Académique Documents

Professionnel Documents

Culture Documents

Part 2 Mechnical Design

Transféré par

Jeff Ong Soon HuatDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Part 2 Mechnical Design

Transféré par

Jeff Ong Soon HuatDroits d'auteur :

Formats disponibles

CN4119 Design I

Part 2 Mechnical Design

References Beer, F. P. and E. R. Johnston, Jr.Mechanics of Materials, Second Edition in SI Units, McGraw Hill, Book Company. Singapore, 1992.

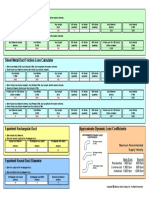

Chapter 1. Tension

1. Stress Mechanics of Materials. Strength and Rigidity. Determination of stresses and deformations of members in a structure. Mechanical design: - Strength requirement: []. - Rigidity requirement: deformations an allowable value. Analysis of stresses and strains. 1.1. Stress Normal stress Consider a rod subjected to a tensile force P at its end. To determine the internal force at any point, we pass through a cross section, consider the equilibrium of either portion of the rod, we have a force equilibrium equation in the axial direction. The internal force at any cross section within the rod is thus equal to the load P . Will the rod break under the action of P ? The ability of the material to withstand the intensity of the internal force, but not the internal force itself. Assume that the internal force P is uniformly distributed over the entire cross section A, we call = P/A the normal (tensile) stress on any point of area A.

In general, consider a small area A around a point Q on a cross section A, on which the internal force is F , we dene = lim F A0 A 101

as the normal stress at point Q. Therefore = (Q) represents the stress distribution over cross section A. Accordingly,

P =

A

(Q) dA.

SI units of stress: N/m2 = P a (Pascal). Multiples of P a: 1 kP a = 103 P a = 103 N/m2 1 M P a = 106 P a = 106 N/m2 1 GP a = 109 P a = 109 N/m2 [],

The design of a rod requires where [] = y /ns for ductile materials, [] = c /ns for brittle materials.

y is the yielding stress of the ductile material specimen and c is the stress of the brittle specimen at break in tensile test, which is coducted in a tensile machine. ns is called the factor of safety, which should be determined by considering the imporatnce of the structure componenet and the price of the material. 1.2. Shear Stress Consider a member AB subjected to transverse forces P and P in a close distance. To determine the internal force, we pass through a section at position C between the two forces and consider the equilibrium for either portion of the member. We conclude the internal force must be in the section and its magnitude is P . We call P in the section shearing force, or simply, shear. upon both the magnitude of P and the value of A. Assume a uniform distribution of P over A, we dene = P/A 102 Whether the member breaks depends

the shear stress at any point on A.

General denition:

= lim

F A0 A

= (Q) is a function of the position Q on section A and represents the intensity of the shearing forces at point Q. Accordingly P =

A

(Q) dA.

Design of bolts, pins and rivets:

[ ], where [ ] is the allowable shear stress of the material used.

1.3. Stress State at a Point and Stress Components Consider a two force member subjected to axial forces P and P . We pass though a section at an angle with the normal plane. What would be the stresses on this oblique plane? Resolving P into components F and V , which are normal and tangent to the section respectively F = P cos , V = P sin . The area A0 of this section is A0 = A/ cos , the normal and shear stress on this section: = = We can see = 0 , = 45 , = P = max , A P , 2A 103 = = 0; P = max 2A F P cos P = = cos2 A0 A/ cos A V P sin P = = sin cos A0 A/ cos A

Consider a body subjected to loads P1 , P2 , P3 , . Consider point Q within this body. To know the stresses at Q, we should calculate the stresses on the three co-ordinate planes at Q. First, pass through point Q a section perpendicular to x-axis. Consider an area element A around Q.

i.e., and depend on the orientation of the section. Scholar, vector and tensor. Stress is a (second order) tensor. It has 32 = 9 components.

Resolve the internal force on A to a normal force F x and a shearing force V x . Further resolve V x to Vyx and Vzx in y and z direction, respectively. The denition of the normal & shear stress at Q on this section: F x , A0 A Vyx , A0 A Vzx . A0 A

x = lim

xy = lim

xz = lim

Note 1) x = xx is the normal stress. 2) xy and xz have two subscripts: the rst indicates the direction of the section, the second indicates the direction of the shear force. 3) If the section is in +x direction, x , xy and xz are + if the force is in + co-ord direction. They are - if they are in - co-ord direction. However, If the section is in -x direction, x , xy and xz are + if the force is in - co-ord direction. They are - if they are in + co-ord direction. Similarly, at point Q, we can dene y , yx and yz on the section of outnormal in y direction and z , zx and zy on the section of outnormal in z direction. The stress state at Q, x xy xz yx y yz zx zy z which is called the stress tensor, or stress matrix. The stress state at Q can also be represented by a small cube centred at Q with various stresses exerted on each of its six faces. 104

The stress tensor is symmetric. The two shear stresses of the same indices is equal.

2. Hookes Law 2.1. 1-D Hookess Law For small deformation, i.e., for < y , from the =E

diagram, we have

which is known as the 1D Hookes law after the English mathematician Robert Hooke (1635-1703). E is called modulus of elasticity, or Youngs modulus after the English scientist Thomas Young (1773-1829). Note since is dimensionless, E has the same dimension as the stress. 2.2. Poissons Ratio We assume that the materials considered are 1) homogeneous; and 2) isotropic. Lets consider a slender bar under an axis loading P in x direction, the stress within the bar is x = P/A. According to the Hookes law, the strain in x direction is x = x /E. From equilibrium consideration, the stress is zero in any lateral direction, i.e., y = z = 0. However, y = 0 and z = 0. The elongation in the axial direction is always accompanied by a contraction in any transverse direction. We call =

y x

z x

Poissons Ratio after the French mathematician Simon Denis Poisson (1781-1840). e In the case of 1D axial loading

x

x , E

x E

2.3. Hookes Law for Multiaxial Loadings We consider a cube and assume it is subjected axial loading x , y , and z , in x, y, and z direction, respectively. If the cube is subjected to x alone,

x

x , E y , E

x E y E

Similarly, we have

y

105

for the single axial load y , and

z

z , E

z E

for the single axial load z . For small deformation, superposition can be applied. That is, we assume that the deformation produced by each load is not aected by other loads. The Hookes law for multiaxial loading:

x

= = =

1 [x (y + z )] E 1 [y (z + x )] E 1 [z (x + y )] E

For < y , there is a proportional segment of the - diagram, which can be determined by test of a specimen in a torsion machine.. Hookes law in shear: xy = Gxy G is called the modulus of rigidity, or the shear modulus. Similarly, yz = Gyz zx = Gzx The six equations are called the 3D Hookes law. They are also called the 3D constitutive equations for linearly elastic materials. 1-D Hookes Law: = E For members under axial loading, both the stress and the strain are uniformly distributed over the member far from the two ends, i.e. = Therefore P A = L

PL EA i.e., the deformation is proportional to the load and the length, inversely proportional to the cross section area. this tension formula is valid for 1) homogeneous rod, 2) uniform cross section area A, and 3) P is loaded at the two end of the rod. =

106

Vous aimerez peut-être aussi

- 02 - Relationships of Stress and StrainDocument48 pages02 - Relationships of Stress and StrainYsaPas encore d'évaluation

- Strain-Hardening of MetalsDocument27 pagesStrain-Hardening of MetalsAsadUllahPas encore d'évaluation

- 5 Week 23 Stress Strain Relashinship SU 2021Document52 pages5 Week 23 Stress Strain Relashinship SU 2021علىالمهندسPas encore d'évaluation

- Mechanics 2Document83 pagesMechanics 2mohammadnw2003Pas encore d'évaluation

- bfc20903 ch1Document55 pagesbfc20903 ch1nabilahasrulPas encore d'évaluation

- Week 8 - Stress+StrianDocument42 pagesWeek 8 - Stress+Strianiwhy_Pas encore d'évaluation

- Emg 2303 - 1Document26 pagesEmg 2303 - 1Kemba DonyePas encore d'évaluation

- Deformations Normal and Shear Strains Material For NotesDocument21 pagesDeformations Normal and Shear Strains Material For NotesKen SelorioPas encore d'évaluation

- Plane Stress and Plane StrainDocument44 pagesPlane Stress and Plane StrainManiPas encore d'évaluation

- Mechanics of Materials (ME-294) : Shear Stress and StrainDocument19 pagesMechanics of Materials (ME-294) : Shear Stress and Strainハンター ジェイソンPas encore d'évaluation

- Chapter 1 Tension, Compression, and ShearDocument27 pagesChapter 1 Tension, Compression, and ShearManolo L LandigPas encore d'évaluation

- Chapter - 1 Stress and Strain PDFDocument21 pagesChapter - 1 Stress and Strain PDFAnonymous rT6y7298% (44)

- Csikos PDFDocument9 pagesCsikos PDFP Yuva RajPas encore d'évaluation

- Lecture7 PressureVessel Combined LoadingDocument22 pagesLecture7 PressureVessel Combined LoadingHarold Valle ReyesPas encore d'évaluation

- Strength of Materials 1Document73 pagesStrength of Materials 1Altamash KhanPas encore d'évaluation

- Strain 2Document37 pagesStrain 2Line PestañoPas encore d'évaluation

- Stress and Strain RelationsDocument12 pagesStress and Strain RelationsnazeemlngPas encore d'évaluation

- Simple Stress Stress - Is Defined As The Internal Resistance of A Material To The Action of ExternalDocument43 pagesSimple Stress Stress - Is Defined As The Internal Resistance of A Material To The Action of ExternalalvinPas encore d'évaluation

- 10.mechanical Properties of SolidsDocument21 pages10.mechanical Properties of SolidsSri DPas encore d'évaluation

- Stress and StrainDocument17 pagesStress and StrainakshatbhargavaPas encore d'évaluation

- Stress Distributed Over Each Sectioned Area That Develops This Shear Force Is Defined byDocument6 pagesStress Distributed Over Each Sectioned Area That Develops This Shear Force Is Defined byJayvee ColiaoPas encore d'évaluation

- Module 1 StressDocument20 pagesModule 1 StressKylla Shane DuntonPas encore d'évaluation

- Homework 1Document8 pagesHomework 1Alferid ShifaPas encore d'évaluation

- Tension Compression and ShearDocument27 pagesTension Compression and ShearRizal Muhammad FaradayPas encore d'évaluation

- Lecture 11 Solid MechanicsDocument17 pagesLecture 11 Solid MechanicsVijayaraghavan GPas encore d'évaluation

- Mechanics of Deformable Bodies PDFDocument27 pagesMechanics of Deformable Bodies PDFEmmanuel Del Rosario82% (11)

- Strength of MaterialDocument80 pagesStrength of Materialpriyankar007Pas encore d'évaluation

- GET 208 Lecture Note 1Document6 pagesGET 208 Lecture Note 1Jehu RanyangPas encore d'évaluation

- Simple Stresses in Machine PartsDocument35 pagesSimple Stresses in Machine PartsAmar Adri Amar AdriPas encore d'évaluation

- Strength of Material Interview Question and AnswersDocument27 pagesStrength of Material Interview Question and AnswersArjun M Betageri66% (29)

- 3 D LectureDocument36 pages3 D LectureAisha AbuzgaiaPas encore d'évaluation

- Stress ResultantsDocument19 pagesStress ResultantsAmyRapaPas encore d'évaluation

- Failure Resulting From Static Loading 1-Ductile Materials and Brittle MaterialsDocument5 pagesFailure Resulting From Static Loading 1-Ductile Materials and Brittle Materialsمحمد خالدPas encore d'évaluation

- Crack-Tip Field: ES 247 Fracture Mechanics Zhigang SuoDocument12 pagesCrack-Tip Field: ES 247 Fracture Mechanics Zhigang SuoRamesh SantanaPas encore d'évaluation

- Mechanical Principle: Prepared by Razaul IslamDocument47 pagesMechanical Principle: Prepared by Razaul IslamRezaPas encore d'évaluation

- Stress Strain 2Document35 pagesStress Strain 2Gautam KamraPas encore d'évaluation

- Solved SOM1Document11 pagesSolved SOM1Subhan FarooqiPas encore d'évaluation

- Mechanical Principle Lecture 1Document47 pagesMechanical Principle Lecture 1rezaPas encore d'évaluation

- Compile of Lab Thin CylinderDocument13 pagesCompile of Lab Thin CylinderKhairi Azri100% (4)

- Ywmx 3 Tksnli B7 Gamxn JNDocument12 pagesYwmx 3 Tksnli B7 Gamxn JNdhanukrishnagPas encore d'évaluation

- SOM Unit I PDFDocument104 pagesSOM Unit I PDFbhargaviPas encore d'évaluation

- StressDocument7 pagesStressapi-296773500Pas encore d'évaluation

- Plates: 1 Basic Stress Analysis in PlatesDocument3 pagesPlates: 1 Basic Stress Analysis in Platesmad007sPas encore d'évaluation

- Som Coures FileDocument20 pagesSom Coures FileChaubey AjayPas encore d'évaluation

- Chapter 2 - STRESSES IN BEAMS-11-11-2020Document84 pagesChapter 2 - STRESSES IN BEAMS-11-11-2020JoaPas encore d'évaluation

- Me 212 Mechanics of Material - I: Credit Hours: Theory 3 Hrs Lab 1 HR Contact Hours: Theory 3 Hrs Lab 3 HrsDocument22 pagesMe 212 Mechanics of Material - I: Credit Hours: Theory 3 Hrs Lab 1 HR Contact Hours: Theory 3 Hrs Lab 3 HrsKifayat UllahPas encore d'évaluation

- Stress and Strain: Solid Mechanics 1 MECH 0004Document30 pagesStress and Strain: Solid Mechanics 1 MECH 0004Vigil J VijayanPas encore d'évaluation

- MODULE 2 Simple StrainDocument7 pagesMODULE 2 Simple StrainGeri LazaroPas encore d'évaluation

- Chapter1 PDFDocument50 pagesChapter1 PDFShueibPas encore d'évaluation

- Strain 1Document31 pagesStrain 1Line PestañoPas encore d'évaluation

- Emg 2303 - 2Document15 pagesEmg 2303 - 2steve ogagaPas encore d'évaluation

- Module 111Document8 pagesModule 111Sol SolPas encore d'évaluation

- BTech 1st Sem: Mechanical Science: Stress & StrainDocument10 pagesBTech 1st Sem: Mechanical Science: Stress & StrainTechno India Group100% (1)

- Notes/Lect 4 MMTDocument19 pagesNotes/Lect 4 MMTKeilla Romabiles LeopandoPas encore d'évaluation

- Pure Bending PDFDocument8 pagesPure Bending PDFAlvin SmithPas encore d'évaluation

- SEISMOLOGY, Lecture 2Document38 pagesSEISMOLOGY, Lecture 2Singgih Satrio WibowoPas encore d'évaluation

- Iso - Iec 17025 (For Test Cal Lab) - JTDocument1 pageIso - Iec 17025 (For Test Cal Lab) - JTJeff Ong Soon HuatPas encore d'évaluation

- Certified Quality Auditor (ASQ Sample Exam Paper)Document24 pagesCertified Quality Auditor (ASQ Sample Exam Paper)Farhan Shariff86% (7)

- Internal Quality Audit For ISO 9001 - 2008Document115 pagesInternal Quality Audit For ISO 9001 - 2008Ashraf S. Youssef78% (9)

- Quality Management System Checklist Iso 9001Document13 pagesQuality Management System Checklist Iso 9001Ayman Hamed MalahPas encore d'évaluation

- D6616.370090-1-Measuring Viscosity at High Shear RateDocument13 pagesD6616.370090-1-Measuring Viscosity at High Shear RateJeff Ong Soon HuatPas encore d'évaluation

- Documentation Requirements For ISO 9001:2008Document4 pagesDocumentation Requirements For ISO 9001:2008C P Chandrasekaran100% (15)

- D5800.370090 1 NoackDocument5 pagesD5800.370090 1 NoackJeff Ong Soon HuatPas encore d'évaluation

- Internal Quality Audit For ISO 9001 - 2008Document115 pagesInternal Quality Audit For ISO 9001 - 2008Ashraf S. Youssef78% (9)

- Co Gasification of Coal and TyreDocument8 pagesCo Gasification of Coal and TyreJeff Ong Soon HuatPas encore d'évaluation

- Modeling and Simulation of Benzene Alkylation Process Reactors For Production of Ethylbenzene, Petroleum & CoalDocument12 pagesModeling and Simulation of Benzene Alkylation Process Reactors For Production of Ethylbenzene, Petroleum & CoalJeff Ong Soon HuatPas encore d'évaluation

- G1312-90010 BinaryPumpSL User EbookDocument168 pagesG1312-90010 BinaryPumpSL User EbookJeff Ong Soon HuatPas encore d'évaluation

- Co Gasification of Coal and TyreDocument8 pagesCo Gasification of Coal and TyreJeff Ong Soon HuatPas encore d'évaluation

- Styrene Monomer Environmental Health Safety and Distribution GuidelinesDocument65 pagesStyrene Monomer Environmental Health Safety and Distribution GuidelinesJeff Ong Soon HuatPas encore d'évaluation

- Corr Guidelines Sept 03Document51 pagesCorr Guidelines Sept 03Jeff Ong Soon HuatPas encore d'évaluation

- Formwork, Joist, Stringer and Shoring Prop Calculation SheetDocument18 pagesFormwork, Joist, Stringer and Shoring Prop Calculation SheetAnh VàngPas encore d'évaluation

- Engineering Is The Application of Mathematics, Empirical Evidence and Scientific, EconomicDocument5 pagesEngineering Is The Application of Mathematics, Empirical Evidence and Scientific, EconomicKylle BedisPas encore d'évaluation

- Serrano y Olalla - Linearization of The Hoek y BrownDocument11 pagesSerrano y Olalla - Linearization of The Hoek y BrownEsteban JamettPas encore d'évaluation

- Module 5Document3 pagesModule 5vijayPas encore d'évaluation

- Permeability AssignmentDocument2 pagesPermeability AssignmentJejomar MotolPas encore d'évaluation

- Molecular Dynamics SiCDocument15 pagesMolecular Dynamics SiCAnoushka GuptaPas encore d'évaluation

- Ampacity of Cables in Solid Bottom Trays With and Without CoversDocument4 pagesAmpacity of Cables in Solid Bottom Trays With and Without CoversStefanos DiamantisPas encore d'évaluation

- MOF Unit 4Document11 pagesMOF Unit 4Ranjith KumarPas encore d'évaluation

- Melting Boiling Condensation SolidificationDocument12 pagesMelting Boiling Condensation Solidificationsalmanismart123Pas encore d'évaluation

- Coe Cient of Consolidation and Its Correlation With Index Properties of Remolded SoilsDocument7 pagesCoe Cient of Consolidation and Its Correlation With Index Properties of Remolded SoilsgangulyshubhayanPas encore d'évaluation

- Bolted Connections LectureDocument65 pagesBolted Connections Lecturerghazzaoui1793100% (1)

- Analysis and Design of One Way SlabsDocument9 pagesAnalysis and Design of One Way Slabsسيف جمال مدين عبداللهPas encore d'évaluation

- CE6402-Strength of Materials PDFDocument22 pagesCE6402-Strength of Materials PDFArun RajPas encore d'évaluation

- Duct CalculationDocument1 pageDuct CalculationDan Nugraha100% (1)

- Well Performance: Skin, Effective Wellbore Radius, Radius of Investigation and Wellbore Storage & Drawdown TestDocument65 pagesWell Performance: Skin, Effective Wellbore Radius, Radius of Investigation and Wellbore Storage & Drawdown TestTheo AnkamahPas encore d'évaluation

- Physical Properties of PolymersDocument2 pagesPhysical Properties of Polymersta9127127Pas encore d'évaluation

- NASA Glass Bubble InsulationDocument10 pagesNASA Glass Bubble InsulationRoy JudePas encore d'évaluation

- Keph 207Document28 pagesKeph 207Abhinav ScientistPas encore d'évaluation

- The Siphon: Physics EducationDocument6 pagesThe Siphon: Physics EducationJuan Sebastian MartínezPas encore d'évaluation

- Design 2Document28 pagesDesign 2Ken Jethro Mamaril CariñoPas encore d'évaluation

- Shaft Design Question On PulleyDocument22 pagesShaft Design Question On Pulleykyaji rautPas encore d'évaluation

- DDDDDDDDDDDDDD: Gas Fired Boiler House Ventilation Project: Job No. PlantDocument2 pagesDDDDDDDDDDDDDD: Gas Fired Boiler House Ventilation Project: Job No. Plantpsn_kylmPas encore d'évaluation

- Adiabatic Wall Temperature Evaluation in A High Speed TurbineDocument9 pagesAdiabatic Wall Temperature Evaluation in A High Speed TurbineSaadPas encore d'évaluation

- Force Stress Equilibrium Coveruing Multiaxial Strain and Multiaxial Stress S PDFDocument4 pagesForce Stress Equilibrium Coveruing Multiaxial Strain and Multiaxial Stress S PDFWaquar TaiyebPas encore d'évaluation

- CEE335 Lab Manual 2017 SPDocument75 pagesCEE335 Lab Manual 2017 SPMotazPas encore d'évaluation

- Cooling Towers Design TrainingDocument57 pagesCooling Towers Design TrainingKagira Drawing Soltuion100% (1)

- D4896Document6 pagesD4896Phillip TaiPas encore d'évaluation

- HMT Assignment 1Document6 pagesHMT Assignment 1Mahmed EdPas encore d'évaluation

- Fatigue Crack Propagation in Steels of Various Yield StrengthsDocument7 pagesFatigue Crack Propagation in Steels of Various Yield StrengthsRodrigo Marin100% (1)

- Civil Booster Civil Engineering Handbook PDFDocument109 pagesCivil Booster Civil Engineering Handbook PDFAnkit60% (45)

- Advanced Modelling Techniques in Structural DesignD'EverandAdvanced Modelling Techniques in Structural DesignÉvaluation : 5 sur 5 étoiles5/5 (3)

- A Welder’s Handbook to Robotic ProgrammingD'EverandA Welder’s Handbook to Robotic ProgrammingÉvaluation : 5 sur 5 étoiles5/5 (3)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!D'EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Évaluation : 4 sur 5 étoiles4/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- To Engineer Is Human: The Role of Failure in Successful DesignD'EverandTo Engineer Is Human: The Role of Failure in Successful DesignÉvaluation : 4 sur 5 étoiles4/5 (138)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindD'EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindPas encore d'évaluation

- Marine Structural Design CalculationsD'EverandMarine Structural Design CalculationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (13)

- Structural Cross Sections: Analysis and DesignD'EverandStructural Cross Sections: Analysis and DesignÉvaluation : 4.5 sur 5 étoiles4.5/5 (19)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresD'EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresÉvaluation : 1 sur 5 étoiles1/5 (2)

- Artificial Intelligence: From Medieval Robots to Neural NetworksD'EverandArtificial Intelligence: From Medieval Robots to Neural NetworksÉvaluation : 4 sur 5 étoiles4/5 (3)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsD'EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsPas encore d'évaluation

- Structural Steel Design to Eurocode 3 and AISC SpecificationsD'EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsPas encore d'évaluation

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureD'EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.D'EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Évaluation : 4 sur 5 étoiles4/5 (5)

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesD'EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Dark Aeon: Transhumanism and the War Against HumanityD'EverandDark Aeon: Transhumanism and the War Against HumanityÉvaluation : 5 sur 5 étoiles5/5 (1)

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsD'EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Pile Design and Construction Rules of ThumbD'EverandPile Design and Construction Rules of ThumbÉvaluation : 4.5 sur 5 étoiles4.5/5 (15)

- How to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionD'EverandHow to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionÉvaluation : 3.5 sur 5 étoiles3.5/5 (129)