Académique Documents

Professionnel Documents

Culture Documents

Conversion Factors - Gas Industry

Transféré par

Kailas NimbalkarCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Conversion Factors - Gas Industry

Transféré par

Kailas NimbalkarDroits d'auteur :

Formats disponibles

FLARE GAS RECOVERY

International Headquarters PO Box 21220 Tulsa, OK 74121-1220 +1 918.234.2903

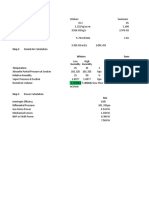

Mass to Volume Calculations

PV = mRT

V = m X (Ru / MW) X Tabs / Pabs

Pabs in kPa or psia : Tabs in K or R : V in m3 or ft3 : m in kg or lbm

MW in kg/kg-mol or lbm/lb-mol (numerically equal)

R = Ru / MW

Ru = 8.314 472 kPam3/(kg-molK) = 10.731 6 psiaft3/(lb-molR)

kPam3/(kg-molK) = kJ/(kg-molK)

SCFM = lbs/hr / 60 X ** / MW

Nm3/hr = kg/hr X ** / MW

mmscfd

= 1,177.529 Nm3/hr

[@ 1 atm & 60F]

[@ 1 atm & 15C]

scfm

= 1.607 466 Nm3/hr

[@ 1 atm & 60F]

[@ 1 atm & 0C]

mmscfd

**

API (Standard)

15 C 101.325 kPa (1 atm) 23.645 Nm3/kgmol

Asia (Normal)

15 C

EC (Normal)

0 C 101.325 kPa (1 atm) 22.414 Nm3/kgmol

1 bar

23.959 Nm3/kgmol

US customary

60 F 14.696 psia (1 atm) 379.482 scf/lbmol

CAGI & ISO

68 F

14.5 psia (1 bar)

390.439 scf/lbmol

IUPAC (Normal)

0C

100 kPa (1 bar)

24.277 Nm3/kgmol

NIST

20 C 101.325 kPa (1 atm) 24.055 Nm3/kgmol

Gas Volume Conversion (T&P in absolute terms)

P1V1/T1 = P2V2/T2

V2 = V1 X P1 / P2 X T2 / T1

Remember (in absolute terms):

double the pressure, half the volume

double the temperature, double the volume

Theoretical Gas HP

(adiabatic, ideal gas, neglecting compressibility)

HP = P1 X V1 X k / (k-1) X 144 / 33000 X [ (P2 / P1)((k-1) / k) -1 ]

Theoretical Discharge Temperature (adiabatic)

T2 = T1 X { [(P2 / P1)((k-1) / k) -1 ] + 1 }

P in psia T in R V in actual ft3/min (acfm)

Converting SCFM to ACFM (and vice-versa)

SCFM = ACFM X 35.374 X (Pact psig + 14.7) / (Tact F + 460)

ACFM = SCFM X 0.0283 X (Tact F + 460) / (Pact psig + 14.7)

(STP - 14.7 psia & 60F)

lb/hr = SCFM X MW X 0.158

Air/Water Properties

property

dimension

MW

lb/lbmol

density @60F,14.7 psia

lb/ft3

K (Cp/Cv)

Cp V

BTU/lb/F

Cp L

BTU/lb/F

Cv

BTU/lb/F

therm cond (100 F)

BTU/hr/ft2/(F/ft)

air

28.964

0.075

1.4

0.241

0.172

0.0243

psi

Bar

kPa

kg/cm2

psi

1

0.06895 6.89476 0.07031

bar

14.504

1

100

1.01972

kPa

0.145

0.01

1

0.0102

kg/cm2 14.223 0.98067 98.0665

1

atm

14.696 1.01325 101.325 1.03323

in W.C.* 0.0361 0.00249 0.24884 0.00254

C

K

R

F

1

P = lbf/in2 ; m = mass (lbm) ; g = 32.17 ft/sec2 ; A = ft2 ; = lbm/ft3

gc = 32.17 lbm-ft / lbf-sec2 ; V = ft3 = A h ; h = ft

= ft3/sec ; v = ft/sec ; = lbm/sec ; r = ft

Cp

MW

NR = Reynolds no. ; D= ft ; = lbfsec/ft2

(BTU/lb/F)

Methane

0.5266 16.043

z = ft ; Hp = pump added head

Hf = friction head ; L = ft ; f = fric. factor

Ethane

0.4097 30.070

k = loss coefficient ; Leq = equiv. L

Propane

0.3881 44.097

H 2O

18.015

62.427

1.326

0.448

1.0

0.363

atm

in W.C.*

0.06804

0.986923

0.00986

0.967841

1

0.002458

27.707

401.856

4.01463

393.701

406.782

1

C

(F - 32) X 5 / 9

(C X 9 / 5) + 32

1

(K - 273.15) X 9 / 5 + 32

K - 273.15

R - 459.67

(R 459.67) X 5 / 9

BTU = British Thermal

Unit = energy required to

raise 1 lb of water 1F at

68F

kcal = energy required

to raise 1 kg of water 1C

at 20C

Fluid Flow

P = Force = Weight = m g = V g = A h g = h g

A gc

gc

Area

Area

A gc A gc

= A v = ( r2) v

=

( A v)in = ( A v)out

NR = v D NR < 2000 -> laminar; NR > 3500 -> turbulent

elevation

velocity

pressure

gc

head

head

head

z1 + v12 + P1 gc + Hp = z2 + v22 + P2 gc + Hf ID (in)

ID = 1.748 [Q(cfm)/v]

2g g

2g

g

ID = 1.341 [Q(m3/hr)/v]

Hf = f L v2 = k v2 ; Leq = k D ; k = f Leq

ID

= 0.639 [Q(gpm)/v]

D2g

2g

f

D

Typical Values of Leq / D

Globe Valve

Leq / D

Conventional 400

Y-Pattern 160

Gate Valve

Fully Open

13

75% Open

35

50% Open 160

25% Open 900

Standard Tee

Flow thru Run

20

Flow thru Branch 60

Check Valve

Conventional Swing 135

Clearway Swing 50

Butterfly Valve

>8 inch, fully open 40

90 Standard Ell

30

45 Standard Ell

16

Return Bend

50

* water @ 60 F

Temp

F

Identities

N kgm/s2

J N m kgm2/s2

kJ kPam3

Pa N/m2 kg/m/s2

Pa 100 mBar

W J/s kgm2/s3

W hr 3600 J

m3 1000 liter

cm3/g liter/kg

Torr mm Hg

(Angstrom)

1 x 10-10 m

0.0001 m

m (Micron)

1 x 10-6 m

0.001 mm

Pump Calculations

H = 2.31 X P / SG

where:

H in ft P in psi

SG = specific gravity

ACFM = gas volume at actual gas T & P

(ignoring humidity effects)

SCFM = gas volume at one of the listed STP

(Standard Temperature & Pressure)

< conditions

ICFM = T & P at compressor inlet flange

Multiply units in left column by proper factor below:

Pressure

Pipe Sizing Velocity

Liquid < 10 fps

Gas < 100 fps

k = Cp / Cv = MW X Cp / (MW X Cp - 1.99)

k = 1.4 air, k = 1.28 typical flare gas

for k = 1.0 to 1.1 gas easily compressed

for k > 1.35 gas difficult to compress

(large T incr. opposes compression process)

= 694.44 scfm

STP

Compressors

Centrifugal approximates

constant head,

variable volume.

PD variable head,

constant volume.

K

(F - 32) X 5 / 9 + 273.15

R

F + 459.67

C + 273.15

1

RX5/9

(C + 273.15) X 9 / 5

KX9/5

1

n-Butane

0.3867

58.124

i-Butane

n-Pentane

0.3872

0.3883

58.124

72.151

i-Pentane

0.3827

72.151

n-Hexane

Ethylene

0.3864

0.3622

86.178

28.054

Propylene

0.3541

42.081

1-Butene

0.3548

56.108

C-2-Butene

0.3269

56.108

T-2-Butene

0.3654

56.108

Isobutene

1-Pentene

0.3701

0.3635

56.108

70.135

CO

CO2

H2S

0.2484

0.1991

0.2380

28.010

44.010

34.076

Hydrogen

3.408

2.016

Oxygen

Nitrogen

0.2188

0.2482

31.999

28.013

Water

Air

0.4446

0.241

18.015

28.964

Latent heat - the

amount of heat added or

removed to produce only

a phase change.

Sensible heat - the heat

added or removed that

causes a temperature

change.

Conversions

CFM = 1.69 9 m3/hr

liter/s = 2.118 9 CFM

[flow rate]

gpm = 8.020 9 ft3/hr

3

m /hr = 4.402 gpm

in3/lb = 36.127 3 cm3/kg

[specific

m3/kg = 16.018 5 ft3/lb

volume]

m3/kgmol = 16.018 5 ft3/lbmol

lb/gal = 119.826 1 kg/m3

gr/cm3 = 62.428 0 lb/ft3

[density]

lb/ft3 = 16.018 5 kg/m3

grain/100 scf = 22.888 35 mg/m3

grain/gallon = 17.118 06 g/m3

ft3 H2O = 62.427 lb

gallon H2O = 8.345 lb

liter H2O = 1 kg

[mass]

kg = 2.204 6 lb

ton = 2,000 lb

metric ton = 1,000 kg

grain = 64.798 9 mg

m = 3.280 8 ft = 39.37 in

inch = 2.54 cm

m = 3.937 x 10-5 in

[length]

mile = 5,280 ft = 1.609 3 km

naut. mile = 1.852 km = 6,076.4 ft

fathom = 6 ft = 1.828 8 m

league = 3 mile = 5.556 km

gallon = 3.785 4 liter = 231 in3

in3 = 16.387 1 cm3

[volume]

m3 = 35.314 7 ft3 = 264.171 4 gallon

3

ft = 7.480 5 gallon = 28.316 8 liter

bbl = 42 gal = 0.159 m3

psi = 2.308 9 ft H2O = 70.375 8 cm H2O

ft H2O = 2.986 1 kPa

kPa = 7.5 mm Hg = 9.806 4 cm H2O

in Hg = 3.386 4 kPa

atm = 33.931 7 ft H2O

[pressure]

atm = 760 Torr = 29.921 3 in Hg

Torr = 133.322 Pa = 1,000 (micron)

bar = 750 Torr = 100 kPa

lb/in2 = 2.036 in Hg

kPa = 20.885 4 lb/ft2

kW = 1.341 hp = 3,412.14 BTU/hr

kW = 1.360 metric hp

[power]

W = 1.627 9 kcal/hr

hp = 550 ft lbf/s = 2,544.43 BTU/hr

hp = 1.014 metric hp

BTU/s = 1.055 056 kW

ton refrig = 12,000 BTU/hr = 3.516 9 kW

kWhr = 3,412.14 BTU = 3.6 MJ

kWhr = 2,655,223.74 ft lbf

hphr = 2,684.52 kJ

[energy]

ftlbf = 1.355 8 J = 1.355 8 Nm

kgfm = 7.233 ftlbf

kJ = 737.562 1 ft lbf

BTU = 1,055.056 J = 0.252 kcal

BTU = 778.169 4 ft lbf

kcal = 3.968 3 BTU = 4,186.8 J

calth = 4.184 J

therm (EU) = 100,000 BTU

therm (US) = 99,976.12 BTU

therm (EU) = 105.505 6 MJ

therm (US) = 105.480 4MJ

BTU/hrft2 = 2.712 5 kcal/hrm2 [heat flux]

kW/m2 = 316.998 BTU/hrft2

BTU/F = 1.899 1 kJ/C [heat capacity]

BTU/ft3 = 37.234 kJ/m3 [heat content]

BTU/lb/F = cal/gr/C

[entropy]

BTU/lb/F = 4.186 8 kJ/kg/C

cal/gr = 1.799 BTU/lb

[enthalpy]

BTU/lb = 2.325 98 kJ/kg

knot = 1.150 8 mph = 1.852 km/hr

ft/s = 1.097 3 km/hr

[speed]

speed sound = 1,125.3 fps

2

1/4 steel plate = 10.2 lb/ft

radian = 180/ = 57.295 8 degrees

rev = 360 = 2 radians

g = 32.174 ft/s2 = 9.806 7 m/s2

dia. human hair = 0.003 5 inch

= 0.088 9 mm

Flare Gas Recovery Its more than just a Compressor Skid

10.10.10 r7.53 reb

FLARE GAS RECOVERY

International Headquarters PO Box 21220 Tulsa, OK 74121-1220 +1 918.234.2903

Atmospheric Pressure at Site Elevation

Feet Meters psia Atm Bar (a) kPa kg/cm2 in Hg mm Hg

0

14.7

1.00

328

100

14.5 0.99

500

150

14.4 0.98

1.013

101

1.03

29.9

760

1.000

100

1.02

29.5

752

0.994

99.4

1.01

29.4

747

656

200

14.3

0.97

0.988

98.8

1.01

29.2

743

1,000

300

14.2 0.96

0.976

97.6

1.00

28.9

734

1,312

400

14.0 0.95

0.964

96.4

0.98

28.5

725

1,500

450

13.9 0.94

0.956

95.6

0.98

28.3

719

2,000

600

13.7

0.939

93.9

0.96

27.8

706

694

0.93

2,500

750

13.4

0.91

0.923

92.3

0.94

27.3

3,000

900

13.2

0.89

0.906

90.6

0.92

26.8

681

3,500

1,070

12.9 0.88

0.888

88.8

0.91

26.3

668

4,000

1,220

12.7

0.86

0.871

87.1

0.89

25.8

655

4,500

1,370

12.4

0.85

0.858

85.8

0.87

25.4

645

5,000

1,520

12.2

0.83

0.842

84.2

0.86

24.9

633

5,500

1,680

12.0

0.81

0.825

82.5

0.84

24.4

620

Retrieved 4.20.2010 from http://www.engineeringtoolbox.com/iso-vg-grade-d_1206.html

6,000

1,830

11.8

0.80

0.811

81.1

0.83

24.0

610

6,500

1,980

11.5

0.78

0.794

79.4

0.81

23.5

597

7,000

2,130

11.3

0.77

0.781

78.1

0.80

23.1

587

ISO VISCOSITY CLASSIFICATION SYSTEM

Many petroleum products are graded according to the ISO Viscosity Classification

System. Each ISO viscosity grade number corresponds to the mid-point of a viscosity

range expressed in centistokes(cSt) at 40 deg C. For example, a lubricant with an ISO

grade of 32 has a viscosity within the range of 28.8-35.2, the midpoint of which is 32.

Rule of Thumb: The comparable ISO grade of a given product whose viscosity in SUS at

100F is known can be determined by using the following conversion formula:

SUS @ 100 deg F/5=cSt @ 40 deg C.

cst= 0.226xSUS-(195/SUS)

7,500

2,290

11.1

0.76

0.767

76.7

0.78

22.7

577

8,000

2,440

10.9 0.74

0.750

75.0

0.76

22.2

564

2,590

10.7

0.737

73.7

0.75

21.8

554

8,500

0.73

Retrieved 4.20.2010 from http://www.bobistheoilguy.com/visc.html

Retrieved 2.11.2009 from http://www.uigi.com/Atmos_pressure.html

Viscosity

Standard NEMA Motor Sizes (HP)

1

1.5

2

0.75

25

30

40

200

250

300

800

900

1000

3000

3500

4000

50

350

1250

4500

60

400

1500

5000

6000

7.5

75

450

1750

10

100

500

2000

7000

15

20

125

150

600

700

2250

2500

8000

Dynamic (absolute) viscosity () = Shear Stress () / Shear Rate ()

Kinematic viscosity () = Dynamic (absolute) viscosity () / Density ()

Pas = Ns/m2 = kg/m/s = 10 P

cP = mPa-s = 10-3 kg/m/s

P = g/cm/s

poise = dynes/cm2 = g/cm/s = 0.01 Pas

cSt = 10-6 m2/s = 1 mm2/s = 92,903.4 ft2/s

(SUS) = 4.63 (cP) / SG

liquid inversely proportional to temperature

gas directly proportional to temperature

SAE

ISO VG

Crankcase

Grade

Oil Grade

22

5W

32

10W

46

15W

68

20W

100

30

150

40

220

50

320

60

Retrieved 4.20.2010 from http://

www.engineeringtoolbox.com/iso-vg-grade-d_1206.html

Standard IEC Motor Sizes (kW)

15

132

400

1250

4000

1.1

18.5

160

450

1400

1.5

22

185

500

1600

2.2

30

200

560

1800

37

220

630

2000

45

250

710

2240

5.5

55

280

800

2500

7.5

75

300

900

2800

9.2

11

90

110

315

355

1000

1120

3150

3550

Power Factor (PF) = Watts / Volts/ Amps

3 Ph kW = V X I X PF X 1.732 / 1000

Synch. RPM = Hz X 120 / # poles

Torque (ft-lb) = HP X 5252 / RPM

Est. starting current or lock rotor current

= 6 X full load current

The information contained in these materials is for

informational purposes only and is provided "AS IS",

without warranties of any kind. John Zink Company, LLC

expressly disclaims any representations, warranties or

guaranties, including without limitation, the implied

warranties of merchantability and fitness for a particular

purpose. John Zink Company, LLC will have absolutely

no liability (whether direct, indirect or consequential) in

connection with the materials including without limitaRetrieved 2.11.2009 from http://www.sengpielaudio.com/calculator-ohm.htm

tion, any liability for damage to person or property.

Flare Gas Recovery Its more than just a Compressor Skid

10.10.10 r7.53 reb

Vous aimerez peut-être aussi

- New Microsoft Office Excel WorksheetDocument16 pagesNew Microsoft Office Excel WorksheetAaron Horton100% (1)

- Conversion table for unitsDocument1 pageConversion table for unitsjakjuPas encore d'évaluation

- Unit Conversion FactorsDocument3 pagesUnit Conversion FactorsCHANADASPas encore d'évaluation

- Conversion WizardDocument4 pagesConversion WizardknsaravanaPas encore d'évaluation

- Wet Air Properties Calculation Sheet: at Low PressureDocument2 pagesWet Air Properties Calculation Sheet: at Low Pressurezsmith0% (1)

- UMUECHEM BOOSTER COMPRESSOR SELECTIONDocument2 pagesUMUECHEM BOOSTER COMPRESSOR SELECTIONNicolas CardonaPas encore d'évaluation

- Pump SizingDocument3 pagesPump Sizingtimayaa1000Pas encore d'évaluation

- Air Receiver Sizing CalculationDocument1 pageAir Receiver Sizing CalculationAziz HaquePas encore d'évaluation

- Detailed energy balance of belt dryer and sterilizerDocument31 pagesDetailed energy balance of belt dryer and sterilizerkennethmsorianoPas encore d'évaluation

- Recip Compressor Calculations For GCP-3Document4 pagesRecip Compressor Calculations For GCP-3Greg GolushkoPas encore d'évaluation

- By Pass System RCD-1 to SP3 RCD-2 to SP2 Pelabuhan Batubara TarahanDocument18 pagesBy Pass System RCD-1 to SP3 RCD-2 to SP2 Pelabuhan Batubara TarahansutanuprojectsPas encore d'évaluation

- Normal To Real Flow Rate and FAD Flow RateDocument25 pagesNormal To Real Flow Rate and FAD Flow RateChristopher LloydPas encore d'évaluation

- Aeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramDocument4 pagesAeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramAshraf KamalPas encore d'évaluation

- Forced Draft BlowerDocument108 pagesForced Draft BlowerTrevor ChandlerPas encore d'évaluation

- PositiveDisplacementBlowerCalculations Brochuremay2017Document4 pagesPositiveDisplacementBlowerCalculations Brochuremay2017hardik033Pas encore d'évaluation

- Bag FilterDocument27 pagesBag FiltermkpqPas encore d'évaluation

- Air Cooler Design (Ujian)Document36 pagesAir Cooler Design (Ujian)Wahyu JatiPas encore d'évaluation

- Air Receiver SizingDocument3 pagesAir Receiver Sizinglutfi awnPas encore d'évaluation

- Chimney/Stack Effect: US Units SI UnitsDocument10 pagesChimney/Stack Effect: US Units SI UnitsSyed Waqas HaiderPas encore d'évaluation

- Fan Selection & PerformanceDocument63 pagesFan Selection & PerformanceVishva Deepak MishraPas encore d'évaluation

- Venturi Scrubber Type U: Adjustable Aerosol SeparatorDocument2 pagesVenturi Scrubber Type U: Adjustable Aerosol SeparatorJIAPas encore d'évaluation

- Rotary Screw Compressor Discussion and Calculations: NotesDocument9 pagesRotary Screw Compressor Discussion and Calculations: Notesfarshad100% (2)

- Clinker Plant Airflow and Fan Efficiency MeasurementDocument109 pagesClinker Plant Airflow and Fan Efficiency MeasurementSantanu PachhalPas encore d'évaluation

- Err:511 Err:511 Err:511 Err:511 Err:511Document2 pagesErr:511 Err:511 Err:511 Err:511 Err:511Anonymous 3ESYcrKPPas encore d'évaluation

- Blower Power CalculationsDocument7 pagesBlower Power CalculationsMuzzamilPas encore d'évaluation

- Condenser Without SubcoolingDocument19 pagesCondenser Without SubcoolingtatvaPas encore d'évaluation

- Static Pressure CalculatorDocument9 pagesStatic Pressure CalculatorTanveer AzizPas encore d'évaluation

- Air Duct CalculatorDocument1 pageAir Duct Calculatoraravoof84Pas encore d'évaluation

- Heat Load EstimationDocument5 pagesHeat Load EstimationSultan FirassuddinPas encore d'évaluation

- Compressor Sizing CalDocument2 pagesCompressor Sizing Calcanada_198020008918Pas encore d'évaluation

- Kalyani Steels Ltd. Media Consumption ListDocument14 pagesKalyani Steels Ltd. Media Consumption Listmadhusri002Pas encore d'évaluation

- FAD CALCULATION FOR AIR DELIVERYDocument4 pagesFAD CALCULATION FOR AIR DELIVERYAnonymous JZK84WzfKPas encore d'évaluation

- System Curve Fan Curve Operating PointDocument45 pagesSystem Curve Fan Curve Operating PointAnonymous I0JAds2SP100% (1)

- Veturi Design ProcedureDocument2 pagesVeturi Design Procedureshivanandr2481Pas encore d'évaluation

- Flare Knock Out Drum Sizing SheetDocument2 pagesFlare Knock Out Drum Sizing Sheetsanjay100% (4)

- Air Receivers Volume CalculationDocument123 pagesAir Receivers Volume CalculationsdgthdtrtretPas encore d'évaluation

- A7CA89 Excel Template Shell and Tube Heat Exchanger Design P1and2 Us UnitsDocument5 pagesA7CA89 Excel Template Shell and Tube Heat Exchanger Design P1and2 Us UnitsMudabbir Shan AhmedPas encore d'évaluation

- Calculating flow and heat transfer in a cement plant cyclone preheaterDocument5 pagesCalculating flow and heat transfer in a cement plant cyclone preheaterhmaza shakeelPas encore d'évaluation

- Blower Calculation ExampleDocument2 pagesBlower Calculation Exampledondapatikirankumar1Pas encore d'évaluation

- Calculate control valve CvDocument3 pagesCalculate control valve CvRio SamudraPas encore d'évaluation

- Moist Air PropertiesDocument12 pagesMoist Air PropertiesLily DianaPas encore d'évaluation

- H&M CalculationsDocument14 pagesH&M CalculationsNITINPas encore d'évaluation

- Vapour Compression RefrigerationDocument11 pagesVapour Compression RefrigerationchinnuPas encore d'évaluation

- Tank or Silo - Volume and Level Calculations-D1.9SDocument24 pagesTank or Silo - Volume and Level Calculations-D1.9SJacques J PienaarPas encore d'évaluation

- Heat Exchanger Design and HT Coefficent Calculation From RC-6 BookDocument20 pagesHeat Exchanger Design and HT Coefficent Calculation From RC-6 BookJag KhadsePas encore d'évaluation

- Transfer of Heat Between Two Fluids - Liquid or Gaseous: General Lay-Out AXA Heat ExchangersDocument1 pageTransfer of Heat Between Two Fluids - Liquid or Gaseous: General Lay-Out AXA Heat ExchangersMarco Ordoñez0% (1)

- FINAL Chapter 6 Conical Dryer 1Document16 pagesFINAL Chapter 6 Conical Dryer 1Milton Dels RosaPas encore d'évaluation

- Fabric Filter Design VariablesDocument14 pagesFabric Filter Design VariablesElumalai Srinivasan100% (1)

- Centrifugal Comp Calc Without ImpellerDocument8 pagesCentrifugal Comp Calc Without Impellersohail1985100% (1)

- Satuan New (Unit)Document29 pagesSatuan New (Unit)Avininda FitriaPas encore d'évaluation

- HVAC unit conversion cheat sheetDocument1 pageHVAC unit conversion cheat sheetPin VongphaiPas encore d'évaluation

- Hoja de ConversionesDocument3 pagesHoja de ConversionesBarack Roderick FarretPas encore d'évaluation

- UnidadesDocument1 pageUnidadesGabrielPas encore d'évaluation

- Sludge ThickenerDocument15 pagesSludge ThickenerDavid LambertPas encore d'évaluation

- Formulas Predicting Power and Piston MotionDocument4 pagesFormulas Predicting Power and Piston MotionAbhijeet FeelproudPas encore d'évaluation

- Flow of Fluids Through Pipes and Turbine Efficiency CalculationDocument9 pagesFlow of Fluids Through Pipes and Turbine Efficiency CalculationAnonymous z4Fe39jPas encore d'évaluation

- Tabela de Conversão de UnidadesDocument1 pageTabela de Conversão de UnidadesrobertaPas encore d'évaluation

- AtmosphereDocument3 pagesAtmospherewakhalewakhalePas encore d'évaluation

- Activity of Heat ExchangerDocument6 pagesActivity of Heat Exchangerzadbiel itai cruz tecuapachoPas encore d'évaluation

- Mud WeightDocument21 pagesMud WeightDelphine KonanPas encore d'évaluation

- THERMODYNAMIC PROPERTIESDocument15 pagesTHERMODYNAMIC PROPERTIESKailas NimbalkarPas encore d'évaluation

- Service Customer DetailsDocument12 pagesService Customer DetailsKailas NimbalkarPas encore d'évaluation

- Radhika Waste ManagementDocument28 pagesRadhika Waste ManagementKailas NimbalkarPas encore d'évaluation

- Authorization LetterDocument1 pageAuthorization LetterKailas NimbalkarPas encore d'évaluation

- Fungal Remediation and Protective Antimicrobial Treatment of A Grossly Contaminated Ten Story HospitalDocument7 pagesFungal Remediation and Protective Antimicrobial Treatment of A Grossly Contaminated Ten Story HospitalKailas NimbalkarPas encore d'évaluation

- MKT 078 04 AG ST Bioactive Surface TreatmentDocument2 pagesMKT 078 04 AG ST Bioactive Surface TreatmentKailas NimbalkarPas encore d'évaluation

- Performance LogDocument1 pagePerformance LogKailas NimbalkarPas encore d'évaluation

- Abhijit Lagare 2018 - 3Document3 pagesAbhijit Lagare 2018 - 3Kailas NimbalkarPas encore d'évaluation

- Specification SheetDocument1 pageSpecification SheetKailas NimbalkarPas encore d'évaluation

- PROPOSAL OF GREEN HC - MSW - Eng - Ver.1Document77 pagesPROPOSAL OF GREEN HC - MSW - Eng - Ver.1Kailas NimbalkarPas encore d'évaluation

- Problem Solving in Solid Waste Engineering: January 2012Document66 pagesProblem Solving in Solid Waste Engineering: January 2012Kailas Nimbalkar100% (1)

- OPERATIONS-Hyderabad CompressedDocument16 pagesOPERATIONS-Hyderabad CompressedKailas NimbalkarPas encore d'évaluation

- 2 Mass Production ProductsDocument12 pages2 Mass Production ProductsKailas NimbalkarPas encore d'évaluation

- Nabl 400Document481 pagesNabl 400parveshnain19Pas encore d'évaluation

- Contact Details of RTAsDocument487 pagesContact Details of RTAsnir0% (1)

- Kailas Nimbalkar expense report listing various items purchased from Aug-Oct 2020Document6 pagesKailas Nimbalkar expense report listing various items purchased from Aug-Oct 2020Kailas NimbalkarPas encore d'évaluation

- Bharti Tools Payment 12980Document1 pageBharti Tools Payment 12980Kailas NimbalkarPas encore d'évaluation

- MouDocument4 pagesMouadishPas encore d'évaluation

- StepsDocument1 pageStepsKailas NimbalkarPas encore d'évaluation

- GoalsDocument8 pagesGoalsKailas NimbalkarPas encore d'évaluation

- Pune Cs CX Mar12Document42 pagesPune Cs CX Mar12Kailas NimbalkarPas encore d'évaluation

- ACAC Council-Certified Indoor Environmental ConsultantDocument1 pageACAC Council-Certified Indoor Environmental ConsultantKailas NimbalkarPas encore d'évaluation

- Method Statement Titania VS 1 2 and Titania FAir (INDIA)Document12 pagesMethod Statement Titania VS 1 2 and Titania FAir (INDIA)Kailas NimbalkarPas encore d'évaluation

- GOALSDocument4 pagesGOALSKailas NimbalkarPas encore d'évaluation

- Eaton Self Cleaning StrainerDocument40 pagesEaton Self Cleaning StrainerKailas NimbalkarPas encore d'évaluation

- E-Way Bill System-DELIVERY CHALLAN-1Document1 pageE-Way Bill System-DELIVERY CHALLAN-1Kailas NimbalkarPas encore d'évaluation

- Pressure Vessel & Air Receiver CatalogDocument16 pagesPressure Vessel & Air Receiver CatalogrenebbPas encore d'évaluation

- Air Receivers: Technology You Can TrustDocument6 pagesAir Receivers: Technology You Can TrustNorman FerdianPas encore d'évaluation

- BSF CatalogDocument2 pagesBSF CatalogKailas NimbalkarPas encore d'évaluation

- Smart OrbitersDocument2 pagesSmart OrbitersKailas NimbalkarPas encore d'évaluation

- Deventer04 MACDocument201 pagesDeventer04 MACFrancisco Solano Reyes EspinozaPas encore d'évaluation

- Pressure Vessel Rivets Welded Joints MDSP PrimeDocument16 pagesPressure Vessel Rivets Welded Joints MDSP PrimeIvanPas encore d'évaluation

- Aso Airfield Standards Quick ReferenceDocument66 pagesAso Airfield Standards Quick ReferenceRahul RanaPas encore d'évaluation

- Crompton Greaves LimitedDocument3 pagesCrompton Greaves LimitedNitish SinghPas encore d'évaluation

- Technical Publications: Direction 2190775 100Document21 pagesTechnical Publications: Direction 2190775 100zakaria alhosinyPas encore d'évaluation

- Grounding Vs BondingDocument2 pagesGrounding Vs BondingVictor HutahaeanPas encore d'évaluation

- ITU ISUP Release Cause CodesDocument5 pagesITU ISUP Release Cause Codesdelgado08Pas encore d'évaluation

- Pipeline Tow MethodDocument25 pagesPipeline Tow MethodctrlaltdestroyPas encore d'évaluation

- 3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFDocument6 pages3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFRene ParedesPas encore d'évaluation

- JU P-Tool Engineering DataDocument1 pageJU P-Tool Engineering Dataazze bouzPas encore d'évaluation

- As ISO 128.23-2005 Technical Drawings - General Principles of Presentation Lines On Construction DrawingsDocument9 pagesAs ISO 128.23-2005 Technical Drawings - General Principles of Presentation Lines On Construction DrawingsSAI Global - APAC0% (3)

- Velp ZX3 Vortex PDFDocument5 pagesVelp ZX3 Vortex PDFarodassanchez0% (1)

- Sodium Citrate AUDocument3 pagesSodium Citrate AUKrishna OgotPas encore d'évaluation

- Microsoft Word - Transistor Models and The Feedback Amp - Docmicrosoft Word - Transistor Models and The Feedback Amp - Doctransistor - Models - and - The - FbaDocument14 pagesMicrosoft Word - Transistor Models and The Feedback Amp - Docmicrosoft Word - Transistor Models and The Feedback Amp - Doctransistor - Models - and - The - FbashubhamformePas encore d'évaluation

- Cassette toilet spare parts guide for models C2, C3 and C4Document21 pagesCassette toilet spare parts guide for models C2, C3 and C4georgedragosPas encore d'évaluation

- Analysis, Specification and Estimate On Road WorksDocument71 pagesAnalysis, Specification and Estimate On Road WorksAnonymous BACdUNvPZ280% (5)

- Guess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerDocument31 pagesGuess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerAlam Shamsher0% (1)

- Essential Roof Truss Design TermsDocument45 pagesEssential Roof Truss Design TermsAnkit SuriPas encore d'évaluation

- CompoundingDocument5 pagesCompoundingMajester RigsPas encore d'évaluation

- 5TH Week EnergyDocument6 pages5TH Week EnergyMira VeranoPas encore d'évaluation

- Technical Presentation - Arik Ethan Kinajil (25231)Document5 pagesTechnical Presentation - Arik Ethan Kinajil (25231)Arik EthanPas encore d'évaluation

- CV Enric Durany enDocument2 pagesCV Enric Durany enenricduranyPas encore d'évaluation

- Nature of Acidity and Lime Requirement in Acid Soils of ManipurDocument8 pagesNature of Acidity and Lime Requirement in Acid Soils of ManipurIJASRETPas encore d'évaluation

- Fire Risk AssessmentDocument13 pagesFire Risk Assessmentteuku zulfikarPas encore d'évaluation

- End All Red Overdrive: Controls and FeaturesDocument6 pagesEnd All Red Overdrive: Controls and FeaturesBepe uptp5aPas encore d'évaluation

- 2009 Energy Storage-U.S. Department of EnergyDocument380 pages2009 Energy Storage-U.S. Department of EnergydiwhitePas encore d'évaluation

- GaN technology powers bright LEDsDocument13 pagesGaN technology powers bright LEDsluciowwPas encore d'évaluation

- 06 HVAC Plumbing PDFDocument727 pages06 HVAC Plumbing PDFTamPas encore d'évaluation

- Boundary Layer Thickness and Heat Transfer CalculationsDocument9 pagesBoundary Layer Thickness and Heat Transfer Calculationsannie100% (1)

- Master Opp GaveDocument84 pagesMaster Opp GaveRizki Al AyyubiPas encore d'évaluation