Académique Documents

Professionnel Documents

Culture Documents

Metalforming Part-Out Made Easy

Transféré par

Balluff SensorsDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Metalforming Part-Out Made Easy

Transféré par

Balluff SensorsDroits d'auteur :

Formats disponibles

Application Spotlight

Metalforming Part Out Sensing Made Easy

In certain metal forming applications, detection of parts exiting the stamping die with standard thru-beam photoelectric sensors is not always reliable. Part detection is often missed when it tumbles out of the light beams path, and having more than one set of energized emitter-receiver pairs does not always help. Light grids offer a greater area a coverage in a single sensor pair, offering a more reliable means of detection. However, even when part ejection is controlled enough to always break the light beams path, die lube mist interferes with the optics of the sensing pair and causes false triggers. That is when good old fashioned, long-range pancake or block-style inductive proximity sensors are ideal. Inductive sensors are immune to any optical inhibitors that would otherwise cause a photoelectric sensor to fail.

Benefits of using Light Grids

n Covers a broader area which increases detection reliability n Single sensor is used to increase detection area rather than setting up several sensors to increase detection area

Benefits of using Long-Range Inductive Sensors

n Immune to dirt, debris, and fluid build-up n Covers a broader detection range n Can see through non-metallic surfaces which act like a chute for ejected parts

Part Detection with Bunkered Light Grid Part Detection with Long-Range Pancake Sensor

Inductive proximity sensors have the ability to function well in die lube mist, cutting fluids and difficult industrial fluids and they are generally IP67 rated. They can also see through non-metallic substances. But these are generally plastic encapsulated and the constant contact with metal components exiting the die will prematurely end their service. So setting up one or even two cost-effective, long-range pancake or large block style sensors in a zone (and being careful to avoid cross talk) works well in this application. To increase the life of the sensor, it can be covered with a large piece of heavy duty, wear-resistant polycarbonate, or other non-metallic material to act as a chute to catch the ejected finished stamped part.

Ordercode BLG0005 BES0225 Part Number BLG 1-010-210-070-PV01-SX BESQ80KA-PAH40BS04Q Description Light grid - PNP, Dark-on, NO + 010 Vdc, 7 mm resolution Inductive Maxisensor - Flush, PNP, NO+NC, Sn = 40 mm

1 2

www.balluff.com/Metalforming

Balluff, Inc. n 8125 Holton Drive Florence, KY 41042 n 1-800-543-8390 n www.balluff.com

PS_061 Metalforming Part Out Detection Made Easy 2012-03

Non-safety-rated light grids, sandwiched between plates of steel for impact resistance are a good option for increasing the detection area without the need to wire up and align multiple thru-beam sensors. However, when excessive die lube mist is heavy and there is no way to integrate an air knife or other blow-off mechanisms to keep the optics clear, the old tried and true long-range inductive proximity sensor for part-out applications is a safe bet.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Chemical Liquid Level Monitoring On A Sight GlassDocument1 pageChemical Liquid Level Monitoring On A Sight GlassBalluff SensorsPas encore d'évaluation

- Reduce Validation Costs by Eliminating Re-ParameterizationDocument1 pageReduce Validation Costs by Eliminating Re-ParameterizationBalluff SensorsPas encore d'évaluation

- BSI Inclination 1211 WEBDocument4 pagesBSI Inclination 1211 WEBBalluff SensorsPas encore d'évaluation

- TA12 Explosion Proof Linear Position Transducer BrochureDocument8 pagesTA12 Explosion Proof Linear Position Transducer BrochureBalluff SensorsPas encore d'évaluation

- Distributed Modular I/O Quick Start Guide For 4 Port IO-Link MasterDocument8 pagesDistributed Modular I/O Quick Start Guide For 4 Port IO-Link MasterBalluff SensorsPas encore d'évaluation

- Color Monitoring Feedback of DeckingDocument1 pageColor Monitoring Feedback of DeckingBalluff SensorsPas encore d'évaluation

- Reliable Cap and Strap DetectionDocument1 pageReliable Cap and Strap DetectionBalluff SensorsPas encore d'évaluation

- Automotive - Distributed Modular I/O On ConveyorsDocument1 pageAutomotive - Distributed Modular I/O On ConveyorsBalluff SensorsPas encore d'évaluation

- Linear 130005 Micro Pulse CatalogDocument132 pagesLinear 130005 Micro Pulse CatalogBalluff SensorsPas encore d'évaluation

- Reduce Set-Up Time For Gripper Position With Analog SensorsDocument1 pageReduce Set-Up Time For Gripper Position With Analog SensorsBalluff SensorsPas encore d'évaluation

- Steel Coil AlignmentDocument1 pageSteel Coil AlignmentBalluff SensorsPas encore d'évaluation

- Automotive - Vacuum Pressure Detection On GrippersDocument1 pageAutomotive - Vacuum Pressure Detection On GrippersBalluff SensorsPas encore d'évaluation

- Cylinder Sensor Stay-Put BracketsDocument1 pageCylinder Sensor Stay-Put BracketsBalluff SensorsPas encore d'évaluation

- MAC Valve Manifold ControlDocument1 pageMAC Valve Manifold ControlBalluff SensorsPas encore d'évaluation

- Solar - Chemical Level MonitoringDocument1 pageSolar - Chemical Level MonitoringBalluff SensorsPas encore d'évaluation

- Positioning Flight Simulator BrochureDocument8 pagesPositioning Flight Simulator BrochureBalluff SensorsPas encore d'évaluation

- Welding Select BrochureDocument32 pagesWelding Select BrochureBalluff SensorsPas encore d'évaluation

- Balluff 315634 Object Detection CatalogDocument612 pagesBalluff 315634 Object Detection CatalogBalluff SensorsPas encore d'évaluation

- Balluff Product News Catalog - Winter 2012Document212 pagesBalluff Product News Catalog - Winter 2012Balluff SensorsPas encore d'évaluation

- Linear 180269 Micro Pulse Pro Compact BrochureDocument6 pagesLinear 180269 Micro Pulse Pro Compact BrochureBalluff SensorsPas encore d'évaluation

- Fluid 215966 Pressure Sensors BrochureDocument16 pagesFluid 215966 Pressure Sensors BrochureBalluff Sensors100% (1)

- Balluff 218263 Corporate+Product Overview BrochureDocument4 pagesBalluff 218263 Corporate+Product Overview BrochureBalluff SensorsPas encore d'évaluation

- Linear - 164996 - BML-S2E Rotary Encoder BrochureDocument8 pagesLinear - 164996 - BML-S2E Rotary Encoder BrochureBalluff SensorsPas encore d'évaluation

- Networking 168997 Power Supply BrochureDocument12 pagesNetworking 168997 Power Supply BrochureBalluff SensorsPas encore d'évaluation

- Networking - 187722 - Passive Connectivity Overview BrochureDocument6 pagesNetworking - 187722 - Passive Connectivity Overview BrochureBalluff SensorsPas encore d'évaluation

- Linear - 181787 - Micropulse Gen 7 BrochureDocument12 pagesLinear - 181787 - Micropulse Gen 7 BrochureBalluff SensorsPas encore d'évaluation

- Linear 182344 Micro Pulse SF BrochureDocument6 pagesLinear 182344 Micro Pulse SF BrochureBalluff SensorsPas encore d'évaluation

- Linear 210292 Micro Pulse PF BrochureDocument6 pagesLinear 210292 Micro Pulse PF BrochureBalluff SensorsPas encore d'évaluation

- Networking 187688 CC-Link BrochureDocument6 pagesNetworking 187688 CC-Link BrochureBalluff SensorsPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Butt Fusion Machines Small-Medium - V2 - LowDocument12 pagesButt Fusion Machines Small-Medium - V2 - LowViorel TomaPas encore d'évaluation

- Fully Integrated, 8-Channel Ultrasound Analog Front End, 0.75 NV/RTHZ, 14/12-Bit, 65 MSPS, 158 MW/CHDocument52 pagesFully Integrated, 8-Channel Ultrasound Analog Front End, 0.75 NV/RTHZ, 14/12-Bit, 65 MSPS, 158 MW/CHJoseph BernardPas encore d'évaluation

- 3132 Datasheet Sensor Magnetico PDFDocument7 pages3132 Datasheet Sensor Magnetico PDFSimPas encore d'évaluation

- P3T32 ManualDocument350 pagesP3T32 ManualdyjimenezPas encore d'évaluation

- 1:1 PLC Communication Replacement: IND131/331 CompatibilityDocument6 pages1:1 PLC Communication Replacement: IND131/331 CompatibilityRonPas encore d'évaluation

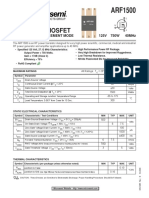

- Arf1500 PDFDocument4 pagesArf1500 PDFbookreader1968Pas encore d'évaluation

- The Impact of Japanese Culture On The Gaming IndustryDocument27 pagesThe Impact of Japanese Culture On The Gaming Industrytempest927189Pas encore d'évaluation

- Sharp Lc32fh500e Lc32fb500e Lc32fh510e Lc32fb510e Lc-Fs510e SMDocument76 pagesSharp Lc32fh500e Lc32fb500e Lc32fh510e Lc32fb510e Lc-Fs510e SMDinca SilviuPas encore d'évaluation

- IEEE Style Manual For StudentsDocument70 pagesIEEE Style Manual For Studentsvamsi_1990Pas encore d'évaluation

- Wireless Communications Dr. Ranjan Bose Department of Electrical Engineering Indian Institute of Technology, Delhi Lecture No. # 38 GSM and CdmaDocument31 pagesWireless Communications Dr. Ranjan Bose Department of Electrical Engineering Indian Institute of Technology, Delhi Lecture No. # 38 GSM and CdmaArun Gopinath100% (1)

- 0 26 enDocument130 pages0 26 enHoangPas encore d'évaluation

- Especificaciones Técnicas - EV1004TURBOX - EV1008TURBOXDocument2 pagesEspecificaciones Técnicas - EV1004TURBOX - EV1008TURBOXnely pabloPas encore d'évaluation

- Flash MemoryDocument15 pagesFlash MemoryCRT07Pas encore d'évaluation

- 3 Blue Copper ProteinsDocument15 pages3 Blue Copper ProteinsSergio BetancurPas encore d'évaluation

- K5 Hardware Manual 1510Document115 pagesK5 Hardware Manual 1510hoavotinh2011Pas encore d'évaluation

- AK4384 DAC DatasheetDocument24 pagesAK4384 DAC Datasheetchuma_riescoPas encore d'évaluation

- Sony CDX Gt527ee Gt570 Gt570sDocument46 pagesSony CDX Gt527ee Gt570 Gt570sMarco DesarrollosmexPas encore d'évaluation

- PN43E450A1FXZA: Fast Track Troubleshooting Manual - Rev 6/5/12Document8 pagesPN43E450A1FXZA: Fast Track Troubleshooting Manual - Rev 6/5/12nistoreduardcristianPas encore d'évaluation

- Optical Sensor For Heart Rate Monitor IC: DatasheetDocument31 pagesOptical Sensor For Heart Rate Monitor IC: Datasheetmaria jose rodriguez lopezPas encore d'évaluation

- NDR Jammer OverviewDocument1 pageNDR Jammer OverviewhardedcPas encore d'évaluation

- Chemical BondingDocument25 pagesChemical BondingpjaindakPas encore d'évaluation

- R999000216 09 2015 Automation Media PDFDocument124 pagesR999000216 09 2015 Automation Media PDFJose Manuel Barroso PantojaPas encore d'évaluation

- Sens Battery ChargerDocument17 pagesSens Battery ChargervjPas encore d'évaluation

- TT273 Field Rangeable RTD Temperature TransmitterDocument2 pagesTT273 Field Rangeable RTD Temperature Transmitterluat1983Pas encore d'évaluation

- Lava Aire Italia - Amit Misty Misting Fan - Owners ManualDocument7 pagesLava Aire Italia - Amit Misty Misting Fan - Owners ManuallavaheatitaliaPas encore d'évaluation

- All Kinds of Faults in An Alternator and Their ProtectionDocument9 pagesAll Kinds of Faults in An Alternator and Their ProtectionFaisalPas encore d'évaluation

- 5 A 66 FDD 55 C 9 EbDocument69 pages5 A 66 FDD 55 C 9 EbAsim KhanPas encore d'évaluation

- TDR & FMCW Radar Level Transmitters Principle Instrumentation ToolsDocument3 pagesTDR & FMCW Radar Level Transmitters Principle Instrumentation Toolskali bangonPas encore d'évaluation