Académique Documents

Professionnel Documents

Culture Documents

Catalytic Growth of CNT and Nano Fibers On Vermiculite

Transféré par

chuasiokleng0 évaluation0% ont trouvé ce document utile (0 vote)

49 vues5 pagesCatalytic growth of carbon nanotubes and nanofibers on vermiculite to produce floatable hydrophobic ''nanosponges'' for oil spill remediation Fla. CVD synthesis of CNT has been extensively investigated in the last years.

Description originale:

Titre original

Catalytic Growth of CNT and Nano Fibers on Vermiculite

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentCatalytic growth of carbon nanotubes and nanofibers on vermiculite to produce floatable hydrophobic ''nanosponges'' for oil spill remediation Fla. CVD synthesis of CNT has been extensively investigated in the last years.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

49 vues5 pagesCatalytic Growth of CNT and Nano Fibers On Vermiculite

Transféré par

chuasioklengCatalytic growth of carbon nanotubes and nanofibers on vermiculite to produce floatable hydrophobic ''nanosponges'' for oil spill remediation Fla. CVD synthesis of CNT has been extensively investigated in the last years.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

Catalytic growth of carbon nanotubes and nanobers on vermiculite

to produce oatable hydrophobic nanosponges for oil spill remediation

Fla via C.C. Moura

a,

*, Rochel M. Lago

b

a

Departamento de Qumica ICEB, Universidade Federal de Ouro Preto UFOP, Ouro Preto, MG, 35400-000, Brazil

b

Departamento de Qumica ICEx, Universidade Federal de Minas Gerais UFMG, Belo Horizonte, MG, 31270-901, Brazil

1. Introduction

Catalytic chemical vapour deposition (CVD) synthesis of carbon

nanotubes (CNT) using a large variety of catalysts, e.g. Fe/Mo, Ni,

Co, and different carbon sources, e.g. CH

4

, C

2

and C

3

hydrocarbons,

CO, ethanol, has been extensively investigated in the last years

[1,2]. Due to its relative simplicity, low cost, high yields and the

possibility to control several features of the CNT the CVD process

has proven to be the most promising large scale carbon nanotubes

preparation process. Different oxides suchas Al

2

O

3

, SiO

2

, MgOhave

been used as support to grow CNT [36]. Well dened surfaces,

such as silicon wafer have also been used to growhighly organized

aligned CNT known as carpets [7,8].

In this work, we have used the surface of vermiculite to grow

CNT and nanobers via CH

4

CVD synthesis. Vermiculite, a clay

mineral, is a very interesting layered material with many potential

industrial and environmental applications [9,10]. Upon sudden

heating at temperatures higher than 700 8C inter lamellae water

molecules evaporate abruptly, separating packets of layers that

produce a highly developed porous structure. This expanded

vermiculite (EV) shows a volume up to 20 times greater and oats

on water due to the decrease in density, ca. 0.050.30 g cm

3

[9,11]. This vermiculite has beenused to remove oil spilled onwater

due to the strong capillary action of the slit shaped pores [1216]. A

strong drawback of vermiculite is the high water uptake and low

absorption of the hydrophobic organic contaminants due to the

strong hydrophilic clay surface. Several works and patents report

different processes to hydrophobize the vermiculite surface using,

for example, siloxanes [17] and polymer coating [13]. However, all

these processes were relatively complex and produced relatively

low oil removal capacity.

Hereon, we report the CH

4

CVD on the vermiculite surface to

produce a dense CNT and nanobers complex entangled structure.

This nanostructuredcarbonproduces a highlyhydrophobic material

witha sponge effect conferring to the absorbent a highoil removal

capacity. This is one of the rst environmental applications of

carbon nanotubes.

2. Experimental

The vermiculite used in this work has the approximate

composition (Al

0.30

Ti

0.04

Fe

0.63

Mg

2.00

)(Si

3.21

Al

0.79

)O

10

(OH)

2

Mg

0.13-

Na

0.02

K

0.10

(H

2

O)

n

. The exfoliation was carried out by introducing

the vermiculite in a quartz tube at 1000 8C for 60 s. The exfoliated

vermiculite was impregnated with solutions of Fe(NO

3

)

3

and

MoO

2

(acac)

2

using H

2

O or methanol as solvents at different

concentrations. The impregnated EV was dried at 80 8C for 3 h and

submitted to the CVD process. The different prepared EV (ca. 1.0 g)

was placed in a quartz tube of 40 mm diameter and heated at

10 8C min

1

to the reaction temperature of 900 8C under H

2

/Ar ow

(150 mL min

1

) and the temperature was kept at 900 8C for 1 h to

pre-reduce the catalyst precursors. The material was then

immediately submitted to a CVD with CH

4

/Ar (1/1 mixture at

1 atm and 600 cm

3

min

1

) at 900 8C for 1 h. The reaction lasted for

Applied Catalysis B: Environmental 90 (2009) 436440

A R T I C L E I N F O

Article history:

Received 30 September 2008

Received in revised form 19 March 2009

Accepted 2 April 2009

Available online 10 April 2009

Keywords:

Carbon nanotubes

Vermiculite

Adsorbents

Environmental application

A B S T R A C T

In this work, chemical vapour deposition (CVD) synthesis of carbon nanotubes (CNT) and nanobers on

the surface of expanded vermiculite (EV) was used to produce a highly hydrophobic oatable absorvent

to remove oil spilled on water. XRD, SEM, TGand Raman spectroscopy showed that the carbon nanotubes

and nanobers grow on FeMo catalyst impregnated on the EV surface to form a sponge structure. As a

result of these carbonaceous nanosponges the absorption of different oils remarkably increased ca. 600%

with a concomitant strong decrease of the undesirable water absorption.

2009 Published by Elsevier B.V.

* Corresponding author. Tel.: +55 31 3559 1710; fax: +55 31 3559 1707.

E-mail address: aviamoura@iceb.ufop.br (Fla via C.C. Moura).

Contents lists available at ScienceDirect

Applied Catalysis B: Environmental

j our nal homepage: www. el sevi er . com/ l ocat e/ apcat b

0926-3373/$ see front matter 2009 Published by Elsevier B.V.

doi:10.1016/j.apcatb.2009.04.003

10 min, unless otherwise stated. After the reaction, the systemwas

cooled under Ar ow.

The vermiculitecarbon composites were characterized by

Raman spectroscopy (Renishaw) with the excitation wavelength of

633 nm and a laser spot size of 20 mm with confocal imaging

microscope. The spectra taken at ten different points were

averaged to minimize dispersion of the sample position.

The powder XRD data were obtained in a Rigaku model

Geigerex using Cu Ka radiation scanning from 28 to 758 at a scan

rate of 48 min

1

. Scanning electron microscopy (SEM) analyses

were carried out in a Jeol JKA 8900RL. TG analyses were carried out

in a Hi-Res TGA 2950 thermogravimetric analyser (TA) instrument,

with a constant heating rate of 10 8C min

1

under air ow

(100 mL min

1

). BET surface area was carried out in an Autosorb

1 Quantachome using 22 cycles N

2

adsorption/desorption and the

mercury porosimetry measurements were performed in a Quan-

tachrome type PoreMaster 60 porosimeter.

The absorption experiments were carried simulating an oil

spilling situation using 10 mL of contaminant, i.e. soy bean cooking,

mineral oil and diesel, in 100 mL water. The produced hydro-

phobized vermiculite (100 mg) was then added to the suspension it

of. After 5 min the vermiculite was removed using a simple metal

sieve and left still for 3 min to drain the excess oil and water.

Previous optimizationexperiments showedthat theEVimmediately

saturates with both oil and water and contact times of 5 min are

enough to reach equilibrium. Also, the drain time in the sieve has no

signicant inuence on the amount of oil and water absorption.

After absorption, the materials were weighed to determine the total

amount of oil and water retained. For vegetable and engine oils the

materials were dried at 80 8C overnight to remove water and

weighed again to determine both the water and oil absorptions. For

the experiments with diesel, the sample cannot be dried at 80 8C

since a signicant part of diesel will volatilize at this temperature.

Therefore after absorption experiment the sample was weighed to

determine the total amount of water and diesel absorbed. The

sample was then extracted with 20 mL hexane and analyzed by gas

chromatography (Shimadzu 17A equipped with FID capillary

column Alltech EC-Wax 30m). From a simple calibration, the

amount of diesel absorbed can be calculated from the total area of

the peaks.

3. Results and discussion

3.1. Preparation and characterization of the composite EV/

nanostructured carbon

The composites vermiculite/carbon nanostructures were pre-

pared by impregnation of Fe(NO

3

)

3

and Mo(acac)

2

O

2

in different

concentrations on the vermiculite surface from methanol or water

solutions. Table 1 shows the prepared precursors with different Fe-

Mo/EV contents and the solvent used in the impregnation.

The precursors were pre-reduced under H

2

/Ar ow at 900 8C

for 1 h and immediately submitted to a CVDwith CH

4

/Ar at 900 8C

also for 1 h.

The obtained materials were characterized by SEM, TG, Raman

spectroscopy and XRD. After CVD all samples were completely

black due to carbon deposition. The samples prepared using water

as solvent in the impregnation step were very brittle and fragile

with almost total collapse of the lamellar vermiculite structure. As

a result of this collapse the Fe(W) samples showed a small decrease

on the surface area (Table 2). On the other hand, samples prepared

with methanol showed the lamellar and porous structure intact

and mechanically resistant.

Fig. 1a shows the scanning electron microscopy of the

exfoliated vermiculite before CVD with regular at surface

lamellae and a slit-type porous structure. After CVD, the sample

Fe

1

(W) appears very brittle and no laments or deposited material

could be observed (Fig. 1b and c). On the other hand, SEM images

for the Fe

2

(M) and Fe

2

Mo

0.30

(M) (Fig. 2di) suggests that the EV

completely changes the texture. Afurther magnicationof the SEM

image clearly showed a surface completely covered with carbon

laments with nanometric diameters and several micrometers

long (Fig. 1ei).

These materials with different forms of carbon were character-

izedbyRamanspectroscopy. Spectraobtainedwiththelaser 633 nm

(Fig. 2) showed the presence of broad G bands at ca. 1595 cm

1

relatedtographitic layers andthe disorder Dpeak at 1330 cm

1

. The

low I

G

/I

D

ratio of the samples Fe(w) without Mo (0.61.0) suggests

the presence of high quantity of amorphous carbon or defects in the

carbon structure. On the other hand, when Mo is introduced in the

sample, i.e. Fe

1

Mo

0.15

(M) and Fe

2

Mo

0.30

(M), a very high I

G

/I

D

ratio of

3.2 and 7.9, respectively, was observed, suggesting the formation of

well graphitized carbon. Also, it is interesting to observe that in the

presence of Mo, the Raman spectra show strong bands at low

wavenumber at 133248 cm

1

related to the formation of single

wall carbonnanotubes (SWCNT) withcalculateddiameters between

0.9 nm and 1.8 nm [18].

TG analyses for all Fe(M)/EV and FeMo(M)/EV samples after

CVD showed a weight gain from 150 8C up to 550 8C (Fig. 3). This

Table 2

General properties of the EV composites prepared.

Sample BET surface

area (m

2

g

1

)

Hg porosimetry

(cm

3

g

1

)

C

a

(%) Forms of carbon

b

Average oil

absorption (g g

1

)

Water

absorption (g g

1

)

EV 5 1.9 More amorphous 0.5 3.7

Fe

1

(W) 3 Ca. 0.1 More amorphous

Fe

2

(W) 3 Ca.0.1 More amorphous

Fe

3

(W) 2 1.6 Ca.0.1 More amorphous

Fe

1

(M) 7 Ca.0.7 More amorphous 1.7 0.5

Fe

2

(M) 9 1.8 ca.2 More amorphous 1.3 0.5

Fe

1

Mo

0.15

(M) 15 1.8 ca.2 SWCNT and graphitic carbon 3.2 0.5

Fe

2

Mo

0.30

(M) 18 1.7 ca.2 SWCNT and graphitic carbon 2.0 0.5

a

From TG.

b

Obtained from the I

G

/I

D

ratio and from SEM analyses.

Table 1

Conditions used to prepare the different vermiculite precursors for the

CVD synthesis.

Sample Fe (wt%) Mo (wt%) Solvent

EV

Fe

1

(W) 1 H

2

O

Fe

2

(W) 2 H

2

O

Fe

3

(W) 3 H

2

O

Fe

1

(M) 1 MeOH

Fe

2

(M) 2 MeOH

Fe

1

Mo

0.15

(M) 1 0.15 MeOH

Fe

2

Mo

0.30

(M) 2 0.3 MeOH

F.C.C. Moura, R.M. Lago / Applied Catalysis B: Environmental 90 (2009) 436440 437

increase is related to the oxidation of iron, molybdeniumand other

metals in the EV which were reduced by H

2

during the CVD

process. Weight losses observed at higher temperatures should be

related to carbon oxidation and were used to estimate the amount

of carbon deposited. TG of samples prepared by Fe impregnation

with water, showed in general a weight loss of only ca. 0.10.2%,

suggesting that no signicant amount of carbon material was

formed. This result suggests that water is not a good solvent for Fe

impregnation on EV. Simple soaking in water strongly decreases

the EV mechanical resistance. Moreover, as vermiculite is a cation

exchange material, the Fe

3+

from solution can migrate into the EV

lamellar structure. Upon pre-reduction with H

2

, the interlayer Fe

3+

is converted to Fe

0

which might lead to a collapse of the local clay

structure. Also, during impregnation, Fe

3+

in H

2

O can hydrolyze to

produce insoluble large particles of Fe(OH)

3

which should be less

active to produce carbon during CH

4

CVD.

On the other hand, the samples prepared with methanol

Fe

1

(M) and Fe

2

(M) showed weight losses of ca. 0.7% and 2%,

respectively, suggesting that the Fe content directly affects the

amount of carbon deposited. The relatively high oxidation

temperature, i.e. 520 8C, indicates the presence of a well organized

carbon. In the catalysts FeMo(M), ca. 2% carbon was formed with a

lower oxidation temperature (440 8C), suggesting that Mo has an

important effect on the types of carbon deposited.

It was observed by XRD (Fig. 4) that the CVD process does not

affect the EVcrystalline. It can be observed a small peak at 468 after

the reduction step suggesting the presence Fe metal. It was not

possible to observe any reection peaks related to Mo.

Fig. 3. TG of the composite EV/nanostructured carbon material, in air.

Fig. 1. SEM images of EV before hydrophobization (a) and after CVD with CH

4

at 900 8C for 1 h for Fe

1

(W) (b and c), Fe

2

Mo

0.30

(M) (dg) and Fe

2

(M) (h and i).

Fig. 2. Raman spectra of the composite EV/nanostructured carbon material.

F.C.C. Moura, R.M. Lago / Applied Catalysis B: Environmental 90 (2009) 436440 438

3.2. Oil removal studies

For the oil removal studies three different model contaminants

were used, i.e. vegetable oil (soy bean), mineral oil and diesel. The

obtained absorption capacities for water and for the different oils

are shown in Fig. 5

It can be observed that the EV before CVD absorbs a high

amount of water ca. 3.5 g g

1

but low absorption capacities for the

oil contaminants, ca. 0.5 g g

1

. For the composites Fe

1

(M) and

Fe

2

(M) better results were obtained with the decrease of the H

2

O

absorption to 0.5 g g

1

and a general increase on the oil removal

capacity 1.31.7 g g

1

. On the other hand, for the composite

Fe

1

Mo

0.15

(M) a remarkable improvement is observed with H

2

O

absorption strongly decreasing to 0.5 g g

1

with oil removing

capacities of 3.5 g g

1

, 3.7 g g

1

and 3.8 g g

1

for vegetable, engine

and diesel, respectively.

In order to rationalize the changes observed on the absorption

properties, Table 2 compares several parameters, such as the BET

surface area, Hg porosimetry results, carbon content and its forms

for the different composites.

BET surface areas do not vary signicantly after CVD for the

samples Fe(W) and only a small increase is observed for the Fe(M).

On the other hand, an important increase on the surface area is

observed for the samples FeMo(M) reaching 18 m

2

g

1

. This

increase is likely related to the large area on the walls of nanotubes

and nanolaments grown on the EV surface. As the amount of

carbon deposits is small, ca. 2 wt%, no signicant change was

observed in the macropore volume, as suggested by Hg porosi-

metry. When these results are analyzed three main factors seem

important for the absorption properties of EV, i.e. the hydro-

phobicity of the surface, the nanotubes/nanobers sponge

structure and the pore volume available for absorption. All

composites were covered with a layer composed of different

forms of carbon, e.g. amorphous, graphitic, bers, and tubes. All

these carbon forms are very hydrophobic in nature and should

produce a very water repellent environment. For this reason the

water absorption by EV decreases from 3.5 g g

1

to ca. 0.5 g g

1

after CVD. Also, this hydrophobic character leads to a better

interaction with the hydrophobic oil molecules and should lead to

a general increase in oil absorption. Nevertheless, the composites

FeMo(M) showed an unexpectedly high oil absorption. Although

the reasons for this behavior are not clear they can be related to the

carbon nanostructures present in these composites. The nanotubes

and nanobers on the EVlamellae should offer extra surface for the

interaction with the oil contaminants as observed by BET. Also,

these entangled tubes and bers produce a sponge-like structure

which should have a strong capillary effect favoring the up take of

the more viscous oils. In general, oils have much higher viscosity,

e.g. 7080 cP for vegetable, diesel and crude oils, compared to

water (1 cP) and the penetration of EV pore structure should be a

critical step.

As expanded vermiculite absorbs liquids into the inter-lamellar

space, the third important factor affecting the oil absorption is the

pore space available. It can be considered that the carbon

structures produced in the inter-lamellae space do not cause a

signicant change in pore volume as suggested by Hg porosimetry.

For this reason the maximum amount of liquid absorbed

(water + oil) is nearly the same for EV and FeMo(M), considering

that water and oil have similar densities, 1 and 0.90.95 g cm

3

,

respectively. Moreover, materials with higher BET surface area, e.g.

FeMo(M) do not show increased liquid (oil + water) removal. This

reinforces the idea that the pore volume lling by absorption

rather than adsorption is more important to dene the amount of

retained liquid.

Fig. 5 also shows the oil and water absorption for two other

modied EV absorbents described in the literature [13] and

commercially available [17]. Although different EV were used to

produce these materials which should have some effect on the oil

removal capacity, it can be observed that the composite Fe

1

Mo

0.15

is much more efcient with higher oil removal capacity and low

water retention. This much lower water absorption reects the

strong hydrophobic character of the carbon deposits compared to

the other hydrophobization processes used in refs. [13] and [17].

We have also carried an experiment with engine oil spilled in

water with 3.5% dissolved NaCl to simulate sea water. The obtained

results showed no signicant effect of NaCl on the absorption

properties of Fe

1

Mo

0.15

(M).

4. Conclusion

CH

4

-CVD can be used to growcarbon nanotubes and nanobers

on the surface of EV with FeMo impregnated catalysts. The

produced carbon/EV nanostructured composites showed high

efciency to absorb different oils (soy bean, engine, diesel) with a

remarkable decrease on H

2

O absorption. These results were

discussed in terms of: (i) a strong hydrophobic character produced

by the carbon structures, (ii) an increase on surface area which

favours interaction with the oils and (iii) a sponge effect

produced by the entangled nanobers and nanotubes favoring

capillarity. Moreover, the CVD process does not cause any

Fig. 4. XRD for the pure EV, EV/Fe

2

Mo

0.30

(M) after reduction and EV/Fe

2

Mo

0.30

(M)

after CVD process.

Fig. 5. Absorption of water and spilled oils (soy bean cooking, mineral oil and

diesel) by the hydrophobic vermiculitenanostructured carbon composites

and two other modied EV absorbents described in the literature [13] and

commercially available [17].

F.C.C. Moura, R.M. Lago / Applied Catalysis B: Environmental 90 (2009) 436440 439

signicant change in the EV pore volume available for liquid

absorption. This novel oatable absorbent/adsorbent can be pro-

duced by a simple process using low cost and available chemicals

and showed very promising results to be used in environmental

remediation especially in oil spilled on waters.

Acknowledgements

The authors are grateful to CAPES, CNPq and FAPEMIG for

nancial support and R. Martel for the laboratory facilities.

References

[1] C. Oncel, Y. Yurum, Fullerenes Nanotubes Carbon Nanostruct. 14 (2006) 1737.

[2] A.C. Dupuis, Progr. Mater. Sci. 50 (2005) 929961.

[3] H. Ago, S. Imamura, T. Okazaki, T. Saito, M. Yumura, M. Tsuji, J. Phys. Chem. B 109

(2005) 1003510041.

[4] J.F. Colomer, C. Stephan, S. Lefrant, G. Van Tendeloo, I. Willems, Z. Ko nya, A.

Fonseca, Ch. Laurent, J.B. Nagy, Chem. Phys. Lett. 317 (2000) 8389.

[5] J. Geng, Ch. Singh, D.S. Shepard, M.S.P. Shaffer, B.F.G. Johnson, A.H. Windle, Chem.

Commun. (2002) 26662667.

[6] L. Qingwen, Y. Hao, Ch. Yan, Zh. Jin, L. Zhongfan, J. Mater. Chem. 12 (2002) 1179

1183.

[7] D.C. Li, L. Dai, S. Huang, A.W.H. Mau, Z.L. Wang, Chem. Phys. Lett. 316 (2000)

349355.

[8] V. Pichot, P. Launois, M. Pinault, et al. App. Phys. Lett. S 85 (2004) 473

475.

[9] P.S. Santos, R. Navajas, Rev. Bras. Technol. 7 (1976) 415431.

[10] C. De la Calle, H. Suquet, H. Vermiculites, in: S.W. Bailey (Ed.), Reviews in

Mineralogy: Hydrous Phyllosilicates, vol. 19, Mineralogical Society of America,

Washington, 1988 , p. 725 (Chapter 12).

[11] P.S. Santos, Tecnologia de Argilas Aplicadas a` s argilas Brasileiras, Ed. Edgard

Blucher Ltda, Sao Paulo, 1975.

[12] L.C.R. Machado, C.B. Torchia, R.M. Lago, Catal. Commun. 7 (2006) 538541.

[13] L.C.R. Machado, F.W.J. Lima, R. Paniago, et al. Appl. Clay Sci. 31 (2006) 207

215.

[14] J. Martins, Patent, Processo Aperfeicoado de Hidrofobizacao de Vermiculita

Expandida, BR. 39004025 (1990).

[15] V.A. Leao, J. Martins, L.C.R. Machado, S.A.V. Filho, in: V. Ramachandran, L.C. Nesbitt

(Eds.), Second International Symposium on Extraction and Processing for the

Treatment and Minimization of Wastes, 1996, pp. 305313.

[16] L.C.R Machado. 2000. Caracterizacao de Vermiculitas Visando sua Esfoliacao e

Hidrofobizacao para Adsorcao de substancias Organicas. Dept. de Geologia, Univ.

Fed. de Ouro Preto, Ouro Preto, MSc. Thesis.

[17] J. Martins, Patent, Upgraded Process for the Production of Hydrophobized

Expanded Vermiculite Application thereof, WO2006017919 (2006).

[18] A. Jorio, C. Fantini, M.A. Pimenta, R.B. Capaz, Ge.G. Samsonidze, G. Dresselhaus,

M.S. Dresselhaus, J. Jiang, N. Kobayashi, A. Gru neis, R. Saito, Phys. Rev. B 71 (2005)

075401.

F.C.C. Moura, R.M. Lago / Applied Catalysis B: Environmental 90 (2009) 436440 440

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Three Moments of An Explosion 50 Page FridayDocument44 pagesThree Moments of An Explosion 50 Page FridayRandom House Publishing GroupPas encore d'évaluation

- Retainingwall bs8110Document11 pagesRetainingwall bs8110unionewPas encore d'évaluation

- Fluid Mechanics and Hydraulics Proceedings of 26th InternationalDocument601 pagesFluid Mechanics and Hydraulics Proceedings of 26th InternationalSwan Zay AungPas encore d'évaluation

- Aerodyn Aeronaut and Fligh MechDocument664 pagesAerodyn Aeronaut and Fligh MechAerospaceAngel100% (5)

- 2020 ACJC Paper 4 Qns PDFDocument18 pages2020 ACJC Paper 4 Qns PDFchuasioklengPas encore d'évaluation

- Comp P2 22Document10 pagesComp P2 22chuasioklengPas encore d'évaluation

- Organic Chemistry Lab Guide to SpectroscopyDocument133 pagesOrganic Chemistry Lab Guide to Spectroscopytheoneandonly1Pas encore d'évaluation

- 2020 JC2 Prelim H2 Chemistry Paper 4 QP PDFDocument21 pages2020 JC2 Prelim H2 Chemistry Paper 4 QP PDFchuasioklengPas encore d'évaluation

- Hotel Design ConsiderationsDocument6 pagesHotel Design ConsiderationsAlther DabonPas encore d'évaluation

- Heating Systems in Buildings - Method For Calculation of System Energy Requirements and System EfficienciesDocument22 pagesHeating Systems in Buildings - Method For Calculation of System Energy Requirements and System EfficienciesDžana Kadrić100% (1)

- Comp P1 22Document8 pagesComp P1 22chuasioklengPas encore d'évaluation

- E Lit 22 - 3Document7 pagesE Lit 22 - 3chuasioklengPas encore d'évaluation

- E Lit 22 - 1Document9 pagesE Lit 22 - 1chuasioklengPas encore d'évaluation

- H2 Chemistry 9729 P3 - Section ADocument9 pagesH2 Chemistry 9729 P3 - Section AchuasioklengPas encore d'évaluation

- H2 Chem Prelim Paper 3Document40 pagesH2 Chem Prelim Paper 3chuasioklengPas encore d'évaluation

- H2 Chem Prelim Paper 2Document28 pagesH2 Chem Prelim Paper 2chuasioklengPas encore d'évaluation

- H2 Chemistry 9729 P3 - Section BDocument4 pagesH2 Chemistry 9729 P3 - Section BchuasioklengPas encore d'évaluation

- ASR 2020 J2Prelim H2Chem P4 QP PDFDocument20 pagesASR 2020 J2Prelim H2Chem P4 QP PDFchuasioklengPas encore d'évaluation

- 2020 JPJC H2 Chem Prelim Paper 4 QP - Final PDFDocument19 pages2020 JPJC H2 Chem Prelim Paper 4 QP - Final PDFchuasioklengPas encore d'évaluation

- Paper 2 QNDocument19 pagesPaper 2 QNchuasioklengPas encore d'évaluation

- Catholic Junior College: Chemistry Higher 1Document9 pagesCatholic Junior College: Chemistry Higher 1chuasioklengPas encore d'évaluation

- Civic Index Chemistry ExamDocument10 pagesCivic Index Chemistry ExamchuasioklengPas encore d'évaluation

- Catholic Junior College: Chemistry Higher 1Document10 pagesCatholic Junior College: Chemistry Higher 1chuasioklengPas encore d'évaluation

- Experiment #14: Preparation of Banana Oil and Characterization Using IR SpectrosDocument8 pagesExperiment #14: Preparation of Banana Oil and Characterization Using IR SpectroschuasioklengPas encore d'évaluation

- Paper 2 QNDocument19 pagesPaper 2 QNchuasioklengPas encore d'évaluation

- The Chemistry of Food: Proposed Sabbatical Program For Hwa Chong Institution (Year 2)Document2 pagesThe Chemistry of Food: Proposed Sabbatical Program For Hwa Chong Institution (Year 2)chuasioklengPas encore d'évaluation

- Anderson Junior College 2007 Chemistry ExamDocument12 pagesAnderson Junior College 2007 Chemistry ExamchuasioklengPas encore d'évaluation

- A CHEM - 2007 - Paper - 2Document14 pagesA CHEM - 2007 - Paper - 2chuasioklengPas encore d'évaluation

- 1530 Specimen Paper & Mark Scheme PDFDocument100 pages1530 Specimen Paper & Mark Scheme PDFchuasioklengPas encore d'évaluation

- Catalogue of Equations - Edexcel Chemistry Syllabus A 1530Document13 pagesCatalogue of Equations - Edexcel Chemistry Syllabus A 1530chuasioklengPas encore d'évaluation

- Part 2Document2 pagesPart 2chuasioklengPas encore d'évaluation

- The Chemistry of Food: Proposed Sabbatical Program For Hwa Chong Institution (Year 2)Document2 pagesThe Chemistry of Food: Proposed Sabbatical Program For Hwa Chong Institution (Year 2)chuasioklengPas encore d'évaluation

- S Jc1 C: Chedule FOR HemistryDocument1 pageS Jc1 C: Chedule FOR HemistrychuasioklengPas encore d'évaluation

- S Jc2 C: Chedule FOR HemistryDocument1 pageS Jc2 C: Chedule FOR HemistrychuasioklengPas encore d'évaluation

- Hemistry Esources: Study GuidesDocument2 pagesHemistry Esources: Study GuideschuasioklengPas encore d'évaluation

- Commentaries - Historical BooksDocument3 pagesCommentaries - Historical BookschuasioklengPas encore d'évaluation

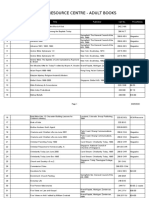

- Adult 2244 & Ref - v1Document147 pagesAdult 2244 & Ref - v1chuasioklengPas encore d'évaluation

- Setting and Atmosphere in Three Victorian Stories Setting in The Signalman'Document2 pagesSetting and Atmosphere in Three Victorian Stories Setting in The Signalman'Muhammad NadeemPas encore d'évaluation

- TLC Analysis of Siling Labuyo Extract ComponentsDocument3 pagesTLC Analysis of Siling Labuyo Extract ComponentsJan Eric Balete0% (1)

- Operator Manual Doppler Speedlog Ds80Document42 pagesOperator Manual Doppler Speedlog Ds80Can KaramanPas encore d'évaluation

- AFU 19740100 APRO Bulletin January-FebruaryDocument11 pagesAFU 19740100 APRO Bulletin January-Februaryratatu100% (1)

- Instant Download Ebook PDF Finite Element Analysis Theory and Application With Ansys 4th Edition PDF ScribdDocument41 pagesInstant Download Ebook PDF Finite Element Analysis Theory and Application With Ansys 4th Edition PDF Scribdlouise.kolar628100% (42)

- Math 54 Le5Document1 pageMath 54 Le5Lester Jason T. ChengPas encore d'évaluation

- Parcel 26 Zone (C)Document17 pagesParcel 26 Zone (C)Dessouki SamakPas encore d'évaluation

- Atmospheric Dispersion Modelling Jun04Document27 pagesAtmospheric Dispersion Modelling Jun04Luke HainesPas encore d'évaluation

- Buat Camera Thermal DGN ArduinoDocument4 pagesBuat Camera Thermal DGN ArduinoelkaPas encore d'évaluation

- A Critical Analysis of The Erasmus Bridge:: Christopher J. HewettDocument10 pagesA Critical Analysis of The Erasmus Bridge:: Christopher J. HewettAndik Mardiyanto MellodyPas encore d'évaluation

- Aplicações Corantes Naturais - ReviewDocument22 pagesAplicações Corantes Naturais - ReviewIlídiaFerreiraPas encore d'évaluation

- Water in MalaysisDocument44 pagesWater in MalaysisAlvaro HuetePas encore d'évaluation

- LCDworkbook PDFDocument102 pagesLCDworkbook PDFkachappilly2012Pas encore d'évaluation

- HL 300 AutoclaveDocument2 pagesHL 300 AutoclaveobinPas encore d'évaluation

- Improvements in The Design of Winch: A ReviewDocument5 pagesImprovements in The Design of Winch: A ReviewIJARTETPas encore d'évaluation

- Cma 4544pf W PDFDocument4 pagesCma 4544pf W PDFAlex RodriguezPas encore d'évaluation

- Setting I T Protection For Direct PWM Commutated MotorsDocument2 pagesSetting I T Protection For Direct PWM Commutated Motorsalpha1ahPas encore d'évaluation

- Mahesh CP 506Document25 pagesMahesh CP 506GURUDEEP PPas encore d'évaluation

- Physics7c Fa00 mt1 Packard ExamDocument2 pagesPhysics7c Fa00 mt1 Packard ExamfrankongPas encore d'évaluation

- Cha 2Document52 pagesCha 2yaredPas encore d'évaluation

- G16 - A21 - DAA 2723 WBPDocument16 pagesG16 - A21 - DAA 2723 WBPanazraf 23MzPas encore d'évaluation

- Trenching Soil TypesDocument1 pageTrenching Soil TypesJerome MansuetoPas encore d'évaluation