Académique Documents

Professionnel Documents

Culture Documents

Chapter 6 Inventory Control

Transféré par

Imad GhoriDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Chapter 6 Inventory Control

Transféré par

Imad GhoriDroits d'auteur :

Formats disponibles

Supply Chain Management Inventory Control Supply Chain Management Inventory Control Inventory System Inventory is the stock

of any item or resource used in an organization and can include: raw materials, finished products, component parts, supplies, and work-in-process An inventory system is the set of policies and controls that monitor levels of inventory and determines what levels should be maintained, when stock should be replenished, and how large orders should be Types of Inventory RawmaterialRaw material PurchasedbutnotprocessedPurchased but not processed WorkWork--inin--processprocess UndergonesomechangebutnotcompletedUndergone some change but not completed AfunctionofcycletimeforaproductA function of cycle time for a product Maintenance/repair/operating(MRO)Maintenance/repair/operating (MRO) NecessarytokeepmachineryandprocessesNecessary to keep machinery and processes productiveproductive FinishedgoodsFinished goods CompletedproductawaitingshipmentCompleted product awaiting shipment OBJECTIVES . Inventory System Defined . Types of Inventory . Independent vs. Dependent Demand . Inventory System Models . Multi-Period Inventory Models: Basic Fixed-Order Quantity Models . Inventory Costs . Multi-Period Inventory Models: Basic Fixed-Time Period Model . Single-Period Inventory Model . Miscellaneous Systems and Issues Inventory One of the most expensive assets of many companies representing as much as 50% of total invested capital

Inventory managers must balance inventory investment and customer service Purposes of Inventory 1. To maintain independence of operations 2. To meet variation in product demand 3. To allow flexibility in production scheduling 4. To provide a safeguard for variation in raw material delivery time 5. To take advantage of economic purchaseorder size

Types of Inventory-2 . Cycle Inventory . Safety Stock Inventory . Anticipatory Inventory . Pipeline Inventory Cycle Inventory . Inventory that varies directly with lot size. . Lot size varies with elapsed time between orders. . The quantity ordered must meet the demand during the ordering period. . Long gaps in the ordering period will require larger cycle inventory. . The inventory may vary between order size Q to zero just before the new lot is delivered. . Average inventory size is therefore Q/2 Safety Stock Inventory . Safety stock inventory protects against uncertainties in demand, lead time, and supply. . It ensures that operations are not disrupted when problems occur. . To build safety stock an order is placed earlier than the item is needed or the ordered quantity is larger than the quantity required till the next delivery schedule. Anticipation Inventory . Inventory used to absorb uneven rate of demand or supply . Predictable seasonal demand pattern may justify anticipation inventory. . Uneven demand often makes the firm to stockpile during low production demand to make better use of production facilities and avoid varying output rates and labor force. . Uncertainties such as threatened strikes, problem at suppliers facilities etc also justify

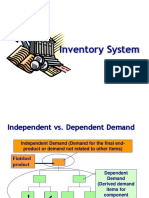

anticipation inventory. Inventory moving from point to point in the material flow system is called pipeline inventory -from suppliers to plant, from one operation to the next in processing, from plant to distribution center and from distribution center to retailer Pipeline Inventory between two points, can be expressed in terms of lead time and average demand (d) during the lead time (L). Pipeline Inventory = dL Pipeline Inventory Independent vs. Dependent Demand Independent Demand (Demand for the final endproduct or demand not related to other items) Dependent Demand (Derived demand items for component parts, subassemblies, raw materials, etc) Finished product Component parts

Inventory Systems Models Inventory Models for --Multi-Period Inventory Models -Fixed-Order Quantity Models Event triggered (Example: running out of stock) -Fixed-Time Period Models Time triggered (Example: Monthly sales call by sales representative) Single-Period Inventory Models -One time purchasing decision (Example: vendor selling t-shirts at a football game) -Seeks to balance the costs of inventory overstock and under stock Independent Demand Need to determine when and how much to order . Basic economic order quantity . Production order quantity . Quantity discount model Holding Costs H HHo oou uus ssi iin nng gg c cco oos sst tts ss ( ((i

iin nnc ccl llu uud ddi iin nng gg r rre een nnt tt o oor rr d dde eep ppr rre eec cci iia aat tti iio oon nn, ,, o oop ppe eer rra aat tti iin nng gg c cco oos sst tts ss, ,, t tta aax xxe ees ss, ,, i iin nns ssu uur rra aan nnc cce ee) ))

M MMa aat tte eer rri iia aal ll h hha aan nnd ddl lli iin nng gg c cco oos sst tts ss ( ((e eeq qqu uui iip ppm mme een nnt tt l lle eea aas sse ee o oor rr d dde eep ppr rre eec cci iia aat tti iio oon nn, ,, p ppo oow wwe eer rr, ,, o

oop ppe eer rra aat tti iin nng gg c cco oos sst tt) )) L LLa aab bbo oor rr c cco oos sst tt I IIn nnv vve ees sst ttm mme een nnt tt c cco oos sst tts ss ( ((b bbo oor rrr rro oow wwi iin nng gg c cco oos sst tts ss, ,, t tta aax

xxe ees ss, ,, a aan nnd dd i iin nns ssu uur rra aan nnc cce ee o oon nn i iin nnv vve een nnt tto oor rry yy) )) P PPi iil llf ffe eer rra aag gge ee, ,, s ssp ppa aac cce ee, ,, a aan nnd dd o oob bbs sso ool lle ees ssc cce een nnc

cce ee Multi-Period Models: Fixed-Order Quantity Model Model Assumptions (Contd.) . Inventory holding cost is based on average inventory . Ordering or setup costs are constant . All demands for the product will be satisfied (No backorders are allowed) Holding, Ordering, and Setup Costs . Holding costs -the costs of holding or carrying inventory over time . Ordering costs -the costs of placing an order and receiving goods . Setup costs -cost to prepare a machine or process for manufacturing an order Multi-Period Models: Fixed-Order Quantity Model Assumptions . Demand for the product is constant and uniform throughout the period . Lead time (time from ordering to receipt) is constant . Price per unit of product is constant

Basic Fixed-Order Quantity Model and Reorder Point Behavior R = Reorder point Q = [Economic] order quantity L = Lead time L L Q QQ R Time Number of units on hand 1. You receive an order quantity Q. 2. You start using them up over time. 3. When you reach down to a level of inventory of R, you place your next Q sized order. 4. The cycle then repeats. Cost Minimization Goal Ordering Costs Holding Costs Order Quantity (Q) C O S T Annual Cost of Items (DC) Total Cost QOPT By adding the item, holding, and ordering costs together, we determine the total cost curve, which in turn is used to find the Qopt inventory order point that minimizes total costs The EOQ Model QQ =Numberofpiecesperorder= Number of pieces per order Q*Q* =Optimalnumberofpiecesperorder(EOQ)= Optimal number of pieces per order (EO Q) DD =AnnualdemandinunitsfortheInventoryitem= Annual demand in units for the Inven tory item SS =Setupororderingcostforeachorder= Setup or ordering cost for each order HH =Holdingorcarryingcostperunitperyear= Holding or carrying cost per unit per y ear AnnualsetupcostAnnual setup cost == ((NumberofordersplacedperyearNumber of order s placed per year)) x(x (SetuporordercostperorderSetup or order cost per order)) AnnualdemandAnnual demand NumberofunitsineachorderNumber of units in each order SetupororderSetup or order costperordercost per order == =(= (SS))DD QQ Annual setup cost = S D Q The EOQ Model

QQ =Numberofpiecesperorder= Number of pieces per order Q*Q* =Optimalnumberofpiecesperorder(EOQ)= Optimal number of pieces per order (EO Q) DD =AnnualdemandinunitsfortheInventoryitem= Annual demand in units for the Inven tory item SS =Setupororderingcostforeachorder= Setup or ordering cost for each order HH =Holdingorcarryingcostperunitperyear= Holding or carrying cost per unit per y ear AnnualholdingcostAnnual holding cost == ((AverageinventorylevelAverage inventory level)) x(x (HoldingcostperunitperyearHolding cost per unit per year)) OrderquantityOrder quantity 22 =(= (HoldingcostperunitperyearHolding cost per unit per year)) =(= (HH))QQ 22 Annual setup cost = S D Q Annual holding cost = HQ 2 The EOQ Model Q = Number of pieces per order Q* = Optimal number of pieces per order (EOQ) D = Annual demand in units for the Inventory item S = Setup or ordering cost for each order H = Holding or carrying cost per unit per year Optimal order quantity is found when annual setup cost equals annual holding cost Annual setup cost = S D Q Annual holding cost = HQ 2 DD QQ SS == HHQQ 22 SolvingforQ*Solving for Q* 2DS = Q2H Q2 = 2DS/H Q* = 2DS/H Basic Fixed-Order Quantity (EOQ) Model Formula H 2 Q +S Q D +DC=TC Total Annual = Cost Annual Purchase Cost Annual Ordering Cost

Annual Holding Cost + + = = = = = = = = TC=Total annual cost D =Demand C =Cost per unit Q =Order quantity S =Cost of placing an order or setup cost R =Reorder point L =Lead time H=Annual holding and storage cost per unit of inventory

Deriving the EOQ Deriving the EOQ The Economic Ordering Quantity (EOQ) = =Q = 2DS H = 2(Annual Demand)(Order or Setup Cost) Annual Holding CostOPT = _ Reorder point, R = d L _ d = average daily demand (constant) L = Lead time (constant) _ We also need a reorder point to tell us when to place an order EOQ Example-1 Determine optimal number of units to order D = 1,000 units S = $10 per order H = $.50 per unit per year == == === = EOQ Example-1a Determine expected number of orders if: D = 1,000 units Q* = 200 units S = $10 per order H = $.50 per unit per year = === == = == = === == EOQ Example-1b Determinetimebetweenordersif:Determine time between orders if: DD =1,000= 1,000 unitsQ*units Q*=200= 200 unitsunits SS =$10= $10 perorderNper order N=5= 5 ordersperyearorders per year HH =$.50= $.50 perunit/yrworkingdays=250days/yrper unit/yr working days= 250 day s/yr === = === = EOQ Example-1c D DDe eet tte eer rrm mmi

iin nne ee c cca aar rrr rry yyi iin nng gg c cco oos sst tt i iif ff: :: D DD = == 1 11, ,,0 000 000 00 u uun nni iit tts ss Q QQ* ** = == 2 220 000 00 u uun nni iit tts ss S SS = == $ $$1 110 00 p ppe eer rr o oor rrd dde eer rr N NN = ==5 55 o oor

rrd dde eer rrs ss p ppe eer rr y yye eea aar rr H HH = == $ $$. ..5 550 00 p ppe eer rr u uun nni iit tt p ppe eer rr y yye eea aar rr T TT = == 5 550 00 d dda aay yys ss T TTo oot tta aal ll c cca aar rrr rry yyi iin nng gg c cco oos sst tt =

== S SSe eet ttu uup pp c cco oos sst tt + ++ H HHo ool lld ddi iin nng gg c cco oos sst tt = == = == = == = === ==

Price-Break Model Formula or Quantity Discount Model Based on the same assumptions as the EOQ model, the price-break model has a similar Qopt formula: Quantity Discount Model or Price-Break Model Annual Holding Cost 2(Annual Demand)(Or der or Setup Cost) = iC 2DS =QOPT i = percentage of unit cost attributed to carrying inventory C = cost per unit Since C changes for each price-break, the formula above will have to be used with each price-break cost value Price-Break Example-2 Problem Data (Part 1) A company has a chance to reduce their inventory ordering costs by placing larger quantity orders using the price-break order quantity schedule below. What should their optimal order quantity be if this company purchases this single inventory item with an e-mail ordering cost of $4, a carrying cost rate of 2% of the inventory cost of the item, and an annual demand of 10,000 units? Price-Break Example-2 Solution (Part 2) units 1,826 = 0.02(1.20) 4) 2(10,000)( = iC 2DS =Q OPT Annual Demand (D)= 10,000 units Cost to place an order (S)= $4 First, plug data into formula for each price-break value of units 2,000 = 0.02(1.00) 4) 2(10,000)( = iC 2DS =Q OPT units 2,020 = 0.02(0.98) 4) 2(10,000)( = iC 2DS =Q OPT Carrying cost % of total cost (i)= 2%

Cost per unit (C) = $1.20, $1.00, $0.98 Interval from 0 to 2499, the Qopt value is feasible Interval from 2500-3999, the Qopt value is not feasible Interval from 4000 & more, the Qopt value is not feasible Next, determine if the computed Qopt values are feasible or not Order Quantity units) Price/unit($) 0 to 2,499 $1.20 2,500 to 3,999 $1.00 4,000 or more $0.98 Price-Break Example -3 Solution (Part 3) Since the feasible solution occurred in the first pricebreak, it means that all the other true Qopt values occur at the beginnings of each price-break interval. Why? Total annual costs So the candidates for the pricebreaks are 1826, 2500, and 4000 units Because the total annual cost function is a u shaped function Price-Break Example -3 Solution (Part 4) Next, we plug the true Qopt values into the total cost annual cost function to determine the total cost under each price-break iC 2 Q +S Q D +DC =TC -= = -= = TC(0-2499)=(10000*1.20)+(10000/1826)*4+(1826/2)(0.02*1.20) = $12,043.82 TC(2500-3999)= $10,041 TC(4000&more)= $9,849.20 Finally, we select the least costly Qopt, which is this problem occurs in the 4000 & more interval. In summary, our optimal order quantity is 4000 units 0 1826 2500 4000 Order Quantity

Price-Break Example -3 Solution (Part 5) Price-Break Example -3 Solution (Part 5 ) How Important is the Item? Segmentation of Inventory -Not all inventory is created equally -Different classes of inventory -Result in different levels of profitability /revenue -Have different demand patterns and magnitudes -Require different control policies ABC Analysis Commonly used in practice Classify items by revenue or value Combination of usage, sales price, etc. ABC Analysis Identify the items that management should spend time on Prioritize items by their value to firm Create logical groupings Adjust as needed ABC Analysis Miscellaneous Systems and Issues ABC Analysis . What is different between the classes? A Items Very few high impact items are included Require the most managerial attention and review Expect many exceptions to be made B Items Many moderate impact items (sometimes most) Automated control w/ management by exception Rules can be used for A (but usually too many exceptions) C Items Many if not most of the items that make up minor impact Control systems should be as simple as possible Reduce wasted management time and attention Group into common regions, suppliers, end users . But these are arbitrary classifications

Miscellaneous Systems: Bin Systems Two-Bin System Full Empty Order One Bin of Inventory One-Bin System Periodic Check Order Enough to Refill Bin Miscellaneous Systems: Optional Replenishment System M Actual Inventory Level, I q = M -I I Q = minimum acceptable order quantity If q > Q, order q, otherwise do not order any. Miscellaneous Systems: Bin Systems Two-Bin System Full Empty Order One Bin of Inventory One-Bin System Periodic Check Order Enough to Refill Bin Miscellaneous Systems: Optional Replenishment System M Actual Inventory Level, I q = M -I I Q = minimum acceptable order quantity If q > Q, order q, otherwise do not order any. Inventory Accuracy and Cycle Counting Inventory accuracy refers to how well the inventory records agree with physical count Cycle Counting is a physical inventory-taking technique in which inventory is counted on a frequent basis rather than once or twice a year Supply Chain Management Inventory Control Safety Stock, Fixed Period Model and Single Period Model Question On average, I sell 150,000 units a year, which I obtain from a wholesaler. I estimate that the cost to me of placing an order is $50 with the average inventory storage cost being 20% per year of the cost of a unit ($5). 1.

What would be the optimal order quantity? 2. I currently order 5 times a year. How much would I save by switching to the optimal order quantity as compared with my current policy of ordering 5 times a year? Planned Shortages with Back-Orders . Shortage: when customer be met . Planned shortages could Cost of keeping item is the profit from selling demand cannot be beneficial more expensive than it e.g. car

Uncertain Demand Uncertain Demand Uncertain Demand-Safety Stock . Buffer added to on hand inventory during lead time . Extra reserved stock . To prevent stock-out under uncertain demand . Safety stock will not normally be used, but it is available under uncertain demand How much safety stock should we hold? Judgment on service level Reorder Level Reorder Level (ROL) = LT x D Reorder Level (ROL) = (LT x D) + Safety Stock Safety Stock Service Level . A target for the proportion of demand that is met directly from stock . The maximum acceptable probability that a demand can be met from the stock . For example 90% service level 90% chance of meeting demand during lead time or 10% chance of not meeting demand (having backorder or lost sales) Probabilistic Models . So far we assumed that demand is constant and uniform. . However, In Probabilistic models, demand is specified as a probability distribution. . Uncertain demand raises the possibility of a stock out (or shortage). Probabilistic Models . One method of reducing stock outs is to hold extra inventory (called Safety Stock). . In this case, we change the ROP formula to include that safety stock (ss).

Safety Stock Example . ROP = 50 units Stock-out cost = $40 per unit . Orders per year =6 Carrying cost = $5 per unit per year Number of Units Probability 30 0.2 40 0.2 ROP 50 0.3 60 0.2 70 0.1 1.0 Example of Probability Curve Demand (No. of Buns): 400 500 600 700 800 900 1000 Probability of Demand 0.05 0.1 0.2 0.3 0.2 0.1 0.05 Safety Stock Example . ROP = 50 units Stock-out cost = $40 per unit . Orders per year =6 Carrying cost = $5 per unit per year A safety stock of 20 units gives the lowest total cost ROP = 50 +20 =70 units Example Probabilistic Demand

Reorder Point for a Service Level Using the Standard Normal Probability Table Reorder Point for a Service Level Using the Standard Normal Probability Table Using the Standard Normal Probability Table = Probabilistic Demand Demand is variable and lead time is constant . Safety stock, SS: = Z standard deviation of lead time =Z s LT =Z dlt . Reorder level: ROL = lead time demand + safety stock = LT D +Z s LT . where s = standard deviation of demand per day and . dlt = s LT Standard deviation of demand during lead time Probabilistic Demand 1. If mean demand L and variation over the lead time, dlt are known you can use this equation . where X = ROP or ROL 2) If daily demand, daily, d, daily variation, s and lead time LT is known . ROP(ROL) = lead time demand + safety stock =(LTd)+ (Z s LT)

. Safety stock, SS: = Z standard deviation of lead time =Z s LT . where s = standard deviation of demand per day and Z X -

= L

dlt . dlt = s LT Standard deviation of demand during lead time . =L*d Lt

Example-3: Safety Stock Mean daily demand, D =500 gm/day Lead Time, LT = 7days Standard deviation, = 50 gm/day Service level required = 98% or 0.98 From normal distribution level Z is determined as z =2.05 ROL = (LT D)+ z LT = (500 x 7)+ 2.05 * 50 * 7 = 3771 gm Safety Stock = z LT = 2.05 * 50 * 7 = 271 gm Example-3: Safety Stock Mean daily demand, D =500 gm/day Lead Time, LT = 7days Standard deviation, = 50 gm/day Service level required = 98% or 0.98 From normal distribution level Z is determined as z =2.05 ROL = (LT D)+ z LT = (500 x 7)+ 2.05 * 50 * 7 = 3771 gm Safety Stock = z LT = 2.05 * 50 * 7 = 271 gm Supply Chain Management Maximum Inventory Level, M Periodic Review System M Actual Inventory Level, I q = M -I I Example-3: Safety Stock . Daily usage at a drug store follows a normal distribution with a mean of 500 gm and a standard deviation of 50 gm. If the lead time for procurement is 7 days and the drug store wants a risk of only 2% determine a) reorder point and b) safety stock necessary

Example: Safety Stock using Z-Score . Mean Demand in lead period, L =3500 gm . Standard deviation, s = 50 gm/day . L= v Lt= 50 7 gm . Z= 2.05 from Table X -

Z = L s L where X is a normal random variable . X=3771gm . Safety stock = 3771 gm-3500 gm =271 gm Inventory Control Periodic Review System P-System: Periodic Review System . In this system, costs are not explicitly considered and order quantity is not fixed. . Time is taken into account and given more emphasis . Inventory is periodically reviewed at fixed intervals and any difference between the present and the last review is made up by replenishment order. . The order quantity is thus equal to replenishment level minus actual inventory on hand.

P-System: Periodic Review System-2 In this system, we are interested in actual and average consumption over a period of time i.e. time between two reviews and lead time. Order quantity can be computed as follows: If L< R then Q= M -I If L> R then Q= M I -Q ord Where L= Lead Time R = Review Period M= Replenishment Level in Units I = Inventory on hand in Units Q =Quantity to be Ordered Qord= Quantity on order (in pipeline) Example: Fixed Period Inventory Control System (P-System) The average monthly consumption of an item is 40 units, Safety Stock is 20 units, review time is 1 month and lead time is 15 days, calculate replenishment level M Safety Stock=B R Replen. Lvl. = M LT 20 40 60 1 2 3 Example-Solution: P-System L<R Replenishment Level, M = Safety Stock (B)+ consumption, D* (Review Time+ Lead Time) M= 20+ 40(1+0.5) = 80 Units Inventory on Hand, I = B + consumption/2 I = 20+ 40/2 = 40 units The Order Quantity, Q = M I Q= 80-40 = 40 Units Example 2: (P-System) Consider a case where Lead time > review time Buffer/safety stock= 50 units D= 100 units/month Review Time= 1 month L= 2 months M= replinsh. Lvl. = B +D (1+2) = 50+ 100*3 M= 350 Units I = B+D/2 = 50+50 = 100 units Order Qty Q= M I = 250 units If Qty already on order is 100 units (review after 1 mth) Q= M-I-Qord = 150 units Single-Period Inventory Model Decision under uncertainity & risk In inventory control, sometimes management has to take risk under uncertainity, though wanting to keep the risk factor to a minimum. How many World Cup shirts to produce, when the shirts will be of little or no value after the Cup.

How many suits to stock for Eid or Xmas season, profit margin is high but the leftover stock will probably be of no value Single-period inventory model Applies in these cases P-System: Periodic Review System-2 In this system, we are interested in actual and average consumption over a period of time i.e. time between two reviews and lead time. Order quantity can be computed as follows: If L< R then Q= M -I If L> R then Q= M I -Q ord Where L= Lead Time R = Review Period M= Replenishment Level in Units I = Inventory on hand in Units Q =Quantity to be Ordered Qord= Quantity on order (in pipeline) Example: Fixed Period Inventory Control System (P-System) The average monthly consumption of an item is 40 units, Safety Stock is 20 units, review time is 1 month and lead time is 15 days, calculate replenishment level M Safety Stock=B R Replen. Lvl. = M LT 20 40 60 1 2 3 Example-Solution: P-System L<R Replenishment Level, M = Safety Stock (B)+ consumption, D* (Review Time+ Lead Time) M= 20+ 40(1+0.5) = 80 Units Inventory on Hand, I = B + consumption/2 I = 20+ 40/2 = 40 units The Order Quantity, Q = M I Q= 80-40 = 40 Units Example 2: (P-System) Consider a case where Lead time > review time Buffer/safety stock= 50 units D= 100 units/month Review Time= 1 month L= 2 months M= replinsh. Lvl. = B +D (1+2) = 50+ 100*3 M= 350 Units I = B+D/2 = 50+50 = 100 units Order Qty Q= M I = 250 units If Qty already on order is 100 units (review after 1 mth) Q= M-I-Qord = 150 units Single-Period Inventory Model Decision under uncertainity & risk In inventory control, sometimes management has to take risk under uncertainity, though wanting to keep the risk

factor to a minimum. How many World Cup shirts to produce, when the shirts will be of little or no value after the Cup. How many suits to stock for Eid or Xmas season, profit margin is high but the leftover stock will probably be of no value Single-period inventory model Applies in these cases

Single-Period Inventory Model This model states that we should stock up to the point where incremental gain (IG) is equal to incremental loss (IL) = IG is the profit per item times the probability of selling x items IG= m. P(x) = IL is the cost per item times the probability that x items will not be sold IL= C. [1-P(x)]. Equating IG& IL and solving the equation we get: = = = m= margin of profit item P (x)= probability of selling the item C= Cost of the item =P(x) = C m+C Single-Period Inventory Model This model states that we should stock up to the point where incremental gain (IG) is equal to incremental loss (IL) = IG is the profit per item times the probability of selling x items IG= m. P(x) = IL is the cost per item times the probability that x items will not be sold IL= C. [1-P(x)]. Equating IG& IL and solving the equation we get: = = = m= margin of profit item P (x)= probability of selling the item C= Cost of the item =P(x) = C m+C Single Period Model Example-4 . Our college basketball team is playing in a tournament game this weekend. Based on our past experience we sell on average 2,400 shirts with a standard deviation of 350. We make $10 on every

shirt we sell at the game, but lose $5 on every shirt not sold. How many shirts should we make for the game? Cu = $10 and Co = $5; P = $10 / ($10 + $5) = .667 = .432 therefore we need 2,400 + .432(350) = 2,551 shirts Z.667 Single-Period Inventory Model uo u CC C P + This model states that we should continue to increase the size of the inventory so long as the probability of selling the last unit added is equal to or greater than the ratio of: Cu/Co+Cu Where : Co = Cost per unit of demand over estimated Cu = Cost per unit of demand under estimated P = Probability that the unit will be sold Example-5 (Solution) uo u CC C P + sold be unit will y that theProbabilitestimated under demand of unit per Cost C estimated over demand of unit per Cost C :Where u o === P Co = Rs 1.5 [(Cost) Loss if demand is overestimated] Cu = Rs 2.5 [(Cost) Profit Loss if demand is underestimated] P [2.5/(2.5+1.5)] P 0.625 Probability of meeting demand is 0.65 at 700 buns. The baker should make 700 buns. Example-6 . Ahmed Juices makes a variety of juices for on-thecounter sales. Ahmed uses ice, which he grates in making these drinks. Ice is supplied to Ahmed in large

blocks, each costing Rs 10. Ice blocks not used during a day gets wasted as the ice melts and cannot be used the next day. If Ahmed is short of ice blocks on any day, he buys them from elsewhere, but at a premium of Rs 5 per block. Each block of ice can be used for 20 glasses of juice. The probability distribution for the demand of ice blocks is as follows . What is the least cost stocking policy for Ahmed Juices? . x ice blocks: 20 21 22 23 24 25 26 27 28 . p Probability 0 0.05 0.10 0.20 0.25 0.20 0.15 0.05 0 The end

Vous aimerez peut-être aussi

- Invtemp 140909235749 Phpapp01Document92 pagesInvtemp 140909235749 Phpapp01Amit VermaPas encore d'évaluation

- Inventory Management 1 PDFDocument31 pagesInventory Management 1 PDFfew.fearlessPas encore d'évaluation

- Unit-3 (Industrial Management)Document48 pagesUnit-3 (Industrial Management)Ankur Agrawal0% (1)

- Inventory Management: Presented By: Apple MagpantayDocument31 pagesInventory Management: Presented By: Apple MagpantayRuth Ann DimalaluanPas encore d'évaluation

- Inventory & Risk PoolingDocument64 pagesInventory & Risk PoolingMohit GuptaPas encore d'évaluation

- Unit 3 Industrial ManagementDocument48 pagesUnit 3 Industrial ManagementImad AghilaPas encore d'évaluation

- Inventory ControlDocument35 pagesInventory ControlSyed Haseeb AhmadPas encore d'évaluation

- Lecture OutlineDocument55 pagesLecture OutlineShweta ChaudharyPas encore d'évaluation

- Inventory: Dr. Akhilesh TiwariDocument50 pagesInventory: Dr. Akhilesh TiwariAbhishek KumarPas encore d'évaluation

- Chapter 20 - PPT OutlineDocument5 pagesChapter 20 - PPT OutlineJanice TangPas encore d'évaluation

- Independent Demand SYSTEMS: Deterministic Model: by AnastasiaDocument40 pagesIndependent Demand SYSTEMS: Deterministic Model: by AnastasiaAraPas encore d'évaluation

- Chap.4 - Inventory Management Edited PDFDocument60 pagesChap.4 - Inventory Management Edited PDFadmasuPas encore d'évaluation

- Inventory ControlDocument26 pagesInventory ControlhajarawPas encore d'évaluation

- UNIT-3: Inventory ControlDocument48 pagesUNIT-3: Inventory Controlgau_1119Pas encore d'évaluation

- Inventory ControlDocument30 pagesInventory Controlchintu_thakkar9Pas encore d'évaluation

- JULY-DEC 2022 BTME 7 SEM V6 BTMEOE704E Notes BTMEOE704E OR UNIT VDocument12 pagesJULY-DEC 2022 BTME 7 SEM V6 BTMEOE704E Notes BTMEOE704E OR UNIT VAjay LoharPas encore d'évaluation

- Traditional Manufacturing EnvironmentDocument4 pagesTraditional Manufacturing EnvironmentJerome Francis Sadie MoralesPas encore d'évaluation

- L6 Inventory Management 1Document16 pagesL6 Inventory Management 1nikhilnegi1704Pas encore d'évaluation

- What Is Inventory?: Parts and Materials Available Capacity Human ResourcesDocument35 pagesWhat Is Inventory?: Parts and Materials Available Capacity Human ResourcesHaider ShadfanPas encore d'évaluation

- InventoryDocument46 pagesInventorySoumitra ChakrabortyPas encore d'évaluation

- Chapter 17. Inventory Control: Inventory Is The Stock of Any Item or Resource Used in AnDocument21 pagesChapter 17. Inventory Control: Inventory Is The Stock of Any Item or Resource Used in AnHassan SalamaPas encore d'évaluation

- Inventory ManagementDocument47 pagesInventory ManagementDhivaakar KrishnanPas encore d'évaluation

- Inventory Management: Bus Adm 370 - CHP 12 Inventory MGMTDocument7 pagesInventory Management: Bus Adm 370 - CHP 12 Inventory MGMTSidharth GoyalPas encore d'évaluation

- Inventory ModelDocument35 pagesInventory ModelPushpa Latha M100% (1)

- What Is InventoryDocument7 pagesWhat Is Inventorydeepmangal222Pas encore d'évaluation

- Inventory Control: Industrial Engineering and Management ME3L504Document14 pagesInventory Control: Industrial Engineering and Management ME3L504Sandeep KumarPas encore d'évaluation

- Material de Inventarios1Document13 pagesMaterial de Inventarios1wam30959Pas encore d'évaluation

- 8 Inventory SystemDocument48 pages8 Inventory SystemPollyPas encore d'évaluation

- Inventory Management-I PPT 16-18Document31 pagesInventory Management-I PPT 16-18Prateek KonvictedPas encore d'évaluation

- 8 Inventory SystemsDocument48 pages8 Inventory SystemsAngeline Nicole RegaladoPas encore d'évaluation

- Definition of InventoryDocument38 pagesDefinition of InventoryMH BappyPas encore d'évaluation

- EBTM365 Handout 08Document8 pagesEBTM365 Handout 08Nirav PatelPas encore d'évaluation

- Inventory ManagementDocument34 pagesInventory ManagementAshutosh KishanPas encore d'évaluation

- Inventory ManagementDocument27 pagesInventory ManagementNandini SuriPas encore d'évaluation

- The Role of Inventory The Role of Inventory: Product Product Supplies SuppliesDocument36 pagesThe Role of Inventory The Role of Inventory: Product Product Supplies SuppliesAjaib ZinabPas encore d'évaluation

- 05 Inventory ManagementDocument47 pages05 Inventory ManagementjackPas encore d'évaluation

- Economic Order QuantityDocument7 pagesEconomic Order QuantityShuvro RahmanPas encore d'évaluation

- IE305 CH 4 Inventory and Economic Order QuantityDocument52 pagesIE305 CH 4 Inventory and Economic Order Quantitymuhendis_8900100% (1)

- OM M8 Inventory Management HandoutDocument39 pagesOM M8 Inventory Management HandoutChandan SainiPas encore d'évaluation

- CH 15 Inventory ManagementDocument21 pagesCH 15 Inventory ManagementAshwin MishraPas encore d'évaluation

- Chap 5 Inventory and Inventory ControlDocument29 pagesChap 5 Inventory and Inventory Controlkira ENTERTAINMENTPas encore d'évaluation

- Inventory Control: Operations ManagementDocument43 pagesInventory Control: Operations ManagementRahul KhannaPas encore d'évaluation

- 05 Conversion CycleDocument24 pages05 Conversion CycleDillon Murphy100% (1)

- Inventory IIDocument37 pagesInventory IISuraj MishraPas encore d'évaluation

- Dependent Versus Independent Demand InventoryDocument2 pagesDependent Versus Independent Demand InventoryPrincessPeach09Pas encore d'évaluation

- InventoryDocument36 pagesInventorynidhi_friend1020032748Pas encore d'évaluation

- APICS Exam Notes - For BSCM PaperDocument19 pagesAPICS Exam Notes - For BSCM PaperPrashant KripalaniPas encore d'évaluation

- Lecture 3.1 Inventory ManagementDocument32 pagesLecture 3.1 Inventory ManagementMd. Mahbub KhanPas encore d'évaluation

- Cosc309 - Video Clip 04 - InventoryDocument57 pagesCosc309 - Video Clip 04 - InventoryOmar AustinPas encore d'évaluation

- 5 1 Inventory ManagementDocument42 pages5 1 Inventory Managementhrithima100% (13)

- Chapter-20 Inventory ManagementDocument20 pagesChapter-20 Inventory ManagementPooja SheoranPas encore d'évaluation

- ch05 PPTDocument23 pagesch05 PPThusnainttsPas encore d'évaluation

- Cycle InventoryDocument13 pagesCycle InventoryUmang ZehenPas encore d'évaluation

- Inventory Control: ©st. Paul's UniversityDocument8 pagesInventory Control: ©st. Paul's UniversityAkbar HossainPas encore d'évaluation

- 8 Managing of Economics of ScaleDocument38 pages8 Managing of Economics of ScaleDwita Permatasari100% (1)

- Introduction To Inventory ManagementDocument71 pagesIntroduction To Inventory ManagementJane LobPas encore d'évaluation

- Economic Order QuantityDocument14 pagesEconomic Order Quantitydhominic0% (1)

- Inventory ManagementDocument30 pagesInventory ManagementAbhayVarunKesharwaniPas encore d'évaluation

- Lesson 122014 ShortDocument20 pagesLesson 122014 ShortAbel PachecoPas encore d'évaluation

- Cost Management: A Case for Business Process Re-engineeringD'EverandCost Management: A Case for Business Process Re-engineeringPas encore d'évaluation

- Bonn BiscuitsDocument71 pagesBonn Biscuitssonabeta07Pas encore d'évaluation

- ResumeDocument3 pagesResumeDebabrata MohantyPas encore d'évaluation

- Chapter 7 - E - CommerceDocument19 pagesChapter 7 - E - CommerceNavin ChandrasekaranPas encore d'évaluation

- Intro ERP Using GBI Data Sheet SD en v3.0Document1 pageIntro ERP Using GBI Data Sheet SD en v3.0Spencer RobeniolPas encore d'évaluation

- Product Life CycleDocument9 pagesProduct Life CycleDeepti ChaudharyPas encore d'évaluation

- Kenya Lubes Market SegmentationDocument12 pagesKenya Lubes Market SegmentationJohn JohnsonPas encore d'évaluation

- LIFEBUOYDocument12 pagesLIFEBUOYBobyPas encore d'évaluation

- Service MarketingDocument36 pagesService MarketingDhara SharmaPas encore d'évaluation

- Chapter 11Document87 pagesChapter 11Sandeep PanPas encore d'évaluation

- A Case Study On Sudhir Telang Machinery Equipment CompanyDocument11 pagesA Case Study On Sudhir Telang Machinery Equipment CompanySoham Pradhan100% (1)

- Chopra4 PPT ch04Document23 pagesChopra4 PPT ch04Tia MejiaPas encore d'évaluation

- E-Commerce vs. Brick and Mortar RetailersDocument5 pagesE-Commerce vs. Brick and Mortar RetailerscontactrnPas encore d'évaluation

- Best Practices For Inventory ReductionDocument36 pagesBest Practices For Inventory ReductionSachin Panpatil50% (2)

- CH 5 RetailstrategyDocument0 pageCH 5 Retailstrategyreee1Pas encore d'évaluation

- Chapter 13Document108 pagesChapter 13Azhar HussainPas encore d'évaluation

- Strategic Management ProjectDocument28 pagesStrategic Management Projectmirandacarolin50% (2)

- Vishal Mega Mart Final ReportDocument21 pagesVishal Mega Mart Final ReportGaurav SrivastavaPas encore d'évaluation

- MSMDDocument27 pagesMSMDvidvenkePas encore d'évaluation

- Retail MarketingDocument15 pagesRetail MarketingVishwajeet KadamPas encore d'évaluation

- Barilla Spa CaseDocument21 pagesBarilla Spa CaseMichael Pashos100% (4)

- ROQDocument8 pagesROQnazirsayyedPas encore d'évaluation

- Chapter 4 Material Requirements PlanningDocument8 pagesChapter 4 Material Requirements PlanningKamble AbhijitPas encore d'évaluation

- Heizer Om10 ch14-rDocument64 pagesHeizer Om10 ch14-rArnab GhoshPas encore d'évaluation

- CarrefourDocument33 pagesCarrefourBinoj V JanardhananPas encore d'évaluation

- Dissertation ReportDocument61 pagesDissertation ReportGeetanshi AgarwalPas encore d'évaluation

- Ch03 - The Environments of Marketing ChannelsDocument25 pagesCh03 - The Environments of Marketing ChannelsRaja Muaz67% (3)

- Berman CH 01 11eDocument30 pagesBerman CH 01 11eKumarinah WatininPas encore d'évaluation

- Mother Dairy - TanviDocument52 pagesMother Dairy - TanviTanvi Nahar60% (5)

- E ProcurementDocument40 pagesE ProcurementSanjay MishraPas encore d'évaluation

- CH 08Document52 pagesCH 08Cyrus Zack100% (5)