Académique Documents

Professionnel Documents

Culture Documents

Wps - PQR Traslape A-36 E-6013

Transféré par

Larc99Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Wps - PQR Traslape A-36 E-6013

Transféré par

Larc99Droits d'auteur :

Formats disponibles

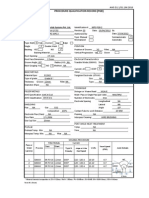

ANNEX N WELDING PROCEDURE SPECIFICATION (WPS) Yes PREQUALIFIED _________ QUALIFIED BY TESTING __________ or PROCEDURE QUALIFICATION RECORDS (PQR)

Identification # WPS-SPCC-003 Company Name Instalaciones Mecnicas Sur S.A.C. Welding Process(es) SMAW Supporting PQR No.(s) PQR-IMESUR-003 JOINT DESIGN USED Type: Lap Joint Single X Double Weld Backing: Yes No X Backing Material: N.A. Root Opening Root Face Dimension Groove Angle: Radius (JU) Back Gouging: Yes No Method BASE METALS Material Spec. ASTM A-36 Type or Grade N.A. Thickness: Groove Diameter (Pipe) FILLER METALS AWS Specification AWS A5.1 AWS Classification E 6013 SHIELDING Flux N.A. Electrode-Flux (Class) N.A. PREHEAT PREHEAT Preheat Temp., Min. Interpass Temp., Min. Plate Pass Thicknes (Weld s Size) Process T = 1/4" 1 (1/4") SMAW Revision 002 Date Authorized by Type Manual X Mechanized WELDING POSITIONS Position of Groove: Fillet: 2F Vertical Progression: 2/1/2012

AWS D1.1/D1.1M:2010

By Date Semiautomatic Automatic

Up

Down

Fillet

1/4"

Gas N.A. Composition N.A. Flow Rate N.A. Gas Cup Size N.A.

Max: Filler Metals Class E6013 Diam. 5/32"

ELECTRICAL CHARACTERISTICS Transfer Mode (GMAW) Short-Circuiting Globular Spray Current: AC DCEP DCEN X Pulsed Power Source: CC CV X Other Tungsten Electrode (GTAW) N.A. Size: Type: TECHNIQUE Stringer or Weave Bead: Stringer Pass Multi-pass or Single Pass (per side) Single-pass Number of Electrodes 1 Electrode Spacing Longitudinal N.A. Lateral N.A. Angle N.A. Contact Tube to Work Distance N.A. Peening N.A. Interpass Cleaning: Brush and/or Grind POSTWELD HEAT TREATMENT Temp. Time

WELDING PROCEDURE Current Type & Polarity Amps Volts DCEN 140-180 22-32

Travel Speed 10-13"

Joint Details

Date and Place Arequipa, 01 February, 2012

Approved By: Sign:

Luis Ramrez Cornejo

ANNEX N Procedure Qualification Record (PQR) #________________ Test Results Specimen No. TENSILE TEST Ultimate Tensile Load, lb Ultimate Unit Stress, psi

AWS D1.1/D1.1M:2010

Width

Thickness

Area

Character of Failure and Location

GUIDED BEND TEST Specimen No. Type of Bend Result Remarks

VISUAL INSPECTION Appearance Undercut Piping porosity Convexity Test date Witnessed by

Radiographic-ultrasonic examination RT report no.: Result UT report no.: Result FILLET WELD TEST RESULTS Minimum size multiple pass Maximum size single pass Macroetch Macroetch 1 3 1 3 2 2 Other Tests All-weld-metal tension test Tensile strength, psi Yield point/strength, psi Elongation in 2 in, % Laboratory test no. Welders name ________________________________ Clock no. Stamp no. Tests conducted by Laboratory Test number Per We, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in conformance with the requirements of Clause 4 of AWS D1.1/D1.1M, (_________) Structural Welding Code-Steel. Signed By Title Date

354

Vous aimerez peut-être aussi

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387Pas encore d'évaluation

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasPas encore d'évaluation

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiPas encore d'évaluation

- Heat Treatment Procedure.Document15 pagesHeat Treatment Procedure.Vijay ShamPas encore d'évaluation

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraPas encore d'évaluation

- PWHT PROCEDURE (11) Rev 0Document14 pagesPWHT PROCEDURE (11) Rev 0AbdulNeyasPas encore d'évaluation

- WPS ListDocument2 pagesWPS ListAdeel OmerPas encore d'évaluation

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizPas encore d'évaluation

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASIPas encore d'évaluation

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónPas encore d'évaluation

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganPas encore d'évaluation

- Material GradesDocument1 pageMaterial GradesshisPas encore d'évaluation

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackPas encore d'évaluation

- Report No. TA-V-1456Document2 pagesReport No. TA-V-1456u04ajf3Pas encore d'évaluation

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanPas encore d'évaluation

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisPas encore d'évaluation

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONPas encore d'évaluation

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXPas encore d'évaluation

- Welding Procedure Specification: Wps For Ss To Cs Material (Gtaw+Smaw)Document1 pageWelding Procedure Specification: Wps For Ss To Cs Material (Gtaw+Smaw)Lipika GayenPas encore d'évaluation

- Ut Format Report For Ut Libra (Naidu)Document4 pagesUt Format Report For Ut Libra (Naidu)vsnaiduqcPas encore d'évaluation

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- Fit Up ReportDocument5 pagesFit Up ReportAkash Singh Tomar100% (1)

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusPas encore d'évaluation

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyPas encore d'évaluation

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocument1 pageWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedPas encore d'évaluation

- AnilDocument7 pagesAnilanil kumarPas encore d'évaluation

- Acceptance Criteria Asme B31.3 PDFDocument1 pageAcceptance Criteria Asme B31.3 PDFAhmad RizkiPas encore d'évaluation

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- 1035 03Document2 pages1035 03Anuj ShahiPas encore d'évaluation

- Ug PipingDocument1 pageUg PipingVinoth KumarPas encore d'évaluation

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH APas encore d'évaluation

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityPas encore d'évaluation

- Electrodes EnglishDocument139 pagesElectrodes Englishcostelino72Pas encore d'évaluation

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- SS WPSDocument1 pageSS WPSMOHAMEDABBASPas encore d'évaluation

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoPas encore d'évaluation

- PQRDocument3 pagesPQRnazirulhakimPas encore d'évaluation

- Electrode Selection ChartDocument4 pagesElectrode Selection Chartsunitbhaumik100% (2)

- Post Weld Heat TreatmentDocument1 pagePost Weld Heat Treatmentthho84Pas encore d'évaluation

- WPS GTAW Stainless SteelDocument7 pagesWPS GTAW Stainless SteelVarun MalhotraPas encore d'évaluation

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationGodwin A.udo-akanPas encore d'évaluation

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Sample API 1104 WpsDocument1 pageSample API 1104 Wpsippon_osoto100% (1)

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoPas encore d'évaluation

- Double-V-Weld Consumption Formula in Excel SheetDocument6 pagesDouble-V-Weld Consumption Formula in Excel SheetvinothPas encore d'évaluation

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Ut PQRDocument10 pagesUt PQRArvind Sahani100% (1)

- Aws PQR FormDocument3 pagesAws PQR Formndi101Pas encore d'évaluation

- PQRDocument3 pagesPQRCatalina Sorina ParfenePas encore d'évaluation

- Procedure Qualification Record (PQR) # Test ResultsDocument2 pagesProcedure Qualification Record (PQR) # Test ResultsEnrique Santiago BenavidesPas encore d'évaluation

- PQR Gmaw3gDocument4 pagesPQR Gmaw3gdevendrasingh2021100% (3)

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- Welding Procedure Specification (WPS) Yes Prequalified Qualified by Testing or Procedure Qualification Records (PQR) YesDocument4 pagesWelding Procedure Specification (WPS) Yes Prequalified Qualified by Testing or Procedure Qualification Records (PQR) YesAugusto Q. SerranoPas encore d'évaluation

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasPas encore d'évaluation

- Form Document Fabrication Review ChecklistDocument2 pagesForm Document Fabrication Review ChecklistIrnaldi Yoza WijayaPas encore d'évaluation

- Welding Procedure Specification Pipe - 6GDocument3 pagesWelding Procedure Specification Pipe - 6Gdndudc97% (29)

- Long Quiz.. Exogenic ProcessDocument3 pagesLong Quiz.. Exogenic ProcessSheryl Lou AngelesPas encore d'évaluation

- ابزاردقیق - مخفف تجهیزات ابزاردقیقDocument3 pagesابزاردقیق - مخفف تجهیزات ابزاردقیقSepidePas encore d'évaluation

- (1967) History of The Lenz-Ising ModelDocument13 pages(1967) History of The Lenz-Ising ModelJakler NichelePas encore d'évaluation

- NEET/JEE: 2020-21: Periodic PropertiesDocument3 pagesNEET/JEE: 2020-21: Periodic Propertiesshantinath123gmailcoPas encore d'évaluation

- Cremophor A GradesDocument8 pagesCremophor A GradesMd.ali-bin-saifullah100% (4)

- Seminar ReportDocument11 pagesSeminar Reporttushar20june71% (7)

- Batch: General InformationDocument5 pagesBatch: General InformationNaik LarkaPas encore d'évaluation

- Ni 1882Document81 pagesNi 1882estradeiroPas encore d'évaluation

- Factual ReportDocument7 pagesFactual Reportlukman arifPas encore d'évaluation

- Seasons Webquest Justin PowersDocument2 pagesSeasons Webquest Justin Powersapi-26408978967% (3)

- IJC H2 Paper 1 and 2 Answers (For Sharing)Document9 pagesIJC H2 Paper 1 and 2 Answers (For Sharing)Sharon HowPas encore d'évaluation

- ACI 301 XdataDocument5 pagesACI 301 XdatadarebertPas encore d'évaluation

- Clay Brick MakingDocument9 pagesClay Brick MakingapihanasPas encore d'évaluation

- Chapter 4 PhyDocument94 pagesChapter 4 PhyDeneshwaran RajPas encore d'évaluation

- JBT GreenDocument3 pagesJBT GreenRagu VenkatPas encore d'évaluation

- Creative Enzymes: Enzyme Engineering Research: Applications and Future PromiseDocument4 pagesCreative Enzymes: Enzyme Engineering Research: Applications and Future PromiseIva ColterPas encore d'évaluation

- Microwave Level SwitchDocument3 pagesMicrowave Level SwitchDidinAndresIIPas encore d'évaluation

- VGScienta Pressure MeasurementDocument16 pagesVGScienta Pressure Measurementdeaanggraeni_9345Pas encore d'évaluation

- Concrete Mix Proportioning Using EMMA SoftwareDocument12 pagesConcrete Mix Proportioning Using EMMA SoftwareYuliusRiefAlkhalyPas encore d'évaluation

- Liquid Viscosity: 5.1. Trial ObjectivesDocument5 pagesLiquid Viscosity: 5.1. Trial ObjectivesririnPas encore d'évaluation

- 2015 JC2 H2 Carboxylic Acids and Derivatives Part 1 Tutorial (Teachers) UpdatedDocument18 pages2015 JC2 H2 Carboxylic Acids and Derivatives Part 1 Tutorial (Teachers) UpdatedJohnPas encore d'évaluation

- Phytochemistry, Antioxidant and Antibacterial Activities of Medicinal Plants - A Comparative StudyDocument12 pagesPhytochemistry, Antioxidant and Antibacterial Activities of Medicinal Plants - A Comparative StudyRigotti BrPas encore d'évaluation

- NGL Fractionation Using HYSYSDocument30 pagesNGL Fractionation Using HYSYSAhmad Deyab100% (3)

- Coal BlastDocument2 pagesCoal BlastAndy AgePas encore d'évaluation

- FireworX Conventional Compatibility IndexDocument13 pagesFireworX Conventional Compatibility IndexFernando CamposPas encore d'évaluation

- Sika Viscocrete: TechnologyDocument13 pagesSika Viscocrete: TechnologyacarthurPas encore d'évaluation

- DD ValveDocument8 pagesDD ValveJunnaid NissarPas encore d'évaluation

- Measurement of Biodiesel Concentration in A Diesel Oil MixtureDocument4 pagesMeasurement of Biodiesel Concentration in A Diesel Oil MixtureFredy Akenaton ArroyoPas encore d'évaluation

- Chem M2 Laboratory Apparatus, Safety Rules & SymbolsDocument32 pagesChem M2 Laboratory Apparatus, Safety Rules & SymbolsDiana Dealino-SabandalPas encore d'évaluation