Académique Documents

Professionnel Documents

Culture Documents

Part330 Precast Concrete Units

Transféré par

Siti Zulaiha ZulaihaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Part330 Precast Concrete Units

Transféré par

Siti Zulaiha ZulaihaDroits d'auteur :

Formats disponibles

Edition: July 2007

Specification: Part 330 Precast Concrete Units

PART 330 PRECAST CONCRETE UNITS CONTENTS 1. 2. 3. 4. 5. 6. 7. 8. 9. 1. General Quality Requirements Manufacture Curing Marking Lifting, Handling and Storage Transportation Specific Requirements for Precast Prestressed Units Hold Points GENERAL

This Part specifies the requirements for the manufacture of precast concrete units. The units to be precast and any special requirements are specified in the Contract Specific Requirements" or on the Drawings. The precast units shall be manufactured in accordance with Part 310 "Formwork", Part 305 "Steel Reinforcement" and Part 320 "Concrete" except where amended or added to in this Part. When prestressed, units shall comply with Part 425 "Prestressed Concrete Work". 2. QUALITY REQUIREMENTS

At a minimum, the Contractors Quality Plan shall include the following documents, procedures and/or instructions: (a) (b) (c) lifting methods (where not shown on the Drawings); minimum concrete strength requirements prior to lifting (where not shown on the Drawings); and where it is proposed to stack units, evidence to demonstrate the strength and stability of the stack.

If not submitted beforehand, this documentation shall be submitted at least 28 days prior to the commencement of site work. Provision of the procedures listed in this Clause shall constitute a HOLD POINT. 3. MANUFACTURE

Formwork shall be of rigid construction and concrete vibration shall be such that intense concrete compaction will be achieved. This may require the use of form vibrators or vibrating tables on some large and/or complex shaped units. Formwork and embedded items shall not restrain movements nor damage precast units within the formwork due to the effects of shrinkage or steam curing. The casting of the precast units shall be carried out on specially prepared casting beds which will prevent any distortion or misalignment of the forms during and after concreting. Each precast unit shall be cast in one continuous operation with no construction joints. If the batch volume is less than 2 cubic metres, the sampling rate in Clause 320.5 "Sampling and Testing" shall be reduced as follows: Less than 2 cubic metres per batch: Less than 0.5 cubic metres per batch: 50% rounded up 30% rounded up.

DPTI XXCxxx

Page 1

Edition: July 2007

Specification: Part 330 Precast Concrete Units

In any case a minimum of 1 test representing each member shall be undertaken. Test specimens, for the purpose of determination of adequate unit strength for lifting and handling, shall be subjected to the same curing regime as the unit they represent. The Contractor shall ensure that sufficient cylinders are provided to enable the required testing to be undertaken. 4. CURING

Concrete shall be: (a) (b) (c) 5. moist cured in accordance with Part 320 "Concrete"; steam cured in accordance with Part 335 "Low Pressure Steam Curing of Precast Units"; or hot water cured in accordance with Part 336 "Heat Accelerated (Hot Water) Curing of Precast Units. MARKING

For the purposes of unit curing, testing, location and orientation within the final structure, each batch of units, or if continuous production methods are used, each days production, shall be clearly identified and indelibly marked to show: (a) (b) unit identification date of manufacture.

Each unit shall be marked on a surface which is unseen in the final structure. 6. LIFTING, HANDLING AND STORAGE

Precast units shall not be lifted or handled before the concrete has attained a compressive strength of 10 MPa or as specified on the Drawings, whichever is greater. The Contractor shall detail in the Quality Plan the measures to be taken to minimise handling stresses, in particular those due to demoulding. The Contractor shall carefully handle precast units by methods that will not damage them or their connections. Units shall be handled from the approved lifting points shown on the Drawings. Beams and slabs shall be lifted and supported with the top surfaces uppermost at all times, unless shown otherwise on the Drawings. Units shall be stored clear of the ground and supported on non-staining timber bearers only at approved bearing points. The thickness and width of the bearers shall be compatible with the strength group of the timber used, the type of precast unit and the site. The bearers shall support the units over their full width at the specified lifting points. The ground or space between the bearers supporting the units shall be carefully cleared and levelled to prevent the unit from being supported at positions other than on the bearers. The bearers shall rest on a firm foundation and adequate precautions shall be taken to prevent subsidence. If units are stacked in tiers, the bearers shall be placed directly over each other. The lowest unit shall not be overstressed. 7. TRANSPORTATION

Unless stated otherwise on the Drawings, units shall not be transported until the concrete has reached its 28 day characteristic compressive strength and is at least 7 days old. For post-tensioned units refer also to Clause 425.5.9.5 "Precautions after Grouting". No unit shall be removed from the casting yard until a lot conformance package has been completed. Submission of the lot conformance package prior to removal from the yard shall constitute a HOLD POINT. Units shall be securely fixed to the transporter by ties fitted with suitable tensioners. Provision shall be made to protect the units from damage caused by these ties.

DPTI XXCxxx

Page 2

Edition: July 2007

Specification: Part 330 Precast Concrete Units

8.

SPECIFIC REQUIREMENTS FOR PRECAST PRESTRESSED UNITS

It is essential that the hog of the units be as uniform as practicable. Accordingly, the Contractor shall ensure that: (a) (b) (c) (d) The concrete in the units is uniform in composition, consistency, compaction and strength. The curing conditions are as uniform as practicable. The concrete in each unit is approximately the same age when prestressed. The units are cast within as short a period of time as is reasonably practicable.

Additional tolerance requirements are as follows: (a) (b) (c) Twist: 1/2 per length of unit. The maximum variation in hog between precast prestressed units shall not exceed 20 mm. The maximum allowable deviation from the required profile in the horizontal plane shall not exceed 7 mm or 0.06% of the length of the unit, whichever is the greater.

For pretensioned units, flame cutting of strands at unit ends will not be permitted. Unless shown otherwise on the Drawings, strands shall be friction cut, flush with the concrete surface. The exposed ends of the tendons and the concrete surface within 50 mm of the tendons shall be abraded to provide a clean sound surface. A liberal coating of epoxy mastic aluminium shall then be applied over the ends of the tendons and abraded concrete, unless shown otherwise on the Drawings. 9. HOLD POINTS

The following is a summary of Hold Points, vide Part 140 "Quality System Requirements", referenced in this Part: CLAUSE REF. 2. 7. Submission of Procedures. Completion of lot conformance package prior to transportation. HOLD POINT RESPONSE TIME 7 days 6 hours

____________

DPTI XXCxxx

Page 3

DPTI XXCxxx

Page 4

Vous aimerez peut-être aussi

- Description & InstalationDocument3 pagesDescription & InstalationEhtesham AliPas encore d'évaluation

- Jack in PileDocument4 pagesJack in PileNyu123456Pas encore d'évaluation

- Specification For Jack in PileDocument4 pagesSpecification For Jack in Pilekhuanoz100% (1)

- Precast Pre Stressed ConcreteDocument6 pagesPrecast Pre Stressed Concretejack.simpson.changPas encore d'évaluation

- 1.1 A. 1.2 A. B. C. 1.3 A. B. C. D. E. F. G. H. I.: Click HereDocument5 pages1.1 A. 1.2 A. B. C. 1.3 A. B. C. D. E. F. G. H. I.: Click HereRiksa AsPas encore d'évaluation

- Part 8 Kerbs, FootwaysDocument11 pagesPart 8 Kerbs, FootwaysElvis GrayPas encore d'évaluation

- Technical Specification For BridgeDocument5 pagesTechnical Specification For BridgeRichard WestonyPas encore d'évaluation

- Installation of Girders and BeamsDocument11 pagesInstallation of Girders and BeamsVladimir Ramos CariPas encore d'évaluation

- Jack in Pile PDFDocument4 pagesJack in Pile PDFlattmdyPas encore d'évaluation

- PCI Structural SpecificationDocument33 pagesPCI Structural Specificationcaojin259Pas encore d'évaluation

- Installation Guide en 1337-11Document3 pagesInstallation Guide en 1337-11Miguel Belda DiezPas encore d'évaluation

- Precast Concrete CurbsDocument3 pagesPrecast Concrete Curbsgskodikara2000Pas encore d'évaluation

- Specification For Jack-In-Piles: 1.0 GeneralDocument4 pagesSpecification For Jack-In-Piles: 1.0 Generalmhamed1Pas encore d'évaluation

- Supply and Installation of Driven PilesDocument7 pagesSupply and Installation of Driven PilesTAHER AMMARPas encore d'évaluation

- Section 503 Prestressed Concrete Members: 503.1 DescriptionDocument7 pagesSection 503 Prestressed Concrete Members: 503.1 DescriptionSyed Ali Raza ShahPas encore d'évaluation

- Division 3 Specs WrittingDocument16 pagesDivision 3 Specs WrittingJaymar Palomares OrilloPas encore d'évaluation

- PillingDocument21 pagesPillingHadiyan RosyidiPas encore d'évaluation

- Precast Substructure SpecificationDocument7 pagesPrecast Substructure SpecificationTimothy CrusePas encore d'évaluation

- Section 705 Prestressed Concrete Members For BridgesDocument12 pagesSection 705 Prestressed Concrete Members For BridgesCarlos SYPas encore d'évaluation

- Structural Precast ConcreteDocument39 pagesStructural Precast ConcreteMherliePas encore d'évaluation

- 3 ConcreteWorksDocument19 pages3 ConcreteWorksMuhammad AgungPas encore d'évaluation

- Guide Specification: 1.1 Related DocumentsDocument33 pagesGuide Specification: 1.1 Related DocumentsJunior Jorge Huacho Vizcarra100% (1)

- QCS 2010 Part 6.08 Kerbs, Footways and Paved AreasDocument8 pagesQCS 2010 Part 6.08 Kerbs, Footways and Paved AreasRotsapNayrbPas encore d'évaluation

- GBSP 18Document4 pagesGBSP 18Mohammad Ibna AnwarPas encore d'évaluation

- Piling Specification To BS5400Document25 pagesPiling Specification To BS5400Atiq ZakariaPas encore d'évaluation

- Guide Specification: Guide Specification Must Be Edited To Fit The Conditions of Use. Particular Attention Should BeDocument45 pagesGuide Specification: Guide Specification Must Be Edited To Fit The Conditions of Use. Particular Attention Should BeAWPas encore d'évaluation

- Procurement of Infrastructure Projects: Hilippine Idding OcumentsDocument6 pagesProcurement of Infrastructure Projects: Hilippine Idding OcumentsAlmira RoblesPas encore d'évaluation

- Piling SpecsDocument6 pagesPiling SpecsElvis GrayPas encore d'évaluation

- Technical Specification For Micropile ConstructionDocument9 pagesTechnical Specification For Micropile ConstructionFFerideKochanPas encore d'évaluation

- Brick Masonry SpecificationDocument14 pagesBrick Masonry SpecificationHeak Hor100% (1)

- Section B3 Steel Structures GeneralDocument3 pagesSection B3 Steel Structures GeneralhavalPas encore d'évaluation

- Item 03100 Concrete FormworkDocument6 pagesItem 03100 Concrete FormworkNurLelyHardiantiZendratoPas encore d'évaluation

- TS 316213.23 Prestressed Concrete Driven Piles - DRAFT - AdjustedDocument22 pagesTS 316213.23 Prestressed Concrete Driven Piles - DRAFT - AdjustedMylfie DultraPas encore d'évaluation

- University of Northern PhilippinesDocument8 pagesUniversity of Northern PhilippinesMichael Mark Deompoc TimoteoPas encore d'évaluation

- Part S16 Cast in Place Concrete Piles (2008)Document3 pagesPart S16 Cast in Place Concrete Piles (2008)CK TangPas encore d'évaluation

- 03400-Precast Concrete-Rev.cDocument10 pages03400-Precast Concrete-Rev.cMithun UdayanarayanaPas encore d'évaluation

- Concrete Formwork SpecsDocument6 pagesConcrete Formwork Specsclive_2201Pas encore d'évaluation

- Technical Specifications I. Demolition WorksDocument14 pagesTechnical Specifications I. Demolition WorksKiel CorpuzPas encore d'évaluation

- PCI Guide Specification ArchitecturalDocument45 pagesPCI Guide Specification ArchitecturalLikhon BiswasPas encore d'évaluation

- Part417 Continuous Flight Auger PilesDocument5 pagesPart417 Continuous Flight Auger PilesNaga RjkPas encore d'évaluation

- S Aa Civ Concrete (Rev.0 2010)Document17 pagesS Aa Civ Concrete (Rev.0 2010)santanudas2001in9040Pas encore d'évaluation

- Annex A - Technical SpecificationsDocument50 pagesAnnex A - Technical SpecificationsGAhr CeredonPas encore d'évaluation

- Method Statement - Structural ConcreteDocument7 pagesMethod Statement - Structural Concretearif_rubinPas encore d'évaluation

- Hollowcore SpecificationsDocument5 pagesHollowcore SpecificationsshindidyPas encore d'évaluation

- Prestressed Precast Concrete Wall Panel (Structure), Item SPV.0165.XXDocument8 pagesPrestressed Precast Concrete Wall Panel (Structure), Item SPV.0165.XXruddy sniderPas encore d'évaluation

- CP 23 Formwork - PDF - Adobe AcrobatDocument34 pagesCP 23 Formwork - PDF - Adobe AcrobatShumei Zhou100% (1)

- Sequatchie Concrete Service: Precast Prestressed Hollow Core Concrete Floor and Roof Systems Design ManualDocument31 pagesSequatchie Concrete Service: Precast Prestressed Hollow Core Concrete Floor and Roof Systems Design ManualNirmal KishorPas encore d'évaluation

- Technical Specification For PCC PolesDocument8 pagesTechnical Specification For PCC Polesexecutive engineer1Pas encore d'évaluation

- Section 5-Part 12-JointsDocument6 pagesSection 5-Part 12-JointsAdamPas encore d'évaluation

- Section 03100-Concrete Forms and AccessoriesDocument4 pagesSection 03100-Concrete Forms and AccessoriesMØhãmmed ØwięsPas encore d'évaluation

- ACI 301 FormworksDocument2 pagesACI 301 FormworksAlvin D. Alonzo0% (1)

- Sec 606Document10 pagesSec 606AlvinPas encore d'évaluation

- Section 6: Foundation: 6.1 GeneralDocument13 pagesSection 6: Foundation: 6.1 GeneralwaliPas encore d'évaluation

- 1.1 A. B. 1.2 A. B. 1.3 A. 1.4 A. B. 1. 2. 3. C. 1.5 A. 1.6 A. BDocument4 pages1.1 A. B. 1.2 A. B. 1.3 A. 1.4 A. B. 1. 2. 3. C. 1.5 A. 1.6 A. Bgener33zPas encore d'évaluation

- Structural Specs 2Document10 pagesStructural Specs 2hadjie ansayPas encore d'évaluation

- Technical Specifications - PilingDocument16 pagesTechnical Specifications - Pilingmkpasha55mp100% (1)

- METHOD Statement of BRIDGE (Major STR)Document6 pagesMETHOD Statement of BRIDGE (Major STR)venkateswara rao Pothina100% (2)

- Particular Specification For Rock-Socketed Steel H-PiwefwlesDocument15 pagesParticular Specification For Rock-Socketed Steel H-PiwefwlesLee Tin YanPas encore d'évaluation

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- Gothic Architecture: 1. Describe in Detail About Reims CathedralDocument6 pagesGothic Architecture: 1. Describe in Detail About Reims CathedralNiharikaPas encore d'évaluation

- Usak Ceramic Price List UsdDocument1 pageUsak Ceramic Price List UsdTanvir Ahmed KhanPas encore d'évaluation

- BOQ For Steel Structure Processing FactoryDocument4 pagesBOQ For Steel Structure Processing FactoryArshad SanPas encore d'évaluation

- Tugas Ergonomy Jemima Kemala WIJAYA / 2702349086: Binus at Bandung Dsgn6597033 - Ergonomy and Anthropometry Tugas ErgonomyDocument39 pagesTugas Ergonomy Jemima Kemala WIJAYA / 2702349086: Binus at Bandung Dsgn6597033 - Ergonomy and Anthropometry Tugas ErgonomyjemiPas encore d'évaluation

- Steel Authority of India Limited Bhilai Steel Plant: 7.0 MT Expansion of BSPDocument32 pagesSteel Authority of India Limited Bhilai Steel Plant: 7.0 MT Expansion of BSPmecon bhilaiPas encore d'évaluation

- SAFI MessyDocument4 pagesSAFI Messynurul qamariahPas encore d'évaluation

- Ernest R. Norling - Perspective Made Easy-Dover Publications (1999) - Parte6Document30 pagesErnest R. Norling - Perspective Made Easy-Dover Publications (1999) - Parte6ivo PereyraPas encore d'évaluation

- Bridge Inspection Format Jan 22 - NewDocument35 pagesBridge Inspection Format Jan 22 - Newvenky0% (1)

- 1100 Midjourney PromptsDocument26 pages1100 Midjourney PromptsMostafaMimoPas encore d'évaluation

- FINAL ITP 2024 CompressedDocument388 pagesFINAL ITP 2024 Compressedhamidjumat77Pas encore d'évaluation

- Indo Sarasenic Architectue PDFDocument22 pagesIndo Sarasenic Architectue PDFUma AgrawalPas encore d'évaluation

- Column Interaction DiagramDocument5 pagesColumn Interaction DiagramuctPas encore d'évaluation

- NCRMP-Ratnagiri UGC Work Action PlanDocument101 pagesNCRMP-Ratnagiri UGC Work Action PlanKULDEEP KUMARPas encore d'évaluation

- 2005 Ikea CatalogDocument28 pages2005 Ikea Catalograhmani bagherPas encore d'évaluation

- How To Use Rule 7 & 8 - by Ar. LeeDocument9 pagesHow To Use Rule 7 & 8 - by Ar. LeeQuinn HarlowePas encore d'évaluation

- District CoolingDocument27 pagesDistrict CoolingFARIDPas encore d'évaluation

- Duct RsesDocument18 pagesDuct RsesSameer AbdullahPas encore d'évaluation

- Architecture: Art AppreciationDocument9 pagesArchitecture: Art AppreciationJoy FrianezaPas encore d'évaluation

- Presentación Ingles Casa de Los SueñosDocument5 pagesPresentación Ingles Casa de Los SueñosVictor Sibaja ReyesPas encore d'évaluation

- Gila Regina LolinDocument6 pagesGila Regina LolinEj Dacir AraoPas encore d'évaluation

- Permanent Formwork For ConcreteDocument6 pagesPermanent Formwork For ConcreteBogdanBPas encore d'évaluation

- DOPPLER ONE Drawings Europe (630kg)Document1 pageDOPPLER ONE Drawings Europe (630kg)Zlatko MPas encore d'évaluation

- TechnicalSheet ESDocument1 pageTechnicalSheet ESAndreja GjureskiPas encore d'évaluation

- Type C: Third Floor Plan Fourth Floor PlanDocument1 pageType C: Third Floor Plan Fourth Floor PlanShivaPas encore d'évaluation

- QDCMP 4.4 Buildings in A Transport Noise CorridorDocument19 pagesQDCMP 4.4 Buildings in A Transport Noise Corridorgoodspeed_phPas encore d'évaluation

- Building Technology: Hearst TowerDocument15 pagesBuilding Technology: Hearst TowerAsavariPas encore d'évaluation

- FAARFIELD Design ReportDocument3 pagesFAARFIELD Design ReportRahul RanaPas encore d'évaluation

- Rate Analysis Dolakha - 17JUneDocument80 pagesRate Analysis Dolakha - 17JUneNiranjan ShresthaPas encore d'évaluation

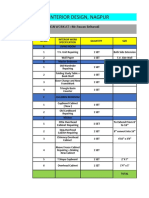

- Interior Costing of MR - Pawan BeltarodiDocument4 pagesInterior Costing of MR - Pawan BeltarodirumsPas encore d'évaluation

- Basotect: Room Acoustics and DesignDocument36 pagesBasotect: Room Acoustics and DesignShiva MohanPas encore d'évaluation