Académique Documents

Professionnel Documents

Culture Documents

Evaluation and Repair of Existing Post Tension Ed Buildings

Transféré par

Gabriel PoloDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Evaluation and Repair of Existing Post Tension Ed Buildings

Transféré par

Gabriel PoloDroits d'auteur :

Formats disponibles

TECHNICAL PAPER

EVALUATION AND REPAIR OF EXISTING POSTTENSIONED BUILDINGS WITH PAPER-WRAPPED TENDONS EXPERIENCING CORROSION DAMAGE

K. DIRK BONDY, S.E.

ABSTRACT Paper wrapped system of post-tensioning that was common in industry 25 years ago has proven to be inadequate to protect the strands in corrosive environments. Many structures with this type of system have suffered severe damage over the years and are in need of repair. The residual strength evaluation of these structures is unique and unlike modern systems with extruded sheathing. The strands are often partially or completely bonded to the surrounding concrete by rust or the corrosion buildup. This can sometimes lead to erroneous conclusions with lift-off tests. The evaluation of a corroded paper-wrapped tendon systems must take into account all of the forensic evidence available, and be performed by an engineer familiar with the intricacies of repair and rehabilitation of a structure with paper wrapped tendons. The evaluation of types of cracking observed is critical, as is the understanding of the deflections and serviceability of the floor system. Without the grease and sheathing, replacement of the strand inside the concrete is usually difficult. Repair often require an external type of strengthening system, along with repair of the concrete. This paper discusses some of these unique aspects of evaluation and rehabilitation of unbonded post-tensioned structures with paper wrapped tendons. RESEARCH SIGNIFICANCE Specialized knowledge is required to evaluate and repair existing post-tensioned structures that were built in the early 1970s. The paper describes some of the aspects of paper wrapped post-tensioned systems that were used in early posttensioning applications that are essential for the engineer to understand before starting a repair/rehabilitation project. It also gives a detailed discussion on the repair of structures using external post-tensioning (EPT). KEYWORDS corrosion; existing buildings; external post-tensioning; repair.

PTI Journal, V. 4, No. 2, December 2006. Received and reviewed under Institute Journal publication policies. Copyright 2006, Post-Tensioning Institute. All rights reserved, including the making of copies unless permission is obtained from the Post-Tensioning Institute. Pertinent discussion will be published in the next issue of the PTI Journal if received within 3 months from the publication.

1.0 INTRODUCTION An engineer who has been called upon to evaluate a posttensioned structure that was constructed more than 25 years ago must be aware that at that time post-tensioning tendons were protected by grease and paper. In addition, the concrete used at that time often contained light-weight aggregate and very well may have contained chlorides, which attack and corrode the reinforcing in these slabs. This combination of construction and concrete has led to a number of corroded tendons and damaged concrete in these older structures. Traditional testing used on extruded tendons has proven unreliable with respect to determining the amount of effective prestress remaining in the paper-wrapped tendons. The reasons for this will be discussed later. The evaluating engineer must be familiar with the expected performance of older but healthy post-tensioned structures in order to be able to discern when something is wrong. He or she must know the difference between typical slab cracks that would be predicted given the restraint conditions, detailing, etc., and cracks that indicated a potential loss of flexural capacity. All of the evidence at hand must be reviewed, such as a careful survey of cracks for rust deposit or efflorescence as well as visual inspections of the tendons and anchorages themselves. 2.0 THE FIRST SIGNS OF POTENTIAL CORROSION DAMAGE An engineer or contractor is often first called to evaluate a project potentially experiencing corrosion damage when sections (sometimes large sheets) of concrete suddenly dislodge and fall, Figures 1 and 2. The mechanism for the spalled concrete is the fact that the tendon is experiencing the growth of corrosion buildup, and this pressure will become great enough to dislodge concrete where the cover is the least. Over time, however, the base metal of the tendon will deteriorate entirely, leaving only a void. Signs that the reinforcement in the slab is corroding include water staining at the underside of the slab, rust deposits and efflorescence, Figure 3.

24 | PTI JOURNAL | December 2006

3.0 EVALUATING THE BROKEN TENDONS When a tendon which is greased and protected in an extruded plastic sheathing breaks, the result is often a looping out of the slab of a portion of the tendon, not necessarily near the point of tendon rupture. The energy stored in the prestressed tendon causes a recoil effect when it is broken, and because there is no appreciable friction the strand is free to rapidly decrease its length. The tendon will find the point of least resistance and often buckle out of the concrete at that location, Figure 4. However, the corroded tendon in a deteriorated paperwrapped sheathing behaves quite differently. There may be no outward sign that the tendon has broken. Because of the large friction and interlock that is created by the rusting and corrosive buildup along the length of the tendon, the release of energy due to breakage is distributed to these areas of resistance to movement. Therefore, the paperwrapped tendons are more likely to corrode and deteriorate quietly in place without revealing that there is a serious problem in the system.

Fig. 1 Dislodged Concrete

Fig. 2 Corroded Tendons

3.1 A LIFT-OFF TEST DOESNT NECESSARILY MEASURE ACTIVE PRESTRESS IN A PAPERWRAPPED STRAND It is common, if access is available, to test the residual prestress in a strand in a greased extruded sheathing by applying a hydraulic jack to the remaining tail at the anchor and stressing until there is movement in the wedges or tendon. At the gauge pressure where the strand begins to elongate it is fair to assume that this is the active prestress in the tendon.

Fig. 3 Water Staining, Rust and Efflorescence at Corroded Reinforcing

Fig. 4 A Broken Tendon in Extruded Sheathing

December 2006 | PTI JOURNAL | 25

4.0 UNDERSTANDING THE CRACKS In the event that the structure has experienced a significant loss of strength due to loss of prestress in the paperwrapped tendons, flexural cracking can be expected. It is critical that this cracking be differentiated from other types of cracking typically found in older post-tensioned structures such as restraint to shrinkage cracking. Flexural cracking in the slabs of older beam-and-slab parking structures is often observed running parallel to the beams in the positive moment area near the slab midspan. A similar slab crack is also commonly seen at a distance of approximately 4 to 6 feet from the beams. The latter crack occurs at this location because it corresponds to the termination of the top slab mild rebar, which is typically the only mild rebar in the slab. This crack emanates from the top, but may also be visible from the bottom. When the crack has penetrated the full depth of the slab and is visible from both top and bottom a potentially dangerous situation exists. There is by definition no pre-compression in the concrete at that location and it is almost certain that a significant amount of prestressing tendons have been compromised. Further, there is effectively no mechanism available to resist the slab bending moments. Slabs in this condition are standing only due to their ability to act as cantilevers off the beam.

Fig. 5 The Underside of a Hydraulic Jack

However, the same test will give inaccurate results if friction exists along the strand, or if the strand has bonded due to corrosion buildup. This is typically the case when the only protection for the tendons is wrapped paper. What is really being measured by the jack is the sum total of all resistance to movement of that tendon. This includes the temporary bond to the concrete due to rust and corrosion, interlock of the corrosion buildup and concrete, friction of the un-greased tendon (the paper rarely is adequate to maintain the grease) against the concrete as well as any remaining prestress. The simple fact that it is often difficult and takes substantial jacking force to remove long tendons even when they are known to be broken should be reason enough for the evaluating engineer to be skeptical of lift-off results on paperwrapped tendons. An engineer or contractor can gain a much better understanding of the condition of the tendons by exposing one to two feet of tendon and exploring the ability of the tendon to be moved out of plane by a crow bar, screwdriver, or even by hand. A f fully stressed tendon is extremely difficult to move out of plane by any of these methods. Another method of evaluating the tendons is to carefully wedge a flat-head screwdriver between the wires at attempt to twist the wires apart. If they move easily, then there has almost certainly been a loss of force in the 7-wire strand.

Fig. 6 Broken Tendons Being Moved By Hand 26 | PTI JOURNAL | December 2006

Fig. 7 Full Length Mid-span Crack Parallel to Beams

In a parking structure, once the crack becomes a throughcrack the vehicular traffic will alternately load each side of the crack, causing a dynamic shearing effect at this location. Eventually pieces of rubble will become noticeable in the crack due to this grinding effect. Again, this is potentially a very dangerous situation. Another notable distinction about flexural cracks due to loss of prestress is that they should repeat in each similar bay, and are usually more pronounced toward the middle of the structure where they superimpose with cracks caused by restraint and shrinkage. It is important to remember that once a post-tensioned tendon is broken anywhere along its length its force is lost for its entire length. Restraint to shortening cracks, which are also common in these same older structures, follow a different pattern. They usually run diagonal to the primary reinforcement and were present only a few days or weeks after the concrete was poured. They are old cracks that stabilized decades ago and emanate from stiff restraining elements such as perimeter retaining walls or interior shearwalls. Whereas cracking due to loss of prestress is more pronounced toward the middle of the structure, restraint to shortening cracks are typically most evident at the farthest corners of the structure. 5.0 STEPS TO TAKE ONCE LOSS OF PRESTRESS HAS BEEN VERIFIED Once it has been verified that a significant loss of prestress has occurred in a paper-wrapped tendon system it is necessary to address both the damaged concrete and reinforcement. The first step is to remove all loose concrete throughout the slab system and to clean the exposed reinforcement of all corrosion buildup. It is then important to make every rea-

sonable effort to protect the reinforcement from further moisture intrusion. The areas of delaminated concrete must be patched with a cementitious material that bonds well to and is stronger than the existing concrete. Cracks in the concrete must be filled with structural grade epoxy for their entire length and depth. Finally, consideration should be given to providing an elastomeric coating on the slab, even if the slab is not directly exposed to weather. Even after performing all of these steps it is important to remember that the existing corrosion process will continue, and is virtually impossible to entirely arrest. The slab should be monitored at least every 6 months and further repair of the concrete may be necessary. The engineer should inform the owner of this long-term maintenance issue. The next step is to address the loss of prestressing reinforcement. In a paper-wrapped tendon system it is very difficult to remove the corroded tendons, and virtually impossible to replace them due to the lack of a greased sheathing duct. Typically, the most structurally effective and cost efficient way to replace the lost strength is to externally provide post-tensioning tendons below the slab.

6.0 EXTERNAL POST-TENSIONING (EPT) External post-tensioning is the process of placing tendons and hardware below the slab and stressing the tendons to effectively jack the slab up. The benefit of the stressed tendons is two-fold. First, an active balancing force is applied to the slab to offset the effects of the gravity loads. Secondly, the harped or double harped shape of the tendons provides the added strength of a truss, with the post-tensioning as the bottom chord and the concrete as the top chord.

" HILTI KWIK BOLT II erection expansion anchors with 1- "embedment per ICC report ER-4627 2 total Do not cut (E) post-tensioning

10" sqr. " plate (gr. 36 min.) w/(2)-" holes at diagonal corners (1-" edge dist. typ.)

TS3 3

9"

" 6" 3 plate typ. ea. pipe end w/ " weld all around 3" x-strong pipe w/" cap plate ea. end ( " weld all around cap plate)

Fig. 8 Patched Concrete

Fig. 9 Detail of King Post December 2006 | PTI JOURNAL | 27

Fig. 10 Double Harped External Post-Tensioning in a OneWay Slab

Fig. 13 Stressing the Galvanized Tendons

Fig. 14 A Double Harp Two-Way EPT System

Fig. 11 X-Ray Markings on a Existing Post-Tensioned Beam

In an EPT application it is always necessary to drill through the existing concrete in order provide a path for the tendons and an anchorage location. If the existing structure is post-tensioned it may be necessary to x-ray in order to prevent damaging existing tendons. Galvanized greased strands in thick extruded plastic sheathing are used in combination with galvanized anchors and anchor caps to provide a durable strengthening system. The cut tendons are treated with a corrosion resistant coating prior to capping the anchorage. The same approach to repair can be applied to two-way flat plate structures. However, given the limited anchoring locations (typically only the columns) the layout needs to involve more creativity, Figures 14 and 15. 6.1 FIREPROOFING OF THE EPT SYSTEM Depending upon the particular situation, fireproofing of the tendons and hardware may or may not be required. This decision ultimately lies with the building official and will depend upon whether or not the external tendons are considered

Fig. 12 Drilling Through an Existing Post-Tensioned Beam

28 | PTI JOURNAL | December 2006

7.0 OTHER METHODS OF STRENGTHENING Methods of repair and strengthening other than external post-tensioning include adding steel beams. However, the relative flexibility in contrast to the stiffness of the concrete often poses incompatibility concerns. Furthermore, unless the deck is jacked up prior to placement of the steel beams, the system must fail further to activate the added beams. The addition of concrete beams is also another potential solution; however the capacity of the existing columns, foundations and seismic systems must all be verified for the added weight. Where clear head height is too limited for an effective EPT system, the application of carbon or glass fibers wrap has been used successfully. This material is useful for strengthening the positive moment regions, but access to the negative moment region is often restricted or impractical such as in parking structures where the top of the slab is the driving surface. Carbon or fiber wraps do not decrease deflections as is possible with an EPT system.

Fig. 15 A Single Harp Two-Way EPT System

8.0 CONCLUSION Existing paper-wrapped tendons often exist in post-tensioned structures more than 25 years old. These tendons have unique properties and behavior once they experience corrosion that require particular care and expertise by the evaluating engineer in order to properly diagnose the existing capacity of the system. Lift-off tests which are appropriate for strands in greased extruded plastic give fictitious results for paper-wrapped strands; therefore particular expertise is required for analyzing the latter system. Proper repair and treatment of the concrete in combination with an external post-tensioning system provide a viable strengthening approach when the original system has experienced a significant loss of strength due to corrosion.

Fig. 16 Fireproofed EPT Tendons and Hardware

primary or secondary reinforcement. The requirement may also depend upon whether or not the concrete cover over the original tendons satisfies todays fire rating requirements. Most building departments will allow the engineer some leeway with respect to the fireproofing issue. In a number of cases the addition of a fire sprinkler system in lieu of applied fireproofing has been accepted as a viable alternative, particularly when a similar new structure would require a fire sprinkler system and when the concrete cover over the existing tendons is less than required by todays codes. Recently, the post-tensioning industry has begun the development of fire-resistive strands, particularly for use in externally strengthening parking structures. This technology is in the early stages of development, but will hopefully be available for general use in the next few years. The technology and testing for these strands are based upon the fact that fires in parking structures differ from fires in other occupancies in that the fire is contained to a small area with almost no potential for horizontal spread. Car fires also have a finite amount of fuel, literally, which limits the heat and duration of the fire.

K. Dirk Bondy, S.E. is President of Seneca Structural Engineering, Inc., a design firm established in 1997 specializing in both internal and external post-tensioning. He is also the president and RMO of The Great American Cable Company II, Inc., a contracting firm specializing in the construction of external post-tensioning systems. Mr. Bondy has been a practicing structural engineer since 1989 and is licensed in the states of California, Nevada and Hawaii.

December 2006 | PTI JOURNAL | 29

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Review of Related LiteratureDocument4 pagesReview of Related LiteratureCarlo Mikhail Santiago25% (4)

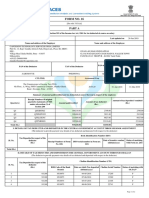

- Form16 2018 2019Document10 pagesForm16 2018 2019LogeshwaranPas encore d'évaluation

- 18PGHR11 - MDI - Aditya JainDocument4 pages18PGHR11 - MDI - Aditya JainSamanway BhowmikPas encore d'évaluation

- D - MMDA vs. Concerned Residents of Manila BayDocument13 pagesD - MMDA vs. Concerned Residents of Manila BayMia VinuyaPas encore d'évaluation

- General Field Definitions PlusDocument9 pagesGeneral Field Definitions PlusOscar Alberto ZambranoPas encore d'évaluation

- WEEK6 BAU COOP DM NextGen CRMDocument29 pagesWEEK6 BAU COOP DM NextGen CRMOnur MutluayPas encore d'évaluation

- Methodical Pointing For Work of Students On Practical EmploymentDocument32 pagesMethodical Pointing For Work of Students On Practical EmploymentVidhu YadavPas encore d'évaluation

- Sky ChemicalsDocument1 pageSky ChemicalsfishPas encore d'évaluation

- QUIZ Group 1 Answer KeyDocument3 pagesQUIZ Group 1 Answer KeyJames MercadoPas encore d'évaluation

- Dry Canyon Artillery RangeDocument133 pagesDry Canyon Artillery RangeCAP History LibraryPas encore d'évaluation

- Strobostomp HD™ Owner'S Instruction Manual V1.1 En: 9V DC Regulated 85maDocument2 pagesStrobostomp HD™ Owner'S Instruction Manual V1.1 En: 9V DC Regulated 85maShane FairchildPas encore d'évaluation

- LOG-2-8-FLEETWAREHOUSE-TEMPLATE-Waybill-Delivery Note-IFRCDocument1 pageLOG-2-8-FLEETWAREHOUSE-TEMPLATE-Waybill-Delivery Note-IFRCMPas encore d'évaluation

- Avalon LF GB CTP MachineDocument2 pagesAvalon LF GB CTP Machinekojo0% (1)

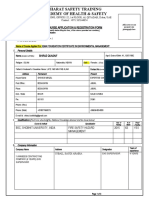

- BST Candidate Registration FormDocument3 pagesBST Candidate Registration FormshirazPas encore d'évaluation

- Proceedings of SpieDocument7 pagesProceedings of SpieNintoku82Pas encore d'évaluation

- ADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementDocument33 pagesADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementNURATIKAH BINTI ZAINOL100% (1)

- What Caused The Slave Trade Ruth LingardDocument17 pagesWhat Caused The Slave Trade Ruth LingardmahaPas encore d'évaluation

- Cancellation of Deed of Conditional SalDocument5 pagesCancellation of Deed of Conditional SalJohn RositoPas encore d'évaluation

- Unit Process 009Document15 pagesUnit Process 009Talha ImtiazPas encore d'évaluation

- Binary File MCQ Question Bank For Class 12 - CBSE PythonDocument51 pagesBinary File MCQ Question Bank For Class 12 - CBSE Python09whitedevil90Pas encore d'évaluation

- Laporan Praktikum Fisika - Full Wave RectifierDocument11 pagesLaporan Praktikum Fisika - Full Wave RectifierLasmaenita SiahaanPas encore d'évaluation

- Oracle FND User APIsDocument4 pagesOracle FND User APIsBick KyyPas encore d'évaluation

- XgxyDocument22 pagesXgxyLïkïth RäjPas encore d'évaluation

- Ss 7 Unit 2 and 3 French and British in North AmericaDocument147 pagesSs 7 Unit 2 and 3 French and British in North Americaapi-530453982Pas encore d'évaluation

- 5 Star Hotels in Portugal Leads 1Document9 pages5 Star Hotels in Portugal Leads 1Zahed IqbalPas encore d'évaluation

- Departmental Costing and Cost Allocation: Costs-The Relationship Between Costs and The Department Being AnalyzedDocument37 pagesDepartmental Costing and Cost Allocation: Costs-The Relationship Between Costs and The Department Being AnalyzedGeorgina AlpertPas encore d'évaluation

- Marine Lifting and Lashing HandbookDocument96 pagesMarine Lifting and Lashing HandbookAmrit Raja100% (1)

- CDKR Web v0.2rcDocument3 pagesCDKR Web v0.2rcAGUSTIN SEVERINOPas encore d'évaluation

- Recommended Practices For Developing An Industrial Control Systems Cybersecurity Incident Response CapabilityDocument49 pagesRecommended Practices For Developing An Industrial Control Systems Cybersecurity Incident Response CapabilityJohn DavisonPas encore d'évaluation

- Computer First Term Q1 Fill in The Blanks by Choosing The Correct Options (10x1 10)Document5 pagesComputer First Term Q1 Fill in The Blanks by Choosing The Correct Options (10x1 10)Tanya HemnaniPas encore d'évaluation