Académique Documents

Professionnel Documents

Culture Documents

ZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)

Transféré par

Vijayaraj KumarDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)

Transféré par

Vijayaraj KumarDroits d'auteur :

Formats disponibles

Data / requisition sheet for PRESSURE VESSELS (Colums, reactors, accumulators, etc.) 1 Equipment No.

: 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 V-8421 Number required: OPERATING/MECHANICAL DATA Produced Water Storage vessel Produced Water 30 59 19.9 0.03 0.05 Atm. NA NA 82 5 7 F.V. As per code Refer Sheet 5 Refer Sheet 5 Refer Sheet 5 Refer Sheet 5 Refer Sheet 5 Refer Sheet 5 N/A N/A VTA 12000 N/A N/A N/A N/A N/A 2:1 Ellipsoidal VTA 3 / 0 / PCS-7b (Note 4) N/A N/A N/A N/A : 127 : * : * : 168 kmph speed (refer SP-2069) 3500

Design book Contr. job MESC

No. : No. : No. : 1

page:

Description Contents Working temperature, max./normal/min. Working pressure - max./normal/min. - normal/min.vac. conditions Design temperature, upper/lower Design pressure, internal/external Test pressure, hydrostatic/pneumatic Liquid - quantity - density at 15C - density at working temperature Vapour - quantity - molecular weight - density at working temperature Heating/cooling medium - max. quantity required Diameter of shell OD/ID Length between tangent lines Total packed height Height per bed Size and type of packing Number of packed sections Number of redistributors Height of skirt to bottom tangent line Type of heads Wall thickness - shell/head Corrosion allowance/lining/cladding Insulation thickness Trays - spacing/number required - type - lay-out in accordance with sheet(s)

Units C bar ga mbar abs C bar ga bar ga kg/s kg/m3 kg/m3 kg/s kg/m3 kg/s mm mm mm mm

mm VTA mm mm mm mm pcs

Total volume Normal liquid volume Volume range required for level control Wind pressure

42 * There will not be any normal operating level in the vessel as the vessel is not 43 in continuous operation and level is not controlled.

2H3 (HOLD) - Type/size : Conventional m3 Relief valve(s) 7 - Set pressure : bar ga m3 - Number required : 1 Note-14 m3 : N/m2 Earthquake factor INFORMATION TO BE SUBMITTED WITH THE TENDER Refer Section 7.1 and Appendix-3 (RED form) of SP-2069.

44 The operation is On/Off. The vessel is filled to its high level and emptied to Low level. 45 46 VTA = Vendor To Advise 47 VTC = Vendor To Confirm 48 49 REMARKS ON REVISIONS 50 R01- Issued for IDC 51 R02- Issued for Comments (IFC) 52 A01 - Issued for Use 53 54 Made by: UEP122S Chk'd by: UEP12S Appr'd by: UEP12S Date

14/09/11

EQUIPMENT : PLANT : CONSIGNEE :

PRODUCED WATER STORAGE VESSEL ZAULIYAH GAS PLANT PDO

Rev. letter

R01

R02

A01

Date

14/09/11

Date 14/09/11 16/10/11 10/12/11 Sign. UEP122S UEP122S UEP122S

Date

14/09/11

Sheet No. 1

continued on sheet No. 2

Eng. by : PDO FEED OFFICE Principal : Petroleum Development Oman LLC. DEP 31.22.00.94-Gen., sheet 1/5, dated 09/98

Equipment No. V-8421 Datasheet No. ZAU-256-MS-2105-00003-0001

Data / requisition sheet for PRESSURE VESSELS (Columns, reactors, accumulators, etc.) - cont. sheet 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 Part Shell Cladding/lining of shell Heads Caldding/lining of heads Reinforcing rings Skirt, base plate, etc. Saddles Jacket Shell flanges Nozzles (line pipe/plate/forged) Liner of nozzles and manholes Flanges (ASME) Flanges (Non- (ASME) Welding fittings Stiffening rings Insulation support rings External attachments / Cleats Internals (welded / removable) Construction in accordance with: MATERIAL SPECIFICATION (Note-2,12) ASTM No. Part SA 516 Gr.60N/70N Downcomers Note-4) Baffles SA 516 Gr.60N/70N Internal pipe fittings Note-4) Stud bolts, external SA 516 Gr.60N/70N Nuts, external Bolts, internal SA 516 Gr.60/70N / SA 285 Gr.C / SA 36 Nuts, internal Gaskets, external Gaskets, internal SA 106 Gr.B Dip pipe / Stilling Well Note-4) SA 105N SA 234 Gr.WPB SA 516 Gr.60N/70N SA 516 Gr.60N/70N FABRICATION AND INSPECTION REQUIREMENTS ASME Section VIII Div-1, SP-2069 & DEP 31.22.20.31-Gen and "U" stamped.

Design book Contr. job MESC

No. : No. : No. : ASTM No. ASTM A193 Gr.B7 ASTM A194 Gr.2H (Note-5) SS316L spiral wound graphite filled -

page:

Inspection Inspection authority Stress relieving Special heat treatment Radiography Other non-destructive testing Chemical analysis Manufacturer's certificate - chemical analysis - mechanical data

Full as per code and DEP 31.22.20.31-Gen.& U stamped. Authorized inspector appointed by Vendor (Vendor to specify the name of the agency in the offer)+TPIA appointed by Purchaser. As per code As per DEP 31.22.20.31-Gen and as per code 100% DEP 31.22.20.31-Gen and as per code. As per ISO 10474 - 3.1B / BS EN 10204 - 3.1 As per ISO 10474 - 3.1B / BS EN 10204 - 3.1 WEIGHTS kg Weight of internals kg Weight of insulation kg Weight of fireproofing

35 Erection weight (shipping weight) 36 Total weight, operating 37 Total weight, full of water 38 39 40 41 Arrangement - construction - outline 42 Standard vessel 43 Additional drawings 45 46 47 48 49 50 51 52 53 54 General remarks for vessels Flanged pipe nozzles Thermowell nozzles Carbon steel flanges Vortex breaker Skirt/saddles/brackets Sliding plate for saddles Pipe flanges inside vessel Stilling Well : : : : : : : : :

: : :

VTA VTA VTA

: : :

VTA N/A N/A

kg kg kg

REFERENCE DRAWINGS/LIST : : : Anchor bolt ring and base plate Lifting lug / trunnion Name plate Support ring for insulation Inspection hole/hand hole/ manhole/davits, etc. Earthing Boss Thermowell : : : : : : :

44 Welding electrodes, rods, etc.: See DEP 30.10.60.18-Gen. S 10.101 By Vendor S 10.114

S 10.010 S 22.002 S 22.003

S 10.070 STD-4-0304-001

The manufacturer is responsible for ensuring that the equipment is designed and constructed in accordance with the specifications and codes referred to on the requisition and/or drawings. Furthermore, the manufacturer is responsible for ensuring that the design, including thicknesses of pressure parts, is satisfactory for the design conditions indicated on the requisition and/or drawings. Calculations and thicknesses of material supplied to the manufacturer are for information and tendering purposes only. The manufacturer shall make his own calculations for which he is fully responsible. The manufacturer shall ensure that the equipment supplied conforms to all applicable codes and national statutory regulations, and he shall obtain all necessary approvals from statutory authorities. Sheet No. 2 continued on sheet No. 3

Eng. by : PDO FEED OFFICE Principal : Petroleum Development Oman LLC. DEP 31.22.00.94-Gen., sheet 2/5, dated 09/98

Equipment No. V-8421 Datasheet No. ZAU-256-MS-2105-00003-0001

Data / requisition sheet for PRESSURE VESSELS (Columns, reactors, accumulators, etc.) - cont. sheet 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 MW 1-3 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 3 Manway Mark N1 N2 N3 N4 N5 N6 N7 N8 Number 1 1 1 1 1 1 1 1 Service Liquid Inlet Liquid Outlet Nitrogen gas inlet Nitrogen gas outlet Utility Connection Relief valve Drain Vent NOZZLE DATA Nom. dia. and flange rating DN 50 ASME B16.5, 150 # DN 150 ASME B16.5, 150 # DN 50 ASME B16.5, 150 # DN 100 ASME B16.5, 150 # DN 100 ASME B16.5, 150 # DN 100 ASME B16.5, 150 # DN 50 ASME B16.5, 150 # DN 100 ASME B16.5, 150 # Remarks with Vortex Breaker

Design book Contr. job MESC

No. No. No.

: : :

page:

C1 C2A/B C3A/B C4A/B C5A/B

1 2 2 2 2

Pressure Instrument Level LL Level Control Level HH Level Gauge

INSTRUMENT CONNECTIONS DN 50 ASME B16.5, 150 # DN 80 ASME B16.5, 150 # DN 80 ASME B16.5, 150 # DN 80 ASME B16.5, 150 # DN 50 ASME B16.5, 150 #

Note-9) Note-9), 16) Note-9) Note-9),15)

MANHOLES ETC. DN 600 ASME B16.5, 150 # with B/F & Davit

NOTES:- (MECHANICAL) 1) All material shall comply with the requirements of DEPs 30.10.02.11-Gen, 30.10.02.31-Gen, 39.01.10.11-Gen. 2) For all carbon steel material including ASTM A-36 material, the carbon content shall be limited to 0.23% and to be killed or semi-killed. All carbon steel material for pressure parts shall be normalised. 3) External attachment/stiffeners of SA 36 material shall NOT be welded directly to pressure containing parts. A pad of the same material as that of shell / dished ends shall be provided between SA 36 attachments and the pressure containing parts. If pads are not provided, then external attachments shall be of the same material as that of the pressure retaining part. 4) The equipment shall be externally coated with PCS-1 and internally coated with PCS-7b as per SP-1246 (based on maximum operating temperature). 5) The nuts shall be of heavy hexagonal type for all external pressure bolting. 6) Lifting lugs/trunnions shall be provided with pads. Lifting lugs/ trunnions shall be designed for a minimum load of 2 times the empty weight of the equipment to allow for dynamic effects. 7) Vendor shall propose the tentative location and orientation of the nozzles on the vessels. Actual location/orientation shall be provided during detail engineering and Vendor to follow the same. 8) Vendor shall indicate the weight (empty, operation & water filled) and foundation loading details in the fabrication drawing. 9) Instrument level nozzle pairs C2A/B, C3A/B, C4A/B and C5A/B shall be in the same orientation and their flange faces shall be in the same vertical plane. 10) Vendor shall submit detailed mechanical design calculation of the equipment and submit the same for Purchaser's approval. Vendor shall be responsible for the design. 11) The vessel mechanical design shall be according to the requirements of SP-2069. 12) The material grade specified in the datasheet is tentative only. Vendor may propose alternative more suitable materials for the service conditions.

49 13) All nozzles shall be fabricated from seamless pipe material. 50 14) Supply of relief valve is by others and not included in vessel Vendor's scope. 51 15) The level gauge to cover full range of level instruments. 52 16)The Level Controller (C3A/B) range shall also cover the High High Alarm LAHH2. 53 54 55 56 57 58 59 60 Eng. by : PDO FEED OFFICE Principal : Petroleum Development Oman LLC. DEP 31.22.00.94-Gen., sheet 3/5, dated 09/98 Equipment No. V-8421 Datasheet No. ZAU-256-MS-2105-00003-0001 Sheet No. 3 continued on sheet 4

Data / requisition sheet for PRESSURE VESSELS (Columns, reactors, accumulators, etc.) - cont. sheet 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 ADDITIONAL DATA FOR SKETCH:

Design book Contr. job MESC

No. : No. : No. :

page:

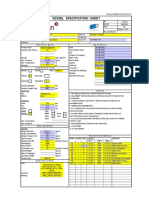

PROCESS EQUIPMENT DATA SHEET - EQUIPMENT SKETCH

N3

N8

C1

MW3

N4

N6

N1 C4A 3500 I.D. C2A

C3A

C5A

MW1

LZAHH2 LAHH1

MW2

C4B 2025 *

C2B

LAH LAL LZALL

C3B

C5B N5

N7

SADDLE SLIDING FIXED SADDLE

N2 TL 875 * continued on sheet 5

TL 875* 875

12000

The below data should be read with sketch. Maximum Allowable Liquid Height LZAHH2 LZAHH1 LAH LAL LZALL

3.200 3.150 3.000 0.850 0.350 0.200 m m m m m m

54 - All dimensions are in mm unless otherwise specified. 55 - All elevations of Liquid level are marked from the reference level from shell inside bottom. 56 - TL = Tan Line. 57 - * Marked dimensions shall be advised and confirmed during detail engineering by the Contractor. 58 59 Eng. by : PDO FEED OFFICE Principal : Petroleum Development Oman LLC. DEP 31.22.00.94-Gen., sheet 4/5, dated 09/98 Equipment No. V-8421 Datasheet No. ZAU-256-MS-2105-00003-0001 Sheet No. 4

Data / requisition sheet for PRESSURE VESSELS (Columns, reactors, accumulators, etc.) - cont. sheet 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Eng. By : PDO FEED OFFICE

Design book Contr. job MESC

No. : No. : No. :

page:

PROCESS EQUIPMENT DATA SHEET - ADDITIONAL DATA

Table 1: Inlet Composition

Component

Nitrogen CO2 Methane Ethane Propane i-Butane n-Butane i-Pentane iP t n-Pentane n-Hexane Mcyclopentane Benzene Cyclohexane n-Heptane Water Total

Mole Fraction

0.000037 0.000041 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0 000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.999922 1.000000

Table-2: Produced Water Characteristics Parameter Units Results

pH @ deg C Temperature for pH Relative Density @ 15/15 deg C Absolute Density @ 15 deg C Calcium Magnesium Iron Chloride Sulphate Carbonate Bicarbonate Sodium Salinity Total Hardness (TS) Total Dissolved Solids (TDS) Resistivity @ 26.6 deg C pH deg C kg/m3 kg/m3 kg/m3 kg/m3 kg/m3 kg/m3 kg/m3 kg/m3 kg/m3 kg/m3 Kg NaCl/m3 kg/m k / 3 kg/m3 ohm.m 5.9 26.5 1159 1157.8 15.24 3.61 0.34 140.7 0.144 0 0.076 66.72 229.2 52.9 52 9 226.8 0.02

Sheet No. 5

Concluding sheet

Equipment No. V-8421 Datasheet No. ZAU-256-MS-2105-00003-0001

Principal : Petroleum Development Oman LLC. DEP 31.22.00.94-Gen., sheet 5/5, dated 09/98

Vous aimerez peut-être aussi

- 000-Za-E-M09402 - C Method Statement For Brown Green Field InstallationDocument21 pages000-Za-E-M09402 - C Method Statement For Brown Green Field Installationsyam prasadPas encore d'évaluation

- Tank Specification OGDocument28 pagesTank Specification OGMadhesh RajuPas encore d'évaluation

- Calculations SheetDocument3 pagesCalculations SheetSami SawalhaPas encore d'évaluation

- MS For Fabrication & Erection of PipingDocument24 pagesMS For Fabrication & Erection of PipingravikumarPas encore d'évaluation

- ENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)Document4 pagesENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)m khaeronPas encore d'évaluation

- PT - Mcci Document Register List Rev.B 110811Document3 pagesPT - Mcci Document Register List Rev.B 110811adityadhPas encore d'évaluation

- Format From EIL 5 2744 0212 F1 - REV2Document27 pagesFormat From EIL 5 2744 0212 F1 - REV2sshastrimechPas encore d'évaluation

- Specifications Typical Drawing Data Sheet For Split TeeDocument9 pagesSpecifications Typical Drawing Data Sheet For Split TeeHugo F. Barrera Alvarado100% (1)

- Plumbing and Pipe Line Work PDFDocument248 pagesPlumbing and Pipe Line Work PDFLoren ViejayPas encore d'évaluation

- ABUS Fabrication Drawings 5Tx18400Document6 pagesABUS Fabrication Drawings 5Tx18400Vijayaraj Kumar100% (1)

- 5ST0307 - 017-T1-Me-Das-259 - 1 PDFDocument5 pages5ST0307 - 017-T1-Me-Das-259 - 1 PDFRishabh Verma100% (1)

- Trunnion Ball Valve - Class 150#Document6 pagesTrunnion Ball Valve - Class 150#adrianioantomaPas encore d'évaluation

- Piping Design CriteriaDocument20 pagesPiping Design Criteriasuman_ghosh6798Pas encore d'évaluation

- Pressure Vessel Dimension InspectionDocument17 pagesPressure Vessel Dimension InspectionEqubal KhanPas encore d'évaluation

- Hydrostatic Test Procedure For Ug Non-Metallic Piping SystemDocument16 pagesHydrostatic Test Procedure For Ug Non-Metallic Piping SystemabrayalamPas encore d'évaluation

- Productsheet Bristle Blaster P-033-EnDocument4 pagesProductsheet Bristle Blaster P-033-EnVijayaraj KumarPas encore d'évaluation

- Siement Turbine Over Hauling Procedure PDFDocument75 pagesSiement Turbine Over Hauling Procedure PDFShankar Jha100% (1)

- Pressure Vessel PlateDocument4 pagesPressure Vessel PlateYetkin ErdoğanPas encore d'évaluation

- Requisition For Piping Work - A01IFRDocument31 pagesRequisition For Piping Work - A01IFRACHMAD.KAMAL100% (3)

- Asme B16.33Document17 pagesAsme B16.33Geovane SouzaPas encore d'évaluation

- FOR Construction: Specifications For Identification of Piping MaterialDocument12 pagesFOR Construction: Specifications For Identification of Piping MaterialajmainPas encore d'évaluation

- TVS Apache RTR 150 Spare Parts CatalogueDocument69 pagesTVS Apache RTR 150 Spare Parts CatalogueVaibhav Sharma83% (12)

- No.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDocument38 pagesNo.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDarshan PanchalPas encore d'évaluation

- Pump CalcDocument5 pagesPump CalcpavanPas encore d'évaluation

- 6-44-0002-Rev 2Document53 pages6-44-0002-Rev 2Vineet Singh100% (2)

- Vendor Document Cover Sheet: Project: Ar4 4 Aromatics PlantDocument18 pagesVendor Document Cover Sheet: Project: Ar4 4 Aromatics PlantHyune Boom SheenPas encore d'évaluation

- 2004-D-Piping SpecialitiesDocument24 pages2004-D-Piping Specialitiessids82Pas encore d'évaluation

- Calcs 4Document19 pagesCalcs 4Syariful Maliki NejstaršíPas encore d'évaluation

- Steam Trap Data Sheet For: Warm Up Load Running LoadDocument1 pageSteam Trap Data Sheet For: Warm Up Load Running LoadShahzaibUsmanPas encore d'évaluation

- Pipe HandbookDocument26 pagesPipe HandbookBeatriz Berçot100% (1)

- (D-101) Pressure Vessels - Rev2 PDFDocument30 pages(D-101) Pressure Vessels - Rev2 PDFmihir_jha2Pas encore d'évaluation

- Jacobs: Equipment Inspection Code: ADocument2 pagesJacobs: Equipment Inspection Code: ASigit BintanPas encore d'évaluation

- MIS-M-DS-04053 50m3 Slop Tank Data Sheet-BDocument2 pagesMIS-M-DS-04053 50m3 Slop Tank Data Sheet-Bhappale2002Pas encore d'évaluation

- Procedure For Positive Material Identification at Vendor'S WorksDocument7 pagesProcedure For Positive Material Identification at Vendor'S WorksAjay BaggaPas encore d'évaluation

- A307 6545 104 Enq Rev0Document283 pagesA307 6545 104 Enq Rev0Yogi YuganPas encore d'évaluation

- A.1) Verification Statement For Pvelite Calculations, As Per Asme Section Viii Div.1 2018Document6 pagesA.1) Verification Statement For Pvelite Calculations, As Per Asme Section Viii Div.1 2018ToniPas encore d'évaluation

- MM ZTK 1B WPX MEC DTS 0013 Rev.C1 Diesel Oil Filter With InternalDocument9 pagesMM ZTK 1B WPX MEC DTS 0013 Rev.C1 Diesel Oil Filter With Internalpragatheesk100% (1)

- Final-Mr For Scaper Traps, Pig Sinallers, Quick Opeing End Closures - 20100209 - 113815Document80 pagesFinal-Mr For Scaper Traps, Pig Sinallers, Quick Opeing End Closures - 20100209 - 113815KalaiYarasanPas encore d'évaluation

- Tech. Spec. For Heat ExchangersDocument5 pagesTech. Spec. For Heat Exchangerssanjay421Pas encore d'évaluation

- Pipe Wall Thickness CalculationDocument1 pagePipe Wall Thickness Calculationfarhad soopithodiPas encore d'évaluation

- Procedure Qualification ReportDocument5 pagesProcedure Qualification ReportDieu TranPas encore d'évaluation

- TBDP A M DS 0007 2Document7 pagesTBDP A M DS 0007 2Bùi Văn HợpPas encore d'évaluation

- TBE For UG Knock Out Drum - Draft For Rev.C1Document22 pagesTBE For UG Knock Out Drum - Draft For Rev.C1pragatheeskPas encore d'évaluation

- ProcessBuildingVentilationSystemDesignDescription - CM A ME 001 R6 PDFDocument37 pagesProcessBuildingVentilationSystemDesignDescription - CM A ME 001 R6 PDFShaimaa SaadPas encore d'évaluation

- Index - Amendment To TBPDocument4 pagesIndex - Amendment To TBPVineet 01Pas encore d'évaluation

- PACE Structured Column Packings: Datasheet For Existing ColumnDocument2 pagesPACE Structured Column Packings: Datasheet For Existing ColumnAabbhas GargPas encore d'évaluation

- Epcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitDocument7 pagesEpcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitKunalPas encore d'évaluation

- AL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCDocument5 pagesAL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCCaptainToniesPas encore d'évaluation

- SKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1Document31 pagesSKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1kebarongan12Pas encore d'évaluation

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Document5 pages18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaPas encore d'évaluation

- Pages From ONGC-SPEC-02-MS-03Document12 pagesPages From ONGC-SPEC-02-MS-03Prathamesh OmtechPas encore d'évaluation

- Material Requisition For Expansion Joint - Rev1Document4 pagesMaterial Requisition For Expansion Joint - Rev1altipatlarPas encore d'évaluation

- Mechanical Engineering Training Calendar 2015Document4 pagesMechanical Engineering Training Calendar 2015dharwinPas encore d'évaluation

- Guideline For Preparing IPDS - Instrument Process Data SheetDocument3 pagesGuideline For Preparing IPDS - Instrument Process Data Sheetbalaji krishnan100% (1)

- Sample2 DrawingDocument1 pageSample2 DrawingSourav HaitPas encore d'évaluation

- 3 OEE 3 144 Mechanical Design Check ListsDocument13 pages3 OEE 3 144 Mechanical Design Check ListsAnonymous HDlK5cXc8Pas encore d'évaluation

- 007-Stand Post Type Fire HydrantDocument6 pages007-Stand Post Type Fire HydrantshabahatPas encore d'évaluation

- IS, I I I: Name of ManufacturerDocument1 pageIS, I I I: Name of ManufacturercynidePas encore d'évaluation

- 0 WD990 EM440 00101 Equipment List RevFDocument20 pages0 WD990 EM440 00101 Equipment List RevFManuel Jesus Perez MelgarPas encore d'évaluation

- Bharat Petroleum Corporation Limited M/S Durgapur EquipmentsDocument3 pagesBharat Petroleum Corporation Limited M/S Durgapur EquipmentsSatyaprakash RayPas encore d'évaluation

- IPS MBD21907 in 522 Datasheet of Emergency Relief Valve ADocument3 pagesIPS MBD21907 in 522 Datasheet of Emergency Relief Valve ANikhil KarkeraPas encore d'évaluation

- 16 B 06 HDocument20 pages16 B 06 HVaibhav Bhoir0% (1)

- Vessel Specification SheetDocument2 pagesVessel Specification Sheetangel gabriel perez valdezPas encore d'évaluation

- Pumps Final TeDocument48 pagesPumps Final Tegharsallah mounaPas encore d'évaluation

- Pump MDSDocument2 pagesPump MDSVipul GandhiPas encore d'évaluation

- Technical Specification of Flange Face Finish S-000-1360-006 - R - 0001Document3 pagesTechnical Specification of Flange Face Finish S-000-1360-006 - R - 0001Ton PhichitPas encore d'évaluation

- General Checklist For Procurement OF Material Handling System / EquipmentDocument8 pagesGeneral Checklist For Procurement OF Material Handling System / Equipmentjkhan_724384Pas encore d'évaluation

- Spool Inspection ReportDocument4 pagesSpool Inspection Reportdj22500Pas encore d'évaluation

- CO-S-004 Document Numbering System Rev.ADocument5 pagesCO-S-004 Document Numbering System Rev.ARanjan KumarPas encore d'évaluation

- 0203 KSS Marker StripDocument1 page0203 KSS Marker StripAgus Heri TulasnoPas encore d'évaluation

- FR48-003-D03-0047 2D MDS Water AccumulatorDocument5 pagesFR48-003-D03-0047 2D MDS Water AccumulatorpragatheeskPas encore d'évaluation

- Hilton Doha, Doha - Updated 2021 PricesDocument15 pagesHilton Doha, Doha - Updated 2021 PricesVijayaraj KumarPas encore d'évaluation

- Product Data: Hempadur Multi-Strength 35530Document2 pagesProduct Data: Hempadur Multi-Strength 35530Vijayaraj KumarPas encore d'évaluation

- Monoethylene Glycol (Meg) (Monoethylene Glycol / MEG)Document5 pagesMonoethylene Glycol (Meg) (Monoethylene Glycol / MEG)Vijayaraj KumarPas encore d'évaluation

- Asme Certificate HolderDocument1 pageAsme Certificate HolderVijayaraj KumarPas encore d'évaluation

- AF3000 Fittings & WeldoletsDocument13 pagesAF3000 Fittings & WeldoletsVijayaraj KumarPas encore d'évaluation

- 1 Mohammad Humaun Sheikh Sohan: S.No. NameDocument3 pages1 Mohammad Humaun Sheikh Sohan: S.No. NameVijayaraj KumarPas encore d'évaluation

- 12x16 Manway DrawingDocument2 pages12x16 Manway DrawingVijayaraj KumarPas encore d'évaluation

- Annex A Optional Design Basis For Small Tanks: (Normative)Document11 pagesAnnex A Optional Design Basis For Small Tanks: (Normative)Jamir Diaz MechanPas encore d'évaluation

- Product Manual 26556 (Revision A) : GS6 Mass Flow Metering LegDocument22 pagesProduct Manual 26556 (Revision A) : GS6 Mass Flow Metering LegRICARDO ALEXIS LARA GALLEGO STORKPas encore d'évaluation

- SONDEX SP 15AST - Gasketed - Heat - Exchangers ManualDocument16 pagesSONDEX SP 15AST - Gasketed - Heat - Exchangers Manualarun kumar100% (2)

- 4NM Winker Light - Jul 2012Document1 page4NM Winker Light - Jul 2012Tripod1970Pas encore d'évaluation

- Cu-Ni Pipes, Flanges & FittingsDocument67 pagesCu-Ni Pipes, Flanges & Fittingssdk1978Pas encore d'évaluation

- Valves PDFDocument150 pagesValves PDFksvvijPas encore d'évaluation

- Comdiflex Kammprofile Gaskets Technical Catalogue.Document6 pagesComdiflex Kammprofile Gaskets Technical Catalogue.Shijumon KpPas encore d'évaluation

- Cảm Biến Báo Mức (Rada Báo Mức Liệu Trong Két)Document255 pagesCảm Biến Báo Mức (Rada Báo Mức Liệu Trong Két)Trần Văn PhúcPas encore d'évaluation

- 023manholes 1 PDFDocument59 pages023manholes 1 PDFAnonymous tL8KytgJ3Pas encore d'évaluation

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasDocument13 pagesASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasShieeplPas encore d'évaluation

- 5a931d082a7d0 PDFDocument83 pages5a931d082a7d0 PDFSuBaRu GTPas encore d'évaluation

- Mueller Resilient Wedge Gate Valves: For Reliable Performance and Long Service Life-Certified To NSF 61Document4 pagesMueller Resilient Wedge Gate Valves: For Reliable Performance and Long Service Life-Certified To NSF 61gad30Pas encore d'évaluation

- Table U-3 Year of Acceptable Edition of Referenced Standards in This DivisionDocument1 pageTable U-3 Year of Acceptable Edition of Referenced Standards in This DivisionSilvana MendesPas encore d'évaluation

- Sachs Bee 125 Ram Typ18Document24 pagesSachs Bee 125 Ram Typ18thebarn9111Pas encore d'évaluation

- DTL 17505 FDocument16 pagesDTL 17505 FSteven FryePas encore d'évaluation

- Hwu Technical Manual Potable Water 2004-04-27Document52 pagesHwu Technical Manual Potable Water 2004-04-27mohdnazirPas encore d'évaluation

- AFF Clamp Connectors-GLok SML v2 4dbf3f7512a5eDocument37 pagesAFF Clamp Connectors-GLok SML v2 4dbf3f7512a5eFakePas encore d'évaluation

- 05.Хидромеханичка Опрема 3delDocument45 pages05.Хидромеханичка Опрема 3delStefan AngelovPas encore d'évaluation

- Cat CSSV 02 14Document12 pagesCat CSSV 02 14Ali MiladianPas encore d'évaluation

- KEUMDUK KDW PumpDocument17 pagesKEUMDUK KDW PumpThairanil AbduljaleelPas encore d'évaluation

- Yuken Gear PumpDocument4 pagesYuken Gear Pumpeddy ortegaPas encore d'évaluation