Académique Documents

Professionnel Documents

Culture Documents

F 15 Manual

Transféré par

scimionettaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

F 15 Manual

Transféré par

scimionettaDroits d'auteur :

Formats disponibles

HIGH-END TECHNOLOGY

F15 for electric ducted fan

RC

First we want to tha nk and congratulate you with your de cision in buying o ne of our Kits.

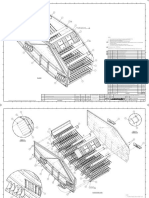

The F15 puts together very easily so there is not much explanation needed. Just look carefully at the pictures . This in not a plane for beginners, and you should have some experience with putting together ARFs.

DATA: Winspan: 850 mm Length: 1220 mm Weight: 1800-2200 gram Ducted fans 2 x 72mm

Items needed to complete:. 4 ch. Computer Radio system w/ 2 servos. 2 Electronic brushless speed controllers 2 fan-units 6904 HETFAN or MF 480. 2 480 size brushless motors e.g. EDF 2W , 3W, 4W or 2W20 Lipo battery 5 or 30 minute epoxy micro balloons CA Glue w/ accelerator Velcro. Standard tools: Drill or Dremel tool Plyer/cutter Scissor X acto Knife Soldering iron.

Fit the hardwood wing joiner in the fuselage and wing and see if the wing fist nicely. Start by gluing one wing panel with 5 or 30 minute epoxy. First apply some epoxy inside the wing joiner slot in the fuselage. Press the wing joiner inside the fuselage. Remove excess epoxy. Now apply epoxy in the wing joiner slot in the wing root and also apply epoxy on the wing root. Slide the wing over the hard wood wing joiner and press the wing against the fuselage. Make the leading- and trailing edge align with the fuselage. Remove the excess epoxy with a clean cloth and cleaning alcohol. When the epoxy has cured you can do the other wing panel the same way.

After the wings the wings are glued one. It is possible to cover the joint between the fuselage and wings with a 3-4 mm wide white or grey trim. (Oracover).

Mark the position for the Pivot-rod ( 2 3 mm steel rods one for each side) 100 mm from the end of the fuselage. Centre of the hole should be 6 mm from the bottom Drill a little oversized hole in the middle at the marked location. We recommend a 4 mm hole. Wait before you glue the pivot rod in place.

Wheel stop installed on pivot rod in gap. Notice taped edge.

Before you glue the Pivot rod in the fuselage with 5 minute epoxy put tape around the root of the Elevon. And also put tape over the fuselage side, see top right picture. Glue one pivot rod at the time, and check the alignment.

Mark the location of the control horn just behind the pivot hole, also mark the surface. Trim the tab to approximately the same thickness as the elevon. Cut a slot as in the picture for the control horn.

Glue the control horn with 5 minute epoxy in place. When the glue has cured make the top hole in the control horn 2mm you can do this with a 2 mm drill.

Now install the pushrod connector in the control horn, see above picture. Secure the nut with some glue so it wont come of when youre flying he plane.

Put tape or a shrinktube around the servo, place the servo on the Plywood former and glue the wood sticks (6x6mm) on the ply wood plate against the servo. Use CA glue. As You can see on the top picture the pushrod and clevis are already installed on the servo control horn.

Mark a 15x 2 mm slot on the bottom of the fuselage starting 45 mm from the Pivoting rod. Centreline of the slot at 45 mm should be 6 mm form the fuselage side. Also the slot should be parallel to the centreline of the fuselage. Look closely at the above pictures.

Put the Stabilizer/ elevon on the pivot tube,( dont forget to place a washer between the elevon and fuselage see top picture on page 4). Route the pushrod from inside trough the slot you just made, and insert the pushrod in the connector mounted on the controlhorn. Check for free movement of the pushrod. Now you can glue the servotray in place with 5 minute epoxy. Repeat this step for the other elevon.

Vertical fin installation.

Mark the position of the trim of area on the front and back of the notch. Cut the front and back off with a Dremel cutter or saw. Do this on both notches for left and right fin.

Vertical fin installation. Trial fit the vertical fin first, you need to trim 8mm from the front and the back of the notch to get a better fit. Mark it first and trim with a dremel cutter or saw. Also sand the inside area of the fin and sand the outside of the notch a little bit. When you heat up the bottom end of the fin with a hair dryer (blower) the glass-fibre will soften up a little. Now mix 5 or 30 minute epoxy with micro balloons and apply a small ridge mixed glue along the inside edge of the vertical fin. You can press the fin in place. Remove the excess glue with a clean cloth and cleaning alcohol. Make sure the Fin is aligned and straight up. Keep the edges of the fin pressed against the fuselage.

CANOPY: Dont get confused about the below pictures because we also show the canopy of our F104 but the steps fro the F15 are exact the same.

Get the canopy bottom , front and the back plate , place on the fuselage . secure the bottom plate with some tape. Now glue the front and back plate to plywood canopy bottom.

Drill a 3 mm hole trough the front plate and fuselage. Let the dowel stick out a couple of mm and glue the dowel to the plywood front former. Remove canopy frame from the fuselage. Now sand the edges of the canopy frame so that it fits within the outlines of the fuselage.

Trim the front, back and bottom edges from the ABS canopy now align it an tape it on the fuselage.

Mark the Outline from the fuselage on the Canopy with a marker. Now trim of the plastic along the marked line. Repeat this step until you have a good fit of the ABS canopy

Put the Canopy floor on the fuselage, and do some last adjustments to the canopy floor and ABS canopy. Glue 2 magnets in the back edges of the cockpit floor. Also glue them inside the fuselage direct under the other magnets. Paint the floor in the colour you want. Now place ( after the paint has dried) a piece of plastic film (cut-open plastic bag) under the frame . Now you can glue the abs canopy in place with 5 minute epoxy or canopy glue.

Put masking tape around the frame line on the canopy and spray paint the top. After removing the masking tape your cockpit should look like this.

Trusttube template

Glue overlap area

Print out twice

Print out the template 2 times cut them out and glue or tape them togetter. This template is A4 size.

Place the template under the supplied pvc sheet and trace the outline with a marker. Do this twice as there are 2 fanunits.

Cut out the unrolled surface for both trust tubes. Put the ovelap area inside. Roll the pvc to a tube and apply outside adhesive tape. The Edge should match the innerline of the overlap area. Now you have a perfect conical trust tube.

Read the installation instruction from your fan-unit first. Install motor and ESC first. You can either install the ESC inside the thrust tube or outside. We recommend to place the ESC behind the motor inside the thrust tube.

On the left picture you see the 4 channel micro receiver attached to the top of the fuselage with Velcro. You can also tape the servo wires to the top. So the wires will not be in the way when you install the ducted fans.

Before you install the fan-unit you must add some tape to the front off the shroud, so that the shroud will fit tight in the intake tube. Do this for both fan-units.

The wires from the ESCs need to be extended all the way to the front. Use at least 4mm2 wires. Because of the length we advise to put in the middle of the extension wire 1 or 2 capacitors e.g. 470 uf 40V. Strip some of the insulation of wire and solder the capacitor(s) to the wires, than insulate with shrink tube.

For the installation of the bungee hook you must align a ruler wit the front of the bottom intakes like in the above picture, mark the middle with a marker. This is the bungee hook location.

Drill a 2 mm hole at the marked location ( the former from the battery-tray in right under here) . Now glue the bungee hook in the hole with 5 minute epoxy.

Battery tray is already installed with a battery holding strap.

This page shows you how to apply decals ( our phantom is shown here)

Cut the decal from the decal sheet leave the protective back on the decal. Trim of 10 mm from the protective back.

Line out the decal on the area where you want to put the decal. Press the adhesive part. Check if the decal is ligned out and remove the rest of the protective back.

Do this for all the decals

Settings: C.G. 95-105 mm from the leading edge of the wing. Elevator throws 13 mm up 13mm down. Use 50% exponential Ailerons throws 13 mm up 13 mm down. Use 30% exponential. Set the Wing incidence, set the main wings level, the elevons must be set to 2 degrees up. This means that the trailing edge from the elevon should be set 4 mm higher than its leading edge. You can do this by placing the main wings level on two horizontal blocks. And measure the height of the leading- and trailing-edge from the elevon with a ruler. First Flight. Use a bungee to start the plane. Before start is good to use some up trim. After start level the plane dont attempt to turn, climb and trim the plane. The F15can be flown very slow with a high AOT But never make turns with a high angle of attack (nose high position) You risk to drop a wing.

You will find the airplane is very nimble but has excellent stability. Loops and snap rolls are easily obtained with adequate entry speeds.. Just remember to land level; as to avoid damage to the plane . Happy Flying.

WARNING!

Although the F15 is a stable airplane, it is not a trainer or first EDF airplane. This airplane is capable of very high speeds and therefore can cause serious personal injury and property damage. We strongly urge you to seek the help of an AMA approved instructor if this is your first aircraft of this type. Please use common sense

Fly in suitable areas for a high-speed aircraft such as an AMA approved field.

High-end Technology Holland assumes no liability for the operation or performance of this product. It is the responsibility of the operator to use this product in a safe and responsible manner.

Vous aimerez peut-être aussi

- Bob's Card Models: Douglas DC-3 "Dakota" (Scale 1:50)Document15 pagesBob's Card Models: Douglas DC-3 "Dakota" (Scale 1:50)erik gomezPas encore d'évaluation

- Wooden Toy Road Grader Plans: List of MaterialsDocument13 pagesWooden Toy Road Grader Plans: List of Materialsasep ridwan0% (1)

- Yamaha Vmax by Nobutaka MukouyamaDocument31 pagesYamaha Vmax by Nobutaka MukouyamaPaperShockPas encore d'évaluation

- PapercraftDocument3 pagesPapercraftchandra efendiPas encore d'évaluation

- T-4.896.425 - C01 - MS ITP For Hot Cold Insulation WorksDocument20 pagesT-4.896.425 - C01 - MS ITP For Hot Cold Insulation Worksshahid imamPas encore d'évaluation

- F-107 Instructions FullDocument20 pagesF-107 Instructions Fullmam73Pas encore d'évaluation

- Mercedes Benz I e LTR (1) QDocument6 pagesMercedes Benz I e LTR (1) QAugusto Manuel Inga SánchezPas encore d'évaluation

- Yzf r1 07 Assembly FullDocument20 pagesYzf r1 07 Assembly FullChoky Masih TopiazPas encore d'évaluation

- TOTAL TrackerDocument11 pagesTOTAL TrackerLuiz Fernando MibachPas encore d'évaluation

- 1926 Chevy 1 TonDocument9 pages1926 Chevy 1 TonLeonardo Santos GomesPas encore d'évaluation

- BD 5 InstructionsDocument13 pagesBD 5 InstructionskokiskoPas encore d'évaluation

- Bob's Card Models: Fairchild C-119G 'Flying Boxcar" (1:72)Document16 pagesBob's Card Models: Fairchild C-119G 'Flying Boxcar" (1:72)Luiz Fernando MibachPas encore d'évaluation

- F22 FOAM Construction GuideDocument26 pagesF22 FOAM Construction GuideFilip Lisičin100% (1)

- 0037 Exercises For Beginner-Dpva5vDocument4 pages0037 Exercises For Beginner-Dpva5vMauro Viana100% (1)

- Plugin Yz450fm Assembly01Document4 pagesPlugin Yz450fm Assembly01wahidnursalimPas encore d'évaluation

- 1911 Buick %U201CBug%U201D Model 14 RoadsterDocument5 pages1911 Buick %U201CBug%U201D Model 14 RoadsterLeonardo Santos GomesPas encore d'évaluation

- Bob's Card Models: Junkers Ju 52 ("Tante Ju" - "Iron Annie") 1:72Document9 pagesBob's Card Models: Junkers Ju 52 ("Tante Ju" - "Iron Annie") 1:72Luiz Fernando MibachPas encore d'évaluation

- F-14 Park Jet Construction Guide 2Document23 pagesF-14 Park Jet Construction Guide 2John MondoPas encore d'évaluation

- T-38 Park Jet Construction GuideDocument16 pagesT-38 Park Jet Construction Guidemam73Pas encore d'évaluation

- Piping ArticlesDocument187 pagesPiping Articlesdhanu1308Pas encore d'évaluation

- Chiefsshop Rockinghorse PDFDocument13 pagesChiefsshop Rockinghorse PDFNicolas TerjekPas encore d'évaluation

- Wright Flyer AeroplaneDocument4 pagesWright Flyer AeroplaneAviation/Space History LibraryPas encore d'évaluation

- T-38 Park Jet Plans (Parts Templates Tiled)Document15 pagesT-38 Park Jet Plans (Parts Templates Tiled)Iruel Street NewPas encore d'évaluation

- FT Mustang v1.1 Full-SizeDocument4 pagesFT Mustang v1.1 Full-SizeAlejandro Lablée50% (2)

- Products DatabaseDocument104 pagesProducts DatabaseAlexPas encore d'évaluation

- F-18 Park Jet Construction Guide Rev ADocument20 pagesF-18 Park Jet Construction Guide Rev ASzymon WójcikPas encore d'évaluation

- Digital Patterns: Designed by Steve GoodDocument10 pagesDigital Patterns: Designed by Steve GoodWilson Roberto de OliveiraPas encore d'évaluation

- F-14 Park Jet Construction GuideDocument23 pagesF-14 Park Jet Construction Guidemam73100% (1)

- MIG-31 Firefox Construciton ManualDocument9 pagesMIG-31 Firefox Construciton ManualChrisPas encore d'évaluation

- City CarDocument9 pagesCity CarDominique VoirinPas encore d'évaluation

- Technical Specifications For 132 KV LineDocument214 pagesTechnical Specifications For 132 KV LineHemant Kumar Sharma80% (10)

- Bondek User GuideDocument0 pageBondek User GuidemarioxguzmanPas encore d'évaluation

- Cardboard Suzuki Hayabusa Chassis: InstructablesDocument15 pagesCardboard Suzuki Hayabusa Chassis: InstructablesmecrishattPas encore d'évaluation

- Micro PittsDocument6 pagesMicro Pittsmam73Pas encore d'évaluation

- "Discovery" XD-1: Assembly InstructionsDocument7 pages"Discovery" XD-1: Assembly InstructionsTaide Ding100% (1)

- Guppyassemblymanual PDFDocument11 pagesGuppyassemblymanual PDFmarianospenza100% (1)

- Heirloom Push ToyDocument13 pagesHeirloom Push ToyLinoPas encore d'évaluation

- Molde Jeep WoodBrArtDocument7 pagesMolde Jeep WoodBrArtBeto Ferraz Flameguista Alencar100% (1)

- Funny AirplaneDocument17 pagesFunny AirplaneAndres Mejia100% (1)

- HG Barnaby PDFDocument2 pagesHG Barnaby PDFJeffPas encore d'évaluation

- Handbook of LNGDocument3 pagesHandbook of LNGKai Yuan Teo0% (1)

- Paper Plane (STREAM-CX) : Pattern: Vertical Fin Wing FilletDocument2 pagesPaper Plane (STREAM-CX) : Pattern: Vertical Fin Wing FilletFransiskus OrganisPas encore d'évaluation

- Martillo PDFDocument14 pagesMartillo PDFIrvin Jovani Torres MagañaPas encore d'évaluation

- Contraseña Paper-Replika - Com CORSAIR 2Document29 pagesContraseña Paper-Replika - Com CORSAIR 2ClaudioAlfredoSpoto100% (2)

- Super Glider e A4Document3 pagesSuper Glider e A4Cayo M ChPas encore d'évaluation

- Rocking Horse Center Body (Cut To Solid Green Line Only) : 1/4" HoleDocument7 pagesRocking Horse Center Body (Cut To Solid Green Line Only) : 1/4" HoleticleanulPas encore d'évaluation

- F-14 Park Jet (Assembly Drawing)Document2 pagesF-14 Park Jet (Assembly Drawing)John MondoPas encore d'évaluation

- Digital Patterns: Designed by Steve GoodDocument9 pagesDigital Patterns: Designed by Steve Goodmmadutza48Pas encore d'évaluation

- Digital Patterns: Designed by Steve GoodDocument7 pagesDigital Patterns: Designed by Steve Goodrichardppz124Pas encore d'évaluation

- Cessna 182 SkaylineDocument56 pagesCessna 182 SkaylineJairo Ramos100% (1)

- p51 WhriligigDocument3 pagesp51 WhriligigToddlewis12692425Pas encore d'évaluation

- Bob's Card Models: Douglas DC-6B 1:72Document18 pagesBob's Card Models: Douglas DC-6B 1:72Luiz Fernando MibachPas encore d'évaluation

- Assembly Instructions For V-2 Rocket: HistoryDocument4 pagesAssembly Instructions For V-2 Rocket: HistoryEmerson URPas encore d'évaluation

- Duck Pull Toy: Project 19247EZDocument3 pagesDuck Pull Toy: Project 19247EZBSulliPas encore d'évaluation

- Build Guide - Landy MiniDocument16 pagesBuild Guide - Landy MiniChandrabhanPas encore d'évaluation

- Polaris Parts Templates (Tiled)Document20 pagesPolaris Parts Templates (Tiled)Leandro AlvarengaPas encore d'évaluation

- Digital Patterns: Designed by Steve GoodDocument3 pagesDigital Patterns: Designed by Steve Goodrichardppz124Pas encore d'évaluation

- Pawnee Parts - FullDocument1 pagePawnee Parts - FullAlejandro LabléePas encore d'évaluation

- SU-47 Parts 6mm Depron PDFDocument19 pagesSU-47 Parts 6mm Depron PDFAlejandro LabléePas encore d'évaluation

- Mobil 1Document3 pagesMobil 1Zosmo Simiao CostaPas encore d'évaluation

- A Summer's Swing: An Easy-To-Build Project For Easy LivingDocument3 pagesA Summer's Swing: An Easy-To-Build Project For Easy LivingWalter AcuñaPas encore d'évaluation

- (Digital Navy) - Cruiser OchakovDocument29 pages(Digital Navy) - Cruiser OchakovtibexxPas encore d'évaluation

- F-22 Construction Guide-Scratchbuild 13Document14 pagesF-22 Construction Guide-Scratchbuild 13Mar PopPas encore d'évaluation

- Motor Glider ManualDocument99 pagesMotor Glider ManualravaiyamayankPas encore d'évaluation

- Clik Evo Build InstructionsDocument5 pagesClik Evo Build InstructionsTony JohanzonPas encore d'évaluation

- Build Instructions:: Download Extra 300 - 900 MM Plans Download Extra 300 - 900 MM Mazda DecalsDocument16 pagesBuild Instructions:: Download Extra 300 - 900 MM Plans Download Extra 300 - 900 MM Mazda Decalsfer freePas encore d'évaluation

- Victaulic Firelock Sprinkler Coating Data Sheet: See Victaulic Publication 10.01 For More DetailsDocument2 pagesVictaulic Firelock Sprinkler Coating Data Sheet: See Victaulic Publication 10.01 For More DetailsRobson Custódio de SouzaPas encore d'évaluation

- 1301A01422 Zaranda 3500Document2 pages1301A01422 Zaranda 3500Edgar FloresPas encore d'évaluation

- 1600 Wall Sys3 - ADocument24 pages1600 Wall Sys3 - ABlack DisciplePas encore d'évaluation

- MENA Reference MBR Durrat Al BahreinDocument2 pagesMENA Reference MBR Durrat Al BahreinNermeen ElmelegaePas encore d'évaluation

- E FSS5 Attm3 Tooling-manual-Lathe Rev1 090330 PDFDocument9 pagesE FSS5 Attm3 Tooling-manual-Lathe Rev1 090330 PDFonnoPas encore d'évaluation

- MBDCDocument2 pagesMBDCRachel RobinsonPas encore d'évaluation

- Ana Aerodur 3001 Hs Base Coat g30424 Pms214c Red enDocument14 pagesAna Aerodur 3001 Hs Base Coat g30424 Pms214c Red enSreejith SPas encore d'évaluation

- Super Silk PDFDocument13 pagesSuper Silk PDFSachin KothariPas encore d'évaluation

- Rexnord Tabletop Mattop English 02Document215 pagesRexnord Tabletop Mattop English 02operationmanager100% (1)

- Product Catalogue Camfil FarrDocument61 pagesProduct Catalogue Camfil FarrTrần Hữu DũngPas encore d'évaluation

- High Voltage Motors: in Power GenerationDocument8 pagesHigh Voltage Motors: in Power GenerationKarim IsmailPas encore d'évaluation

- Drveni Zidovi PDFDocument35 pagesDrveni Zidovi PDFMartinJankovićPas encore d'évaluation

- Pharm. LinimentsDocument38 pagesPharm. LinimentsDr-Md Abul BarkatPas encore d'évaluation

- HR Datasheet RotoscanDocument2 pagesHR Datasheet RotoscanRaúl Jiménez AcevesPas encore d'évaluation

- TSP 23 No 1Document44 pagesTSP 23 No 1Primitivo GonzálezPas encore d'évaluation

- SHD450 Butt Fusion Welding Machine - WuXi Sun Hill New Energy Technology Co.,Ltd - WuXi Sun Hill New Energy Technology CoDocument4 pagesSHD450 Butt Fusion Welding Machine - WuXi Sun Hill New Energy Technology Co.,Ltd - WuXi Sun Hill New Energy Technology CoPrageeth Nalaka ArambegedaraPas encore d'évaluation

- Rock Cycle Crayon LabDocument4 pagesRock Cycle Crayon Labapi-251355123Pas encore d'évaluation

- Cryoseal: Liquid Nitrogen Containers (Dewars) : Also Available 340/550 Liters Bulk Storage ContainersDocument2 pagesCryoseal: Liquid Nitrogen Containers (Dewars) : Also Available 340/550 Liters Bulk Storage ContainersDr. Awanish MishraPas encore d'évaluation

- Troubleshooting-Overhauling of A Centrifugal PumpDocument3 pagesTroubleshooting-Overhauling of A Centrifugal PumpSrini VasanPas encore d'évaluation

- ACI 363r 92 State of The Art Report On HDocument55 pagesACI 363r 92 State of The Art Report On Hosama anterPas encore d'évaluation

- Egg Hatching Poster en 2015Document1 pageEgg Hatching Poster en 2015mahmudPas encore d'évaluation

- Research Paper Additive ManufacturingDocument9 pagesResearch Paper Additive Manufacturingbt19109019 Aditya VermaPas encore d'évaluation

- Specifications Virgin Fuel Oil D6: Method Units Test Result UnitDocument1 pageSpecifications Virgin Fuel Oil D6: Method Units Test Result UnitDavid garzaPas encore d'évaluation

- Acc Gearbox ManualDocument47 pagesAcc Gearbox ManualShivakumar100% (1)