Académique Documents

Professionnel Documents

Culture Documents

Si 1175

Transféré par

user10002Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Si 1175

Transféré par

user10002Droits d'auteur :

Formats disponibles

CLASS II

SERVICE INSTRUCTIONS

No. 1175 ATA Code 77-00

SUBJECT: ENGINE INDICATING MODIFICATION AND CALIBRATION OF AIRCRAFT INSTRUMENT AND DEVELOPMENT INCORPORATED ENGINE INSTRUMENT CLUSTERS NOTE These Service Instructions supersede and cancel BEECHCRAFT Service lnstructions No. 1065. EFFECTIVIN: BEECHCRAFT Duchess 76, serials ME-1 through ME-349; Skipper 77, serials WA-1 through WA-101 and WA-104; and any other Duchess 76 and Skipper 77 airplanes which may have installed a replacement engine instrument cluster manufactured by Aircraft Instrument and Development Incorporated with any of the following serial numbers: MODEL ENGINE INSTRUMENT CLUSTER PART NUMBER ENGINE INSTRUMENT CLUSTER SERIAL NUMBER 1 through 419, 1000 through 1068 and 1088 through 1091

105-389011-5 (14 volt system) or 105-389011-31 (28 volt system)

1 through 279

NOTE These Service lnstructions affect only engine instrument clusters manufactured by Aircraft Instrument and Development Incorporated. Other engine instrument clusters are not affected. REASON: COMPLIANCE: To provide improved reliability of the engine instrument cluster. At the owner's discretion, however, Beech Aircraft Corporation recommends that this modification be accomplished and the engine instrument cluster be recalibrated the next time the engine instrument cluster is removed from the airplane for any type of maintenance.

No BECP

301 11

8, .

Beech Alrcraft Corporat~on Issues servtce lnformatton for the benef~t owners of and flxed base operators In the form of three classes of Service lnstructlons CLASS I (Red Border) are changes tnspectlons, and rnod~ftcattons that could affect safety The factory cons~ders cornpl~ancemandatory CLASS II (Green Improvements or lnspectlons the factory Border) covers changes modlflcat~ons, feels will beneftt the owner and although h~ghlyrecommended, they are not cons~deredmandatory cornpl~ance, t~nlessspec~ftedat the tlrne of Issuance Class I and II are malted to

BEECHCRAFT Internattonal Owner Notification Service List. (c) Those havlng a publications subscript~on.

CLASS Ill (No Border) covers changes whlch are opttonal, matntenance a~ds. product Improvement k~ts and miscellaneous servlce lnforrnat~onCornpltance 1 s at the owner or operators prerogarlve Coptes of Class Ill are dlstrtbuted per a on Service or Subscr~ptlons be can and c above lnformat~on Owner Not~ftcatton obtalned through any BEECHCRAFT Aero or Av~atlonCenter, lnternat~onal Dlstrlbutor and Dealer or the Factory As Service lnstruct~ons are ~ssued. s (a) BEECHCRAFT Aero or Avtat~onCenters and Intervat~onal temporary notatlon In the Index should be made until the tndex 1 revlsed D~str~butors Dealers and Warranty will be allowed only when spec~flcally deflned In the Servlce lnslructlons (b) Owners of record on the FAA Reg~strationlfst a i d the and In accordance wlth Beech Warranty Poltcy

4 3

M e m b e r 01 G A M A M.nvfaclurcr% Anooot8on Generat Avw#non

Service lnstructions No. 1175

APPROVAL: MANPOWER:

FAA Approved.

The following information is for planning purposes only: Estimated man-hours: 4 hours. Suggested number of men: 1 man.

MATERIAL:

The following parts required for this modification may be ordered through BEECHCRAFT Aero or Aviation Centers and International Distributors and Dealers. PART NUMBER DESCRIPTION QUANTITY PER AIRPLANE 12 (Duchess 76) 6 (Skipper 77) As Required

Mylar Strip

'476

Black Vinyl Tape

*PIN of Minnesota Mining and Manufacturing Company, 3M Center, St. Paul, Minnesota 55101. May be obtained from local sources. The value of the parts required to incorporate these Service lnstructions on one airplane is to be advised. Prices, when issued, will be subject to change without notice.

WARRANTY:

BEECHCRAFT Warranty on a new airplane is 180 days from delivery or 180 days from the date noted on the Owner Warranty Card. Warranty credit for parts and labor to the extent noted under MATERIAL and MANPOWER will be allowed on BEECHCRAFTS within warranty at the time these Service lnstructions are released. All warranty reimbursements are handled through franchised BEECHCRAFT Aero or Aviation Centers and International Distributors and Dealers. Owners and operators should arrange with these outlets to perform the work and have them submit the standard Beech Aircraft Corporation warranty claim form through BEECHCRAFT Parts and Equipment Marketing Wholesalers or International Distributors.

SPECIAL TOOLS: WEIGHT AND BALANCE: REFERENCES:

None.

None. BEECHCRAFT Duchess 76 Maintenance Manual, PIN 105-590000-7or subsequent, Chapter 77-00; BEECHCRAFT Skipper 77 Maintenance Manual, PIN 108-590000-7 or subsequent, Chapter 77-00; BEECHCRAFT Duchess 76 Wiring Diagram Manual (14 Volt), PIN 105-590000-158 or subsequent, Chapter 77-20; BEECHCRAFT Duchess 76 Wiring Diagram Manual (28 Volt), PIN 105-590000-21 or subsequent, Chapter 77-20; BEECHCRAFT Skipper 77 Wiring Diagram Manual, PIN 108-590000-158 or subsequent, Chapter 91-15.

PUBLICATIONS AFFECTED:

It is recommended that a note to "See Service Instructions No. 1175" be made in the following: BEECHCRAFT Duchess 76 Maintenance Manual, PIN 105-590000-7or subsequent, Chapter 77-00; BEECHCRAFT Skipper 77 Maintenance Manual, PIN 108-590000-7or subsequent, Chapter 77-00; BEECHCRAFT Duchess 76 Parts Catalog, PIN 105-590000-9B or subsequent, Chapter 39-10; BEECHCRAFT Skipper 77 Parts Catalog, PIN 108-590000-9 or subsequent, Chapter 39-10.

Service Instructions No. 1175

ACCOMPLISHMENT These Service lnstructions may be accomplished as follows: INSTRUCTIONS:

1. Turn off andlor disconnect all electrical power and disconnect the battery. 2. Remove the instrument panel glareshield. 3. Inspect the engine instrument cluster and determine if it was manufactured by Aircraft Instrument and Development Incorporated. 4. If the engine instrument cluster was not manufactured by Aircraft lnstrument and Development Incorporated, reinstall the glareshield and reconnect the battery. No further action i s necessary. 5. I f t h e e n g i n e i n s t r u m e n t c l u s t e r was manufactured by Aircraft lnstrument and Development lncorporated but does not have one of the serial numbers listed under EFFECTIVITY, reinstall the glare shield and reconnect the battery. No further action is necessary. 6. If t h e e n g i n e i n s t r u m e n t c l u s t e r w a s manufactured by Aircraft lnstrument and Development lncorporated and does have one of the serial numbers listed under EFFECTIVITY, continue with step 7. 7. Refer to the Maintenance Manual, Chapter 77-00 and remove the engine instrument cluster.

NOTE Steps 8 through 15 must be accomplished by an appropriately rated instrument repair facility.

10. Using a magnifying glass, inspect each meter movement for dirt and debris. Pay particular attention to the area between the armature and the magnet in each meter movement. Clean the meter movements as necessary. 11. Using the resistance and voltage values specified in Table 1, calibrate the engine instrument cluster as follows:

NOTE Before applying power to the engine instrument cluster, test resistances must be connected to the pins corresponding to each module to be tested or the unused pins should be grounded to prevent damage to the meter movements. Any pin left open may cause the corresponding meter movement to go rapidly to full scale and possibly damage the meter movement.

a. Connect a regulated 14 volt DC (for PIN 105-38901 and PIN 108-384003-23) 28 volt DC (for 1-5 or 1-31) power supply to pin 1 of engine PIN 105-38901 instrument cluster electrical connector. Connect pin 2 to ground. Ground the chassis of the power supply to the instrument cluster case. b. For fuel quantity, fuel pressure, oil pressure, oil temperature and cylinder head temperature indicators, connect the appropriate resistance for the low scale indication as specified in Table 1 between the appropriate pin of the electrical connector (see Table 2) and ground. Adjust the zero (Z) adjustment potentiometer (see Figure 2) so the meter reads at the low scale mark on the meter dial face. c. Connect the appropriate resistance for the high scale indication from Table 1 in place of the resistance used in step 1 1 b and adjust the span (S) adjustment potentiometer (see Figure 2)so the meter reads at the high scale mark on the meter dial face. d. Substitute resistances for the various midrange indications from Table 1 for the resistance used in step llc and observe that the meter indicates within 1/16inch of the appropriate mark on the meter dia! face. e. On PIN 105-38901 1-5 and 105-38901 1-31 engine instrument clusters only, connect a variable power supply to pin 1 1 (see Table 2).Set the voltage at 14 or 28 volts, as applicable, and gradually reduce the voltage until the undervoltage light is illuminated. The light should illuminate at 12.2+ .1 volts on 14 volt clusters and 23.75? .5 volts on 28 volt clusters. The undervoltage circuit potentiometer (see Figure 2) should be adjusted within these limits. Clockwise increases the voltage at which the light illuminates. engine instrument f. On PIN 108-384003-23 clusters only, connect a 0-50 ohm 10 turn linear potentiometer between pin 4 (see Table 2)and ground and gradually reduce the resistance. The LH fuel quantity gage should drop and the low fuel light should illuminate at 1 1 -

8. Refer to the wiring diagrams in Figures 4,5 and 6 and repair the engine instrument cluster i f required. 9. Prior to reassembling the cluster, remove any

and all tape that may be found around the meter movements and on the inside of the face mask. Install PIN 49-0037mylar strips on the front of each meter movement by securing the strips under the heads of the screws that attach the dial face to the meter movement as shown in Figure 1.

~ l A PIN 49-0037MYLAR T ~ ~ ~ STRIP UNDER THE DIAL FACE MOUNTING SCREWS ON THE FRONT OF EACH METER

Figure 1

Service Instructions No. 1175

/

RH FUEL QUANTITY

DUCHESS 76 INSTRUMENT CLUSTER ADJUSTMENT POINTS (105-38901 & 105-38901 1-5 1-31)

DUCHESS 76 INSTRUMENT CLUSTER UNDER VOLTAGE CIRCUIT ADJUSTMENTS ( 05-38901 & 105-38901 1 1-5 1-31)

ZERO ADJUSTMENT SPAN ADJUSTMENT SPAN ADJUSTMENT

ND SKIPPER 77 FUEL PRESSURE, OIL PRESSURE, OIL TEMPERATURE AND CYLINDER HEAD TEMPERATURE GAGES FUEL PRESSURE ZERO ADJUSTMENT

?

DUCHESS 76 LOADMETER OR SKIPPER 77 AMMETER

LOW FUEL POTENTIOMETER

RH FUEL QUANTITY SPAN ADJUSTMENT RH FUEL QUANTITY ZERO ADJUSTMENT LH FUEL QUANTITY SPAN ADJUSTMENT LH FUEL QUANTITY ZERO ADJUSTMENT SKIPPER 77 INSTRUMENT CLUSTER ADJUSTMENT POINTS

(108-384003-23)

SKIPPER 77 LOW FUEL LIGHT 1 ADJUSTMENTS ( 08-384003-23)

Figure 2 Engine Instrument Cluster Adjustment Points

Service Instructions No. 1175

CHECKTO ASSURETHATTHE PIN 476 BLACK VINYL TAPE IS INTACT ALONG THE TOP EDGE OF THE INSIDE OF THE ENGINE INSTRUMENT CLUSTER CASE

ENGINE INSTRUMENT CLUSTER CASE

Figure 3 Duchess 76 Engine lnstrument Cluster Case

50 MICRO AMP W 1 MA SHUNT

I PIN 105-389011-29

WIRED

-14 VDC

+14 VDC RIGHT SIDE SAME EXCEPT OMIT 6 PM

7219 LAMPS

RLP LENS BEP SOCKET

Figure 4 Duchess 76 Engine Instrument Cluster Wiring Diagram (105-389011-5 14 Volt)

Service Instructions No. 1175

50 MICRO AMP W 1 MA SHUNT

I PIN 105-38901 1-29

OIL PRESS

A @

W ERN

W RED

28 VDC

+ 28 VDC

Figure 5 Duchess 76 Engine Instrument Cluster Wiring Diagram (105-389011-31 28 Volt)

12 ohms. Resistance must be reduced very gradually because the low fuel light has a 3 second delay before it illuminates after the threshold has been reached. Adjust the low fuel potentiometer (see Figure 2) to these limits. Connect the 0-50 ohm potentiometer between pin 8 (see Table 2) and ground and repeat the procedure for the RH fuel quantity gage. Check operation of the low fuel quantity light test switch in both the left and right positions. g. Disconnect the power supply and ground from pins 1 and 2 on the engine instrument cluster electrical connector. h. On PIN 105-389011-5 and PIN 105-38901 1 31 engine instrument clusters, apply voltages of 0, 25 and 50 millivolts to pins 9 + and 10- (see Table 2) and observe that the loadmeter indicates 0, 50% and 100% respectively. Meter indications should be within 1116 inch of the appropriate mark on the meter dial face. Adjust the load meter span adjustment potentiometer (see Figure 2) as required to obtain the proper readings. i. On PIN 108-384003-23 engine instrument clusters, apply voltages of 0, + 50 and - 50 millivolts to

pins 9 + and 10- (see Table 2) and observe that the ammeter indications are 0, CHG and DIS respectively. Meter indications should be within 1/16 inch of the appropriate mark on the meter dial face. Adjust the ammeter span adjustment potentiometer (see Figure 2) as required to obtain the proper readings. 12. Reassemble the engine instrument cluster into the engine instrument cluster case.

NOTE On PIN 105-389011-5 and 105-38901 1-31 engine instrument clusters, check to assure the tape is intact along the top edge of the inside of the engine instrument cluster case (see Figure 3). If necessary, replace the tape with PIN 476 black vinyl tape. This tape reduces the possibility of the fuel quantity gages shorting against the engine instrument cluster case.

8uvbo lnmucmm No. 1175

13. Check the operation of the engine instrument cluster at a sufficient number of points as specified in step 11 to assure that reassembly has not caused any mechanical interference and all gages operate properly. 14. Seal the outside edge between the engine instrument cluster and the engine instrument cluster case with PIN 476 black vinyl tape. 15. Seal all adjustment holes in the engine instrument cluster case with PIN 476 black vinyl tape. 16. Refer to the Maintenance Manual, Chapter 77-00 and adjust the fuel quantity and fuel pressure gages as

required to match the airplane system. Reseal any adjustment holes as required with PIN 476 black vinyl tape. 17. Refer to the Maintenance Manual, Chapter 77-00 and reinstall the engine instrument cluster in the instrument panel. 18. Reinstall the glare shield and any other equipment or panels which may have been removed to accomplish these Service Instructions.

19. Ground run the airplane and check the engine instrument cluster for proper operation.

7219 U M P

BEP SOCKET

I

Figure 6 Skipper 77 Engine Instrument Cluster Wiring Diagram (108-384003-23)

Sewice Instructions No. 1175

MODEL 76 FUEL QTY QTY E 114 112 314 F

7

MODEL 77 FUEL QTY TOL QTY

OHMS 6 25 38 48 61

OHMS

TOL OHMS

t 1/16 IN -c 1.2 OHM

t 1.5 OHM t 1.5 OHM

-c 1.2 OHM

76 AND 77 FUEL PRESSURE PSI .5 8 12 OHMS 12.9 54.5 76.8 TOL OHMS 1.9 t 1.9 2 2.8

-t

76 AND 77 OIL PRESSURE PSI 25 60 100 OHMS 39.5 80.8 128.0 TOL OHMS

+ 2.4 t 3.5 2 2.4

76 AND 77 OIL TEMPERATURE

OF

MODEL 76 CYL HD TEMP

OF

OHMS 95.74 107.96 126.00 137.00

TOL OHMS

t 1.4

60 120 200 245

OHMS 76.8 107 143.8

TOL OHMS

t 2.0

r 1.4 t 1.4 t 1.4

200 350 500

2.0 t 1.3

MODEL 76 LOADMETER

O o /

MODEL 77 AMMETER

O / o

VOLTAGE 0 MV 25 MV 50 MV

TOL MV

t 1 t 1.5

-t

VOLTAGE -50 MV 0 MV +50 MV

TOL MV

t 1.5 -t 1.0 t 1.5

0 50 100

1.5

DIS 0 CHG

Table 1 Calibration Resistances and Voltages

Service Instructions No. 1175

+ 14 VDC OR + 28 VDC

RIGHT FUEL QUANTITY INDICATOR (IN) RIGHT FUEL PRESSURE INDICATOR RIGHT OIL PRESSURE INDICATOR RIGHT OIL TEMPERATURE INDICATOR RIGHT CYLINDER HEAD TEMPERATURE INDICATOR LOAD METER LOAD METER OVER VOLTAGE LIGHT UNDER VOLTAGE LIGHT OPEN GROUND

14VDC GROUND 14 VOLT LIGHTS LH FUEL QUANTITY FUEL PRESSURE OIL PRESSURE OIL TEMPERATURE RH FUEL QUANTITY AMMETER + AMMETER OPEN OPEN

+ +

+ 14VDC OR + 28VDC

LEFT FUEL QUANTITY INDICATOR (IN) LEFT FUEL PRESSURE INDICATOR LEFT OIL PRESSURE INDICATOR LEFT OIL TEMPERATURE INDICATOR LEFT CYLINDER HEAD TEMPERATURE INDICATOR LOAD METER LOAD METER OVER VOLTAGE LIGHT UNDER VOLTAGE LIGHT + 14V LIGHTS OR 28VDC

MODEL n 108-384003-23 (14 VOLT)

GROUND MODEL 76 105-389011-5 (14 VOLT) 105-389011-31 (28 VOLT)

Table 2 Engine Instrument Cluster Electrical Connectors

RECORD COMPLIANCE:

Upon completion of these Service Instructions, make an appropriate maintenance record entry.

Vous aimerez peut-être aussi

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsD'EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsPas encore d'évaluation

- Engine BWA - 2.0 FSI Timing Belt Installation - Not OEMDocument22 pagesEngine BWA - 2.0 FSI Timing Belt Installation - Not OEMJonathan AmirmadhiPas encore d'évaluation

- C 172Document199 pagesC 172zamuray34100% (1)

- Robinson r44 SystemsDocument15 pagesRobinson r44 SystemsLuiz Fernando MibachPas encore d'évaluation

- I4 - Radio Navigation-Use of ADFDocument69 pagesI4 - Radio Navigation-Use of ADFAbel MathewPas encore d'évaluation

- 9 RollingDynamicsDocument10 pages9 RollingDynamicsSonia YadavPas encore d'évaluation

- KirkKenton Cessna182Q ChecklistDocument2 pagesKirkKenton Cessna182Q ChecklistJesus M. Espinosa EchavarriaPas encore d'évaluation

- Checklist Msfs Atr42Document4 pagesChecklist Msfs Atr42Takanobu1984Pas encore d'évaluation

- Cessna Fuel System Inspection GuideDocument7 pagesCessna Fuel System Inspection GuideJohan Louie RayosPas encore d'évaluation

- Section 2 Limitations: SubjectDocument46 pagesSection 2 Limitations: SubjectFelipe Pedroso100% (1)

- Info Codes GeodimeterDocument13 pagesInfo Codes GeodimeterUjog MariusPas encore d'évaluation

- Normal Circuits DA42Document23 pagesNormal Circuits DA42DavidPas encore d'évaluation

- MPT S PDDocument12 pagesMPT S PDJasim isamPas encore d'évaluation

- Manual SkyconnectDocument62 pagesManual SkyconnectCarlos GomezPas encore d'évaluation

- Complete Guide On Proteus ISISDocument295 pagesComplete Guide On Proteus ISISberija1968Pas encore d'évaluation

- Master SoCal Backcountry Airstrip GuideDocument10 pagesMaster SoCal Backcountry Airstrip GuideAnthonyPas encore d'évaluation

- PA34-200T Quick Study GuideDocument4 pagesPA34-200T Quick Study GuideAli SuleimanPas encore d'évaluation

- Electrical Interview QuestionsDocument43 pagesElectrical Interview QuestionsIsabella SwanPas encore d'évaluation

- IGCSE Physics Practice Electromagnetism QuestionsDocument20 pagesIGCSE Physics Practice Electromagnetism QuestionsFahim Ahmed67% (6)

- PA28-161 Piper Cadet & Warrior Maneuvers Manual Revised September 9, 2014Document34 pagesPA28-161 Piper Cadet & Warrior Maneuvers Manual Revised September 9, 2014Máté SzászPas encore d'évaluation

- Checklist For Diamond DA42 TDI "Twin Star": Comments Explaining Edition # 18Document17 pagesChecklist For Diamond DA42 TDI "Twin Star": Comments Explaining Edition # 18Miguel Angel MartinPas encore d'évaluation

- Janda KotDocument52 pagesJanda KotdarrenPas encore d'évaluation

- The MultitesterpowerpointDocument21 pagesThe MultitesterpowerpointAngel AlarasPas encore d'évaluation

- Generating Set SpecificationsDocument7 pagesGenerating Set SpecificationsAaron VillaretePas encore d'évaluation

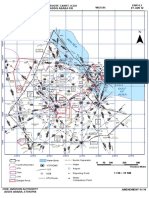

- Ethiopia Enroute Chart with Addis Ababa FIR boundariesDocument1 pageEthiopia Enroute Chart with Addis Ababa FIR boundarieskemoam birhanuPas encore d'évaluation

- T.O.L.D. Aircraft PerformanceDocument2 pagesT.O.L.D. Aircraft PerformanceAnthony RiveraPas encore d'évaluation

- Cessna 172Document4 pagesCessna 172James DeatoPas encore d'évaluation

- ORGANIZE YOUR INSTRUMENT APPROACH WITH WRIMTMDocument2 pagesORGANIZE YOUR INSTRUMENT APPROACH WITH WRIMTMAnonymous ib89TVPas encore d'évaluation

- ICAO CodesDocument32 pagesICAO CodesSoftcom982Pas encore d'évaluation

- S7 U9 WorksheetsDocument15 pagesS7 U9 WorksheetsKomal Bhardwaj (Academic Team)100% (2)

- Northern Antique Vocational School Quarterly Exam in Technology and Livelihood Education Electrical Installation and MaintenanceDocument5 pagesNorthern Antique Vocational School Quarterly Exam in Technology and Livelihood Education Electrical Installation and Maintenancerizaldy valente100% (2)

- TB9 ChecklistDocument16 pagesTB9 ChecklistMark MaidenPas encore d'évaluation

- Appendix F To CAAP 5.14-2 (0) - A K - K A TDocument6 pagesAppendix F To CAAP 5.14-2 (0) - A K - K A TSam RogersPas encore d'évaluation

- JDK Procedures (July 2017)Document12 pagesJDK Procedures (July 2017)Ethan PoonPas encore d'évaluation

- FAA certification data Cessna 510 turbofanDocument5 pagesFAA certification data Cessna 510 turbofanEmanuel PerezPas encore d'évaluation

- IZMIR ADNAN MENDERES INTL AIRPORT INFORMATION AND CHARTSDocument36 pagesIZMIR ADNAN MENDERES INTL AIRPORT INFORMATION AND CHARTSHalil OnarPas encore d'évaluation

- KAP140 Autopilot Quick Reference Card PDFDocument1 pageKAP140 Autopilot Quick Reference Card PDFJoe ThompsonPas encore d'évaluation

- Embraer EMB-135BJ Quick Reference Handbook QRH-135.1568-03 (12th December 2002 Revision 4 - 31st March 2005)Document180 pagesEmbraer EMB-135BJ Quick Reference Handbook QRH-135.1568-03 (12th December 2002 Revision 4 - 31st March 2005)Blaze123xPas encore d'évaluation

- PMDG 737 Cold & Dark To Secure V2Document6 pagesPMDG 737 Cold & Dark To Secure V2Rodolfo WolffPas encore d'évaluation

- Flight PlanningDocument46 pagesFlight Planningmehul da aviator100% (1)

- Multi-Function Display Pilot's Guide: Software Release 4 or LaterDocument184 pagesMulti-Function Display Pilot's Guide: Software Release 4 or LaterAlexandre F. M.Pas encore d'évaluation

- X-ATC-Chatter 1.6.3: User's GuideDocument26 pagesX-ATC-Chatter 1.6.3: User's GuideMax HayesPas encore d'évaluation

- LTFH Çarsamba PDFDocument25 pagesLTFH Çarsamba PDFtroyapilotPas encore d'évaluation

- Atm QuestionsDocument23 pagesAtm QuestionsAziz YoussoufouPas encore d'évaluation

- VOR ApproachesDocument19 pagesVOR ApproachesT.h. MinPas encore d'évaluation

- Cassese CS20 ManualDocument57 pagesCassese CS20 ManualJagath0nPas encore d'évaluation

- VTBDDocument15 pagesVTBDFajar Dwi SetyawanPas encore d'évaluation

- Zibo 737 ChecklistDocument31 pagesZibo 737 ChecklistMax HayesPas encore d'évaluation

- AlignmentDocument6 pagesAlignmentJyoti vermaPas encore d'évaluation

- MooneyafmDocument18 pagesMooneyafmJavierPas encore d'évaluation

- A4CE Rev 48-2Document44 pagesA4CE Rev 48-2amalecadanPas encore d'évaluation

- G1000 PBMDocument288 pagesG1000 PBMEduardo Almeida SilvaPas encore d'évaluation

- Cessna 172 Y 152 Checklist Emergency ProceduresDocument1 pageCessna 172 Y 152 Checklist Emergency Proceduresajcd110Pas encore d'évaluation

- Part Catalog Bonanza Beechcraft 36 SeriesDocument2 pagesPart Catalog Bonanza Beechcraft 36 Seriesmarco saucedo lijeronPas encore d'évaluation

- NDB/VOR Track Interception using only DIDocument13 pagesNDB/VOR Track Interception using only DIPeter Tin LattPas encore d'évaluation

- 5.air Data JAA QUESTIONSDocument31 pages5.air Data JAA QUESTIONSchoppingcloudsPas encore d'évaluation

- ML B 200 B200amm466 PDFDocument18 pagesML B 200 B200amm466 PDFAlbanyPas encore d'évaluation

- METAR TAFDocument12 pagesMETAR TAFcplowhangPas encore d'évaluation

- Aircraft Engine Illustrated Parts Catalog: For Reference OnlyDocument47 pagesAircraft Engine Illustrated Parts Catalog: For Reference OnlyPabloLamelaPas encore d'évaluation

- Obstacle Restriction and RemovalDocument34 pagesObstacle Restriction and Removalpangolin_79Pas encore d'évaluation

- Seminole ChecklistDocument10 pagesSeminole ChecklistFarah Afiqah NasihaPas encore d'évaluation

- FMS 800 Software User ManualDocument14 pagesFMS 800 Software User Manualaivanov3Pas encore d'évaluation

- Manual de Overhaul Io-520Document133 pagesManual de Overhaul Io-520Alfredo Ergueta CorilaPas encore d'évaluation

- The Artificial HorizonDocument18 pagesThe Artificial HorizonSherįl AlexxPas encore d'évaluation

- Fly 15 DME Arc Gomat Arrival No WindDocument1 pageFly 15 DME Arc Gomat Arrival No WindMan DenzoPas encore d'évaluation

- RANS S-6ES Pilot's HandbookDocument52 pagesRANS S-6ES Pilot's Handbookviorelu99Pas encore d'évaluation

- Measuring Current and Voltage Using a Variable Resistance and the Voltmeter-Ammeter MethodDocument12 pagesMeasuring Current and Voltage Using a Variable Resistance and the Voltmeter-Ammeter MethodMoh'd M. GharbiehPas encore d'évaluation

- DL Stock List - 07aug23Document2 pagesDL Stock List - 07aug23Kurnia IlhamPas encore d'évaluation

- Teaching & Examination SchemeDocument28 pagesTeaching & Examination SchemeSHYAM SUNDAR OJHA SHYAMPas encore d'évaluation

- Level 2 Questions Electromagnetism and Electricity Q1.: Figure 1 Shows Two Iron Nails Hanging From A Bar MagnetDocument8 pagesLevel 2 Questions Electromagnetism and Electricity Q1.: Figure 1 Shows Two Iron Nails Hanging From A Bar MagnetLouie Bridgeman-RivettPas encore d'évaluation

- Aberdeen Electronics PrinciplesDocument8 pagesAberdeen Electronics PrinciplestettehsackeyPas encore d'évaluation

- Technical SpecificationDocument17 pagesTechnical SpecificationPMSi Cal6Pas encore d'évaluation

- Optical Fiber Design Modification for Medical ImagingDocument6 pagesOptical Fiber Design Modification for Medical ImagingNAJMILPas encore d'évaluation

- Unit II MCQ Electricity, Magnetism and SemiconductorDocument14 pagesUnit II MCQ Electricity, Magnetism and SemiconductorUmesh PatilPas encore d'évaluation

- Zeftronicsr25101 2a TSNDocument2 pagesZeftronicsr25101 2a TSNScott HartleyPas encore d'évaluation

- Da Vinci Physics HW Series and Parallel CircuitsDocument7 pagesDa Vinci Physics HW Series and Parallel CircuitsClaudia HuoPas encore d'évaluation

- XII Chapter 15 Electrical Measuring InstrumentDocument7 pagesXII Chapter 15 Electrical Measuring InstrumentMaryum ZahidPas encore d'évaluation

- Dept. of EEE Rajalakshmi Engineering College Two Mark Question AnswerDocument8 pagesDept. of EEE Rajalakshmi Engineering College Two Mark Question AnswerRadha NandhiniPas encore d'évaluation

- Electrical Measurement 2nd Elect.2022-2023 Lecture1 PDFDocument39 pagesElectrical Measurement 2nd Elect.2022-2023 Lecture1 PDFHero ModePas encore d'évaluation

- Current Electricity Question BankDocument7 pagesCurrent Electricity Question BankchallapallinikhilPas encore d'évaluation

- EETPaperIIIYR2 PDFDocument109 pagesEETPaperIIIYR2 PDFpsychic_jason0071319Pas encore d'évaluation

- Physics Brevet Sample 2Document3 pagesPhysics Brevet Sample 2RAmi RamiPas encore d'évaluation

- Notes of Instrumentation and MeasurementDocument8 pagesNotes of Instrumentation and MeasurementRavi Shankar 31Pas encore d'évaluation

- De Anza College Class Assignment Optimized for SEODocument3 pagesDe Anza College Class Assignment Optimized for SEOJingyu ZhangPas encore d'évaluation

- P142 PDFDocument47 pagesP142 PDFashish sahuPas encore d'évaluation

- Lab 3 Breadboard and Ohms LawDocument6 pagesLab 3 Breadboard and Ohms LawRasul Amirov100% (1)

- Open circuit and load characteristics of DC shunt generatorDocument5 pagesOpen circuit and load characteristics of DC shunt generatorramniwas123Pas encore d'évaluation

- Yes, Midway Between The Wires. 2. Yes, 12 CM From The 5A Wire. 3. Yes, 7.7 CM From The 5A Wire. 4. NoDocument60 pagesYes, Midway Between The Wires. 2. Yes, 12 CM From The 5A Wire. 3. Yes, 7.7 CM From The 5A Wire. 4. NoSrynnEPas encore d'évaluation

- Lab Manual12thphyDocument89 pagesLab Manual12thphysolitary_monkPas encore d'évaluation