Académique Documents

Professionnel Documents

Culture Documents

Service Basic Hd-c2

Transféré par

nyusiantoDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Service Basic Hd-c2

Transféré par

nyusiantoDroits d'auteur :

Formats disponibles

Motor and pump

Basic training HD / HDS

Pressure and flow control, manual with overflow valve

3 4 1 2

5 6 10

9

2 3

14 13 12 11 2 2 11

14 13 12 15

16 16 10 10

C20

Basic training HD / HDS

Motor and pump

Pressure and flow control, manual with overflow valve

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 High-pressure outlet Injector Rotary knob Regulating spindle Pressure valve Cylinder head Piston Suction valve Water inlet with strainer Suction chamber Pressure chamber Connecting channel Piston Control chamber Spring Overflow valve spindle As a result of the action of the injector (2), (see page D2), the pressure in the control chamber (14) is lower than in the pressure chamber (11). This means that the spindle (16) in the overflow valve remains in the upper position and closes off the path between the pressure chamber (11) and the suction chamber (10). By turning the rotary knob (3) to move the regulating spindle (4) downwards, the overflow valve can be opened in a continuous movement. A part of the pump capacity then flows from the pressure chamber (11) into the suction chamber (10) and the operating pressure and flow rate drop to the amount that has been set by turning the knob. 2. When the handgun is closed 1. Manual pressure and flow control by turning rotary knob

When the handgun is opened, the entire pump capacity flows through the injector (2) to the high-pressure outlet (1).

When the handgun is closed, no water flows through the injector (2). The pressure chamber (11) and the control chamber (14) are linked by a connecting channel (12) and the pressure in both areas are the same. As the surface of the piston (13) in the control chamber (14) is larger than in the pressure chamber (11), it is pressed downwards together with the overflow valve spindle (16). This causes the entire pump capacity to flow from the pressure chamber (11) into the suction chamber (10) (circulation mode). The pump continues to run, but only maintains the circulation pressure. 3. When the handgun is opened

When the handgun is opened, the pressure in the pressure chamber (11) and in the control chamber (14) drops suddenly. The spring (15), together with the restricted pressure at the entrance to the injector (2), pushes the piston (13) upwards. The overflow valve spindle then closes off the circulation of water between the pressure chamber (11) and the suction chamber (10) and the pump builds up the operating pressure once more. This switch-over action will not function if there is no injector fitted or it is worn out.

C21

Motor and pump

Basic training HD / HDS

Pressure and flow control, Servopress or manual with overflow valve

1

6 7 4 3 2 1 8 9

10 17 16 15 14 13 12 11

14

12

C22

Basic training HD / HDS

Motor and pump

Pressure and flow control, Servopress or manual with overflow valve

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Injector Non-return valve Pressure channel Piston Rotary knob Spring Valve spindle Valve spindle cone Valve seat Pressure valve Cylinder head Pressure chamber Bypass channel Suction chamber Spring Ball High-pressure outlet 1. Manual pressure and flow control by turning rotary knob (5)

When the handgun is opened, water is conveyed out of the pressure chamber (12), through the pressure valve (10), non-return valve (2) and the injector (1), to the high-pressure outlet (17). Turning the rotary knob (5) adjusts the initial tensioning of the spring (6). Depending on how this spring is set, the valve opens later when the initial tension is greater (higher operating pressure), or earlier when the initial tension is lower (lower operating pressure). 2. When the handgun is closed

When the handgun is closed, the pressure within the system reaches its maximum level. This pressure acts upon the piston (4) via the pressure channel (3) and pushes the piston (4) and valve spindle (7) downwards. The ball (16) is pushed away from the valve seat (9) and the entire pump capacity flows through the bypass channel (13) back into the suction chamber (14). As soon as the handgun is closed the pressure is trapped between the handgun and non-return valve (2). This trapped pressure holds the Instream valve in the by-pass mode. The pump continues to run in low pressure operation. 3. When the handgun is opened

When the handgun is opened again, the pressure trapped between the handgun and the nonreturn valve (2) drops and the piston (4) is pushed back upwards again by the spring (6). The ball (16) closes off the valve aperture and the system builds up full working pressure again.

C23

Motor and pump

Basic training HD / HDS

Pressure and flow control, Servopress with overflow valve

C24

Basic training HD / HDS

Motor and pump

Pressure and flow control, Servopress with overflow valve

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Threaded plug Pressure holding valve Spring Ball Valve seat Connecting channel to suction chamber Piston Threaded fitting Spring Rod Pressure switch Locking nut Adjusting nut for pressure switch Locking nut Adjusting nut for operating pressure High-pressure outlet Control pressure injector Connecting channel between injector and overflow valve Pressure chamber Pressure gauge connection 2. The Servopress handgun is partially closed

When the handgun is partially closed, the pressure in the pressure chamber (19) does not increase. Due to the decreased water flow rate, the effect of the injector action (17) is reduced, so that the pressure in the connecting channel (18) rises. The piston (7) and rod (10) are pushed to the left slightly against the spring pressure (9). The tapered tip of the rod pushes the ball (4) away from its seat (5) slightly, so that a part of the pump flow rate flows into the suction chamber (6). Note: Opening or closing the Servopress handgun while the cleaner is operating in highpressure mode does not result in a change to the motor current consumption. The current consumption is only reduced when the cleaner is being operated in cleaning agents mode. 3. The Servopress handgun is completely closed

1.

When the Servopress handgun is opened

When the Servopress handgun is fully opened, water flows out of the pressure chamber (19), through the pressure holding valve (2) and injector (17) then on to the high-pressure outlet (16). The ball (4) in the overflow valve is pressed against the valve seat (5) by the pump pressure and closes off the connecting channel (6) to the suction chamber. The pressure gauge shows the operating pressure within the pressure chamber (19). The action of the injector (17) results in a pressure level in the connecting channel (18) that is approx. 30 bar lower.

As the handgun closes, the pressure in the pressure chamber (19) rises abruptly. This peak of pressure acts upon the piston (7) via the connecting channel (18) and forces the rod (10) all the way to the left (approx. 4 mm). The tapered tip of the rod (10) pushes the ball (4) completely off its seat, so that the entire pump flow rate flows through the connecting channel (6) into the suction chamber. As soon as the handgun is closed, the pressure holding valve (2) closes. This trapped pressure holds the valve in the by-pass mode. When this position is reached, the pressure switch (11) is actuated, the electrical supply interrupted and the motor switched off. 4. The Servopress handgun is opened

If the handgun is opened again, the pressure in the system drops off abruptly. The overflow valve is pushed back towards the right into its original position by the spring. The pressure switch (11) reconnects the electrical supply and the motor is switched on again.

C25

Motor and pump

Basic training HD / HDS

Pressure and flow control, manual with regulating spindle

11

10

C26

Basic training HD / HDS

Motor and pump

Pressure and flow control, manual with regulating spindle

1 2 3 4 5 6 7 8 9 10 11 Left piston Valve seat Spindle cone Centre piston Cylinder head Return channel to suction side Conical sleeve Pressure spring End limit screw Regulating spindle Rotary knob Pressure and flow rate can be continuously adjusted with the regulating spindle. 1. The regulating spindle (10) is fully rotated inwards

In this position the spindle cone (3) and the conical sleeve (7) completely close off the corresponding apertures. The entire pump flow rate is directed towards the handgun. 2. The regulating spindle (10) is partially rotated outwards

In this position the spindle cone (3) has opened. As a result the volume of water delivered by the centre piston (4) flows back to the suction side through the return channel (6), the pressure level and water flow rate are reduced by approx. 3040%. 3. The regulating spindle (10) is rotated outwards until stopped by the end limit screw

In this position the spindle cone (3) and the conical sleeve (7) have opened completely. The volume of water delivered by the centre piston (4) and the left piston (1) flows back to the suction side through the return channel (6), the pressure level and water flow rate are reduced by approx. 6070 %. Steam can only be generated when this position has been selected. Note: The bore in the valve seat (2) varies in accordance with the delivery capacity of the particular unit (see Spare Parts List).

C27

Motor and pump

Basic training HD / HDS

Pressure and flow control, Servopress or manual with overflow valve

5 6

C28

Basic training HD / HDS

Motor and pump

Pressure and flow control, Servopress or manual with overflow valve

1 2 3 4 5 6 7 8 Rotary knob Pressure spring Piston Valve seat Return channel Pressure switch (in circuit diagram B7) Water inlet Suction chamber 1. Manual pressure and flow control by turning rotary knob If the rotary knob (1) is turned counter-clockwise, the initial tension in the pressure spring is reduced (2). This causes the piston (3) to lift off the valve seat (4), even at a lower pressure level and a part of the pump flow rate is directed through the return channel (5) into the suction chamber (8). The pump continues to run but at a reduced pressure level. The pressure level and water volume at the high-pressure nozzle decrease according to the setting. 2. Pressure and flow control with Servopress handgun If the Servopress handgun is partially closed, the pressure within the system rises. The piston (3) is raised off the valve seat (4), so that a part of the pump flow rate flows through the return channel (5) to the suction chamber (8). The pump continues to run at high pressure. The pressure level and water volume at the highpressure nozzle decrease according to the setting. 3. The Servopress handgun is closed If the Servopress handgun is completely closed, the piston (3) opens fully and the entire pump flow rate flows through the return channel (5) to the suction chamber. The dynamic pressure that builds up at the entrance to the return channel actuates the pressure switch (6), which then switches the unit off. Note: The bore in the return channel (5) can vary according to the delivery flow rate of the particular unit (see Spare Parts List).

C29

Motor and pump

Basic training HD / HDS

Pressure switch, two pressure switches with overflow valve

1 14 13 11 12 3 4 2

6 7

16 10 9 8

15

1 2 3 4 5 6 7 8 9

Rotary knob Pressure spring Piston Valve seat Return channel Pressure switch Water inlet Suction chamber Suction valve

10 11 12 13 14 15 16

Pump piston Pressure switch Non-return valve Pulsation damper Pressure valve High-pressure connection Pressure gauge connection

In this system the pump is switched on and off by two separate pressure switches.

C30

Basic training HD / HDS

Motor and pump

Pressure switch, two pressure switches with overflow valve (Schematic)

5 3

4 6

7 12 11 8

9 10

0 Volt

1 2 3 4 5 6 7 8 9 10 11 12

High-pressure outlet (no pressure) Pulsation damper Pressure gauge (no pressure) Non-return valve (closed) Rotary knob Overflow valve (closed) Restriction bore Pressure switch (closed) Water inlet Motor switch contacts (open) Pump (not running) Pressure switch (closed)

1.

The unit is switched off

If the unit is switched off and the handgun has been opened, there is no pressure in the system and no electric current flows. Both pressure switches (8) and (12) as well as the overflow valve (6) and non-return valve (4) are closed. The motor switch contacts (10) are open.

C31

Motor and pump

Basic training HD / HDS

Pressure switch, two pressure switches with overflow valve (Schematic)

5 3

4 6

7 12 11

9 10

24 Volt

1 2 3 4 5 6 7 8 9 10 11 12

High-pressure outlet (operating pressure) Pulsation damper Pressure gauge (operating pressure) Non-return valve (open) Rotary knob Overflow valve (closed) Restriction bore Pressure switch (closed) Water inlet Motor switch contacts (closed) Pump (running) Pressure switch (open)

2. The unit is switched on and the handgun opened After the unit has been switched on and the handgun opened, the motor contactor responds and its contacts (10) close. The motor then starts up and the pump builds up the operating pressure. The non-return valve (4) and pressure switch (12) open, but the overflow valve (6) and pressure switch (8) remain closed. Because pressure switch (8) is closed, the contacts on the motor contactor (10) also remain closed.

C32

Basic training HD / HDS

Motor and pump

Pressure switch, two pressure switches with overflow valve (Schematic)

5 3

4 6

7 12 11 8

9 10

24 Volt

1 2 3 4 5 6 7 8 9 10 11 12

High-pressure outlet (cut-out pressure) Pulsation damper Pressure gauge (cut-out pressure) Non-return valve (closed) Rotary knob Overflow valve (open) Restriction bore Pressure switch (open) Water inlet Motor switch contacts (open) Pump (not running) Pressure switch (open)

3.

The handgun is closed

As the handgun is closed, excess pressure is generated within the system for a short interval. This causes the overflow valve (6) to open, the entire pump flow rate flows through the restriction bore (7) into the pump suction chamber. A dynamic pressure builds up at the entrance to the restriction bore (7). When it reaches approx. 10 bar, it opens the pressure switch (8), this interrupts the electrical circuit. The contacts (10) in the motor contactor open and the motor is switched off. As soon as the overflow valve (6) opens, the nonreturn valve (4) closes, the dynamic pressure is retained in between the handgun and the nonreturn valve (4). The pressure switch (12) is held open by the retained dynamic pressure. As soon as the motor has ceased to rotate, the overflow valve (6) and the pressure switch (8) close. The contacts (10) on the motor contactor remain open however, as there still is no flow of electric current due to pressure switch (12) being open. C33

Motor and pump

Basic training HD / HDS

Pressure switch, two pressure switches with overflow valve (Schematic)

5 3

4 6

12

11

9 10

24 Volt

1 2 3 4 5 6 7 8 9 10 11 12

High-pressure outlet (no pressure) Pulsation damper Pressure gauge (no pressure) Non-return valve (closed) Rotary knob Overflow valve (closed) Restriction bore Pressure switch (closed) Water inlet Motor switch contacts (closed) Pump (starts up) Pressure switch (closed)

4. The handgun is opened again while the unit is switched on As soon as the handgun is opened, the pressure dissipates that was retained between the nonreturn valve (4) and the handgun. The pressure switch (12) closes. The electric circuit is completed again, the motor contactor responds, its contacts (10) close, the motor starts up and the pump builds up the operating pressure again.

C34

Basic training HD / HDS

Motor and pump

C35

Motor and pump

Basic training HD / HDS

One pressure switch with overflow valve

3 2 1

10

11

18

17

16

15

14

13

12

C36

Basic training HD / HDS

Motor and pump

One pressure switch with overflow valve

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 Injector Pressure chamber Detergent non-return valve Connection for detergent supply Control chamber Detergent metering spindle Rotary knob Pin Pressure switch Pressure relief valve Connecting channel Suction valve Pressure valve Water connection with strainer Pressure spring Overflow piston Non-return valve High-pressure outlet 1. The handgun has been opened With the handgun open and the pump running, the injector (1) causes the pressure in the control chamber (5) to be approx. 10 bar lower than in the pressure chamber (2). The overflow piston is in the upper position, where it actuates the contact in the pressure switch (9) via the pin (8). The electrical circuit is completed and the motor runs. 2. The handgun is closed If the handgun is closed, water no longer flows through the injector (1). As a result the pressure in both the pressure chamber (2) and the control chamber (5) is the same. Due to the larger surface of the overflow piston (16) in the control chamber (5) than in the pressure chamber (2), the overflow piston is pressed downwards and opens the connection between the pressure chamber and the suction chamber. At the same time the contact on the pressure switch (9) is opened by means of the pin (8), the electrical circuit is interrupted and the motor is switched off. When the handgun is closed, the pressure in the pressure chamber rises abruptly for an instant. The non-return valve (17) closes and before the motor comes to a halt, the peak of pressure is dissipated through the connecting channel (11) by the pressure relief valve (10). The cut-out pressure remains in the system for as long as the handgun is closed. 3. The handgun is opened If the handgun is opened again, the pressure in the high-pressure hose and in the control chamber (5) drops off. The pressure spring (15) underneath the overflow piston (16) pushes the piston upwards and closes the contact in the pressure switch (9) by means of the pin (8). The electrical circuit is completed and the motor starts without any back pressure.

C37

Motor and pump

Basic training HD / HDS

One pressure switch without overflow valve

4 5 6 7 8

9 10 11

12 13

14

16

15

C38

Basic training HD / HDS

Motor and pump

One pressure switch without overflow valve

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Electrical connecting cable Cover Adjusting cam Microswitch Pin Spring Upper piston Range of movement for rod Outer spring Inner spring Rod Disc Lower piston From the pump Strainer To the low-water protection The pin (5) and spring (6) serve solely as a safety buffer. If the piston (7) is pushed too far upwards, the pin (5) and spring (6) prevent any damage occurring to the microswitch (4). The cut-out pressure remains in the system for as long as the handgun is closed. 3. The handgun is opened If the handgun is opened, the pressure within the system drops and the rod (11) is pushed downwards again by the inner (10) and outer (9) springs. Due to its range of movement (8) the rod (11) in the upper piston (7) is subject to a short delay (approx. 12 sec) before it too is drawn downwards, so that the microswitch (4) is switched on again. During this interval however, the pressure in the system can be almost entirely dissipated, so that the motor can start up without any back pressure. The adjusting cam (3) is used to set up the microswitch (4) so that the unit is switched off when the pressure rises to approx. 10 bar above the working pressure. The pressure switch is a safety device. It has therefore been sealed in the factory. 1. The handgun has been opened With the handgun open and the pump running, the lower piston (13) is pushed upwards by a few millimetres against the tension of the inner spring (10). Due to the range of movement (8) of the rod (11) in the upper piston (7), this is not sufficient to actuate the microswitch (4). 2. The handgun is closed If the handgun is closed, the pressure rises abruptly. The lower piston (13) is pushed upwards until it touches the disc (12). The rod (11) is then pushed further upwards slightly (approx. 0.71.7 mm), against the tension of the inner (10) and outer springs (9), until the pin (5) actuates the microswitch (4), which in turn switches the unit off.

C39

Motor and pump

Basic training HD / HDS

Safety valve and low-water protection

7 8

5 4 9 10 3 2 1

14

13

12

11

15

C40

Basic training HD / HDS

Motor and pump

Safety valve and low-water protection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Inlet from the pump Strainer Valve seat Seal Piston Housing Adjusting screw Pressure spring Outlet to float tank Reed switch Threaded plug Pressure spring Clamping screw Magnetic piston Outlet to handgun Safety valve The safety valve protects the pump from becoming damaged should the pressure switch or overflow valve malfunction by directing the entire pump flow rate into the float tank. When the handgun has been opened, the safety valve is closed and the entire pump flow rate flows out to the handgun (15) at operating pressure. If the pressure within the high-pressure system rises to approx. 20 bar above the operating pressure, the piston (5) is raised off the valve seat (3) and the entire pump flow rate flows into the float tank (9). The pressure required to open the safety valve is set up by means of the adjusting screw (7). The safety valve is an important safety device, therefore the adjusting screw (7) has been sealed in the factory. Low-water protection The low-water protection prevents the burner from igniting if there is no or insufficient flow of water. When the handgun has been opened and there is an adequate flow of water, the magnetic piston (14) is pressed against the pressure spring (12). The magnetic piston (14) causes the contact on the reed switch (10) to close. The strainer (2) prevents dirt from entering into the low-water protection area. The low-water protection is a safety device and therefore the threaded plug (11) and the clamping screw (13) have been sealed in the factory.

C41

Motor and pump

Basic training HD / HDS

Installation information for O-ring/support ring

1 2 3 4

Pressure flow direction O-ring Support ring Piston or spindle

O-rings are frequently used whenever a seal is required between two areas with different pressure levels. Above a certain level of pressure the O-rings are made more stable by the inclusion of support rings to prevent them from becoming deformed. It is important that they are mounted facing the right direction. The side of the support ring with the groove must always face the O-ring. The following rule applies to their installation: Pressure flow direction --> O-ring --> support ring Always use a mounting mandrel and silicone grease for installation in order that no damage is caused to the support ring during the assembly process. Two support rings are used if the pressure flow direction alternates.

C42

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Manual de Taller - Yamaha Crux 2006Document0 pageManual de Taller - Yamaha Crux 2006Insomnia Dj Chile100% (13)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- QT5 Roc 104Document20 pagesQT5 Roc 104Dino Martin Mercado QuispePas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Parts Catalog For ZS1100 Engine: Cylinder Block AssemblyDocument22 pagesParts Catalog For ZS1100 Engine: Cylinder Block AssemblyWidi Prasetyo100% (5)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Yfm350fwa07 5uhg GrizzlyDocument83 pagesYfm350fwa07 5uhg GrizzlyHercílio JuniorPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Workshop Manual: 3LD 450 3LD 510 3LD 450/S 3LD 510/S 4LD 640 4LD 705 4LD 820Document33 pagesWorkshop Manual: 3LD 450 3LD 510 3LD 450/S 3LD 510/S 4LD 640 4LD 705 4LD 820Ilie Viorel75% (4)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- MS Operating & Maintenance ManualDocument32 pagesMS Operating & Maintenance ManualJohn Mue100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Project Report VajDocument15 pagesProject Report VajTamil SelvanPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Scorch 49cc & Flash 49cc EngineDocument15 pagesScorch 49cc & Flash 49cc EngineCoughman MattPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Bullet Muffler StudyDocument86 pagesBullet Muffler StudySrinivasan RPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Shanghai - Kaili Yarn Splicer: - Working Manual. - Spares Parts Catalogue.Document27 pagesShanghai - Kaili Yarn Splicer: - Working Manual. - Spares Parts Catalogue.Deepak Kumar0% (1)

- CMO 20-30 and TCMO 20-30 Reciprocating Compressor Unit: Spare Parts ManualDocument42 pagesCMO 20-30 and TCMO 20-30 Reciprocating Compressor Unit: Spare Parts ManualSarin Ramakrishna Kartha HariPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Land Rover V8 Overhaul ManualDocument49 pagesLand Rover V8 Overhaul Manualsteven100% (4)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shalaka Potdar CV MumbaiDocument2 pagesShalaka Potdar CV Mumbaiapi-3800762Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- p1k Pde2577tcuk 052009 PDFDocument20 pagesp1k Pde2577tcuk 052009 PDFwalid8311Pas encore d'évaluation

- BakerHughes ReciprocatingCompressors Overview-030321Document16 pagesBakerHughes ReciprocatingCompressors Overview-030321ganesh upadhyayaPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Restsco01 PDFDocument13 pagesRestsco01 PDFAly Kamal SabbahPas encore d'évaluation

- ATP IndexDocument356 pagesATP IndexRicardo zafra100% (1)

- Cylinder ConditionDocument21 pagesCylinder ConditionGustavs GabajevsPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Maintenance Challenges of Wankel Rotary Engines and Utility in Aviation ApplicationsDocument12 pagesMaintenance Challenges of Wankel Rotary Engines and Utility in Aviation Applications임학진Pas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- m2x m5xDocument19 pagesm2x m5xMohamed ElmakkyPas encore d'évaluation

- Racine Vane and Radial Pumps: PSV 10, 15, 20, 25 PSV 40, 80, 100 PVF, PVQ, PVR, PVK, PVT, PVS, VPV C11, H20, H80Document5 pagesRacine Vane and Radial Pumps: PSV 10, 15, 20, 25 PSV 40, 80, 100 PVF, PVQ, PVR, PVK, PVT, PVS, VPV C11, H20, H80Gustavo EncarnacionPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Manual Partes NavistarDocument68 pagesManual Partes Navistarpowermanager100% (1)

- Navistar 2017.03Document48 pagesNavistar 2017.03alxsscabalPas encore d'évaluation

- David Lowe Thesis PDFDocument201 pagesDavid Lowe Thesis PDFKRISHNA VAMSHIPas encore d'évaluation

- SATO FA-82B 4 Stroke Single Engine Instruction Manual: Manuals+Document11 pagesSATO FA-82B 4 Stroke Single Engine Instruction Manual: Manuals+ZamriPas encore d'évaluation

- Ic Engines-Bme Ae&iDocument53 pagesIc Engines-Bme Ae&iAshitaPas encore d'évaluation

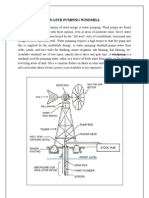

- Water Pumping WindmillDocument11 pagesWater Pumping WindmillSaravanapriya Karthik100% (1)

- 7 Overhaul Protocols COP 1132 - FORMDocument2 pages7 Overhaul Protocols COP 1132 - FORMChachou MohamedPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Identifying Compressor Mechanical FailuresDocument13 pagesIdentifying Compressor Mechanical FailuresDesiderio BourdetPas encore d'évaluation

- Piaggio Xevo 400 Workshop Manual PDFDocument376 pagesPiaggio Xevo 400 Workshop Manual PDFsamasca_serban100% (1)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)