prescribed percentages of milk fat and milk solids not fat.

CHEMICAL COMPOSITION OF MILK

Table No. 1 Constituent Buffalo Milk % 1. 2. 3. 4. Water Fat Protein Lactose 84.2 6.6 3.9 5.2 Cow Milk % 86.6 4.6 3.4 4.9

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

INTRODUCTION

The Gurgoan and Rohtak Cooperative milk producers union limited. Vita milk plant is situated on Rohtak-Gohana road. As the name of the plant itself suggests. It is a co-operative milk plant. It is some 5-6 km. North of the main bus stand and railways station on Rohtak city. It is an ISO-9002 and HACCP certified unit. This plant was established by National Dairy Development Board (NDDB) in 1976. The capacity of the working staff is about 270.

Vita milk plant, Rohtak is having regional chilling centres located at Jhajjar, Jatusana, Bhiwani and Narnaul. The chilling capacity of these centres has been mentioned as below :

In summer (it./day) Narnaul Jhajjar Bhiwani Jatusana 550 750 800 1000

In winter (It./day) 4000 5500 4000 25000

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

MILK PROCUREMENT SECTION

It is one of the important section of the plant. The milk is procured from nearby villages of Rohtak, Bhiwani, Sonepat, Bahadurgarh, Hisar and Gurgon cities. The milk procurement section is supervised by a Senior Milk Procurement officer which is assisted by three to five Assistant Milk Procurement Officers (A.M.P.Os). Each A.M.P.O. has 5 subordinate officers. The procured milk is paid with standard price depending on the quality of milk. The quality of milk in turn is determined by measuring percent fat and percent S.N.F. The standard rate for 1kg. fat is Rs. 164.25 and the kg. fat is calculated by using following formula.

Weight of milk X fat % Total kg. fat = ----------------------------------------100

Deduction or addition to the price is made correspondingly with the S.N.F. percentage. Milk measuring S.N.F. below 8.8% will be paid a price deducted at the rate of 1.5 paise per point.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

If S.N.F. percentage is 8.0-7.5% the price is deducted at rate of 10 paise per point. The milk containing S.N.F. and fat 7.5% and 3% respectively will be paid 50% of the actual rates.

The milk is procured from registered co-operative societies. At present there are 495 registered functional milk producers co-operative societies in the area.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

The following processed products are manufactured.

1.

FLUID MILK a) b) c) d) Full cream milk Toned milk Double toned milk skim milk

2. 3.

Table butter Ghee

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

RAW MILK RECEPTION : Milk procured from various co-operative societies is received in this section. It also includes the weighing of milk and preparation of truck sheet. The reception of milk has been illustrated by following schematic flow chart. Flow Chart for Reception of Milk :

Unloading of Cans

Placing the cans on the conveyor

Dumping the cans of a particular society in the weighing bowl

Drawing of sample from the milk of a particular society

Passing the cans to can washer

Trafficking of milk to the processing section with suction motor

Washing the cans with water mixed with soda or detergent* Cleaning the cans by hot water at 90oC Drying the cans by circulating air at 90oC * Trisodium phosphate

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

The place where the raw milk is received from the vehicles is called dock. Various chemical and organoleptic tests are conducted at this place for checking the quality of milk and termed as dock testes or platform tests. A sample of 200ml is kept in laboratory for 24 hours as a satisfying measure so that is the vendor is not satisfied with tests, then the same may be carried out again. The various testes carried out for first hand quality checking of milk are listed below :

1. 2. 3. 4. 5. 6.

Fat SNF Acidity Sediments C.L.R. Specific gravity

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

PROCESSING OF MILK : Processing of milk involves operations. The raw milk can be processed into a number of processed products of consumer liking. Only good quality milk is allowed for processing to obtain good quality products.

The products are following :-

1. 2. 3.

Fluid Milk Table Butter and Ghee

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

PASTEURIZED MILK : MANUFATURING, PACKAGING AND STORAGE : Flow chart for pasteurized milk.

Reception of milk

(Grading, Sampling, Weighing and Testing) Pre heating at 35-40oC

Filtration/Clarification Cooling and Storage (5oC or below)

Standardization Pasteurization (63oC/30 min. or 72oC/15 Sec.)

Homogenization 2500 (psi.)

Bottling and packaging Storage(5oC or below)

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

Receiving Milk : Milk is received on the dock and various dock tests or platform tests are carried out which include test for smell, appearance, acidity, lactometer reading, clot on boiling and MBRT.

Pre-heating : Heating the incoming milk just before the processing operations is called preheating. This operation is carried out to facilitate efficient filtration and clarification also for efficient flow of milk. The temp. of preheating is set at 35-40oC.

Filtration/Clarification : Filtration removes suspended particles, dirt etc. by straining process. Clarification removes the same by centrifugal sedimentation. The main object of this step is to improve the aesthetic quality of milk as it removes visible foreign matter.

Chilling and Storage : The filtered milk is cooled and stored at 5oC or below to extend the shelf life of the milk prior to further processing.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

Principal and Working of the chiller : The chilling process is based on the basic principal of heat exchange through media. A typical chiller is constructed of tightly packed/stacked stainless steel plates with gasket in between to protect and leakage of milk. The plates are so adjusted that milk goes from first plate to the third and then to fifth plate. Chilled water runs in counter direction from second plates to fourth and so on. Chiller have two inlet valves and two outlet values. After chilling to a temperature of 5oC. The milk is transferred to large

storage tanks also referred as silos. The capacity of chiller depends upon the number plates. A chiller with 50 plates has chilling capacity of 5000lt./hr. The capacity of silos in use at this plant ranges from 10,000 to 33,000 liters.

Standardization : It refers to adjustment i.e. raising or lowering, of fat and solids-not-fat percentages of milk to a desired value. Milk is standardized by addition of milk or cream with a higher or lower fat% than that of the material to standardized. For standardizing, usually persons square method is used.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

Specification of Processed Liquid Milk :

Fat%

SNF%

1.

Full cream milk

6.0

9.0

2.

Tonned milk

3.0

8.5

3.

Double tonned milk

1.5

9.0

4.

Skim milk

0.5

9.0

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

Pasteurization : The terms pasteurization, refers to heating every particle of milk to atleast 63oC for 30 min. or 72oC for 15 sec. so as to destroy maximum pathogenic micro-organisms and to improve the keeping quality to the milk.

A typical pasteurizer has following sections.

a. b. c. d.

Regeneration section Heating section Holding section Chilling section

Process of Pasteurization : Milk received from balance tank enters into the regeneration section where it gets heated by the outgoing pasteurized milk at 72oC. The temp. of milk coming from balance tank reaches to 40-42oC and flows through valve to filter. After being filtered, the milk proceeds further to heating section where it gets heated with the help of hot water or steam to a temperature of 72oC. if the milk is properly pasteurized then it moves to regeneration section where it becomes somewhat cool as it comes in contact with the incoming milk, but if the pasteurization temperature is not reached properly then milk is diverted back for reprocessing by a flow diversion valve.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

Specification of Pasteurizer : Capacity of Pasteurizer Temperature of heating section Temperature of chilling section Temperature of hot water Temperature of chilled water Holding time for milk 10,000lt./hr. 72. 5oC 4.5oC 80oC 4o C 15-20 sec.

After pasteurization is over, the processed milk is packed into poly packs and them stored.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

QUALITY CONTROL TESTS FOR MILK

When milk is received on the platform, it has to undergo a number of examinations and tests. These tests are carried out to determine the quality of incoming milk and it is on the basis of these tests whether a particular lot is to be rejected. The most common of these are determination of fat%, SNF, total solids and sediments etc.

Organoleptic Test The sensory evaluation of milk is of utmost importance to the market milk industry. The sale of fresh milk is a major activity of the Indian dairy industry. Since milk is consumed in the liquid state by all classes of people, it is judged daily be the consumers. All the five senses viz., sight, smell taste, touch and sound are used in judging and grading of milk.

Objectives To accept/reject raw milk on the basis of sensory observations.

Procedure Removal of lid of the can Smell the milk and lid in case of any doubt, taste it by putting a small quantity on the tongue and spit it out in a spittoon. Feel the coldness/warmth of milk from outside the can. In case of doubt, temperature may be observed with the help of a thermometer.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

Observe for any abnormality in colour and extraneous matter in milk.

Observations Smell/odour of milk Taste of milk Colour Sediment Temperature Interpretation

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

Correct Lactometer Reading (C.L.R.) The estimates the amount of solid-not-fat (SNF) present in the milk sample. For this purpose Lactometer is used. Prior to filling the metallic cylinder upto brims with milk sample the temperature of milk (29oC) is noted. The lactometer is then inserted inside the cylinder containing milk, and the temperature of the milk is noted again. The scale of lactometer projecting above the milk gives the lactometer reading. If the temp. of the milk is 29oC then the lactometer reading itself is taken as CLR and if the temp. is below or above 29oC, then for each degree rise or fall of temp. o.5 is added or deducted from the observed lactometer reading. Solid-not-fat is determined by using following expression.

SNF = CLR + 0.21 fat + 0.66 4 Suppose CLR is = 28.0 and Fat% = 6% then. SNF = 28 + 0.21 x 6 + 0.66 4 = 7 + 1.26+0.66 SNF = 8.92%

Clot on Boiling Test (COB) : Principle : COB test will be positive if acidity is more than 0.2%

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

Procedure : Take about 5ml of well mixed sample in a test tube. Keep it in a water bath for 5 min., or rotate it almost horizontally on a spirit lamp so as to boil the milk. Interpretation : Clotting of milk on the side of tube or at the bottom indicates poor keeping quality. Keeping quality. COB + ve milk should be separated and not mixed with good milk. For good quality of milk COB should be ve i.e. no clot should form on boiling. Natural Acidity of Milk : Ten ml of milk is mixed well with as much amount of distilled water in a flask and the 1-2 drops of phenolphthalein indicator are added. Then N/9 NaOH is run down from a burette to the content is the flask until a light pink color appears. The amount of N/9 NaOH utilized is noted down. 1 ml of N/9 NaOH solution is equivalent to 0.01 g of lactic acid. Good quality milk has 0.12-0.15% lactic acid, sour milk has 0.15-0.20 lactic acid and curded milk has 0.7 to 2.0% lactic acid.

pH OF MILK USING pH PAPER : Certain indicators show change in colour with the change in pH. The pH paper or strips are impregnates with these indicators such as

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

bromothymol blue (pH 6.0 to 7.6) and bromocresol purple (pH 5.2 to 6.8). pH papers in narrow range and wide range are available. Objectives : To study the freshness of milk. Reagents : pH paper strips Procedure : Take a small quantity of milk in the test tube. Dip the pH strip in the milk. Compare the colour changes with standard chart and note the pH. Precaution The result with pH paper are not precise and for more precision pH meter is used. The pH strips should be stored in a glass bottle properly stoppered in dry conditions. Observations Sample No. 1 = Sample No. 2 = Sample No. 3 = Sample No. 4 = Interpretation Normal milk pH is between 6.6-6.8. pH above 6.9 is indication of mastitic milk/late lactation milk.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

Phosphate Test : This test is taken as an indicator of proper pasteurization. To determine whether a lot of milk is properly pasteurized or not. 10ml of the pasteurized milk sample is mixed with 1 ml. of p-nitrophenyl disdium. This is then kept at 37oC temp. for 30 minutes and observed for appearance of yellow coloration. Underpasteurized milk give yellow color while properly pasteurized milk will give no coloration. Alcohol Test : The alcohol test determines the susceptibility milk of coagulate due to developed acidity or unbalance salt. This test is of prime importance in milk to detect milk which has a tendency to curdle during processing sterilization or pasteurization. Procedure : Five ml of raw milk is mixed with 5ml of 8% absolute alcohol, if precipitation occurs then the alcohol test is + ve i.e. milk is least heat stable. Absence of any precipitation indicates appropriate heat stability of milk. Methylene Blue Reduction (MBRT) : MBRT is one of the most important tests for quality assessment of milk. It is an indicator of shelf life or keeping quality of milk in addition of checking whether milk is properly pasteurized or not. To determine the test, 10ml milk is taken in a test tube and to it 1 ml of methylene blue dye is mixed. The content is heated and kept in a water bath at a temp. of 37oC.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

Methylene blue dye is prepared in oxidized form. Bacteria Present in milk reduce this dye in a short time. So if blue colour in the test tube (dye+milk) is changed to white in short time, this shows that larger count of bacteria is still present in the milk which is attributed to improper pasteurization. Detection of Starch added as Adultrant in Milk : To detect the presence of added starch in milk sample thoroughly mixed sample of 2 ml is mixed with 2 ml of 1% iodine solution and observed for blue coloration. Appearance of blue color indicates presence of added starch. Detection of Added Carbonates and Bicarbonates in Milk : Milk samples containing added carbonates or bicarbonates develop a rose red color with rosalic acid, pure milk on the other hand gives only a brownish coloration. Observation : 1. Interence : a. b. Inference : a. No carbonates/bicarbonates present. Carbonartes and bicarbonates are present. Light brown/Light red rose colour. Red Rose Color

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

Detection of Added urea in Milk : Two ml of milk is taken in a test tube and mixed with 2ml of amino benzaldehyde and observed for coloration. Presence of deep yellow color indicated the presence urea in milk. Appearance of light yellow color indicates absence of urea. Moisture content : The percent moisture content in ghee and butter is determined by following method. About10g. of the sample (ghee/butter) is weighed in a dried aluminum dish. The sample is heated on a hot plate till the moisture is removed which is indicated by disappearance of bubbles or commencement of smoke. The sample in dish is cooled in desiccator and is weighed again. The % moisture is calculated as: Initial Wt. Final Wt. Moisture (%) = ----------------------------------Initial Wt. Ghee should not contain more than 0.3% moisture and butter should not have moisture content more than 16%. X 100

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

DETECTION OF ADULTERANTS 1. CANE SUGAR :

Principle : Sugar is added to increase the density to prevent detection of added water. Procedure a. b. c. d. Take 10ml of milk in a test tube. Add 1ml of conc. HCL and mix. Add 0.1g of resorcinol powder and mix thoroughly. Place the tube in a boiling water bath for 5 min. and observe the colour. Interpretation : Red color obtained indicates the presence of cane sugar.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

BUTTER

Definition : Butter may be defined as a fat concentrate which is obtained by churning cream, gathering the fat into a compact mass and then working it. According to PFA Rules (1976), table or creamery butter should contain not less than 80% fat, not more than 1.5% curd and not more than 3.0% common salt. Constituent Butter Fat Moisture Salt Curd Percentage 80.2 16.2 2.5 1.0

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

MANUFACTURING, PACKAGING AND STORAGE

Flow diagram of manufacture of butter :

Receiving milk Grading Weighing Sampling Testing

Receiving milk

Pre-heating (35-40oC) Separation (Centrifugal)

Neutralization

Cream Standardization (35-40%fat) Pasteurization (82-88oC/No hold) Cooling (20-22oC) Cooling Ripening(20-+22 C) Agening (5-10oC) Churning Washing Salting and Working Packaging and Storage (-23to 29oC)

Downloaded from : www.multihelpline.com

o

WELCOME MULTI HELP LINE

Details of Various Steps : 1. Neutralization of Cream : This refers to the partial reduction of the acidity. The most commonly used neutralizers are Sodium bicarbonates and Calcium hydroxide. The main purposes of neutralizing the cream are to avoid excessive fat loss in buttermilk that results from the churning of highly acidic pasteurized milk to improve the keeping quality of butter and to guard against the production of the undesirable off-flavours. 2. Standardization of Cream : The adjustment of the fat levels of the cream to the desired percentage, conforming to the standard requirements is called standardization. The standard fat requirement for cream is 30-40%. This is achieved by addition of calculated amount of skim milk. 3. Pasteurization : It refers to the process of heating every particle of cream to not less than 710C (1600F). The pasteurization operation in very important and is carried out keeping in view the following objectives.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

a.

To destroy the pathogenic micro-organisms in cream so as to make it and also the resultant butter safe for human consumption.

b.

To destroy undesirable mico-organisms and to inactive the enzymes present, so as to prolong the keeping qualities of cream and butter.

c. d. e.

To complete the neutralization process. To eliminate some of the gaseous tainting substances, and To make possible the removal of some volatile off-flavour (such as feed and weed flavours) during vacreation.

4.

Cooling and Ageing of Cream : Cream is cooled to 5-10oC and hold at as much temperature for a few hours. After pasteurization it becomes necessary to cool and age the cream to make churning possible. Cream will not chum until the butterfat in the fat globule has at least partially solidified or crystallized. If cooling and ageing of the cream are not optimum, the fat globule will not solidify sufficiently there by causing excessive loss of fat in butter milk which in turn results in unsatisfactory and weak body.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

5.

Ripening of Cream : This refers to the fermentation of cream with the help of desirable starter culture. The starters used for ripening are Streptococcus lactis and/or Streptococcus cremoris that produces aroma (diacetyl) in combination with Streptococcus diacetilactis and Leuconostoc citrovorum. Produces pleasing pronounced characteristic flavour and aroma. Provides exhaustive churning i.e. a low fat loss in buttermilk.

6.

Churning : Churning of cream consists of agitation at a suitable temperature (9-110C) until the fat globules adhere, forming larger and larger masses and until a relatively complete separation of fat and serum occurs.

7.

Salting : This signifies the addition of a calculated amount of salt to butter. This is done for following reasons : a) b) c) To improve keeping quality To enhance taste To increase overrun

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

8.

Working : The working of butter portrays kneading of the butter to achieve following objectives. a) To completely dissolve uniformly distribute and properly

incorporate the salt. b) To expel buttermilk. c) To control the moisture content of butter. d) To fully incorporate the added make up water in the butter. 9. Storage : The worked butter is stored under cold storage condition wherein temp. ranges from -230C to 290C.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

QUALITY CONTROL TESTS FOR BUTTER

1.

MOISTURE (GRAVIMETRIC METHOD) :

Procedure : a) b) c) Take clean dry flat bottom aluminum dish and weigh. Take 10g of sample into the dish and weigh it. Put the dish on steam water bath or on hot plate with frequent stirring until no moisture is seen at the bottom of the dish and curd particles turn slightly brown in color. d) Wipe the bottom of the dish and keep in an oven at 100+10C for 90 min. e) f) Cool the dish in a dessicator and weigh. Repeat the process of heating (30min.) cooling, weighing until the difference between two consecutive weighting does not exceed 0.1mg. Interpretation : Moisture % should not exceed 16%.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

B.

SALT :

Procedure : a) b) Weigh 10g of butter in a beaker. Add hot distilled water to melt the butter and transfer it into a separating funnel without disturbing the top fat layer, run down the water layer in a 250ml volumetric flask. c) Wash repeatedly the fat left in the separating funnel thrice with small quantities of hot distilled water and collect the washings. d) Cool the contents to room temperature and make up voloume to 250ml mark with distilled water. e) Take 25ml of this sol and add 1ml potassium chromate indicator and titrate against 0.1N silver nitrate until a brownish colour persists for min. Interpretation : Salt % = 5.85 x N x B/A N B A Normality of AgNO3 Vol. of AgNO3 used Wt. of butter i.e. 10g

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

GHEE MANUFACTURING

Definition : According to PFA Rules (1976), ghee is the pure clarified fat derived solely from milk or from desi (cooking) butter or from cream to which no coloring matter is added.

METHOD OF MANUFACTURING

Near about 80% of the Indias total ghee production is contributed by country of desi method of ghee making. The remaining 20% is manufactured by the organised sector of the industry. In the Vita milk plant Rohtak ghee is manufactured by using cream butter process.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

To understand the method used in the plant for ghee manufacturing a comparison with desi method has been done diagrammatically as under :

Milk

Centrifugal Separation

Fermentation

Cream

Curd

Ripened / Unripened

Churning (Indigneous)

Churning

Creamy Butter

Desi Butter

Direct Clarification

Pre-stratification

Ghee

Cooling / Granulation Packaging and Storage

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

The cream is separated from milk by making use of centrifugal forces. The cream thus obtained to get butter. This solid mass of butter is transferred to double jacketed large vats. The butter is then melted into the vats by hot water or steam. On the later stages of heating, the temperature of vats is raised so that the melted mass temp. is made constant till all the vapour is driven out. During the entire course of conversion of butter into ghee, constant agitation is maintained. The scum which gathers on the top of surface of the boiling mass is removed from time to time with a perforated ladle. From her the melted butter is transferred into kettles provided with opening valves at the bottom. The temperature of the mass/product is raised to 90-100oC. This step has to be monitored carefully. Appearance of effervescence and browning of curd particles indicate the end point. The ghee is now cooled at a temperature 45-50oC and sedimented. This is then filtered through a fine muslin cloth and then goes for granulation and packing.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

Specification : Particulars 1. 2. 3. Adaptation Stages By products Creamery Butter Method Large Scale Three (Cream, Butter, Ghee) Buttermilk, Ghee Particles

Standards and Specification of Ghee Moisture F.F.A. Taste Residue 0.25% max 0.5% Pleasant Absent

Packaging of Ghee : Ghee is packaged in the packaging section in 1kg., 2kg., pouches or tins and also in tins of 14kg. of capacity.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

QUALITY CONTROL TESTS FOR GHEE

1. MOISTURE :

Procedure : a) b) c) d) e) f) Weigh a dried and cooled moisture dish. Weigh 10g of sample in this dish. Keep the dish in hot air oven at 105+1oC for 1 hr. Take out dish from oven and cool, weigh it. Keep the dish in the oven for hr., cool and weigh it. Repeat heating, cooling and weighing until the loss of wt. between two consecutive weightings does not exceed mg. Interpretation : B-C x 100 Moisture % by wt. = -------------------BA

B C A

Wt. of sample in dish Wt. of dish after heating cooling of ghee Wt. of empty dish Moisture should not more than 0.3%.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

2.

FREE FATTY ACID (AS OLETIC ACID) :

Procedure : a) b) Weigh 10g of sample in a 250ml conical flask. Add 50ml of neutralized alcohol in the flask and mix the contents. c) Digest the mixture over a hot water bath at 50oC for 15 min by continuously agitating the flask. d) Titrate immediately with 0.1N Sodium hydroxide using 1ml of phenolphthalein indicator. e) The end point of the titratin is reached when the addition of a single drop produce a slight, but definite change, persisting for 15 sec. f) Read the volume of Sod. Hydroxide used during titration (v).

Interpretation Free fatty acid (%oleic acid) = A 2.82 V/A

Wt. of Sample taken.

Free fatty acid should not be more than 1.2%. 3. MINERAL OIL TEST :

Procedure : Take 50ml of ghee. Boil it. Add 22ml of alcoholic KOH and 25ml boiled distilled water. Wait for a minute.

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

Interpretation : If ppt. occur then adultration of mineral oil but if clear or transparent solution it indicates no adultration of mineral oil. 4. BUTYRO REFRACTOMETER TEST (B.R.TEST) : It ranges between 40-43. Procedure : For testing of sample by Butyro Refractometer, the apparatus is maintained at 40oC by circulating water at least 10min. Now oil/Fat to be tested is put on the glass of B.R. and it is covered now reading is observed on the scale. That reading is B.R. value of given sample. B.R. Value of same imp. Oil/Fat Sr. No. 1. 2. 3. 4. 5. 6. 7. Oil Fat Palm Oil Parachute Coconut Oil Dalda Ghee Soyabean Oil Mustard Oil Groundnut Oil Sunflower Oil B.R. Value 47 34 51 62 60 65.5 62

Downloaded from : www.multihelpline.com

WELCOME MULTI HELP LINE

LIST OF TABLES AND FLOW CHARTS

____________________________________________________________ TABLES Chemical Composition of Milk Specification of processed Liquid Milk Composition of Butter B.R. Value of some important oils ____________________________________________________________ CHARTS Milk Constituents Organisational Structure Chart for Reception of Milk Manufacturing, Packaging and Storage of Milk Flow Diagram for Manufacture of Butter PAGE NO. PAGE NO.

Downloaded from : www.multihelpline.com

Vous aimerez peut-être aussi

- Breastfeeding and Nutritional Requirements in ChildrenDocument64 pagesBreastfeeding and Nutritional Requirements in Childrenapule geraldhumble100% (1)

- Saras Dairy Visit ReportDocument12 pagesSaras Dairy Visit ReportPreeti ChouhanPas encore d'évaluation

- Postpartum Nursing PowerpointDocument3 pagesPostpartum Nursing PowerpointAntonella VitalePas encore d'évaluation

- Milk Analysis in Verka 1307073649 Phpapp02 110602230930 Phpapp02Document62 pagesMilk Analysis in Verka 1307073649 Phpapp02 110602230930 Phpapp02Jeganathan RajuPas encore d'évaluation

- Icici BankDocument2 pagesIcici BankAbhranil Gupta100% (1)

- Breast Feeding: OM Nursing Academy Anil Kantiwal GudhaDocument3 pagesBreast Feeding: OM Nursing Academy Anil Kantiwal GudhaBijay Kumar MahatoPas encore d'évaluation

- Introduction of Milk Scope and Object of Study Instrumentation and MethodsDocument57 pagesIntroduction of Milk Scope and Object of Study Instrumentation and MethodsSai CharanPas encore d'évaluation

- Maternal Recognition of Pregnancy in Domestic AnimalsDocument3 pagesMaternal Recognition of Pregnancy in Domestic AnimalsAjay YadavPas encore d'évaluation

- Physical and Physiological Changes in PregnancyDocument35 pagesPhysical and Physiological Changes in PregnancyAYO NELSONPas encore d'évaluation

- Milk & Milk Hygiene-4Document5 pagesMilk & Milk Hygiene-4Y.D. SharmaPas encore d'évaluation

- Gmail - Icici Bank Probationary Officer Recruitment GD & PiDocument5 pagesGmail - Icici Bank Probationary Officer Recruitment GD & Pi11090482Pas encore d'évaluation

- A Presentation On " Germicidal Properties of Milk": Veterinary Public Health B.Vsc.&A.H. (V Sem.)Document15 pagesA Presentation On " Germicidal Properties of Milk": Veterinary Public Health B.Vsc.&A.H. (V Sem.)Sushil ChalisePas encore d'évaluation

- Comparison of Growth Pattern in Neonates On BreastDocument7 pagesComparison of Growth Pattern in Neonates On BreastOman SantosoPas encore d'évaluation

- Infants Nutritional NeedsDocument5 pagesInfants Nutritional NeedsSukQin KongPas encore d'évaluation

- Effect of Post - Milking Teat Dipping On Hygienic Quality of Cows Milk - D. Kučević, M. Plavšić, S. Trivunović, M. Radinović, D. S. KučevićDocument9 pagesEffect of Post - Milking Teat Dipping On Hygienic Quality of Cows Milk - D. Kučević, M. Plavšić, S. Trivunović, M. Radinović, D. S. KučevićCk_psihPas encore d'évaluation

- ParagDocument97 pagesParagGuman Singh100% (2)

- Clarification, Separation, Bactofugation and StandardizationDocument18 pagesClarification, Separation, Bactofugation and StandardizationNishkarsh AgarwalPas encore d'évaluation

- Lesson Plan of Conference PDFDocument44 pagesLesson Plan of Conference PDFRahul DamorPas encore d'évaluation

- Steps of PasteurizationDocument2 pagesSteps of PasteurizationMichel AdamPas encore d'évaluation

- Practical No.10 Title: Methods of Milkings: ObjectiveDocument2 pagesPractical No.10 Title: Methods of Milkings: Objectivekushal NeupanePas encore d'évaluation

- Indian Dairy Product Market PDFDocument5 pagesIndian Dairy Product Market PDFharisankar sureshPas encore d'évaluation

- Active Management of LabourDocument4 pagesActive Management of LabourHytham AtiaPas encore d'évaluation

- GDMDocument30 pagesGDMCharlz ZipaganPas encore d'évaluation

- 3 - Puerperium and LactationDocument29 pages3 - Puerperium and LactationKholoud KholoudPas encore d'évaluation

- Advantages of Breast FeedingDocument4 pagesAdvantages of Breast FeedingRollan MaulasPas encore d'évaluation

- MCN HandoutsDocument22 pagesMCN HandoutsFRANCYM PRINCESSRICH BATENGAPas encore d'évaluation

- Marketing and Regulatory Issues For Functional Food and NutraceuticalDocument23 pagesMarketing and Regulatory Issues For Functional Food and NutraceuticalRadwan AjoPas encore d'évaluation

- Fermented Dairy ProductsDocument23 pagesFermented Dairy ProductsNilesh MehtaPas encore d'évaluation

- TOG 2018 Volume 20 Issue 2Document58 pagesTOG 2018 Volume 20 Issue 2esraa yaminPas encore d'évaluation

- Composition of Milk: AcknowledgementDocument23 pagesComposition of Milk: AcknowledgementShallu SharmaPas encore d'évaluation

- East FeedingDocument5 pagesEast FeedingJeya vanithaPas encore d'évaluation

- Industrial Training at Verka Mohali DairDocument42 pagesIndustrial Training at Verka Mohali DairAbhinavPas encore d'évaluation

- Implant TraingDocument41 pagesImplant Traingishwarya saravananPas encore d'évaluation

- Kangeroo Care Final 1Document22 pagesKangeroo Care Final 1api-438174007Pas encore d'évaluation

- Study of Quality Testing of Milk Powder in SterlinDocument3 pagesStudy of Quality Testing of Milk Powder in SterlinMuratPas encore d'évaluation

- MCNDocument12 pagesMCNIan CarodanPas encore d'évaluation

- Immunization For New-Born ChildDocument19 pagesImmunization For New-Born ChildyashPas encore d'évaluation

- Module 7 - Breastfeeding and NBCDocument13 pagesModule 7 - Breastfeeding and NBCKat EstoniloPas encore d'évaluation

- Problems With The PassengerDocument58 pagesProblems With The PassengerJim NavarroPas encore d'évaluation

- Types of Milk Testing During ProcurementDocument20 pagesTypes of Milk Testing During ProcurementNitish KulkarniPas encore d'évaluation

- Leaflet - Milk FermentationDocument3 pagesLeaflet - Milk FermentationNoor SultanPas encore d'évaluation

- Perineal Care ProcedureDocument12 pagesPerineal Care ProcedureShikarin KitaPas encore d'évaluation

- Nestle PresentationDocument24 pagesNestle PresentationGunjan Goel100% (1)

- Ps of LaborDocument28 pagesPs of LaborErvina Luisa Delias CampusPas encore d'évaluation

- Fetal Malpresentations: Abundo, Esther Ellise Espinol, Hazel AnnDocument21 pagesFetal Malpresentations: Abundo, Esther Ellise Espinol, Hazel AnnEsther Ellise Abundo100% (1)

- Hygienic Milk Handling and Processing by FAODocument7 pagesHygienic Milk Handling and Processing by FAOChevronellePas encore d'évaluation

- Introduction of DairyDocument33 pagesIntroduction of DairyMahesh Kumar0% (2)

- Nursing Care of The High Risk NewbornDocument8 pagesNursing Care of The High Risk NewbornFebie GonzagaPas encore d'évaluation

- Breastfeeding Handout and ActivitydocxDocument22 pagesBreastfeeding Handout and ActivitydocxCrystal MaidenPas encore d'évaluation

- MastitisDocument5 pagesMastitisAnonymous Kv0sHqFPas encore d'évaluation

- Dairy Lab Mannual CompleteDocument40 pagesDairy Lab Mannual CompleteZarakhankhan KhanPas encore d'évaluation

- A Study To Assess The Knowledge of Postnatal Mothers Regarding Breast Engorgement in Nerkundrum IIDocument9 pagesA Study To Assess The Knowledge of Postnatal Mothers Regarding Breast Engorgement in Nerkundrum IIEditor IJTSRDPas encore d'évaluation

- 2 - Factors Affecting Milk Quality and Quantity of MilkDocument21 pages2 - Factors Affecting Milk Quality and Quantity of MilkFachruddin100% (1)

- Milk 140711044543 Phpapp02Document57 pagesMilk 140711044543 Phpapp02Kajan SatkunanathanPas encore d'évaluation

- Forceps Delivery Treatment & Management - Preoperative Details, Intraoperative Details, Postoperative DetailsDocument10 pagesForceps Delivery Treatment & Management - Preoperative Details, Intraoperative Details, Postoperative DetailsAnonymous wYz8FtLLOPas encore d'évaluation

- Project On Milk ProteinsDocument11 pagesProject On Milk ProteinsPeeyush0% (1)

- Evidence Based Practices in ObstetricsDocument46 pagesEvidence Based Practices in Obstetricsvikas takPas encore d'évaluation

- Partograph - INTRAPARTUMDocument1 pagePartograph - INTRAPARTUMcoco lucaPas encore d'évaluation

- PR ReDocument29 pagesPR ReMonty KushwahaPas encore d'évaluation

- FageDocument8 pagesFageapi-282903171Pas encore d'évaluation

- Welcome On BoardDocument46 pagesWelcome On BoardLohayne LimaPas encore d'évaluation

- Wihr Filipino Dog EatersDocument17 pagesWihr Filipino Dog Eatersmaye tumzPas encore d'évaluation

- SFAC Value Chain AnalysisDocument176 pagesSFAC Value Chain Analysis6rajeevkPas encore d'évaluation

- Jadual Spesifikasi Ujian (Jsu) : Subject: Science Class: Year 6Document2 pagesJadual Spesifikasi Ujian (Jsu) : Subject: Science Class: Year 6Masnizan Binti HamdanPas encore d'évaluation

- Engineering Book-EDITOR VERSIONDocument110 pagesEngineering Book-EDITOR VERSIONEdys PutraPas encore d'évaluation

- Bsctnregulations2010ver2 PDFDocument112 pagesBsctnregulations2010ver2 PDFanita rajenPas encore d'évaluation

- What's Cooking? Preparing and Sharing Food in Ambai's Tamil Short StoriesDocument1 pageWhat's Cooking? Preparing and Sharing Food in Ambai's Tamil Short Storiesusernaga84Pas encore d'évaluation

- Reading and Writing Practice 4 DAYS With AnswersDocument30 pagesReading and Writing Practice 4 DAYS With AnswersNông Thị ThắmPas encore d'évaluation

- EluruDocument28 pagesEluruFood Testing Lab hyderabadPas encore d'évaluation

- Presentation EthnobotanyDocument15 pagesPresentation EthnobotanyzadiPas encore d'évaluation

- Sexton Plath ExtrasDocument12 pagesSexton Plath ExtraschrissiemavPas encore d'évaluation

- T5 - Cobibma Global Marketing Plan Yellow Cab VietnamDocument109 pagesT5 - Cobibma Global Marketing Plan Yellow Cab VietnamSean Gabriel SuayanPas encore d'évaluation

- Giant Cinnamon Roll by TastyDocument4 pagesGiant Cinnamon Roll by TastyCraigPowerPas encore d'évaluation

- HLTH 634 - Final Program PlanDocument11 pagesHLTH 634 - Final Program Planapi-232845707Pas encore d'évaluation

- B NG GIÁ Cg2-Tăng GiáDocument8 pagesB NG GIÁ Cg2-Tăng GiáKiệt PhạmPas encore d'évaluation

- KEBF Prelim ReviewerDocument18 pagesKEBF Prelim ReviewerButterfly43134Pas encore d'évaluation

- Gastronomic Tourism, A New Trend For Contemporary Tourism??: Georgică Gheorghe, Petronela Tudorache, Puiu NistoreanuDocument10 pagesGastronomic Tourism, A New Trend For Contemporary Tourism??: Georgică Gheorghe, Petronela Tudorache, Puiu NistoreanuMuhammad RojaliPas encore d'évaluation

- Funkcje Językowe 8 KlasaDocument53 pagesFunkcje Językowe 8 KlasaKlaudia MaczekPas encore d'évaluation

- A Restaurant Review and RubricDocument2 pagesA Restaurant Review and Rubricandres apontePas encore d'évaluation

- Final Test - LOOK 1Document4 pagesFinal Test - LOOK 1achochiquePas encore d'évaluation

- Tenses KelompokDocument5 pagesTenses KelompokricodaPas encore d'évaluation

- Activities: Quitor, Marjorie M. BSHM 2C HPC 4Document25 pagesActivities: Quitor, Marjorie M. BSHM 2C HPC 4Math TangikPas encore d'évaluation

- Quantitative Determination OF AND: Vitamin A Vitamin EDocument20 pagesQuantitative Determination OF AND: Vitamin A Vitamin EAras RafiqPas encore d'évaluation

- Final Exam in PE and Health 10Document1 pageFinal Exam in PE and Health 10Mary Grace Palis-MaulionPas encore d'évaluation

- The Difference Between Needs Vs WantsDocument4 pagesThe Difference Between Needs Vs WantsJane MoracaPas encore d'évaluation

- The Family Recipe: Chicken-Biryani - JPGDocument9 pagesThe Family Recipe: Chicken-Biryani - JPGSnigdha BrightyPas encore d'évaluation

- LampiranDocument17 pagesLampiranAldi KurniawanPas encore d'évaluation

- Claim Your Six Pack AbsDocument122 pagesClaim Your Six Pack AbsLeo Angelo Salinel100% (2)

- FFFAI Value Added Services in IndiaDocument47 pagesFFFAI Value Added Services in IndiaYashpal NegiPas encore d'évaluation

- The Obesity Code: Unlocking the Secrets of Weight LossD'EverandThe Obesity Code: Unlocking the Secrets of Weight LossÉvaluation : 4 sur 5 étoiles4/5 (6)

- Surprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideD'EverandSurprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideÉvaluation : 4 sur 5 étoiles4/5 (6)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldD'EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldÉvaluation : 3.5 sur 5 étoiles3.5/5 (5)

- Mostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyD'EverandMostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyÉvaluation : 4 sur 5 étoiles4/5 (11)

- Magnolia Table, Volume 3: A Collection of Recipes for GatheringD'EverandMagnolia Table, Volume 3: A Collection of Recipes for GatheringÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Waiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterD'EverandWaiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterÉvaluation : 3.5 sur 5 étoiles3.5/5 (487)

- Instant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookD'EverandInstant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Chicano Eats: Recipes from My Mexican-American KitchenD'EverandChicano Eats: Recipes from My Mexican-American KitchenPas encore d'évaluation

- Pati's Mexican Table: The Secrets of Real Mexican Home CookingD'EverandPati's Mexican Table: The Secrets of Real Mexican Home CookingÉvaluation : 4 sur 5 étoiles4/5 (9)

- Authentic Mexican: Regional Cooking from the Heart of MexicoD'EverandAuthentic Mexican: Regional Cooking from the Heart of MexicoPas encore d'évaluation

- Not That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsD'EverandNot That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsPas encore d'évaluation

- Eat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthD'EverandEat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthÉvaluation : 2 sur 5 étoiles2/5 (1)

- Body Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomD'EverandBody Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomÉvaluation : 4 sur 5 étoiles4/5 (1)

- The Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingD'EverandThe Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingPas encore d'évaluation

- Eating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyD'EverandEating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyÉvaluation : 4 sur 5 étoiles4/5 (1)

- Poilâne: The Secrets of the World-Famous Bread BakeryD'EverandPoilâne: The Secrets of the World-Famous Bread BakeryPas encore d'évaluation

- Instant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayD'EverandInstant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayÉvaluation : 4 sur 5 étoiles4/5 (4)

- The Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoD'EverandThe Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoPas encore d'évaluation

- Just Feed Me: Simply Delicious Recipes from My Heart to Your PlateD'EverandJust Feed Me: Simply Delicious Recipes from My Heart to Your PlateÉvaluation : 2 sur 5 étoiles2/5 (1)

- The Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingD'EverandThe Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingÉvaluation : 4 sur 5 étoiles4/5 (3)

- Waiting: The True Confessions of a WaitressD'EverandWaiting: The True Confessions of a WaitressÉvaluation : 3 sur 5 étoiles3/5 (7)

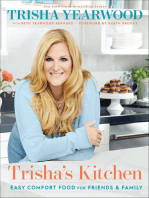

- Trisha's Kitchen: Easy Comfort Food for Friends & FamilyD'EverandTrisha's Kitchen: Easy Comfort Food for Friends & FamilyÉvaluation : 4 sur 5 étoiles4/5 (5)

- Saved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayD'EverandSaved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayÉvaluation : 4 sur 5 étoiles4/5 (10)