Académique Documents

Professionnel Documents

Culture Documents

Flange Design Mmcobc 3.3 2010

Transféré par

bakellyCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Flange Design Mmcobc 3.3 2010

Transféré par

bakellyDroits d'auteur :

Formats disponibles

27-March-2012

ASME BPVC-VIII-1 (2010)

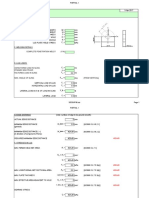

DESIGN OF CIRCULAR STEEL FLAT-FACE FLANGE WITH METAL-TO-METAL CONTACT OUTSIDE THE BOLT CIRCLE - PLAIN LOOSE TYPE FLANGE & BLIND FLANGE WITH SELF-SEALING GASKET REFERENCE DRAWINGS: DESIGN CONDITIONS: DESIGN CODE =

ASME BPVC SECT. VIII - DIV. 1 [2010] [CLASS 3 ASSEMBLY / CATEGORY 3 FLANGE] C MPa

DESIGN TEMPERATURE DESIGN PRESSURE NON-REDUCING FLANGE MATERIAL DATA: PLATE MATERIAL DESIGN TENSILE STRENGTH @ AMBIENT DESIGN TENSILE STRENGTH @ DESIGN TEMP. MODULUS OF ELASTICITY @ OPERATING TEMP. BLIND FLANGE MATERIAL DATA: PLATE MATERIAL DESIGN TENSILE STRENGTH @ AMBIENT DESIGN TENSILE STRENGTH @ DESIGN TEMP. MODULUS OF ELASTICITY @ OPERATING TEMP. BOLT/STUD DATA: MATERIAL PROOF STRENGTH DESIGN TENSILE STRENGTH @ AMBIENT DESIGN TENSILE STRENGTH @ DESIGN TEMP. MODULUS OF ELASTICITY @ OPERATING TEMP. NOMINAL DIAMETER AREA NO. OF THREADED ENDS (BOLT = 1 STUD = 2) FLANGE DIMENSIONS (REFER FIG. Y-3.2 FOR NOTATION): PIPE OUTSIDE DIAMETER OUTSIDE DIAMETER INSIDE DIAMETER BOLT CIRCLE DIAMETER NO. OF BOLTS BOLT HOLE DIAMETER OUTSIDE DIAMETER OF SPACER (=A, IF NONE) GASKET DATA: MATERIAL DIAMETER GASKET FACTOR MIN DESIGN SEATING STRESS OUTSIDE DIAMETER INSIDE DIAMETER DIA. @ LOCATION OF GASKET LOAD REACTION BOLT-FORCES / MOMENT ARMS (REFER FIG. Y-3.2 FOR NOTATION): HYDROSTATIC END-FORCE H'STATIC END FORCE ON AREA I/S OF FLANGE GASKET LOAD HYDROSTATIC END FORCE MOMENT ARM MOMENT ARM MOMENT ARM FLANGE MOMENTS: MOMENT MOMENT MOMENT MOMENT

= P=

= Sf = Sf = EI =

MPa MPa MPa

SECT II-D T (1A) SECT II-D T (1A) SECT II-D T (TM-1)

= Sf = Sf = EII =

MPa MPa MPa

SECT II-D T (1A) SECT II-D T (1A) SECT II-D T (TM-1)

Fy Sa Sb E db Ab/n

= = = = = = = =

MPa MPa MPa MPa mm mm

SECT II-D T (3) SECT II-D T (3) SECT II-D T (TM-1)

A B C n D

= = = = = = =

mm mm mm mm mm mm

F (Y-3.2) F (Y-3.2) F (Y-3.2) C (Y.3(a)) F (Y-3.2)

= = m= y= = = G=

mm MPa mm mm 0.0 mm T (2-5.1) T (2-5.1)

F (Y-3.2)

H= HD HG HT hD hG hT = = = = = =

0 N 0 0 0 0.0 0.0 0.0 N N N mm mm mm

C (Y.3(a)) C (Y.3(a)) C (Y.3(a)) C (Y.3(a)) T (2.6) T (2.6) T (2.6)

MD = MG = MT = MP=

0 N.mm 0 N.mm 0 N.mm 0 N.mm

C (Y.3(a)) C (Y.3(a)) C (Y.3(a)) C (Y.3(a))

90078856.xls.ms_office

Page 1

SUGGESTED TRIAL VALUES: B1 = FLANGE THICKNESS FLANGE THICKNESS FLANGE THICKNESS BOLT AREA SUGGESTED SUGGESTED SUGGESTED SUGGESTED TRIAL FLANGE THICKNESS TRIAL BLIND FLANGE THICKNESS TOTAL AREA OF BOLTS AREA OF BOLT ta = tb = tc = A b' = tI tII Ab Ab/n = = = = #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! 0.0 mm mm mm mm mm mm mm mm 0 mm C Y.3(a) E (39) E (40) C Y.9(b)) E (42) T T T T (Y-9.1) (Y-9.1) (Y-9.1) (Y-9.1)

RADIAL DIST. FROM B.C.D. TO BEARING CIRCLE SELECTED VALUES: SELECTED FLANGE THICKNESS SELECTED BLIND FLANGE THICKNESS SELECTED AREA OF BOLT RADIAL DIST. FROM B.C.D. TO BEARING CIRCLE

hC =

C Y-4(a)(2)

tI = tII = Ab/n = hC = hCmax = =

mm mm 0 mm mm 0 mm mm

C (Y.3(a))

THICKNESS OF WASHERS, ETC MISCELLANEOUS CALCULATIONS: SHAPE FACTOR SHAPE FACTOR BOLT HOLE ASPECT RATIO

a AR rB

= = = =

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! 0.0 mm #DIV/0! #DIV/0! #DIV/0! 0 0 0

C C C C

(Y.3(a)) (Y.3(a)) (Y.3(a)) (Y.3(a))

Jp = Js = CALCULATED STRAIN LENGTH OF BOLT ELASTICITY FACTOR FACTOR FACTOR FACTOR FACTOR l= rEI = C1 C2 C3 C4 = = = =

C (Y.3(a)) C (Y.3(a)) C (Y.3(a)) C (Y.3(a)) E (1) E (2) C (Y.3(a)) C (Y.3(a)) E (6c)

F I' = RIGID BODY ROTATION OF FLANGES TIMES E*: FACTOR FACTOR FACTOR

E I* = EII* = X= EI*.rbI = EII*.rbII =

0 0 #DIV/0! #DIV/0! #DIV/0!

C (Y.3(a)) C (Y.3(a)) C (Y.3(a)) E (17) E (18)

TOTAL FLANGE MOMENT AT DIAMETER B 1: MSI = MSII = UNBALANCED FLANGE MOMENT AT DIAMETER B 1: MuI = MuII = BALANCED FLANGE MOMENT AT DIAMETER B 1: MbI = MbII = SLOPE OF FLANGE AT DIAMETER B 1 TIMES E: FLANGE I: SLOPE #DIV/0! #DIV/0! N.mm N.mm E (23) E (24) #DIV/0! #DIV/0! N.mm N.mm E (21) E (22) #DIV/0! #DIV/0! N.mm N.mm E (19) E (20)

EIBI =

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

MPa.rad rad deg MPa.rad rad deg

E (25)

BI = =

EIIBII =

FLANGE II: SLOPE

E (26)

BII = =

90078856.xls.ms_office

Page 2

CONTACT FORCE BETWEEN FLANGES AT h C: HC = BOLT LOAD AT OPERATING CONDITIONS: W m1 = BOLT AREAS: REQUIRED BOLT-AREA TOTAL BOLT-AREA OPERATING BOLT STRESS: #DIV/0! N E (28) #DIV/0! N E (27)

Am = Ab =

#DIV/0!

mm2 0 mm2

C (Y-4(b))

b =

DESIGN PRESTRESS IN BOLTS: Si = % OF BOLT PROOF STRESS TYPE OF LUBRICANT NUT FACTOR (TORQUE CO-EFFICIENT) BOLT PRELOAD BOLT TORQUE RADIAL STRESS IN FLANGE I AT BOLT CIRCLE: SRI = RADIAL STRESS IN FLANGE I AT INSIDE DIAMETER: SRI = TANGENTIAL STRESS IN FLANGE I AT INSIDE DIAMETER: STI = LONGITUDINAL HUB STRESS IN FLANGE I : SHI = RADIAL STRESS IN FLANGE II AT BOLT CIRCLE: SRII = RADIAL STRESS IN FLANGE II AT DIAMETER B 1: SRII = TANGENTIAL STRESS IN FLANGE II AT DIAMETER B 1: STII = RADIAL & TANGENTIAL STRESS AT CENTRE OF FLANGE II: SRII = STII = ALLOWABLE FLANGE DESIGN STRESSES: BOLTS: Sb FLANGE I: SR ST FLANGE II: SR ST DESIGN SUMMARY: FLANGE I STRESSES FLANGE II STRESSES BOLT STRESS = = = = = = = = = =

#DIV/0!

MPa

E (29)

#DIV/0! #DIV/0!

MPa %

E (30)

#DIV/0! #DIV/0!

kN N.m

#DIV/0!

MPa

E (31)

0.0 MPa

E (32c)

#DIV/0!

MPa

E (33c)

0.0 MPa

E (34c)

#DIV/0!

MPa

E (35)

#DIV/0!

MPa

E (36)

#DIV/0!

MPa

E (37)

#DIV/0!

MPa

E (38)

0.0 MPa

C (Y-7(a))

0.0 MPa 0.0 MPa

C (Y-7(c)) C (Y-7(d))

0.0 MPa 0.0 MPa

C (Y-7(c)) C (Y-7(d))

Sact/Sall = Sact/Sall = sb/Sb =

#DIV/0! #DIV/0! #DIV/0!

90078856.xls.ms_office

Page 3

Vous aimerez peut-être aussi

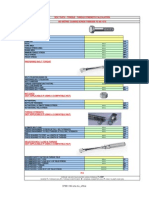

- Bolt Torque ASME B16.5 Flanges - Sheet Gaskets 02Document26 pagesBolt Torque ASME B16.5 Flanges - Sheet Gaskets 02bakelly100% (7)

- Bolt Torque ASME B16.5 Flanges - Sheet Gaskets 02Document26 pagesBolt Torque ASME B16.5 Flanges - Sheet Gaskets 02bakelly100% (7)

- Pressing Force Calculator UpdatedDocument25 pagesPressing Force Calculator Updatedanush_swaminathanPas encore d'évaluation

- Flange Design Mmcobc 1.1 2010Document5 pagesFlange Design Mmcobc 1.1 2010bakellyPas encore d'évaluation

- Clamp Design-2Document6 pagesClamp Design-2Harpreet SinghPas encore d'évaluation

- Weld Stress CalculationsDocument9 pagesWeld Stress Calculationspurav_patel20079232Pas encore d'évaluation

- Design of Flanges - Weld Neck Type 2010Document58 pagesDesign of Flanges - Weld Neck Type 2010bakellyPas encore d'évaluation

- Youngs Modulus b3 2010Document2 pagesYoungs Modulus b3 2010bakellyPas encore d'évaluation

- Metric Bolt Torque - Thread StrengthDocument7 pagesMetric Bolt Torque - Thread StrengthbakellyPas encore d'évaluation

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocument31 pagesBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- F F F F Data:: ASTM A 307 Grade A Foundation Anchor BoltsDocument6 pagesF F F F Data:: ASTM A 307 Grade A Foundation Anchor BoltsAnonymous qejp7t100% (1)

- RCC Beam For Biaxial Moment Shear Torsion and Axial Load As Per ACI 318 95 EdDocument5 pagesRCC Beam For Biaxial Moment Shear Torsion and Axial Load As Per ACI 318 95 EdanandamPas encore d'évaluation

- Monorail Beam Design 07Document5 pagesMonorail Beam Design 07bakellyPas encore d'évaluation

- Design of Flanges - Welded-On Integral Type 2010Document59 pagesDesign of Flanges - Welded-On Integral Type 2010bakellyPas encore d'évaluation

- Lifting Lug Design AnalysisDocument22 pagesLifting Lug Design AnalysisbakellyPas encore d'évaluation

- Lifting Lug Design AnalysisDocument22 pagesLifting Lug Design AnalysisbakellyPas encore d'évaluation

- Horizontal Cylindrical Pressure Vessvessel Zick 03Document12 pagesHorizontal Cylindrical Pressure Vessvessel Zick 03bakelly0% (1)

- Horizontal Cylindrical Pressure Vessvessel Zick 03Document12 pagesHorizontal Cylindrical Pressure Vessvessel Zick 03bakelly0% (1)

- Metric Bolt Data - Torque - Thread StrengthDocument10 pagesMetric Bolt Data - Torque - Thread StrengthbakellyPas encore d'évaluation

- Metric Bolt Data - Torque - Thread StrengthDocument10 pagesMetric Bolt Data - Torque - Thread StrengthbakellyPas encore d'évaluation

- Costing Calculations:: Date: 31-Mar-2016 Revision: 0 Costing Preet Vihar MezzanineDocument5 pagesCosting Calculations:: Date: 31-Mar-2016 Revision: 0 Costing Preet Vihar MezzanineRakesh SharmaPas encore d'évaluation

- Xcalcs: Circular Flat Flanges Without Hubs: 2.7:+looseDocument2 pagesXcalcs: Circular Flat Flanges Without Hubs: 2.7:+looseayushPas encore d'évaluation

- Yield Strength 01Document2 pagesYield Strength 01bakellyPas encore d'évaluation

- Bolt Torq. (Moss+Farr)Document9 pagesBolt Torq. (Moss+Farr)Bahtiar Anak LaNang100% (1)

- Machine Design Spreadsheet AnalysisDocument89 pagesMachine Design Spreadsheet AnalysisfsijestPas encore d'évaluation

- Shear Strength of High-Strength BoltsDocument61 pagesShear Strength of High-Strength Boltsloox600Pas encore d'évaluation

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Pipe Pressure RatingDocument1 pagePipe Pressure RatingbakellyPas encore d'évaluation

- Base Plate Design - For Staad Forces-Channel DesignDocument16 pagesBase Plate Design - For Staad Forces-Channel DesignSanthoshkumar RayavarapuPas encore d'évaluation

- Design of Flanges - Optional Type 2010Document59 pagesDesign of Flanges - Optional Type 2010bakellyPas encore d'évaluation

- Design of Flanges - Optional Type 2010Document59 pagesDesign of Flanges - Optional Type 2010bakellyPas encore d'évaluation

- Anchor Bolt (CSA) Rev1.1Document10 pagesAnchor Bolt (CSA) Rev1.1coolkaisyPas encore d'évaluation

- Asme BPVC II Part D Material Strengths 01Document7 pagesAsme BPVC II Part D Material Strengths 01bakellyPas encore d'évaluation

- PIPE+STUB-IN Rev1Document4 pagesPIPE+STUB-IN Rev1genergiaPas encore d'évaluation

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)stalin_83Pas encore d'évaluation

- Load case and design calculations for pressure vesselDocument11 pagesLoad case and design calculations for pressure vesselCaptainToniesPas encore d'évaluation

- Flange Design Mmcobc 1.3 2010Document3 pagesFlange Design Mmcobc 1.3 2010bakellyPas encore d'évaluation

- Deflection Calculation Due To Imposed Load On Corridor JoistDocument14 pagesDeflection Calculation Due To Imposed Load On Corridor JoistranjitPas encore d'évaluation

- Pipe Span Without Point LoadsDocument36 pagesPipe Span Without Point Loadsbakelly100% (4)

- Pipe Span Without Point LoadsDocument36 pagesPipe Span Without Point Loadsbakelly100% (4)

- 2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFDocument12 pages2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFvlad lupasteanuPas encore d'évaluation

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TPas encore d'évaluation

- Heat ExchangersDocument30 pagesHeat ExchangersvpjagannaathPas encore d'évaluation

- Calculating Pressure Loss Using Equivalent Pipe LengthDocument1 pageCalculating Pressure Loss Using Equivalent Pipe LengthmanikantanPas encore d'évaluation

- Ramset Specifiers Resource Book Ed3 - Mechanical AnchoringDocument52 pagesRamset Specifiers Resource Book Ed3 - Mechanical Anchoringapsapsaps19880% (1)

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuPas encore d'évaluation

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakellyPas encore d'évaluation

- Calculation 1Document8 pagesCalculation 1BALAPas encore d'évaluation

- Linear Thermal Expansion b4 2010Document2 pagesLinear Thermal Expansion b4 2010bakellyPas encore d'évaluation

- Linear Thermal Expansion b4 2010Document2 pagesLinear Thermal Expansion b4 2010bakellyPas encore d'évaluation

- Mechanical Design SpreadsheetDocument1 pageMechanical Design SpreadsheetHoney TiwariPas encore d'évaluation

- Reff: A Text Book of Machine Design - Chapter 10, RS. KHURMIDocument5 pagesReff: A Text Book of Machine Design - Chapter 10, RS. KHURMIAsep MulyadiPas encore d'évaluation

- Expansion Loop Flexibility Analysis (Weaver)Document3 pagesExpansion Loop Flexibility Analysis (Weaver)bakellyPas encore d'évaluation

- M 452 ContentDocument63 pagesM 452 ContentprasannaPas encore d'évaluation

- LiftingLugStress Rev 1.5Document20 pagesLiftingLugStress Rev 1.5ilijarskPas encore d'évaluation

- Design of Flanges - Loose Type 2010Document53 pagesDesign of Flanges - Loose Type 2010bakellyPas encore d'évaluation

- Design of Flanges - Loose Type 2010Document53 pagesDesign of Flanges - Loose Type 2010bakellyPas encore d'évaluation

- Flange Design Mmcobc 3.1 2010Document6 pagesFlange Design Mmcobc 3.1 2010bakellyPas encore d'évaluation

- ASME B16.5 Class 150 & 300 Flanges Studbolt LengthDocument3 pagesASME B16.5 Class 150 & 300 Flanges Studbolt LengthbakellyPas encore d'évaluation

- Synechron: Customer Name Date Created byDocument1 pageSynechron: Customer Name Date Created byneelPas encore d'évaluation

- Bearing CheckDocument6 pagesBearing CheckdhanushkaPas encore d'évaluation

- 3000 FittingsDocument4 pages3000 FittingsAbbas RizviPas encore d'évaluation

- Shaft Torsion 1Document2 pagesShaft Torsion 1neelPas encore d'évaluation

- SDV SDocument12 pagesSDV SElinton De Jesus SarmientoPas encore d'évaluation

- AB 520 Finite Element Analysis FEA Requirements PDFDocument4 pagesAB 520 Finite Element Analysis FEA Requirements PDFbello imamPas encore d'évaluation

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuPas encore d'évaluation

- Blind Flange Design CalculationsDocument4 pagesBlind Flange Design CalculationsamaPas encore d'évaluation

- My Load Summary Form - BusDocument4 pagesMy Load Summary Form - Busmr_badihiPas encore d'évaluation

- Welding SymbolsDocument12 pagesWelding SymbolsrsrtnjPas encore d'évaluation

- Detail Dimensi Material GRPDocument5 pagesDetail Dimensi Material GRPdwi noviana nugrohoPas encore d'évaluation

- Comp 2Document9 pagesComp 2YYo YudiPas encore d'évaluation

- Find Eq - Length (M) :: Manual Pressure Drop CalculationDocument7 pagesFind Eq - Length (M) :: Manual Pressure Drop Calculationcryptic postPas encore d'évaluation

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayPas encore d'évaluation

- Lug CalcionulatDocument1 pageLug CalcionulatkurniawanandreasPas encore d'évaluation

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroPas encore d'évaluation

- Is 4049 Part 2Document9 pagesIs 4049 Part 2Otavio123Pas encore d'évaluation

- Pin Base ModuleDocument16 pagesPin Base ModuleMd Ahsanul KabirPas encore d'évaluation

- Desuperheater Boiler Feed Water RequirementDocument2 pagesDesuperheater Boiler Feed Water RequirementMichael HaisePas encore d'évaluation

- Ch03 Section14 Pressure Vessel DesignDocument10 pagesCh03 Section14 Pressure Vessel DesignSeid AragawPas encore d'évaluation

- Design Parameter:-Geo-ParameterDocument50 pagesDesign Parameter:-Geo-ParameterpandyatusharPas encore d'évaluation

- Company Name: Calculation SheetDocument7 pagesCompany Name: Calculation SheetVenkatesha HebbarPas encore d'évaluation

- 05 CalDocument53 pages05 Calnatarajan RavisankarPas encore d'évaluation

- Stair CaseDocument15 pagesStair CasePremasiri KarunarathnaPas encore d'évaluation