Académique Documents

Professionnel Documents

Culture Documents

Spices Flavor Chemistry and Antioxidant Properties

Transféré par

aaaw2003aDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Spices Flavor Chemistry and Antioxidant Properties

Transféré par

aaaw2003aDroits d'auteur :

Formats disponibles

-

A C S S Y M P 0 S I U M S E R I E S 660

Spices

Flavor Chemistry and Antioxidant

Properties

Sara J. Risch, EDITOR

Science By Design

Chi-Tang Ho, EDITOR

Rlltgers, 71l e Stale University of New Jersey

from symposium

the DIVIsIOn of Agncultural and Food .

American Chemicol Society, WOshington, DC

Uhnry or Congr''!! Calalos;ng.!n. I'ubUu !lon Ila!a

Sl'tc,,: Il.wor che,niWy and pmpcrtie . I S,,.n I, Ri""h, rJilOI,

110. wiU)",

p. cm.-{ACS . ympo<ium series, ISSN 0097--61 660)

n.:",lopa l from a , ymposi um l ponsored by tile of

al ti,e 2 111h National Muting oflhe Anoerio.:an Cloemic"1

S<lci.,ly. New Much 24_28, 1\I'}6.'"

ISHN O M412_3495_7

.. SI'I<:<:.,-Congre. .. e... 2.

I. Ri:h. Sara 1., 1958- n. HO,o.iTang. 19044- III. American

C1Icmk.,1 SOCiely. Division of Agrieultulal und F"od O'CII,iSlry. IV. AUlerican

SOCtcty. Meeting (2 1 Ith: 1996: New OrIeIlllS, La .. ) V. SC'.!eS.

1996

664'S--<:Ic21

This book; < IJf\ Kid free, recycled paper.

Copy.iht C 1997 Amer;can l.'hr:micaJ Society

All Reproaraphic beyond that pcnnitted by Section5 107 or 108 of Ihe U.s.

CopyriGht Act;s allowed fOf ,nlern.1 use only. provided that a pc1-chap1er fee of plus $0.25 pcr

i5 paid to the CopyriGht Oearance Center. Inc., 222 Rmewood Dri'e. Dan'crs. M,\ 01923,

Republic-.ahon or re l"oducliOft for sale of in book i, permined only un<kr licen<e f.om ACS.

Di=I lhQC and othet jlCm1issions requesls 10 ACS Copyright Office, Publiutions Divi sion. 161h

SlIcet. N.W" Washington. OC 20036.

The ci talion of trade nanoe. andlor namc. of in thi s pubfication not to be con5\nH:d IS

an or as ap>"oval by ACS of the CQlnmefeial producu 01' ",."iets .de.ent ed hcn:in; 00f

sbovld the meTC .... ein to any drawing. speciflC"ioo. che ....ical process. 0, other data be

regarded as" Ikense or "5 con"ey"nc, of any riMll t or permission to the holdc:r. reade or any odler

or corporation. to m3l1ufx,u.e, .(produce. use, or sen any palcnled inventiort ()( copyrighted

work in be related thereto. names, tra<lemarh. etc .. used in

. "en wil llOUt indication thereof, arc not 10 be considered unprotected by law.

PRll\'TED];O; Tim UNIll; D OF AMERICA

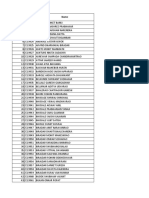

Advisory Board

ACS Symposium SerI es

Robert J. Alaimo

l'roeler & Gamble PhJ'lI1l1<:euticals

Mark Arnold

University of Iowa

David Baker

Uoivenity ofTenne5$<'e

Arindam Bose

I'filtr Rcsearcl,

Robert F. Brady. Jr.

Re.o;car(h t abomtory

Mary E. Castellion

ChemEdil Company

Margaret A . Cavanaugh

NallQn.1 Science Foundatioo

Arthur B. Ellis

Univer,;ity of Wiscon!in at Madison

Gunda I. Georg

or Kansas

Mnddcine M. Joullie

Uni "cl"$ity of l'cnnsylvania

Lawrence P. Kl emann

1'00<15 GIOUp

Douglas R. Ll oyd

'Ille University of Teus at

Cynthia A. Maryanoff

R. w, JOII05011 J'llarmaccut ;cal

dt Instit ute

Roger A. Minear

University of 1I1ioois

M Urbnna- Chalnp"ign

Omkaram Nalarnasu

AT&T Ikll

Vincent Pecoraro

of

George W. Roberts

Non" Carolina StAte UniVeriiiity

John R. Shapley

University of Illinois

I! Urba.na-013mpalgn

Douglas A . Smith

Concurrent Teeh!lolvgies Corporation

L. Somasundaram

DuPont

Midlad D. Taylor

l'hilftnaCeutical Reseuch

William C. Walker

DuPont

Peter Willett

University or Sheffield (England)

Foreword

THE ACS SYMPOSIUM SERIES W3S first publi shed in 197410 provide

a mechanism for publishing symposia qui ckly in book form. The

purpose of Ihis series is to publish comprehensive books developed

from symposia, which are usually "snapshots in time" of the current

research bei ng done on a topic. plus some review material on the

lopic. For this reason, it is nccess:uy that Ihe papers be publ ished as

qui ckly as possible.

Before a symposium-based book is put under contract, the

proposed tllble of contents is reviewed for appropriateness 10 the topic

and for comprehensiveness of the collecti on. Some papers are

excl uded al this point, and others are added to round Qut the scope of

the volume. In addi ti on, a draft of each paper is peer-reviewed prior (0

fi nal acceptance or rejection. This anonymous review process is

supervi sed by the organizer(s) of the symposium, who become the

editor(s) of the book. TIlt": authors then revi se thei r papers according to

the recommendations of both the reviewers and the edi tors. prepare

camera-ready copy, and submit the final papers to the editors, who

check that all necessury revisions have been made.

As a rule, onl y original research papers and original review

papers are included in the volumes. Verbatim reproductions of

previously published papers are not :! ccepled.

ACS BOOKS DEPARTMENT

Contents

Preface ............................................................................................................. ix

GENERAL OVERVIEW Al"' D METHODS

I . Sllices: Sources, Processing, and Chemistry..... ......................... ..... 2

Sara J. Risch

2. Methods of Dactel"ial Reduction in Spices ................... .................... 7

W. Leistritz

FLAVOR CIl EMIS1"RY

3. The Principal Flal'or Components of Fenugreek ( l'rigo1lelfa

foe1lum-graecum L) ............................................................................... 12

Imre Blank. Jianming Li n, Stephani e Dev3ud,

R e n ~ Fumeaux, and L:l.Urent n. Fay

4. Vanil\ll............................... ........................................................ .............. 29

Daphna Havkin-Frcnkel and Ruth Dorn

5. Onion Flavor Chemistry and Factors Influencing Flavur

Intensity.................................................................................................. 41

Will iam M. Randle

6. Cuntribuli on IIf Nonvolati le SuUur-Containing Flavor

PI'ecursors of the Genus Allium to the Flavor of Thermally

I'rocessed Allium Vegetables ................................ "............................ 53

Tung"lsi Yu

ANALYTICAL 1):CHNIQUES

7. Characterization of Saffron Flavor by Aroma Extract

I)ilution Analysis................................................................................... 66

Keith R. Cadwall ader, Hyung !-Icc 8aek. and Min COli

,

H. Tile (]wracteri 7.atinn of Volatil e :lntl Se mi vulatile

in I'uwdered Turmeric hy Dired Therm:l l Extractiun

( ;a5 ChruIIllIlugr:lphy- M:lss Sllectrumetry ..................................... 1:10

Rich:l rd D. Iliscrodt , a li-Tang 1-10, and Robert T. Rosell

'J. !,unge nt Flavor I'rnfil es and Component s of Spices

by Chrolll., tugraphy and Chemiluminescent Nit r ngen

Ilc tectinn ...................................... " .............................. ..... ".................... 98

E. M. Fujinari

10. Supercritical "' Iuid Extracti on nf AlliulII Species ............................ 11 3

Eli;r.abcth M. C.,lvey and Erie Block

11. Determination of Glucosinolates in Mustard

by High. Performance: Liquid Chromatography-

Electrospray M:lss Spect rometry ....................................................... 125

Carol L. Zrybko and Robert 1'. Rosen

12. Reasons fur the Vari ation in Compos ition of Some

COInnler cial Essenti al Oil s ........................................... ..................... .. 138

Chi-Kuen Shu and Brian M. L1wrence

13. Cumponent of Mixed Spices .............................................. 160

C. K. Cheng, C. C. Chen, W. Y. Shu, L. L Shih,

and H. H. Feng

ANll0XIDA."lT PROPERTIES

14. Antioxidati ve Activity of Spices and Spice Extracts ....................... 176

Helle Lindberg Madsen, Grete Bertelsen,

and Leif H. Skibsted

15. Ant ioxidat ive Effect and Kineti cs Study of Capsanthin

on the Chlorophyll -Sens itized I)hotooxidation of Soybean Oil

and Selected Flavor Compounds ....................................................... 188

Chung-Wen Chen, Tung Ching Lee, and Chi-Tang Ho

16. Cureumin: An Ingredient that Reduces Plate let Aggregation

and Hyperlipidemia, and Enhances Antioxidant and Inunune

Functions ................................................................................................ 199

Yaguang Li u

17. Antioxidant Activity of L:l vandin (LtlVam/lIia x illfermedill ) Cell

Culture s in Relati ll n to Their R"s marinic Acid Content._ ............ 206

T. L6pez-Arnaldos, J. M. Zapata, A A. Calder6n,

and A. Ros Barccl6

18. Anti -innanunatory Antioxidants from Trupic:!1 Zingiberaceae

Plant s: Isolation and Synthes is of New Curcuminoids ................. 219

Toshiya Masuda

19. Curcumin: A Pulse Radiolys is Investigll tinn of the Radical

In Micellar Systems: A Model for 8eha\' ior 3S a Biological

Antioxidant in Both Hydrnphobic and Hydrophilic

EnvironJllents ......................................................................................... 234

A A Gorman, I. Hamblett, T. J. Hi ll . H. Jones,

V. S. Sri nivasan, and P. O. Wood

INDEXES

Author Index .................................................................................................. 246

Affil iati on I ndex ............................................................................................. 246

Subject Index .................................................................................................. 247

Preface

S PI CES ARE WIDELY USED IN FOOD PRODUCTS to create the di stinctive flavor

and I:haruClcr that is representative or di fferent cui sines. The symposium on the

flavor and antioxi dant propenies of spices was organized \0 look al new

development s in the area o[ spicc chemi stry.

111C nature of the volatile components in different spic..:s is important in

understanding the fl avors they impart 10 food products. Research is being

conducted \ 0 determine the significant volut il c and nonvolatile compounds thnl

create the di stinct flavor of various spices. Vari ations in spi ces C;l1l occur

dependi ng on the region in which Ihey arc grown and the climatic condit ion ...

which can dramatically infl uence their composition. This information j-.;

imponant in formulating food products and maintaining their (I\,...:r

time_ As spices vary in their flavor profile, adjust ments may need to be made in

the fonnulution of a product or spice blend to maintain the desired !lavOL

Comput er modcls are being developed to eVlllullte spi ces [lnd spice blends to

determine thcir composi tion and other rekvllnt variables_

Another major arcu of interest today is the antioxidant properties of spices.

Although spices have long been used to help preserve food, it has not been

known what components give the preservative eITect. Research in this area has

expanded beyond the use of spices as preservati ves 10 the potcnti ol hcalt h

benefits they confer as antioxi dants in the body_ There is considerable evidence

tha t specific components in spi ces may provide these benefi cial cl1ccts.

Research is being carried oul to determine the aclive components and \0 explai n

the mechanism of action. With increasing interest in the use of food product s to

help maintain health and prevent disease, spices may playa significtlnt role.

-Ille symposium on whi ch this book is based was sponsort..-d by the Division

of Agricult ural and Food Chemistry at the 21lth National Meeting of the

Americtlll Chemicill Socicty, which took place in New Orleans, Louisiana, from

March 24- 28, 1996. n lis symposi um provided a forum for researchers from all

over the world to prcsent information on possible specific roks .)J" spices ill

di sease prevcntion.

We thank all of the panicipants in thc symposium as well as ad,litioll;11

aut hors who have contributed papers \0 thi s hook_ All or 'lIlT wi",

gtlve of their time to Hssist in the review of the an: r,-n':'I !i/l-.I , ; lIltl

Ihei r work is ~ i n c c r d y appreciatcd. Thc American Spice Trauc Associati un was

helpful in providing general information about spices and their usage.

SARA J. Ri sen

Scicnce Oy Design

50S :-Jorth Lake Shore Drive, 113209

Chicaso. IL 606 11

CIIITANG 1-10

Dcp:_u1ment ofFoocl Science

Cook College

Rut gers, '111C Siale University orNcl\' Jersey

New Brunswick. NJ 08903- 023 (

Novcmber 22, 1996

GENERAL OVERVIEW AND M ETHODS

Chapt er 1

Spices

Sources, ProceSSing, and Chemist rY

Sara J. Risch

Science By DeSig n, 505 North L'lke Shore Drive, #3209,

Chicago, IL 60611

Spices are used throughout the world to season food products and

create the unique characteri st ic fl avors of different cuisi nes,

Spices are grown primarily in tropical count ries although the

United States has recently started growing a number of different

spices to supply the domestic needs. The use of spices has

increased significantly over the past few years, due in pan to the

high level of interest in different types of foods that use a wide

variety of spices. Interest is also developing in the ability of spices

to act as antioxidants in addition to seasoning a product

Spices have long been important for food products. It was found that small amounts

or various plants could be used to enhance the flavor of a food and also served to

help preserve that food. In somc cases spices wefe even used to mask spoilage or

off-flavors in products. This use continued for centuries wi thout any real

understanding of how the spices were being effective. People simply understood 1hat

spices helped create a more desi rable taste in the foods that were being prepared.

Different cuisines are noted for using types of spices to create their

characterist ic fl a\ors.

People also viewed spices as being imponant because in early history the

entire ecollomy of many regions was based solely on spice trade. Spices were the

major item of trade and the region that could control spice trade dominated as a

world power. That situation has changed dramat ically with spices now accounting

for less than 0. 1 percent of world trade. Other raw materials as well us processed

foods account for a larger percent agc of world- wide trade than spices. There are

still several countries that rely heavily on the trade of a specific spice. In

the production of clove account s for a large percentage of that country's economy.

Tanzania grows about 213 of tile world requirement for cloves. About half Granada's

revenue is derived from the sales of nutmeg and mace. !fyou also consider vanilla,

(tI l991 American Chemicat Society

1. RI SCH Sp i"fls: S(//m:u, l'rocb'l';ng, allll CJII'IIris(ry

which is noIteclmicaJly /I spice but is a Vf%'J 'Nidcly used flavoring material that comes

from a plant grawn in tropical regions, it is the second largest prodllct in the

Malagasy Republic.

There are 36 different herbs and spices that are generally recosnized and

commonly used, White and black pepper account for the largest amount of spices

used in terms of doll ar value The ne.'l:t highest value spices consumed are cloves,

nUlmeg, cardamom, ci nnamon ginger, mace and all spice It should be noted that

accurate figures for the value of spice imports and exports are difficult to track. ,

Countries typically do nOt repon spices separately from other food products

Most spices that are imported into the United States come in whole or

unprocessed, There are requi rements that they meet minimum standards for purity

and cleanliness. The Food and Drug Administration performs inspections on the

incoming spices mainly to conlirm that they are free from undesirable filth and that

they are safe for use in food. The American Spice Trade Association (I) and AOAC

(2) have defined specific tests for spices. A complete list of for the

quali ty of herbs and spices was developed a number of years ago by Heath (3) This

provi des a comprehensive listing of tesls that can give infor mation on Ihe volatile oil

cont ent as well as other quality related factors in spices.

Spices and herbs come from a number of di fferent pans of plants. This cnn

incl ude the bark, seeds, berries Dnd leavcs of a plant. In the United States, spices

have a legal definition that is spelled out in the Code of Federal Regulations (4). This

states that spices are "any arommie vegetable substance in whole, broken or ground

fonn, except those which have been traditionally regarded as foods, such

as onions, garlic and celery; whose significant function in food is seasoning rather

than nutritional; that is tAre to name; and from which no ponion of any vola:ile oil or

other na\'ori ng principle has been removed". nle form that the spice is use<! in ollen

depends on the application in the food product In some cases it is desirable to have

large, visible pieces of spice while in others the spice may be finely ground to be more

easily incorporated into the product. Some of the appl ications for whole spices

include peppercorns in sausages, bay leaves in soups and various seeds thllt are used

on or in breads and other baked products includi ng caraway seeds, sesame seeds and

poppy seeds.

For the vast majority of applicat ions, the spice is processed before using in a

food product. General processing of spices usually involves some means of panicle

size reduction. Processors use different to achieve the desired panicle

size. The process of grinding spices breaks down some of the cell structure to make

the volatile oils in the plant more readily released when used in a product than if the

spice were left in the whole form. Care must be laken during the gri nding process

to insure that the desired volatile oil level is maintained in the spice. One process Ihal

has been investigated to help preserve the qual ity of the spice is cryogenic grinding.

In addit ion to grinding or comminution of the plant part , a mcans or bacterial

reduction is also needed. The different methods empl oyed to reduce the bacterial

load on spices. including irradiation, steam trcatment and ethylene oxi{!c, will be

covered in a subsequent chapter in Ihis book. A comprehensive review ofindividllill

,

SI' II.:F.S: flAVOR CIII': MJ STIl V fi NO ANTlOXJUflNT l' IIOI'lmTJK"

spi..:;cs intludinij thcir flavor characters and various applicati ons is included in the

Source Book of Flavors by Reineccius (5). This rererence al so includes inrormation

aboUI processing ofspice5 as well as the specific volatile oils and the procedures that

arc lI sed to extract the oils from spices. The flavor of herbs and spices is derived

from the volatile viis that arc present in the plant. The only exceplion to this is the

which give The flavor to peppen. The essential oil content of herbs is

Ollcn less Ihan 1%. The conlenl of other spices ranges up to 18% essential oil in

clove buds Essential oils arc recovered from herbs and spices by steam distillati on.

'111i5 recovers The vollllile oils but not the non-volat ile components which contribute

to the pungency of some spices such as ginger and pepper. Oleoresins are oblained

by solvent extraction which yields both volatile and non-volatile components.

While spices have long been used in food products, their usage continues to

gro w al a significant rate. A recent estimate by Ihe American Spice Trade

Association indicates that the usage in the U. S. alone could reach one billion pounds

by the year 2000 (AST A personal communication, 1996). Interest in spices started

growing aner World War II and saw a sharp rise beginning in the 1980's. This

likely be attributed to first, the exposure that many people had to other spices in the

1940's and. more recently. to increased interest in different ethnic cuisines. 11 should

be noted that the consumption figures that are reported include dehydrated onion and

garlic even though by legal definition they are not spices. These items may be used

as spices in a food in the U. S. but must be listed separately on an ingredient

statement. The average consumption today is about 50"10 greater than the average

a decade AgO with the annual per capita consumption of spices in the United States

ovcr three pounds (ASTA, personal communication, 1996). The spices that have

shown the largest increase in use include sesame seeds., oregano and paprika. II is

likely that the growth in usc of sesame seeds parallels the growth in fast food

restaurants using sesame seeds on sandwich buns.

The other trends in spice consumption in thc U.S. follow thc growth of

cenai n food categories. One area is in hot foods where the AInerican public is

becomi ng much more adventuresome in the foods that they will eat . Consumption

of rcd peppcrwas up 105% from 1988 to 1992. Our bland foods arc becoming much

spicier One company rc:ccnlly introduced a fudge sauce for icc cream that contains

blnck pepper, red pepper and cinnamon ill addition to dark chocolate. At the 1996

Institute of Food Tcdlnologists convenlion, one demonstration showed thc use of red

pepper sauce in browni es. In cont rast, another area of growth is in the mild herbs

including basil and oregano. This growth follows the increase in consumplion or

piua and a proliferation of commercially available spaghcui sauces. As the desire for

ncw and unique foods cont inues, it is expected the use of spices will continue to

grow.

Spices are commonly grown in tropiCI'll regions ofthc world. This can present

chall enges to companies that are trying to fmd a consistent source of spices both from

a qlJal ity and supply perspective. Fanners in the U. S. have Slarted growing a number

of di fferent spices to meet our growing demand. When dehydrated onion and garlic

ar c includcd in the figures, the U.S. in 199] was able to supply 38% of its needs

I. JUSCI! Spices: SOllrces, Pmce.I'.I'i/'I:. and Chemistry

(ASTA, personal communication, 1996). The other countries that are impoJ' lant

sources of spices include India, Indonesia, Mexico, Guatemala, China and Canada.

Canada has gained prominence: for its production of mustard, caraway and coriander

seeds.

With the growt h in the use of spices., there has been continued research into

the active components of spices not only from a flavor standpoint but also from

functi onal perspective 10 explore the antioxidant properties of spices. Differcnt

spices are known to contain hundreds of acli ....e compounds. One area of interest is

to identify Ihe specific compounds in a spice that make the most significant

contribution to the flavor of that product. A technique that has been applied to flavor

compounds to detennine thclr relative importance to Oavor of a product is gas

chromatography coupled with effluent sniffing, referred to as GC-O (gas

chromatography-olfactometry). Several variations on this te<:hnique, including aroma

extract dilution analysis, can be used to determine the compounds that are most

important to the aroma. This uses the human nose to determine characteristic and

importance ofindividual compounds to compliment gas chromatography which can

only give an indication of relative amounts of different compounds but cannot give

any information on importance to the flavor profile. It is known that flavor

compounds can have widcly varying sensory thresholds so having only the analylical

dala does not teUthe entire story regarding importance of the individual compounds.

The two specific spices that were evaluated and are presented in later chapters were

salll'on (Cadwallader and Back) fenugreek (Blank et el). This data be used

in developing flavor systems that may be able to replace or supplcment spices in food

products.

There is ongoing de\-dopmcnl of new analytical techniques to evaluate spices

to dcvclop specific information about their composi tion. These techniques may nol

be applicable only to spices but are to expand our knowledge of spices and

their active components. One method is supercrit ical extraction which is used to

more effectively removc Ihe volatile compounds from a spice and eliminate Ihe

interference of olher plant malerials. Once the compounds are isolated, one detector

that is being employed is specific to nilTogen and can aid in determining Ihe amounts

of capsaicinoids which contribute the heat or pungency to different types of peppers.

Spice companies and food manufacturers arc also concerned about

maintaining the consistency of the spices and spice blends that they li re using. It is

know that a number offactors can influence the abundance of the aelive components

in spices. The climatic conditioJlll can have a significant impact on spi ce quality from

one year to the ne.'!:t . One chapter later in Ihis hook will address the influence or

different growing conditions on the volatile compounds that are present (Randle).

The same species of plant that is grown in different regions of the country can have

a diffcrent volatile profile from that grown in another region. Understanding these

dilTerences"is important for manufacturers to be able to maintain consistent flavor of

a product when the spice being used may be sourced from different areas. A variety

of plant species have been investigated to develop fingerprints of spices from different

growing regions. This information can be used to det ermine authenti city or a spice

,

6

. ,

SPICES: H.AVOM CIlt-:l\II STMY ANIl ANTlUXILIANT j' IWI'EMT1KIi

and determine optimum blends that should be used to maint!!.in the desired flavor

profile. Statistical programs arc also bting developed \0 be used 10 detemune the

most likely constituents in a spice blend and aid in replication oCa slJCCi lic blend.

This is presented in the chapter by Chen el al.

An area of considerable interest and the focus of many research projects is the

antioxidant propenies of spices. As was mentioned earlier, one of the earliest uses

of spices was to help preserve foods. Liule was understood III that time about the

mode of aaion of the spices. It was simply known that they would help maintain the

quality of the food to be stored, The area of antioxidant propenies of spices is

imponant for preserving the quality of foods but may also provide beneficial health

effects for people consumi ng the spices. This area will be covered in much more

detail in an ollCl"View of the antioxidant properties of spices that is presented later ill

this book in the chapter by Madsen et a!. One spice component in particular that has

received atlemion is curcumin. Several chapters address the effectiveness of

rurcumin and possible ways to synthesize new curruminoids. The investigators have

looked at the various ways in which the compounds may be effective as an

antioxidant in different systems. This is an area that will continue to receive attention

in the research conununity as people cominue [ 0 look for Ihe specific health benefilS

Ihal certain foods may offer. Spices will remain important for Ihe flavor lhat Ihey

impart to foods and may al so gain significance for other benefits they have to offer.

Lit er at ure Cited

I . Analytical Methods orthe American Spice Trade Association, )rd ed. ASTA..,

Englewood Cliffs, NJ.,1978.

2. Official Methods of Analysi s. 14th ed. AGAC, Washington, D.C. 1984.

3. li eat h, t-I . B. Call. lnSI. Food 'f"e,h. J. 1968, 1(1), pp. 936.

4. Code of Fcderal Regulations, Title 21, U.S. Government Printing Office.

1995.

5. Source Book oj Flavors; Reineccius, G. A., Ed., Second ed.; Chapman and

Hall, One Penn Plaza, New York, NY, 1994, pp234 255.

Chapter 2

Methods of Bacterial Reduction ill Spices

w. L..e is tr itz

limit ed, 185 Alexll ndr a Way, Carul Stream, IL 60 188

There IIfC three major Incthods for b.lclerial reduction currently being us.:d

in the spicc industry. These arc ethyknc oxide, irnlliiation and Sh::.m.

Irradiation has received a gl"l!lll deal of pn:ss and although tnc popul;Hity uf

this mcthod is increasing, there is still whether or nol Ilk: consurno::r will

IIcccpt it. The induslry h.1S $t:icntific theory but the consulTler activists :lrc

concerned about the unknown ruture consequences o f the k chnolo);.v.

Another method that is not new bu has nOl been used in thc U.S. i;; stcam

steriliLation using supcrhealcd steam. This is a consumcr friendly method

that may be the solution tlmt the world is ror. The nlCth(l\l is

efti!ctive and viewed liS being safc. A comparison of the three Ill<:toods will

be presenll""d and the adv.lrltages and disndvuntages of cach method delllikd.

Spices are grown all the world, in many cases it is in areas wh..'re the cle:'lnlincss is

not closely controlled. There is 110 dian made to limit contamination of the spices wither

during growing or harvesting. While there are some specifications and regulations

concerning imponed spiccs, it is oncn necessary to process the spices to reduce the

bacteriallond prior to use in food products. The oot:h:rialload varies with thc type or

spice and total plate counts in excess of one mill ion colony unit s per 11:1\e

been reponed in some spkt:s (I). Diflerenl types of pcpp..:r are known to ()fien h:'lVC very

high bacterial counts.

The original need sterilized spices cnmc from a demand by the U.S. armed r(\Tecs.

I'rior to World War 11 , they were seeking roods that coukllx: ItI,: ld for long pcri<.. 'lls (l rtill"ll:

without spoiling. One source orlh.: bacterial contamination that rcduced the ... or

some products was the spice or seasoning being used. By reducing the \J f

in the spice, products could be made "ith significant I)' longer slk:lf-l i\"cs. Till: nll . ."thud !;lr

doing this rJCedcJ to dcstroy the bacteria without changing the Havor or color "I" th, spicc.

Sterili7.ation tcduliqucs \\ierc developed and were so successrul ror prndu<."l s I;,r th.:

I1rmcd rorces, that it soon became a gcnemlly accepted tedl!lilJllc Ii,r m' ,\ ' I'in' 'lIkl

c:r t9!17 ChCI1lK.":li S ... ;kly

St'U .. , VOlt Cl IEMtS'fllY A:"I II ,\ NTIOXIIJANT ..

"la". All 'I'to.:e" ,m.1 .,",a:mings tk, lint ro:ttuin: h:to.: lel'i;11 reJudMlI1. hUI 111I.r.: is a

l i,1.. I:,el"f wilh all ,'Ilhe '1 he "w,d in;1I111t:1llllrcr In wcil:!h lito.: ri"l..s " f

il1;1llri;.ls 111:,1 p"lentially high ha( lerial loao wil h any .. tin r-.;r(CI'1Mm

tl1l' I,' 111;1)" he ,dth th,: pr'lI.:cs.sin!!- nfthe spi..:e.

Ill<' treal n .. "t nf spices hi r"'llll(e Ihe h."lI:kri;d k'ad is "nl'lI IdeneJ h' ....

\l': ll li/"tMIII. In !<Ome c .. II ... spke nk!) ;lCt'l:llIy be IMwl'{.""er. H m,'re a<.:l"1.rat ..

h:I(I .. ,-i:11 ,-.. duetMUI. TIll: lirst mctlK.d 111;11 W;lS dc,ck'po."d 1<1 retlu .. e the

<,n "I'icl's ill\'lIl\'cd lhe u <;c o f cthykne oxide nne (omllany th;lt is using a

,,I'-.KIIl ,,(this to,by is (iriflith MicruSeicnee. The trealment (If a lillll.'lI,

I",," tnnpernt,u'e (yel<.: "r ....1eulll11 gas.sing with Cl hylcn( "xide 0' propyknc oxide. The

;:"IK'ral pr"l,ess now is below.

t . t'rodu..:t p!;J.;eu in a scak:d chaml'l(."r about the width or" standurd l l.S. palkt

(.j() x 42 in). The chamber may ...ary in k,ngth and height, hut it is critical thnt it

1\ot be too wide.

2. A \,<I": UUI11 is pulled within the chanlbcr.

3. "l'he..:h.1111hcr is heated to bring the temperature up to 110120 I:.

4. I tumidit)' is introduced. ([t sllll uld he IlOteJ thatlhe .. ombinatioll of lle,lt and

humidi ty are essential to activnte the within the sllice.)

5. I:.thylcllc oxide gas is int roduced into the ch.'lmber.

6. Th..: spice is held in Ihe dl'l mber under Ihesc conditions fu r a period

uf time which is ,Iire .. tly relah ..d to the bulk density of the spice lind the level uf

reduction thai is

1. The gas is c)(pclk.xI rrom Ih,: chambcr and it is Ilushed scveral limes with air

prior to rcl uming it to pressure.

S. The product is then ren ...J\ed to a '-Iuarantine area until it is pro ...en th.1t IMl

gas can be detected.

TIl;S pro"cn method fo r spices .. particularly wit h wlMl\e sp;"; .. and sectls. I ln"" .. \".. r.

the usc of gas for grourMl spices is eontro'-crsial today. method is e't p:lhlc of

r..:dllcing Ihc bacterial load by 31 least I x I 0'. nit' proecss may be repeated if the initial

docs IMlt llleCI customer requirement s. Using ethylenc oxide gas rC\jui .. a

luner time period than irradialion (If steal11 .. wilh a lYl'ical process requiring anyhc re

Ir01;1 12 to 18 hours. l'roduclivity is il,nucnced by the Si7,C and amount uf eham[:.,:rs

:l\"3ibblc. nle cost pcr pound of spice trellted is based upon volun .. trcated, bul l.. densit ),

ami iength ofli1ne Te(luirl'd to obtain the desired b.1cterial reduction.

Irwdiation h;l s become a popular method o f rcUueing b:leteria in spkes anJ

since it s introduction in the early 1980's, lIcc,lrding to the personnel at

SkriGeJ1ics ill Schaumberg, 1L. the cont ro lled release of Cob:llt 60, P:1SS

through a hetun or gamma energy that dcstroys b.1cteria. The amount o f energy is clil led

the radiatioll absorbed dose !IIKI is nleasureo in fads ( I rad = 100 ergs/g). Most .. es arc

tre .. ted at a Icvcl of 1.0 1.5 ntds which is less than 50% of the rate allowed by Ihe Food

and Drug Administ rat iun (FDA). TIM; gamma process requires (onlf()1 of onl y o11C

1).'lf'U1lCter and that is time of exposure. SleriGeni(s literature lK)tes thnl their process is

klh,11lH mlol! pathogenic microorganisms in spices. The following Sleps describe

the SteriGcnies method fo r usc o f irradiation to reduce bacterin in spkes.

2. U : t STKIT"l. 11 Bael cri(l/ Helillel iOlI i n Spitt{ 9

I. I'roduct is loaJnl 011tO a ( arrier and travels alo ng a .. onveyor through a series

or doors and locks int" the cdl ll r .... containing eoixlh 60.

2. The product pa.<;scs IImWJJ and then tl .. t .....o shelvcs nfisotopes where the

greatest pcrcent .. ge reduction occurs. While in the cell. the product

i: hombarded with energy lit lower as ....'CII.

3. The product rctUfl\.<; through Ihe of doors ,mo locks o n a tin){'(.( schedule

and to its origin. The entire takes between 5 and IS hours,

depending upun the initial bacterial klad and the reduction that is required.

l11is is a cost clfoxtivc method IIk!tllffers 11 number of1:ll:ocfits to the consumcr. The main

I>.:ndit is its overall effecti"encss. There is no add .. d to the spice and thcre are

no ad ...erse cfkets on the wlatilc oi ls o r rMlI1volatiJe components so the fla vor pmfile

!lOt negatively impat:ted. The irrnJilil ion wi ll completely penctrate packaging materials

so that they can be processed withoulthe need o r opening a package.

The major concern with irradiatilln cent crs upon the fear ofeOllsumer a(ti ... isl

groups, bot h domest ic and international. that nOI enough dnla hns been gathered to

dl .. terrnine the long term effects o f eoting rood product s which have been irradiated or

which contain ingr .. xlicnts tl101t have For this reason. the usc o f irradiation

or spices and has been Nmn .. d in scveral fo reign countries. Some U.S. I{)od

manufact urers ha ...e also made it a policy not to usc any ingredients which have been

irradiated. SteriGenics, the leading company offering irradiated spices is currently

these cono;crns bot h to go\,emmental ageneics and to consumer groups.

The usc or steam to reduce the b.1eterial count in spices has been gaining

momentum due to the C"oneerns with the ofbol h gas and irradiat ion. Sleam is

considered III bc a safe form orblleterial reduction throughout the workl . There arc I WO

melhods o f steam bacteria reduction being olli:red in the U.S. today. One o f tllcse is a

wet method and the Oilier is a dry pwc .. ss.

'I'hcrc are scvcrnJ mClhods o f .....et Sleam systems for bacterial reduction available

in the U.S. These include lhe MicroMaster ufoCd by McCormick. Fuchs Micro

c<) ntfoJ and the Kikkom. 1n continuous steam process. These systems use eit ner closed

chambers or continuous fced systemS. The key to all orthe:'\C syst ems is the ability to

penetrate the whole spices or Sl.'Cds with wet steam at II temperature o f 100 C or great .. r

for a period o r time. The bulk density is another critical facto r v.hk h hel ps

determine till: flow rate. moisture piek.up and e ...entually the cost per pound.

A l'(lnsistent cOllecn! with tho:: wet steam process is the anilit y to properly dry the

during with OIM; or treatmcnt after It may bei;ome ncces.o;.ary to

re.dry lhe product at a II>\\ cr temperalure 10 achieve the desired moi sture le,els. TIle

overaU .. " sls for using wet steam 11\.11ch those nfusing gas.

The usc or dry steam (superheated) is the lot esl stl'<lml echnology being used for

lind seasoni ngs. The cquipmentlo produce spices by this method was recently

installed by SpiceTec Lt d. in their plant in Carol Stream. II.. [t is the first usc of this

me thod in thc United Slales. The process tlow for system is described below.

I. Continuous precle:med product is drupped through <In airlock into a closed

chamber that contains a shaking bed.

10 SI' I( "K'i: . "IAVtllt ClI EMISTRY ANI) ANTl()XIIlANT

2. The product is sterilized (Iuiddy "t a Icmpcrulurc between 108 and 125 C.

DUring this process, the stearn is supcr+hcall:d and turns into saturated steam or

vapor. A continuous airflow system bcltins the cooling Of111<: spi<.:cs immediately.

3. TIle product drops through im airlock inlo a St:cond closed chamber where the

cooling prol:CSS is continued with ambient air withom Jhe dcvc10prncnl of

condensation. Dust is fLhered out during the entire process.

proc<''SS, which is viewed as being safe also offers a number ofbcncfits. COntinuous

flow of the produd yields exccl!cnl productivi ty. AU different fo rms of spkcs can oc

treated including whole and ground spices, herbs and ground seasoning blends. 'I'll<:

efficiency of the process oilers the potential for cost savings when compaflxl to both the

gas and wet steam process.

All t hree mcthods of o r bacterial reduction offer bot h benefits and

disadvantages. Irradiation i;; the most effective means of bacterial reduction, however,

there are COtlSlUllCr oonccms about the safety of tile product. Ethylene oxide is a proven

method that has been in usc fo r years but has recently come under the scrutiny of FDA

and the Enviroruncntal Protect io n Agency (EPA). The weI steam process is not quite as

e ffective as irradiation and the COSI is slightly higher, howevcr, it is regarded as a SlIle

method. The dry steam method is highly effective and the newest method available. It

more expensive than irradiation but k ss expensive a process than both cthylene oxide

and weI steam. No one nlCthod is perfect. The selection of thc method to be used is up

10 the individually processor and must meet the needs of the customer.

I. Reineccius, G., Ed., Source Book of Ftav(Jrs. Chapman and Hall , New York, 1994, p.

244.

FLAVOR CHEMl STRY

Chapler 3

The Principal Flavor Components

of Fenugreek (Trigonelia Joenum-graecum L.)

Imre Blank, J innming Lin, Su! phanie De\'aud, J<"unleaux,

and uwrent B. fay

Nestec Limited, Research Center, Vers_chcz_les_Ulanc,

P.O. Box 44, CJI - IOOO t.au sa nne 26, Swil7.erla nd

3- l-I ydroxy-4,5-dimethyl-2(5N)-furanone (sotolone) was established as

the character impact flavor compound of fenugreek on the basis of gas

chromatography-olfactomelry. Solo[one was found to occur

predominantly in the (5.\) enantiomeric form (95%) and to have a

olJCroo value of -19.7%0 About 2-25 ppm sotoJone were determined

in fenugreek of different origins using the isotope dilution assllY

technique. Sotolone was generated in model systems by themlally

induced oxidative deaminalion of 4-hydroxy-L-isoleucine (lUI.) using

different carbonyl compounds. Up to 24 11101% yields were obtained by

boi ling HI L and melhylg[yoxal as react ive -dicarbonyl at pH 5 for 10.

h. Strecker degradali on of HI L was found to be a competi tive react ion

resulting in the formal ion of 3-hydroxy-2-melhy[bulana1. The

of HJL, 3.arnino-4,S-dimelhyl-3.4-dihydro-2(5fl)-furanone, was found

10 be a better precursor of sotoione. It generated about 36 1001%

SOlolone in the presence of methy[glyoxal

f enugreek is the dried seed of 7i-igoneflajoelllllrl-graeclim L. (Fabaceae). The plant

is an annual herb widely cultivated in Medilerranean count ries and Asia (I) The pods

contai n about 10-20 yellowish seeds with an appetil':ing pleasing aroma. Toasted and

ground fenugreek seed is an essenti al ingredient of curry powders and is often mixed

with breadstum. It is used as a seasoning in food products such as pickles, chutneys,

vanilla extracts, artificial maple syrup, Hnd olhers.

Several volatile constituents have been reported in fenugreek (1), mainly

terpenes and fatty acids. However, 110 systematic wOlk has yet been published on

compounds that contribute to the characteristic aroma of fenugreek, 3.Hydroxy-4,S-

di mcthyl-2(5H)-furanone (sololooe) was suggested as an important volatile

constituent offenugreek due to ils seasoni ng-l ike flavor note (3, -I) .

I{) t997 American Chemical SocH:ty

J. IlI.ANK IT AL. Principal Havor of Ft nllgTUIc IJ

SOlo[one is a powerful flavor compound found in several food! and spi,,;es (.')

It contributes to the burnt/sweet note oCaged sake (6), cane sugar (7), and conce (S).

10 Ihe spicy/curry note of lovage (9) and condiments (J(J); M well as tn the

nutty/sweet flavor ofbolryt ized wines (/I) and fl or-sherry wines (/1). The lIavoring

potenlial of soto[one is due 10 its low threshold values, that of 0.02 ngll air (8).

0.3 water (detection/nasal, 10), and 0.036 water (deteclionJl'etronasal. f Jl.

The structural similarity beTween soto[one and 4.hydroxy-L. isolcllcine (111 1.).

Ihe mosl abundant free amino aeid in fenugreek seeds, was pointed oul (/4. fJ). I I

was postulated thai Ihis unusual amino acid could be the pre<:ursor of sotolune in

fenugreek (/5) (Figure I). This hypothesis has rec;ent[y been supponed by the f.1C1

that only the (5S) enantiomer of soto[one was found in fenugreek (16). This is in gond

agreement with the stereochemistry of HIL isolated from fenugreek, i.e. (2S, 31l. '1.\)

(/7). However, these authors failed to discuss possible formation pathways.

OH '1Hl

, 1 2 !!.

o

(lS,3RJ.'l)-HJL (5S) Sotolone

Figure I . STereochemistry of 4-hydroxy-L-i soleucinc (HIL) and sotolone found in the

seeds of fenugreek (Trigo/ref/a jrx!IIum-gracclIlII L).

The purpose of the present sludy was to identify those volatile compounds

which significantly contribute to the seasoning.like note of fenugreek using the

approach of sensory directed chemical analysis. Gas chromatogmphy in combinat ion

with olfactometry and mass speclrometry have been used as key sleps of this

approach (/8, /9). The formation of flavor impact compound(s) was studied in model

systems using the quantification technique Isotope Dilution Amy (10, 2/). The

mechanist ic study was based on a hypothetical pathway proposed for The formation of

sotolone via thermally induced oxidative deamination of HIL (10).

E:lperiOl cntal

Materials. Commercially available fenugreek seeds of different geographical origins

and fenugreek oleoresin were used. Sotolone was from Aldrich and diethy[ 2-methy[-

3-oxobutancdioate, L- isoleueine, Olethylglyo){al (40% in water), phenylglyoxal, 2,3-

butanedione. and 2,3-pentanedione from Fluka, Solvents and other chemicals were of

anal)1ical gradl'l'from Merck.

Synl hesis. 3 -Amino-4, 5-dimethyl-3, 4-dihydro-2(5H}-furanone hydrochloride (ADF)

and 4-hydroxy-L-isoleucine (HIL) were obtained as diaslereomeric mixtures by

photochemical chlorination ofL.-isoleucine (Figure 211), i,e. (3S,4R,5R13S,4R,5S) and

(2S,3R,4R12S,3R,4S), respectively (17, 12, 13). (S,6_

13

C]-3 -Hydroxy-4,S-dimethyl

-- ,

14 SPICFS: HAVOM CIIEMISTHY A."il) ANT.oxmANT

2(5H)-furanone (fUC1]-sotolone) was prepared by condensat ion of diethyl 2-methyJ-

3-oxobutanedioate and (I,2.

IJ

Q-acetaldchyde followed by lactonization and

subsequent decarboxylation under strongly acidic condit ions (Figure 2b) (1U) , The

structures of the synthesized compounds were verified by elemental analysis. mass

spectromtlry (MS), and nuclear magnetic resonance spectroscopy measurements CH-

NMR, IlC_NMR) (14).

Gas Chromfilogra phyOlfaclometry. GC-O was performed on a Carlo Erba (Mega

2) equipped Wilh a cold on-column inject or, FID and II sniffing-pon. Fused sil ica

capillary columns of medium (DB-OV 1701) and high polarity (DB-tFAP) were used

as previously described (9), both 30 m x 0.32 mm with a film thickness of 0.25 I-Im.

The temperature program was: 50"e (2 min), 6C/min 10 180"C, IO"C/min to 240"C

(10 min). Linear retention indices (RJ) were calculated according 10 van den 0001 and

Kratz (25). The sensory significance of each odorant was evaluated and expressed as

the flavour dilution (FO) factor (/8).

M:l$s Spectromr try

QUll litative Analysis_ Elet.:tron impact (EI) and positive chemical ionisation

(PCI, ammonia) mass spectra were obtai ned on a Finnigan MAT 8430 mass

spectrometer MS-EI were gener-.ded at 70 eV and MS-CI at 150 eV with ammonia

as the reagent gas Non-volatile samples were directly introduced into the ion source

held at 200 ec. Volatil e component s were introduced via a Hewl ett-I'ackard HP-S890

gas chromatograph (GC-MS) usi ng a cold on-column injection. DB-FFAP fused silica

capillary columns were used (30 m x 0.25 mm, film thickness 0 25 The carrier

gas was helium (90 kPa). The temperature program was: SOec (2 min), 4C/min to

180"C, lOoCJmin to 240"C (10 min).

Quantitative Aml lysis. Sotolone was quant ified by isotope dilution assay

using [

13

C:zl-sotolone as internal standard (10, 2.f). Quantification experiment s were

performed wi th a HP-597 I GCMS using the following conditions: DB-Wax capi llary

column (30 m x 0.25 111m, film thickness 0.25 1-1111) ; carrier gas: helium (100 kPa);

spli tl ess injection (250"C); temperature program: 20

e

C (0.5 min), 300C/min 10 lOO"C,

4"Cllllin to 145"C, 70C/min to 220"C (10 min); El ionisation at 70 tV; selected ion

monitoring (SIM) of sotolone (mh 128) and the labeled internal standard (mil 130).

The concemration of sotolone was calculated frolll Ihe peak areas using II calibration

factor of 1. 1 (Figure 3). A good linearity was found in the cOllcentration range 3- 150

)1g1ml. All samples were injected twice.

Fast At om Bombul'dlll f nt (FA8-l\1S). This was applied to study the

lactonization of IIi L 10 ADF. FAI3-MS was performed on a Finnigan MAT 8430

double focusing mass spectrometer. FAB ionisation was carried out with a saddle-

field atom gun (Ion Tech, Teddingt on, UK) which was operated at 2 rnA and 7-8 kV

with xenon. Glycerol was used as matrix. The positive ions at mlz 130 (protonated

molecular ion of AOF) and 148 (protonated molecular ion of HIL) were recorded.

lsotOll e Rati o Mass Spectrometry (GC-IIU\'I S), This was performed with a

Finnigan MAT delta S isolOpe MS coupled on-line with a Varian 3400 GC via a

combustion interface. Isotope ratios were expressed as Ii- values [%oj versus the 1'01'

3. Il IANK 1\1_

Prilll:ipal COl1lptmtn'.f v/ Ftllll/:reek

15

A

Lel,hv

--.

2. Hydrolysis

"

B

n 0

OE<

'CH;CHO

EtOH

AOF

HIL

J=(

o

F!gure 2. Synthesis of 4-hydroxy. L-isoh:ucine (}-IIL) and 3-amino-4,5-dimct hyl _3 4-

hydrochloride (AoF) (A), and [S, 6-13Cj-3-hydro .... y-4:5_

dlmethyl-2(5H)-furanonc ([ nC

2

1-soIOJone, used as internal standard) (D)

ISOOOO

I,.

"

Ion mh 128

0

H3C OH

sototone

100000

):0(

0

H3C o ..

SOOOO

' .00 W.OO II (1)

11.00 lJ.OO 14. 00

0 80000

" 0

Ion mh 130

ii

H]C OH

GOOOO

labeled sotolone

0

'0000

20000

9.00 1000 11.00 12.00

JJ.OO 14.00

Retention time (min.)

:igure 3. Quantificati on of sotoJone by isotope di lution IIssay using lJCl-sotololle as

mternal standftrd. The ions mlz 128 Mnd mlz ))0 wer, ',"o,d"d by GC '10 .

...... -IV opcralmg

III the selected Ion monitoring mode. (Adapted from ref. 24.)

SI' [CES: nA\'OK ANIl ANTIOXIIl" ." T

siandani having II ["CJ/I"C) mlio uf 0.011237 fur CO! yielded by

combusliun of C;lCO) (reedee Belemnite) The GC ellui llred with n 013-

FFAI' fused silica capillary column (30 m x 0 25 mrn, film thickness 0.25 J.m) using

hdium as carrier gas (100 kPa) and Ihe split injection mode (220C). The tempcralUre

pmgrnm was the same liS mentioned above.

S" lI lplc l'I"fl' 3raii oli

Qualit:.l \i lr for GC-Olraflomrlry. The gr(lund fenugreek seeds

{(OO 1;) wcre extracted wilh dicthyl elher (EtlO. 200 1111) by stirring the for

h The S(livent was separated and the extraction W;lS c(lntinlled wit h

,;"Ivent (200 1111) overnight. The extracts were combined. filtered and cuncentrat ed

(SO ml) llil Yigrellx column. Non-volatile by-products were separated by vacuum

(YS). i.e. \Tapping volatiles under high vacuum conditions mbaT)

illto 1raps cuoled with liquid N] (2/). The sample was introduced drop-by-drop into

the vaCU1I1Il to increase the yields. Then. EIlO (30 ml) was added to the

residlle and lite procedure was repeated. The condensates of the traps were

cOlllbilled and concentrated to I IllI on a Yigreux column.

Qualit ative Aualysis for GC- IRMS. Sotolone W;lS isolated from fenugreek

oit:oresin, An aqueous solution of the oleoresin (35.5 gllOO ml) was extracted wilh

containing 5 % etlmMI (5 x 100 011) . The organic phase was concentrated to

100 mland extracted with NalCO

I

(0.5 mol/L. 3 x 100 ml). After ;lcidification of the

aqueous phase to pH 2 (HC1. S moUL). sotolone was re-extracted with EtlO (4 x 100

ml). The sample WitS dried O\'er anhydrous Na!SO. and concentrated to 20 ml

Sotololle was separated from nonvolatile by-products by sublimation in vacuum (10.

1

mbar) (1/). The condensates of the traps were collected and concentrated 10 2 mi .

Qualil:Hh'e Analysis ror FAR-MS. HIL was dissolved in phosphate buITers

(0. 1 moUL) with different pH values (pH 3.0, 4.0. 5_0, 6.0, and 7.0). The soilit ions

were boiled for I h in scaled glass tubes. The samples were rapidly cooled down and

directly analysed by FAD-MS.

QUlI. llt ila l ive Analysis in Ftllugreek Serds (10). The material (5-10 g) was

homogenized in wateT"ethanol (50 ml , 95:5). [

IJ

C

2

]-Sotolone (10-20 was added

as internal standard and the suspension was stirred for 30 min. After centrifugation

(30 mi n. 10000 rpm). the supernatant was extracted with EtlO. The acidi c

components were isolated with NalCOJ (0.5 moVL). The aqueous solution was

acidified to pH J (5 mollL HCI) and re-extracted with EtlO Finall}'. the organic layer

was washed with saturated NaCI solut ion. dried over Na2S04 and concentratcd 10

ilbOiIl 0.2 ml using a Yigreux column and micro-distillation.

Quanlilati vt AII l_l ysis in Model (14). I-IIL (2-10 IIIg) and

ADFHCI (2-10 mg) were each dissolved in a phosphate buffer (0. 1 molll.... pH 5.0).

ACter adding the carbonyl reactant. the solution was boiled for I h in a sealed glass

lube. The molar ratio of precursor to carbonyl was 1:10. Water and the internal

standard ([ 13C

l

]-sotolone) were addcd to the cooled reaction mixlure. The sample

was saturated with NaCl and the pH adjusted to 4 (Hel, I moVL). Sotolone was

c."macted from the rcaclion mixture with Et20 for 8 n. The extract was dried

(Na2S04) and concent rated to I 011. All experiments were performed in duplicate.

3. RlANK ET Principal Hal'flr Cmnpnntnl.\ of Fenugreek 17

Resull s 311 d Diu uuion

Aroma Compusi li on of Fr- nugruk. Liquid.liquid ex'raetion using diethyl ether

resulted in an aroma exlract which represented the characteristic note of the origmal

product. Ihal i.e. is seasoning-like, spicy, herbaceous, and fenugreek-like. The

representativeness of the SIImples before and after purification was checked by

sensory evaluation.

GC-Olf;lctometry (GC-O) was used 10 detect Ihe odor-aclive

present in the aroma extract orrenugreek. It is II simple but effective mel hod to select

those volatiles which contribute to Ihe overall flavor (18,19). On the basis of Ge-o.

seventeen odorants were detected in the original aroma extract (Figure 4). An an.ma

extract dilution analysis (AEDA) was applied to eiassify the aroma into

three groups having different sensory relevance. "high"' (no. 17), "medium" (nos. ,t, 6,

16). and "background" (nos. 1-3, S, 7-15). Hence. identification experiments were

focused on the odorants belonging to the firs' two groups. Compound no. 17 was of

particular interest because of its high FDfactor lind seasoning-like nole.

n

FD-factor (2 )

..

- - - - .. - -- - - - --- - -- - - - - - .. --- - -- - - -- - -- - - - -. - - - - - - - - - - -- 17 -

14

12

high sellst)ly relcI'flnce

10 - - -- -- - ----- --- --- .. - , . - . -- .--- - - .- ... ------- --- . .. - -

6

",eJi,il1, S"'"S0ry rde.unce

- --- -- _. - ---- .. _- --_ ... -

4 I.

4 - backgrOlmd nm",

--

"Ie TlT

,

2

-,

BOO 1000 1200 1400 1600 1BOO 2000 2200

(Retention index, FFAP)

Figure 4. of an aroma extract obtained Crom fenugreek seeds.

The chemical (Figure 5) of the odorants were mainly elucidated by

GC-MS (Table I). Compound no. 17 was identifi ed as sotolone (Figure 6A). Sotolone

is likely the character impact compound of fenugreek as indicated by the high FD-

factor of 2". correspondingly low sensory threshold and characteristic aroma note.

,.

18 SPICES: ruvolt ANI) ANTIOXIDANT

Sowlone was detected by GC-O even after more than IOOOOfold dilution of the

original aroma c){lraCI. It s FD-faclor was than those of acet ic acid

(FD'" 2

1

), (Z)-I ,5-ocladiene-3-one (FD- 2), and 3-ami no-4,5-dimethyl-3, 4-dihydro_

2(5H)-furanonc (FO" 21) which belong to Ihe group wilh medium sensory relevance

(Figure 4).

The FO-faclOrs of the remaining compounds were lower. They mosl likely

cont ribut e to the background of Ihe fenugreek [Iavor. These odorants art short chai n

falty aci ds (nos. 10, 11 , 14), lipid degradati on product s (nos. 3, 12), and al kylaled

mel hoxypyrazines (nos. 5, 7). All odorants listed in Table I, except nos. 15 and 17,

were identified for the first time as constituents of fenugreek aroma.

Table I. Odor-a ctive Compounds Detected in a n Aroma Extract or Fenugreek

Seedli 011 the Basis of GC-O (II is the IHllllber of dilution steps)

No Compound Relention index Arol1la qlwliry FD-filClor

FFAP OV-170f (Ge-O) r1")

I Diacety[' 990

'"

BUllery

2 Unknown 1020 , d. Fruity. metallic 3

3 1296 106> Mushroom-like

4 (l)- I,S-Octadicne-3-oroc 1369 1090 Metallic, tteraniu1\l .li kc

,

,

3-lsopropyl-2 Inethoxypyr:l.7.,ue

b

14211 1145 Roasl)', earthy 3

6 aCid' 1445

'"

Acidic, pUlIgent 7

7 3 lsobuty-2- 1518 1235 Roasty. plprikalike 3

8 Linalool ' 1543 11 93 Flowery 4

9

U""""".

1554 n.d. Sulfury, roasty 3

to Butanoic acid' 1624 968 S .....eaty, ranci d 3

II Isovaleric acid' 1663 102S S .....eaty, rancid 4

12

U""""".

1760 n.d. Fatty 3

13 UnknoWll 1823 n.d. Flowery, citrus-like 3

14 Caproic acid' 1845 1! 63 Musty 3

"

Eugenol' 2163 I SIlO Spiq 4

16 3-Amil\O-'l,5-dimcthyl- 21 90 , d. ScaSOfling.like

,

3, 4.dihydro-2(5J f)-furanone'

17 SOIolone' 2210 1350 Seasoning. like 14

Idcll1ifical ion by comparison wilh the refcrCllCe compound on ,I>< basis of retention

indices, aron18 quality and GC-MS.

Identification by comparison with the reference compound OIl

""

basis of rdcntion

indices and aroma quality. The amounts were too small for verification by GCMS.

n.d. detennincd

Terpenes and terpenoid compounds do not playa maj or rolc. Only linal ool

was detected. by GCO (no. 8). Most of the Icrpenes ident ified by GCMS wefe

odorless at the concentration prescnt in the arOma extract, i.e. 0.- and p-pi nene,

sabinene, 3-carene, menthol, p-Ierpineol, cineol, anethol, p-terpinyl acetate, 11'

3. BlANK I:,'T AI_

Principal (if flIIlgruk

19

acetat e, carvone, and several sesqui terpenes. Further volatiles of low or

no sensory relevance were I-pentano!, l . hexanoJ, 2-rnethyl -2.butcnc-l.ol, 2-methyl.

2-butenal, 2-pentylfuran, formic acid, propanoic acid, and fu rther longer chuin f;nty

acids, -y-butyrolactone and several 5-alkylated -y- Iactones, )-amino-4,5-dilllethyl_

2(3}f)-fllnmone, and others.

0

)lOti

6

o

8

4:

17

0

,

DOH

II

"

.hIll

o 0

16

0

3

o

"

,

7

Fi gure 5. Sensory relevant compounds idemified in the cxt .... ct uf Ji.m,!-',cc:'

The numbers correspond to those in Table I.

20 SI'ICES: t"IAVOR Ult:MISTJt Y ANI) ANlIOXl llANT

100")

A

'"

:. 80 ":

.

" c 50

1

ID

c 29

ID

40 -

ro

20 Lj

0;

0:

72

113

'-..

43

55

83

128

20 40 60 BO 100 120 140

mass I charge

100

70

"

B

0

80

b"Jl' .

"

o 0

c 60

..

C

ID

"

85

56

-" 20 43

ID

,.1.1.

129

0:

20 40 60 BO 100 120 140

mass I charge

Figure 6. Mass spectra of3-hydroxy-4,5-dimelhyl-2(5H)-fur3none (sololone) (A) and

of :; -ami no-4, 5-d ime! hyl- 3, 4-dihydro-2(51f)-furanone (8).

Sterenisn meric Ch:ml. cterisat ion of 50101001'. In fenugreek seeds, sotolonc occurs

in the (50) enantiorneric form (95%). This is in good agreement with

the data reported by Sauvaire et aL (16)

The OI 'C values of natural and 5ynthesi7.ed sotolone were determined by

isotope ratio mass spectrometry (IRMS) using the GC combustion technique (26), As

shown in II, natural sololone was characterised by a OllCroa value of -19.7%0.

On the contrary, a racemic mi:dure of synthesized 50tolone showed a significantly

higher value (-23.3%0).

Sotolone isolated from a commercial product revealed a ,sl lCPOII value of

-22.3%0 indicating a mixture of natural and synthetic compounds. This was confirmed

by chirospeciflc GC analysis resulting in a ratio of 65:35 for (5S):(SR). Hence, both

3. ntANK ET AI . Principal Comp(mellis of Fenugreek

21

GCIRMS and chirospeciflc GC suggest that about 213 of the sotolone found in rhe

conunercially available liquid seasoning was contaminated with synthetic sOlolonc

Table II. slle Values (%e PDP) of Solo lone of Synthdic and N:lIural Origin

SQ/o/Olle

Synthetic

Natural (fenugreek oleoresin)

Natural (fenugreek seeds)

Liquid seasoning (commercial)

23.30 0. 20

-19.69O.20

-19.75 0.20

-22.28 0.20

Quantitalion or SotolOllf in Fenugreek. The concent ralion of sololone

determined by isotope dilution assay (10, 24) using labelled SOlolone as internal

standard. As shown in Table !II, the typical concenlralion range of sotolone was

about 3-12 mglkg fenugreek seeds. However, the amouots depend on the

geographical origio. Fenugreek seeds from Egypt smelled more intensely and, in

agreement with that, more sotolon was found in these samples. Some Trigoncl/Q

species do not contain any 501010ne as reported by Sauvaire et a!. (11i) and,

consequcl1tly, they lack the characteristic seasoning-like note.

The sensory relevance of 50tolone is due to ils low threshold value of 0.3

water (10). In fenugreek seeds, the concentration of sotolone is usually at least

300{) times higher than its threshold, thus indicating the sensory impact of sololooe to

the overall flavor of fenugreek and products fenugrtck . As shown io Table

III, hi gh amounts of 501010ne were found in curry powder and some commercial

liquid seasonings

Table HI. Co ncentration of 50tolone in Fenugreek and Products Cont a ining

' <enugreek

Sample

Fenugreek, seed (Egypt, 1985)

Fenugreek, seed (Egypt, 1995)

Fenugreek, seed (Australia, 1991)

Fenugreek, seed (lOrance, 1996)

Fenugreek, seed (India, 1996)

Fenugreek, seed (Turkey, 1995)

Curry powder (containing fenugreek)

Liquid seasoning A

Liquid seasoning B

S%lone /mglkgj

25.1

12.2

4.2

3.3

5.1

3.4

39.7

1.4

88.9

I

!

I

22 SPI Cf.:S: nAVOk CIIi':MI!o.'TJ.l.Y ANI) ANTlOXIUMH l 'IWf'Elnn:s

Formati on of So to lone from !' ,'tcu rsol'S

Pret ursorJ Present in Ihe Allueous EXlracls of Fenugreek Seeds. The

presence of g!ycosidically bound sUlolone was examined by treat ing an aqueous

extract of fenugreek wi th ex- and p-glucosidases. As shown in Table IV, this

enzymatic treatment did 1101 si!,lni li cantly enhance the amount s ' of 5010100e compared

10 the reference sample. On the other hand, boiling of the exlrHcl under acidic

conditions (pH 2.4) for I h led to a more than 10 fold increase.

These trials indicate the presence of precursors in fenugreek that can be

Iransfomled to sotolone using specific condi tions, particularly an acidic medium and

heat treatment. 4.1!ydroxy-L.isoleucine, known to be a characteristic amino acid of

fenugreek (14, J 5), may be Ofle of these precursors.

Table IV. Formation of So to lone from Pre( ursors Present in the Aqueous

[:ltra cts of Fenugreek Seell s.

Addition (0 the Reaclioll cOIlfiiliollS Solo/Qlle

aqueous extrocl pH Trel I {mi'" {mglkg]

None 6.8 25 120 18.9

a-Glucosidase (200 U) 6.8 25 120 19.2

(200 U) 6. ' 25 120 20.2

None 2.4 100 60 252.3

SOURCE: Adapted from ref 10.

Formation of Solololl t frolll 4-lI ydro:ly-L-isoleudne (II IL). The formation

of sotolone was studied in phosphatebuftered model systems (pH 5.0) by react ing

HIL with different mono- and a-dicarbonyl compounds at 100"C for I h. Rot h 2,3

but anedione and 2,3.pentanediont rormed only low amounts of sotolont (Table V)

Higher yields were achi eved with the u. \.:eloaldehydes methylglyoxal (7.4 mol%) and

phenylglyoxal (2.5 mol"!. ), producing about 70-200 times more sotolone than Ihe

corresponding reaction with the u-dikefones. Monocarbonyl compounds, such as

propionaldehyde and phenylacetaldehyde, generated less than 0 I molo/. 50tololle (U ,

27).

Formation or SOlolone f .. olll 3-Amino-4,S-dimcthy!-l,4. dihydro-2(S/J)-

furanone (ADF). The emciency of ADF, the lactone of HIL. to generate sotolone

was tested in the same modd system as described above. As shown in Table V,

signifi cantly higher amount s of sotolone were generated from ADF as compared to

!ilL Using methyl glyoxal, the yields were increased from 64 Ilg (7.4 mol%) to 274

(35.9 mol%), thus indicating ADF to be a more efficient precursor than the free

anlino acid (HIL).

3. HLANK t.T At-

PrillCipai Flayor Comptmtlll.f of ,.',rwgn:t!k

Table V. Fornllllion of SOlolonc from the ,'recurJo rs 4. lI ydroxy. I,,..jsolruci ne

(H and 3_Amino_4,S_dimt lhyl_3,4_d ihydro- 2(SII)_fur:lII one (A I)F)b

in Fenugreek Seeds.

(l.DiC(lf"bollyf

",ccllrxo,c StJIO/OIle<i 1"1.:'"

JIlL AJ)F {jlg/mg filL] {mo/%j

2,J Outanedione

,

0.34 0.03 <0 I

2,3.Pentanedione

,

0.30 0.03 <0. 1

Methylglyoxal

e +

64.2 0.3 74

Phenylglyoxal

+

22.2 0.3 2S

2, 3Pentanedione

+ 5.4 0.3 0.7

Methylglyoxal

+ 274.4 :t 3.4 35.9

'Control experiment (without a.carbonyl) yielded less than 0.01 molo/. sotolonc.

b Cont rol experiment (without a-carbonyl) yielded 0.03 11101% sotolone.

c The molar ratio of precursor to a.dicarbonyl was I : 10.

d Data are means of at least twO experiments, each injected twict .

e Control experiment (without HIL) yielded 0.07 sotolont.

Mechan ism of the FOl"Ill;lt ion of Sotol one (J<'igure 7, 1) ;lt hwny A). The

data reported above confinn the hypot hesis of the formation by thermally

induced oxidative deami nation of Hl L (10) Acid camlyzed cyciLzalion of HIL leads to

the corresponding lactone (ADF) which rtacts with an a-dicarbonyl (e.g.

methylglyoxal) to form a SchilT base (pathway A) and subsequent.

hydrolysis gives rise to sotolone. The data show that a-<hcarbonyls are cap.ablt ot

generating sotolone from both HIL and the lactone ADF. the

emcient in producing sotolone. Furthermore, the relatively low Yields achieved With

HlL indicate an alternative degrRdation pathway.

SO'ecker () egndation of n i L as ;) Comll eti tive (Figure ?,

Ilathway B). The lower yitlds obtained wi lh Hi t might be a pamal

Strecker degradation of the amino acid I ilL in the of an Q.dl carbonyl,

e,g. Illt:thylglyoxal. As shown in Fi gure 7, the reacti on of 1IlL

methylglyoxal results in a SchilT base which may tither cychze or decomp:Jse

decarboxylation. 11le Strecker aldehyde of IIIL .. IS

released by hydrolysis and this compound was tentatIVely Ident ,hed by GCMS ( . ./) as

a mixture of diastereomers.

In the sample based on tilL and methylglyoxal, Ihe ratio of St recker aldehyde

to sotolont was about 1:2 at pH 5 (Table Vl). Consequently, the Slr(!(:ker

degradation of liIL is a competit ive reaction to Ihe format ion of 1 II

I I of

Strecker aldehyde were detecled in Ihe sample conl ;\IIuns Ihe la<:I" "I'

on y races .' ... . . I .

ADF

bout 50 times less than in the reactIon wllh HI!. I he lurlll;ltllUl "t ",In " lit

, I.e. a

from ADF is the favoured reaction. most likely due to the hluded )" ''''')'

HAVIlK .... wn{Y ANI> ANTlnXJllANT

Tahl!' VI. Jt!lfio or Solololl e 10 3- lI ydrO:fY

M

2-1II!'lhylbu l:lllal l'Or lll ed in tll otlrl

Based 011 Mr_tbylglyoul and Ih e Prrcursors 4- lI ydro:fy- l...- isoleli dne

(III L) !llld 3

w

Amino-4,S-dimclhyl-3,4-dihydro-2(511)-rurall olle (A 1>,.' )

I,ff IIlL AJ)F

J I : 17 , 50

5 1.2 ' 50

b , 2 : ]0

7 I I.S : 40

____ '\---(NII,

'\ ,)...j,

H2

0

0 0

IlI L

o

/y"

11

2

0 ..

MG 0

.-.. ) N"0

II,

o 0 .. ./

11,-., N=CI/ - {; -CII

,

o u

,"

t-. CO, 1l

N-CH=C -(;11

'r---I' I

/-. ..... A, mJ

o 0

It

2

0

o 0

figure 7. Formati on of 5Ololone (palhway A) and 3.hydroxy-2.methylbutanal

(pathway 8 ) from 4.hydroxy.L-isoleucine (HIL) and 3-amino-4,S-dimclhyl'],4.

di hydro2(5/1).furanone (AOF) using mcthylg1yoxal (MG) as carbonyl reac:tant .

3. tHANK Kf A I M PrinciJl(JI HMor Compollents of f enugredc 25

Innuenee or Ihe pH. II is well known that Doth lactooiz.ation and the format ion of Ihe

Schiff base strongly depend on Ihe pH of the reaction medium. As shown in Figure 8,

the lactonlzation step (I-liL ADF) was favored under acidic: oondi tions and the

yields were about 50 .;. at pH ], but only 10 % at pH 5. On the other hand, Schiff

bases are readily formed under neutral and sl ightly basic condi ti ons.

The reactivity of the carbonyl c:ompound is another crucial parameter for the

formation of the Sc:hiff base. o.- Ketoaldehydes are much more effic:ient than a-

diketones (Table IV) and a-keto acids, whic:h generate only low amounts of sotolone

from HIT- (27).

7 6 5

,

}-igure 8_ Lac:loni7,..i1ti on of 4.hydroxy- Lisoleudne (!-lIT-) as a function of pH.

To fllld the optimum pH, methylglyoxal was reacted with HlL and the lactone AD!',

respectively. The reac:lion of methylglyo)(at and HIL was favoured at pH 5 whic:h

apparenlly is the best c:ompromise belween the lactonizalion slCP and the reac:livily of

the amino group to form the Schiff base (Figure 7). Once Ihe lactone (ADF)

formed the amino-c:arbonyl reac:lion was favoured al pH 56. In general, Ihe yiel ds

obtained with the lactone were significantly higher compared to the amino acid,

partic:ularly al pH 6 (40_2 molo/. ).

The reaction of HJL and methylglyoxal at pH 5 performed in waler yielded 2.8

mol% sotolone c:ompared to 7.4 mol% when using the phosphate buffered system.

This suggests a catalytic: effeC:1 of phosphate on the formation of sotolone from HIL

2. SI'I C.:S, FlAVOR CII t:MISTRY AND AN .... O)(IUMIIT l'IW"t: RTIES

!o:(ftcl of Reaclion Temperalufe Time. The sotolone yiel ds from tilL and

mcthylglyoxal were slrongly dependent on both reaction lime and temperature.

Significant amounts were generated above 70C Crable VJJ ). At II constant

temperature of 100C, the yield of sotorone continuously increased over a period of

to h, wilh no significant increase thereafter (Table VUI). About 23 to 210

sotolone were gcneraled from 30 min to ]0 h which 2.7 mol% and

23.8 rnol%, respectively.

Methylglyoxal reacted wilh 1-fTL al SOC for 48 h resulted in 3.8 mol%

5010100c, thus indicating that II long reaction lime and mild reaction conditions arc

also suitable for generating significant amounts of sotolone. Therefore, hot climatic

conditions might favour the fomlal ion of so to lone from HIL

Table vn. for mati on of Solo lone frolll n i L as a FUllcl ion of lhe React ion

TemllcrMur e Using !\Iet hylglyoxrli as Carbonyl Reacta nt

Temperature Sol()lolI'.b Yield

,

b

b

fOCI HILI {mol%{

50 0.31 0.01 0.03

60 1.150.03 0. 13

70 4.00 0 05 0.46

80 12.5 0.5 1.44

90 27.9 1. 8 3.2

100 64.2 OA 7A

Reaction condi tions: phosphate buffer (0.1 mol/I., pH 5.D), 501 OOC, \ h.

Data are means of at least two experiments, each injected twice.

Trible VIII. Fon n:Hion of Sotolone frolll H[L as Affected by the Reaction Ti me

Using Melhylglyoxal lU C;lrbunyl lleaclant :t

Time SOloloneb Yield

{II] Ipglmg HlL] {mul%]

0.5 23.4 0.8 2.7

1 64.2 0. 4 7A

2 102./ 4,5 11 .7

5 170,25,1 19.5

10 206.7 10 23.8

15 208.3 6.4 24.0

24 229.9 5.) 26.4

Reaction conditions: phosphate buffer (0. I moVL, pH 5.0), lOO"C, 0.524 h.

Data are means of at least two experiment s, each injected twice.

3. Bl ANK t>:1 AI . Principtli "lavQr Cvmponents lif f'tnu/;rtek

Concl usion

The role of as a character impact compound of fenugreek was

corroborated and its formation from 4.hydroxyL-isoleueinc (IIIL) via thermally

induced oxidative dcamination Wil S The lactone of !-IlL, 3-atnino4.5-

dimcthyl. 3,4. dihydro.2(5fl).furanone (ADF), was found 10 be lI. better precursor 11ulI\

the acid. a-Ketoaldehydes wcre more effective in generat ing sotalone frum

both IIIL and ADF than adiketoncs. The reactivity of the dicarbonyl and the

lactonization step are important parameters, particularly for the formation of the

Schill' base. The transformation yields from IUL into sototone greatly depend on the

reaction conditions., such as temperature, time, pH and amount of dicarbonyl Iligh

amounts ofsot olone were obtained by boiling methytgtyoxal with HJL for 10 h:lt pI-!

5 (24 mulOV.). Even better results (40 mol%) were achieved using ADF as precursor (I

h, pH 6), most likely due to inhibition of the Strecker degradation by the blocked

carboxyl group,

Acknuwlcdgmeul s

We are gratt-ful to V Krebs for expert techni cal assistance, Dr. H. Schierbeek for

performing the GC-IRlvIS and Dr. E. I' rior for cri tically reading the

manuscript . We also thank Prof A. Mosandl, Universi ty of Frankfurt, Germany, for

the chi rospecifle GC analysis.

Li terat ure Cited

I.

2

3.

4.

5.

6.

7.

9.

10.

Lew;s, V,S, (Ed.), tlml Herbs/ur Ihl! Pucxl 'l/dusfry; Food Trade Press.

Orpington, England, 1984; pp. 141 - \42.

Girardon, 1' .; Ilessiere, 1.M., Baccou, J C.; Sauvaire, Y. PIal/faMed., 51.

533-534

Rijkens, F.; Doelens, H. In Proc. 1111. S)lmp. Aruma Maarse, r I. ,

Groenen, 1) .1 ., Eds.; Pudoc: Wageningen, The Net herlauds, 1915; pp. 203220

Girardon, P.; Sauvaire, V.; Baccou, J -C,; Bessiere, J -M. I.eben.",". /V,.\ .....

Tedmol. 1986, 19, 44-46.

Kobayashi, A. In FI<lI"Or 01,,",i.II1)'. Trelllil- and IJew:lopmellf.\;. Teranishl .. R ,

BUllery, R.G., Shahidi, E, Eds.; ACS Symp. SeT. Amencan Ch,..nllclil

Society: Washington, DC, 19119; pp 49-59.

Takahashi, K,; Tadenuma, M. ; SalO, S, Agr. /Jiol. ('lwlIl. 1'176, ./0, 325330

TokitunlO, Y.: Kobayashi, A. , T,: MurHki. S. /'/"11('. Japall A('(/d

1980, 56/J, 451-462.

Blank, I.; Sen, A.; Grosch W. Z. Leb"mm. U'Jlers. 1992, 195,23')-245

Blank, I ; Schiebtrle, P. Plav. hagr. J. 1993, 8, 191195.

Blank, I., Schieberle, P.: Grosch W. III I'rogrtss ill Plltllf)Jlr a",1 Prenll'sur

Sflldie.f; Schreier, P.; Winterhalter, P., Eds.; Allur I'ubl.: WhealOn, USA. 19'.13.

pp. 103.109.

"

SPICt:S, ... .AVOR I.: IIEMISTIl\' ANI) ANTl OXILlANT l'IW,' ,;KTlE.-;

II Masuda, M , Qkawa, E., Nishimura, K.; Yunomc, H A.I!r. /J/(}f. Chem. 19114,

48,2707-271 0.

12. Martin, B.; Eti evarll, P.x. ; Le Quere, J.L., Sehlieh, P. J. A;:ric. Food ('//(.",.

1992,40,475-478,

lJ. Wild , H. Cirelli. Ind., 1988, 580-SS6.

14. I'owden, L. ; Pratt, H.M.; Smi th, A PhYfochemistry 1973,12, 170117 11.

Sauvaire, Y.; Girardon, P.; BaceQu, l e .; Risteruoci, A.M. I'IIYffldll.'misllY

1984, }1, 479-486.

If> Sauvaire, Y.; Srenae, P.; Guichard, E.; Fournier, N. In FOllr/h Imemllfifmal

Works/lOll all Seeds, VO/lllne 1; Come. D.; Corbineau, F., Eds., ASFIS. Paris,

France, 1993; PI'. 201-206.

17. Alcock, N.W., Crout, 0 H.; Gregorio. M.V.M., Lee, E.; Pike, G , Samuel, C J.

Phyfochemistry 1989, 28, 1835 184 J.

ll! , Grosch, W. Trends F()()(/ Sci. Teehl/ol. 1993, 4, 68-73,

19, Acree, T.E. III F/OI'(Ir Science. alld Acree,

T E.: R. , Eds : Ameri can Chemi cal Society. DC, 1993;

pp. 1-18.

20. Schieberle, P. : Grosch, W. J. Agrie. Food Chem. 1987,35,252-257.

21. Sen, A., Laskawy, G ; Schieberle, P.: Grosch, W. J. Agrie. Food Chem. 199 1,

39, 757-759.

22. Faulstich, H., [}QlIi ng, J ; Michl, K.: Wieland T. Liebigl AIIII. Chem. 1973,560-

'6'

23. Hasan, M. In Nelli Trellds ill Natllral Products Chemi.flry. Rahman, A.: Le

QUesnc, P.W., F..ds.; Studies in Organic Chemistry, Vol. 16, El sevier Sci r ubl.