Académique Documents

Professionnel Documents

Culture Documents

00 - Full Report

Transféré par

Mohammed ChimloDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

00 - Full Report

Transféré par

Mohammed ChimloDroits d'auteur :

Formats disponibles

HEF1000 Professional Skills Component

THE MILLAU VIADUCT

Geoffrey Kieme Gitau, 7432798 Peter Tadros, last name and student number Sarmad Iftikhan, 7432763 Mohammed Kassim Ali, 7433794

ABSTRACT

The Millau Viaduct is one of the greatest Civil Engineering projects in Europe. The main fascination towards this project is the fact that its very high above the ground and yet construction was finished within three and a half years only. Its a great money making machine for the construction company, EIFFAGE, who put their own money for construction under concession from the French governent. Its a great tourist attraction and thus promoting Millaus economy drastically. The Millau Viaduct sets new standards of bridge building, having; a steel deck being built away from the bridge, tallest piers in the world and pylons that are 700 tonnes each.

KEYWORDS

Cables, concrete, construction, cost, deck, Eiffage, Eiffel, loading, materials, Millau, piers, Pylons, road, steel, Viaduct.

INTRODUCTION

One of the biggest and most beautiful structural marvels ever to be conceived by mankind, connecting Europe and the Mediterranean, The Millau Viaduct, at 343m high is the tallest bridge in the world, so tall that it glides over the clouds.

Figure 1: Millau Viaduct over the clouds.

HEF1000 Professional Skills Component The Millau Viaduct (French: Le Viaduc de Millau) is a triumph of engineering, imagination and will. The initial rough design by a French architect was for the Bridge to have 9 piers; the insanity of the design led the French government to bring in a Mastermind. Lord Norman Foster, Britains most famous and finest architect. He instead designed the bridge with two less piers and thus for the bridge to touch the valley at seven points only. The structure coasted around 320 million euros, financed and constructed by the EIFFAGE group themselves under concession from the French government for 75 years. The EIFFAGE had to sell some of their offshore properties to assure a smooth and a steady construction of the Viaduct. Search for a beautiful yet durable structure led to the choice of a multi cable-stayed viaduct with lean piers and a very light deck. From the start, the construction team faced four daunting challenges: One; build the tallest piers in the world on a hilly land, two; put a thirty six thousand tonnes freeway on top of the piers, three; erect seven steel pylons each weighing seven hundred tonnes and four; they had to do this all hundreds of meters above ground, so high that you would still be looking up if you were standing on the Eiffel Tower. Construction on the Viaduct began on 10th October 2001 and was intended to take three years, but irregular weather conditions delayed the schedule. A revised schedule aimed for the bridge to be opened in January 2005. The viaduct was inaugurated by President Chirac on 14th December 2004 to open for traffic on 16th December, a few weeks ahead of schedule. Table 1: The important statistics on the Millau Viaduct (Janberg, N 2004) Statistics : The Millau Viaduct Bridge Total length of the roadway 2,460 m (8,071 ft) Number of piers 7 Height of the shortest pier: Pier 7 77 m (253 ft Height of the tallest pier: Pier 2 343 m (1,125 ft) Height of each Pylon 87 m (285 ft Number of shrouds 154 Average height of the roadway 270 m (886 ft) Thickness of the roadway 4.20 m (13 ft 9 in) Width of the roadway 32.05 m (105 ft 2 in) Total volume of concrete used 85,000 m (111,000 cubic yards) Total weight of the bridge 290,000 metric tons (320,000 short tons) Estimated daily traffic 10,00025,000 vehicles Horizontal radius of curvature of the road 20 km (12 mi) deck

DESIGN

The Viaduct 343m high to the top of the pylons is the biggest and the most beautiful civil engineering structure on the A75 motorway crossing the Tarn valley. The bridge also holds the title of the worlds longest multi-span cable stayed bridge with a total length of 2460m, slightly

The Millau Viaduct

HEF1000 Professional Skills Component curved in plan with radius of 20km and a constant upward slope 3% from north to south. Road Layout and deck section. (Steel Bridge, 2004),(Structurae),(50Detail.de).

Figure 2. Elevation view of the viaduct. Road Layout and deck section The cross section of the deck is a trapezoidal steel box girder. In the core centre there are two vertical rods 4m apart and 4.2m deep. As the structure and core are entirely made of steel it consists a mass of 36,000 metric tons (40,000 short tons), is 2,460m and 32m wide. It comprises eight spans. The two of them are 240m and the other six are 342m. These spans are composed of 173 central box beams. The central beams have a 4m cross-section and a length of 15-22m (49-72ft) for a weight of 99 tons. In strong wind conditions, the deck has an air foil shape providing negative lift. (Steel Bridge, 2004),(Art of Design).(Enerpac)

Figure3. Functional cross-sectional of the deck. Pylons The seven masts, each 87 m (290 ft) high and weighing around 700 metric tons (770 short tons), are set on top of the pylons. Between each of them, eleven stays (metal cables) are anchored, providing support for the road deck. (Steel bridge, 2004).

HEF1000 Professional Skills Component

Figure 4. Elevation and cross-section of pier and pylon. Cables Each span is arranged in a single plane in half-fan pattern supported by eleven pair of cables. Depending on their length, the stays were made of 55 to 91 high tensile steel cables, or strands, formed of seven strands of steel. Each strand has triple protection galvanization. The idea is to avoid running water which, in high winds, could cause vibration in the stays and compromise the stability of the viaduct. (Steel bridge, 2004).

Figure 5. General view of the cables. The materials The pylons and the deck, entirely made of metal, are made of steels of grade S460 and S355. B60 concrete is used to construct the piers. This concrete was chosen due to its strength, durability and high mechanical resistance. (Steel bridge, 2004).

The Millau Viaduct

HEF1000 Professional Skills Component

CONSTRUCTION

Construction of such an enormous structure unsurprisingly came with a puzzle on how to actually pull of the design in the most economical manner. Its huge distance and the fact that it was way above the ground was the biggest concern. At such heights construction is almost impossible and weather change is a constant threat. The Piers The piers had to be brought up to support the bridge. The bridge was covering a distance of around 2500m, a single or two piers couldnt support weight the bridge, thus by careful calculations, seven piers were to be built. Each pier was treated as a separate worksite. A total of seven formwork systems were installed on the site. The concrete for the foundation of the piers and the latter was produced in nearby plants so as to reduce transportation costs and assuring the concrete is as fresh as possible. The foundation of the piers consisted of four bored piles ranging in depths of 9m to 16m. The foundation piles were then concealed after construction so as not to corrupt the look of the Viaduct.

Figure 6. Head Of A Pier The piers closest to struts were first initially erected so as for the launch of the deck to start while the remaining piers were being constructed. The formwork of the piers was a revolutionary self-climbing device using hydraulics; this significantly reducing the cost of the manual labour. Checks were made by GPS to ensure a precision of 5mm in both X and Y directions after an every four meter rise. The tallest piers built for the bridge are 245m and 223m high and these are the tallest piers ever built in the world to date. The top 90m of the piers are split into two so as to allow contraction and expansion due to weather changes and also to increase the visual beauty of the Viaduct. Temporary Piers 5

HEF1000 Professional Skills Component The deck of the Viaduct was launched by a hydraulic technology from ENERPAC, a US Multinational that specializes in large scale Hydraulic Systems. The hydraulic system was designed and built by Enerpacs Construction Centre of Excellence in Madrid, Spain. This system is designed to push the 27.35m wide deck from both sides onto the seven concrete piers. Temporary metal piers were placed to support the launching. The first of the seven temporsry piers was erected using cranes but the rest were raised using a hydraulic telescopic system also designed and built by Enerpac.

Figure 7. Overview of temporary and permanent piers. The Deck The deck was constructed of steel from the Eiffel Company. Steel parts were manufactured in the factory and then transported to the worksite. There they were welded together to create the skeleton of the deck and thus pushed along the piers. The state of the art deck is a two-lane dual highway with a 32.05m width.The deck of the Millau Viaduct consists of a trapezoidal profiles metal box girder with a maximum height of 4.2m at the axis with an upper orthotropic decking made up of 12-14mm thick on the greater part of the main spans (Steelbridge Article, June 2004). The Pylons Before the pylons were connected to the bridge, the whole deck was dramatically flexible as its made from steel. The Pylons and the cables were installed to pull the deck straight. Each pylon is 90m high and weighs 700tonnes. A technique used in ancient Egypt to erect odalisques in the sand. On top of the road deck two enormous steel cranes were installed capable of raising a 1000tonnes. Each pylon is then lifted, as it raises, it rotates little by little until its vertical, its then lowered safely into its anchorage point. Hydraulic Systems The enormous yet light deck was pushed by means of hydraulic devices on each pier which first lifted and then pushed the deck. Each system consists of a lifting cylinder with a capacity of 250 tonnes, lifting the deck of the supporting structure of the pier, and two or four skates, each

The Millau Viaduct

HEF1000 Professional Skills Component equipped with two 60 tons cylinders which retract to launch the deck at a maximum of 600mm. All this relies on a system of single-acting lock nut cylinders supporting both the launching process and the deck. Each push cycle moves the deck 600mm and takes 4 minutes.

Figure 8. Initial, Lifting, Launching, Lowering and Final Position of the hydraulic system. There were 24 support cylinders of 600 tonnes. Valves were used to make the cylinders independent of each other so as to control the height and the angle of the deck, each system having an independent control centre for the skates and the jacking cylinders. The Nose of the Deck As the deck is being pushed forward, naturally it curves downwards thus approaching the next deck below the suitable level. To control this problem, an independent nose recovery system is built at the end of the deck. This system consists of four 270 tons cylinders pulling the nose upwards to the level of the skate. Another hydraulic system allows the nose-end to pivot.

Figure 9. Nose of the deck at work The cylinders extend, pulling the spindle bar and raising the nose. The nose is blocked with respect to the column by means of the nuts and the cylinders are withdrawn. The cylinders 7

HEF1000 Professional Skills Component extend again, repeating the operation until the support area of the nose passes beyond the level of the balancing device. The Bridge is moved forward by operating the balancing device until the support area of the nose reaches the balancing device. The cylinders withdraw until the nose rests on the balancing device and finally the skate support device is withdrawn from the nose.

PROJECT MANAGEMENT

Millau Viaduct is the tallest bridge in the world with the height of 342m over the tarn valley connecting the small city of Millau in Paris to Bziers. Millau Viaduct is the longest cable bridge in the world with a total length of 2460m of steel deck.and also technically, known as A75, the last link of Clemont Ferrand-Bziers motorway (Buonomo, M, Servant, C, Virloguex, M, Cremer, J-M, Goyet, V, & Del Forno, J-Y 2004) Background of the Companies Involved Eiffage was formed in 1992, that is made up from several companies such as Fougerolle (founded in 1844), Quillery (founded in 1863), Beugnet (founded in 1871) and La Societe Auxiliaire d' Enterprises Electriques et de Travaux Public, better known as SAE (founded in 1924). Effage Company is one of France's top construction and civil engineering groups. During the 1980s the plan had been decided but it took ages to study a perfect way of construction, a least costing one and a durable design. Finally in 2001 the design of the bridge had been proposed which actually looks like the one that had been constructed.

Figure 10. The Completed Millau Viaduct The Eiffage Company proposed the idea to build the Millau Viaduct; it is the same company that constructed the Eiffel tower. The contract was to construct the bridge with a booth (Tallest booth in the world) that contains eighteen lanes and is six kilometres far from the bridge to the north side. The profit from the booth will belong to the company. The Eiffage Company chose a design that made them construct the bridge with 50% concrete and 50% steel. Meanwhile the Millau Viaduct was upright the tarn river; a steel deck that was used to make the road surface was a perfect choice in sense of weight and price. This gave them the chance to transfer less weight to the site as well as using less cable to handle the light weighted road.

The Millau Viaduct

HEF1000 Professional Skills Component Time Management The Eiffage Company had considered time as a big factor and that was one of the leading reasons in choosing to build a steel deck instead of a concrete oneSteel gave Eiffage the flexibility to start building the piers as well as the deck and thus saving time. On the other hand if they used concrete they had to build the piers first then get started with the deck. Building the Millau Viaduct had to be in an accurate way such as placing the piers and the exact location of the road surface. the global positioning system (GPS) has played a big role in positioning the piers. Hydraulic jack system was used to move and put them in place. And that was used for the piers matter. What hold the Millau viaduct is 7 piers that distance of 342m difference between each, except for the two end spans with 204m each. It took Effiage 38 months to accomplish the construction of the Millau Viaduct. The construction began on the October 10.2001 and was considered to be done in 3 years. But the weather conditions such as wind stress and others didnt allow the bridge to finish on time and therefore, a new schedule had been calculated, and the target was to inaugurate it on the January of 2005 . The viaduct was officially capitalized by President Chirac on December 14 2004 and opened to traffic on December 16 2004; a few weeks ahead of the revised schedule. Timeline 16 October 2001: work begins 14 December 2001: laying of the first stone January 2002: laying pier foundations March 2002: start of work on the pier support C8 June 2002: support C8 completed, start of work on piers July 2002: start of work on the foundations of temporary, height adjustable roadway supports August 2002: start of work on pier support C0 September 2002: assembly of roadway begins November 2002: first piers complete 2526 February 2003: laying of first pieces of roadway November 2003: completion of the last piers (Piers P2 at 245 m (804 ft) and P3 at 221 m (725 ft) are the highest piers in the world.) 28 May 2004: the pieces of roadway are several centimetres apart, their juncture to be accomplished within two weeks 2nd half of 2004: installation of the pylons and shrouds, removal of the temporary roadway supports 14 December 2004: official inauguration 16 December 2004: opening of the viaduct, ahead of schedule 10 January 2005: initial planned opening date Cost Management The Eiffage Company stated that constructing the bridge would approximately cost about 300 million .the Bridge users will provide the income for the company while the construction of the bridge amounted to around 394 million and extra 20 million for the toll plaza which was placed 6 km north of the bridge. For 75 years the income for the bridge will belong to the company which is till 2080 on the other hand if they achieved profit from the income, by 2044 the government will be taking over the bridge till 2044.

HEF1000 Professional Skills Component

Resource Management Materials. The design of the bridge has given several advantages, such as producing a quality of board and lightens for the structures, while during construction, decrease amount work on the site, they had builded a factory near the site to bond the steal segmented deck ,to reduce the volume and the amount of materials that will be needed and used on the site. Steel. The amount of steel that has been used in the site was 36,000 tons of metal frame, 7 times the Eiffel tower. Steel Wire Ropes. The steel cables had played a big role in the bridge, in such that it will be attached on the pillars and give the whole support to carry the weight of the pillar and the sides of the deck. They were sustained on the midway between in each pillar to handle it. This technique had been normally used thru bridge construction history, and it became a special use for those with a greater number of instalments, as in the case of the Millau viaduct.

Figure 11: Cables tensors steel. Concrete. The concrete was used to make the 7 piers that took amount of 205000 tonnes of B60 concrete, 40 times the Eiffel tower. Safety Barriers. The Millau viaduct is prepared with a safety barriers to tough to shocks for trucks, Transparent wind screens with the height of 3 m. the lighting ensures a perfect vision for the drivers.as well as placing a emergency telephones are placed every 400 m in case of accidents or breakdown. Engineers involved with this structure Designer - Michel Virlogeux - Overall concept Architect - Lord Norman Robert Foster Technical advisors to the owner: Jean-Claude Foucriat - Steel Jean Piccardi - Steel Franois Schlosser - Geotechnics Equipment/Machinery Enerpac Company was the company that supported the project with the hydraulic machines that helped to construct the bridge in faster and easier way. 10 The Millau Viaduct

HEF1000 Professional Skills Component There are two main parts for the of the telescopic system, a 12m base of a cubic structure which accommodate the whole system, the system equipped with toothed racks which are installed at its vertices in meters. The second is the lifting mechanism which consists of hydraulic cylinders and hydraulic control systems. The four vertices of the cube are used to place the hydraulic cylinders which are anchored to supports and linked to the tooth racks. The successive insertion of locking chocks in the toothed rack allows the pier structures and hydraulic machinery to be displaced in vertical directions. 1000mm lifting steps The process of operating the system is simple plain;using the chocks the cylinders are locked in the toohed rack which supports the cylinders while the sturucture of the pier is left alone.then oil is pumped into the cylinders by the operators who use a software which includes all the safety options.pumping the oil pumped produce a thrust against the structure of the pier by raising the rams.this raises the structure of the piers. The cylinders contains a stroke of 1100 mm and the toothed rack has cut every 1000mm , the extra 100mm is available to ensure for the possible unexpected circumstances.

MAINTENANCE

In summary Maintenance are all actions which have the objective of retaining or restoring an item in this case the Millau Viaduct bridge to a state which it can perform its required function. Maintenance Aspects in Design

Figure 12: Elevation of the Viaduct The viaduct comprises of seven concrete piers and steel pylons. The concrete used in the piers is B60 grade. This concrete was chosen more for its durability than for its high mechanical resistance (The Millau Viaduct official website, Eiffage). The top of the piers is split into two shafts, to allow for contraction and expansion effects due to temperature changes, and above where the pier splits, the concrete is pre-stressed using eight cables. The steel deck of the viaduct and pylons are made from S355 and S460 grade steel. These grades were chosen due to their high tensile strength; the maximum load that a material can support without fracture when being stretched, divided by the original cross-sectional area of the material (Foster & Partners Projects)

11

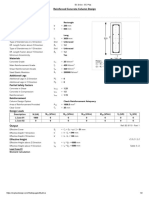

HEF1000 Professional Skills Component Usually cable stayed bridges have a set of cables called backstays which tie the pylons to the ground to transfer the load from the bridge. In contrast to this the Millau Viaduct does not have any backstays and all set of cables are anchored to the spans of the bridge deck itself. This means stresses and loading in each section are transferred to the adjacent sections and the pylons deflect towards the most heavily loaded span. In order to reduce the vertical movement in the deck the piers and pylons are fully fixed to the deck. This is achieved from the connection of four large spherical bearings on each pier. This also reduces the forces which are transferred to the adjacent spans. The piers and pylons were therefore designed to have high stiffness to allow for a more slender and flexible deck as shown in Figure 2 below

Figure 13; Cross section of the Millau Viaduct deck. Above the bearings there is a frame which continues up to the pylons providing further rigidity as shown below. The pylons have an overall height of 87m and consist of an A frame with legs 38m tall. The upper mast section is 49m high where the cables are anchored but the top 17m of the upper mast section provides no structural function (The Millau Viaduct official website, Effiage)

Figure 14: Pier, deck and pylon connection. Each pylon supports 11 pairs of steel cables which are arranged in a semi fan arrangement in a single plane with anchor points spaced equally on the deck 12.51m apart in the central

12

The Millau Viaduct

HEF1000 Professional Skills Component reservation following the curve of the bridge. This arrangement allows support from the cables along the majority of spans of the deck. Each cable consist of a collection between 45-91 1 T15 cable strands which have been protected by a white PEHD outer casing which has been equipped with a double helical weather strip to prevent water running down the cables reducing vibrations (Buonomo et al. June 2004). The tension in the stays is stated in (The Millau Viaduct official website, Eiffage) as being between 900 tonnes and 1200 tonnes therefore providing more rigidity. Beyond the deck the parapets are extended 2.2m away from the road and are 3m high see Fig 2. This is to discourage people from looking over the edge of the bridge and slowing down too much to take photos. The parapets are deigned to reduce the wind load by 50% (Caetano, E et al Flamand, O. et al. 2004) Maintenance aspects of Construction Materials The choice of materials to be used in construction determines the cost in maintaining a structure. In this case the material of choice is steel, so to therefore reduce the cost of maintenance the quality of steel to be used has to be tough and of good quality to avoid any unpredictable repercussions. Three main steel types are used to achieve this. 1. Thermo mechanically rolled steel which has high yield strength and retains good weld ability and high thickness without preheating. 2. Longitudinally profiled steel plates also known as variable thickness plates. This varying thickness is important since it prevents the bridge from collapsing through weight reduction, it also helps to lower the cost of fatigue, performance and number of welds to be used. 3. Weathering steel plates are low alloy steels coated with a protective layer that prevents damage due to atmospheric pressure, therefore reducing the cost of maintenance on repainting and increases the permanence of the structure (IBELL, T.2004) Durability. In the contract it was stated that the bridge had to be designed for a useful life of 120 years. This meant that all structural parts had to be long wearing. As previously mentioned grade B60 concrete was used and was chosen for its good durability properties. Each steel strand within the cables is protected by galvanization, a petroleum wax coating and an extruded polythene covering. On top of this, the collection of strands is protected from moisture and UV fatigue damage by a plastic outer casing. The deck has been designed to resist fatigue over time by using 14mm steel sheets on the upper decking which is then covered in 4mm of bitumen and sealed at 400c to protect it from the risk of corrosion. Serviceability. In order to monitor the viaduct over its life a network of accelerometers, anemometers, inclinometers and temperature sensors are fixed to the piers, deck pylons, and stays. This sends data to a central monitoring station where movements of the Viaduct are taken to measure creep, the components resistance to wear and tear over time and the responses of the structure in extreme wind conditions. The system can make measurements to high degrees of accuracy, especially in critical areas of the structure such as pier 2, the highest of the bridge. Another aspect of maintenance is constant inspection undertaken to ensure the performance of the bridge is safe. Throughout the inspection any damage of the bridge can be detected and repaired. Inspection is done in the following four ways; visual inspection, electromagnetic inspection, x-ray inspection and ultrasonic inspection. The last three are used to detect any

13

HEF1000 Professional Skills Component internal damages not visible to the human eye such a road crack, broken wires, abrasion and corrosion. Ultrasonic inspection is the most effective of the three as it can control the entrance of the cable into their elements and therefore any crack inside can be located.

SAFETY

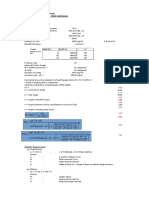

Loading Loading is critical to safety of the bridge as it gives one a true estimate of the loads and stress levels a bridge can withstand. So in the case of the viaduct although the bridge was designed to French standards, In this report the analysis the loading is using (BS 5400-2, 2006), the British standards for steel, concrete and composite bridges. The loads taken into account encompass dead loads, super imposed loads dead loads, live traffic loads, secondary live loading including skidding and impact loads, wind loads and temperature loads. Load combination and factors. Each load type is not considered individually, but in various combinations that provide the designers with worst case scenarios to check the adequacy of the bridge design. They are five load combinations. 1. Permanent loads plus the primary live loads 2. Combination 1 plus wind loading and temporary erection loads where erection is considered. Traffic loads can replaced by construction traffic loads 3. Combination 1 plus loads induced due to the changes in temperature plus temporary erection loads where considered. Traffic loads can be replaced by construction traffic loads. 4. Permanent loads plus secondary live loads and primary live loads associated with them. Secondary live loads are considered separately and do not have to be in combination. 5. Permanent loads plus loads due to friction at supports. 6. Dead loading and superimposed dead loading. As a collective, dead loads are referred to as permanent loads. The dead loads of the bridge deck refers to the steel box girder, plus the wind shields as these are always present and would never be removed. The pylons and cables could also be considered as dead loads after construction is finished, as they would not be removed. The super imposed dead loads are the deck surfacing, steel and concrete impact barriers, lighting hand rails and drainage fittings. All of this are not structural elements and could be potentially removed at various points through the bridges life. In order to calculate the nominal and design dead load one has to use the weight and span of the steel deck stated on the viaducts official website as 36,000 tonnes and 2460m respectively. From the same reference the thickness of the bitumen layer is given as 4mm with a density approximated to the same as asphalt of 2300 kg/m3. Its assumed the lower bitumen layer covers the whole deck surface up to the outer edge of the hard shoulder (total width of 27.8m) The total weight of the upper special bituminous concrete surface material over the whole deck is stated as 9500 tonnes (BS 5400-2, 2006) resulting into the following Tab le 2. Dead Loads

Load type Dead Nominal (KN/m) 146.3 SLS load KN/m 146.3 ULS load (KN/m) 169.98

14

The Millau Viaduct

HEF1000 Professional Skills Component

Super imposed dead; bitumen SID bituminous concrete Total super imposed dead 2.51 38.62 41.13 49.36 79.18

The above table shows that the dead loading due to steel is within the permissible stress levels of the steel grades used in the construction of the viaduct. Secondary live loading. This is a loading combination that is associated with traffic loads on the viaduct. Because the curve of the Millau Viaduct is greater than 1000m centrifugal loading can be ignored. Other loads considered are horizontal loading caused by braking of either HA vehicles (personal vehicles) or HB vehicles (PSVs) according to (BS5400 6.10) it is applied longitudinally at the road surface in one notional lane only. From the same reference the HA loading which has a nominal uniformly distributed load (UDL) of 8Kn/m of the loaded length of 2460m plus 750KN maximum over the width of the notional lane and loaded length. For HB loading it would be 450KN over two axles of the HB vehicle 1.8m apart. Secondary loading also considers accidental loading such as skidding and collision with the parapets, for skidding the loading is taken as a 250KN point load acting parallel to the surface but in any direction and in one notional lane only. Both the local and global effects due to loading from collision with parapets are covered under the sub topic Accidents and Vandalism. Wind loading and natural frequency. The location and height of the viaduct means it is exposed to high wind speeds, strong gusts and adverse funneling effects from the valley. Although the wind loading analysis in (BS5400 5.3) does take into account relevant variables such as topography factors and gust factors which could account for this. They can only be applied to bridges up to 200m long and up to 300m above sea level. Therefore the British standards would not be sufficient for a bridge as long and as high as the viaduct. The wind loading was a critical factor in the design of the bridge. Comprehensive wind tunnel studies mentioned in (Buonomo et al. June 2004) were undertaken to find the stresses and deflections of the structure under wind loading. Funneling and gusting due to the topography was also taken to account and the aerodynamics of each part of the structure was tested including the torsional effects on the deck. The actual aero foil shape of the deck; see Figure 2 was designed to reduce wind load effects and the parapets halve the wind load on the road. The transverse displacement under serviceability limit state design was calculated to be 0.6m and the vertical displacement under SLS was 0.75m as stated in (Buonomo et al. June 2004). The natural frequency of the bridge needed to be found as the light structure combined with high wind speeds could cause great acceleration and deflections of the bridge. Different dynamic tests were undertaken to analyse the natural frequency of the bridge including the installation of 21 accelerometers and 4 seismographs on the deck for the ambient vibration and free vibrations tests. Another method called the Polymax method identified 20 natural frequency modes in the range of 0.1Hz to 0.8Hz which are acceptable levels (Caetano, E et al Flamand, O. et al. 2004) Temperature Loading. They are two ways in which temperature variations causes stresses in the bridge, the first being expansion and contraction caused by changes in the effective temperature around the bridge. The effective temperature is the average found using the ratios of different 15

HEF1000 Professional Skills Component temperatures and cross sectional areas at different levels on the bridge. A maximum, minimum and overall effective temperature range can be found. The effective temperature range of the Mill au Viaduct is stated as being a maximum of 40c (The Millau Viaduct official website, Effiage), so the deflection can be calculated.

(1) So there can be approximately 0.6m movement at each end of the structure. This means the stress in the deck due to any possible restraint is (BS 5400-2, 2006).

(2) This is within the permissible stresses of the steel grades mentioned earlier. Because of the high rigidity of the piers and pylons and the fixed bearing connection to the deck, high stresses in some of the piers could occur due to temperature variations in the deck. During design this deflection was found to be above the resistance levels of the concrete in the two ends of the piers so the splitting of the section into two shafts was designed to accommodate for this. Similarly the bottom section of the metal pylons has been split into two shafts.

Figure 15. The split section design in the piers The other temperature effect is the stresses and bending induced in the deck from localized differences in temperature between the top and bottom of the deck. The average temperature for the Millau is 10.5c, which is within a safe range. Using British Standards the following graphs can be produced showing the temperature difference which arise in the steel deck (BS 5400-2, 2006)

16

The Millau Viaduct

HEF1000 Professional Skills Component

Figure 16. Deck temperature distribution graph. Loading used in Structural Assessment. The intensity of the live loading can be found and converted to a transverse UDL. This is then used in combination with the dead and superimposed dead loading mentioned above and converted to transverse UDLs to analyse the transverse bending moments in the deck. As there are 11 pairs of cables set 12.51m apart with the larger spans between the two central cables and the outer cables and pylons. The large spans are approximated to 30.6m so the maximum longitudinal length that a support would have to carry would be 30.6m (at the pylons)( BS 5400-2, 2006)

Figure 17. Longitudinally spacing of supports

Figure 18: Transverse loading arrangement with key

(3)

17

HEF1000 Professional Skills Component

Figure 19. Transverse bending moment diagram. This would not be the worst case scenario on the deck as the asymmetrical loading would create a torsion which is a particular problem on the Millau Viaduct due to the single plane of cable supports providing low torsional rigidity. The pylons and piers also lie within this plane which provides less torsional stiffness than if there were two pylons or an A or H frame arrangement. (BS 5400-2, 2006)

Figure 20. Torsional loading arrangement The torsional moments are reduced by the steel deck cross section which has high torsional rigidity provided by the box girder, steel cross bracing and trapezoidal deck shape. Accidents and Vandalism. The bridge must also be safe guarded against intentional damage. Because the viaduct is such a great landmark and symbol of pride for France, one could think that no one would want to damage it. However its possible some people will. If anyone were to try and damage the bridge by driving into the barriers, they have been designed to take high impact loads without doing damage to other parts of the bridge. Hypothetically if an aircraft were to hit the bridge, they would most likely be failure of the structure. During construction of the bridge deck could withstand the bending stresses associated with cantilevering from one of the piers, showing the super structure of the bridge could stay up if a section of the deck or pylon were to be damaged (Buonomo et al. June 2004)

SUSTAINIBILITY PRACTICES

One of the main purposes to build the Millau Viaduct was to avoid the traffic .the only way to make French people go the south cost was through long ways around the valley and drive in a very narrow area to avoid traffic and that takes a lot of time. Specialized engineers and ecologist had to design a way to decrease the damage that have done by the toxic pollution from the heavy traffic. The viaduct had successfully reduced the number of the traffic for the past years, especially in holidays season where the French usually spend in south cost. (Godfrain 2006)

18

The Millau Viaduct

HEF1000 Professional Skills Component The Eiffel Company have use special concrete known as b60 concrete by the engineers that will give the piers more durable comparing to high mechanical resistance. Millau Viduct deck is made by 100% steel and that makes it so light, recommended by buonomo et al. (2004),the piers that support the viaduct from The valley of the river tarn near Millau in southern France and its design that it just be supported with seven pillars passing through the valley. And that shows that viaduct is an environmental-friendly bridge. The valley of the river tarn near Millau in southern France Cable stayed to balance the weight of the metal long road surface so that the piers will support the roadbed which is also made of metal in the Millau viaduct. Eiffel Company had the idea to use multiple pillars of metal cable to help and support the load. The benefit behind using cable stayed is to reduce the longitudinal flexion of the redistributing effort via the stays as recommend by the Eiffel Company. The cable has uncountable spirals that involve eleven in each as the resolve to fight the combination effects of rain and wind which leads to vibration. (Infotua, April 2004). Building the Millau Viadtuct with steel was a magnificent idea, because practically all steel has the ability to weld together. The best part was Eiffel Company have done all the accumulated and painted in indoor workshop, which gave the quality and safety to workers who avoided welding all the parts together in this height.

Figure 21: The Millau Viaduct Moreover another major advantage of steel is that it could be recycled within a large amount. Secondly by using steel it made constructing the bridge with less stone aggregate and with less water. Thirdly and more important it has done in a very dry area with a gorgeous natural landscape. The idea of structure of the lightweight steel was to make it half the weight of structure of concrete, which helped to deliver few trucks loaded with material that is needed in the site, and that gave less fuel consumption and less pollution from exhaust emissions. Finally, the structure of the steel didnt require a heavy and amount of foundations, actually it took fewer pylons and cables to support it comparing if they used concrete structure .which gave a big benefit to reduce the total cost of the price of the project.

Risk assessment

19

HEF1000 Professional Skills Component As bridges are complex structures with a multitude of components and structural forms, a comprehensive management system is required. Risk assessment can be defined as the qualitative or quantitative value of risk related to a concrete situation and a known hazard. For the Millau Viaduct Bridge case, the main types of risk assessments are: Risk assessment in structural design The Millau Viaduct is a multi-span cable-stayed bridge. Having the multiple spans, there are no back stays as with most cable-stayed bridges to enable the pylons to have a rigid support. Due to the height of bridge, the pylons have a relatively low bending stiffness compared to the piers. Moreover, pylon have a bending moment caused by the cables, one leg of the pylon will experience tension and the other compression. These forces can be transferred to the ground by the split piers. By cables, the steel deck is set into compression. The pre-stressed concrete deck is used due to its good compressive strength and durability. However, it is mentioned that the deck is made of steel. A concrete deck is possible to crack under its own weight which may lead to problems during its service ability life time. Preventing such cracking during the launch would require pre-stressing the deck in advance using tendons and also completely arising the pylons and cables before launching; effectively pre-stressing the deck super structure. It was time consuming, thus was considered most efficient and effectual option. It was seen that the steel deck moved in a wavy form during the construction but did not create any lasting effect due to its high ductility. The single plane of cable stays introduces potential problems associated with torsion. Undesirable live loading on one side of the cables and no live loading on the other side will result in torsion. Using an 'A' shaped frame or other similar pier design fixed to the deck itself would provide torsion restraint limiting the torsion effects in between spans. (Steel Bridge, 2004).

Figure 22. deformed shape of Millau vVaduct. Risk assessment in public safety. In the case of the Millau viaduct bridge, risk assessment of public safety can be defined as the characterization of potential undesirable effects or results of human exposures to environmental hazards. Driving on the bridge itself can pose accidents to occur. Hence, safety measures are done before and after construction of the bridge as well as during the construction of the bridge. (Steel Bridge, 2004).

20

The Millau Viaduct

HEF1000 Professional Skills Component One of the safety measures includes provision of an emergency telephone every 400 meters on the bridge. Besides that, a 24-hour surveillance system incorporating such as video recording of traffic, weather stations and programmable message boards are installed. Some other safety measures are specially designed for safety barriers to resist truck impacts and wind-breaking screens to reduce the wind factor problem. This is because; the engineers and architects must also consider the disaster factor, for example, occurrence of storms and hurricanes etc. Risk of damages occurring is also present. If that happens, the authorities should consider the damages cost and repairing cost. (Steel Bridge, 2004)

Figure 23. Safety measures during construction.

SOCIAL IMPACTS

During the first eighteen months of construction, an estimation of more than five hundred thousand tourists visited the bridge under construction. According to Godfrain (2006), more than a million motorists have used The Millau Viaduct just for the sole purpose of admiring it.

Figure 24. The Millau Viaduct as a great tourists attraction. Impacts on Society Locals had expected the bridge to cut down their income as drivers will no longer pass by the town of Millau but contrarily more and more tourists, photographers, journalist kept pouring in. 21

HEF1000 Professional Skills Component More and more hotels, restaurants and shops have been built in Millau just to suit the needs of the travellers and thus increasing the economy of Millau. Jos Bov, a union leader who is France's leading opponent of globalization, organized the destruction of a McDonald's restaurant to protest the Americanization of France. Nevertheless, the McDonalds was rebuilt within few months and went on with business as usual. On a National Scale, the French government has started using the bridge as a selling tool for France. The Tour de France announced that its annual bicycle race will be routed under the bridge next year An Ad campaign by the French government intended to lure the foreign investments to France by using the Millau Viaduct as a symbol of modernity. The campaign concludes with the line, The new France, where the smart money goes. Undeniably, the bridge is a rare example of private money financing a project so dear to France. The construction of Millau Viaduct came to a total of approximately three hundred and twenty million euros, which was not provided by the government of France, instead by the Engineering company of the Viaduct, the company was not stable enough financially to afford the construction of The Viaduct, thus leading them to sell some of their offshore properties to raise money. However, this will be repaid by tolls over 75 years. It takes around six-seven dollars to cross the bridge for a normal car and around thirty one dollars for a truck and thus making this bridge a very profitable investment. The Millau Viaduct serves its purpose to relieve traffic congestion at Rhone Valley which connects Northern Europe with Spain and Portugal. It allows travellers to reach their destination quickly while enjoying the beautiful scenery at the same time. The Viaduct lessens the time taken to travel from Paris to Bziers up to three hours. Since the building of the Millau Viaduct, the traffic on The A75 Motorway has increased by more than 20%. Despite having various routes to choose from for tourists travelling from Northern to Southern France, majority choose the A75 Motorway Route as its the cheapest and the most beautiful. After the completion of The Millau Viaduct, more than one hundred and fifty construction workers and welders from The Millau Vidauct were employed by the EIFFAGE to work on other projects. Since the company is also managing the Bridge, it has employed people to work at the toll-gate and engineers perform maintenance on the Viaduct. This has led to a reduction of the unemployment rate from 10.2% to 9.1% (Republique Francais, n.d.). Environmental Impacts The Millau Viaduct has decreased air pollution dramatically. It only takes twenty minutes for vehicles to cross through The Viaduct compared to the initial three hours at Rhone Valley before the construction of Millau. The construction of the motorway has had positive ecological impacts as it clears the rainwater in clarification tanks before supplying it to the nearby countryside. The EIFFAGE company has employed Ecologists and Engineers to make sure that the Viaduct causes no harm to the environment.

22

The Millau Viaduct

HEF1000 Professional Skills Component

CONCLUSIONS

The Millau Viaduct is certainly an engineering success and pride of France. With seven piers only and a deck made up of hundred percent steel, it certainly revolutionized the concept of Bridge Designing and construction. Such a task was not easy to carry out but with expertise of Europes best Engineers the Viaduct was completed with no major accidents or fatalities within a staggering period of 38 months. Steel was used for the deck as it is lighter and less costly as compared to concrete. The Millau Viaduct has definitely promoted the economy of Millau drastically as its a major tourist attraction now in France. The bridge was opened in 16th December 2004, a few weeks ahead of its schedule. The bridge has provided various job opportunities for the locals; jobs for maintenance, toll attendants and security personnel. Imagine standing on top of the Eiffel tower and yet looking up at the Viaduct, a bridge that glides over the clouds and a bridge that glows in the dark. The Millau Viaduct is definitely an engineering marvel and sets new levels of bridge designing and construction.

REFERENCES

Amy Nutt, The Most Popular Buildings/bridges/structures Around The World, April, 2008. Andre Czlapka, EOS Magazine, Millau Viaduct at night, 24th September 2009. Buonomo, M. Servant, C. Virgoleux, M et al. June 2004, The design and construction of the Millau Viaduct, Steel Bridges extend structural limits, Steel bridge 2004, Millau, France. Bridge Pros, Millau Viaduct Project, http://bridgepros.com/projects/Millau_Viaduct/, visited 24th April 2011. BS-5400-2, 2006, Steel concrete and composite bridges part 2: specification for loads, London England. Bright hub, Millau Viaduct The Tallest Bridge in the World, http://www.brighthub.com/engineering/civil/articles/57785.aspx#ixzz1Ktg3EcfQ, visited 20th April 2011. Caetano, E, et al, Flamand, O. et al, comparison of stochastic identification methods applied to the natural response of the Millau viaduct, Faculty of Engineering of University of Porto, Portugal, Centre Scientifique et Technique du Batiment, Nantes, France Capita Simonds, Millau Viaduct Refinancing, http://www.capitasymonds.co.uk/projects/all_projects/millau_viaduct_re-financing.aspx, visited 20th April 2011. Chandler, R.F 2004, 'A Comparison of Conventional Concrete Joints and Engineered Cementitious Composite Link Slabs', Life-Cycle Cost Model for Evaluating the Sustainability of Bridge Decks. Daily mail UK, From the Millau Viaduct to the Pyramids Ten of the greatest feats of engineering, October 2010. Discovery Channel, Extreme Engineering, Season 2 Episode 18, the Millau Viaduct. EIB 2011, Project Finance Magazine applauds record number of EIB projects in 2007, http://www.eib.europa.eu/about/press/2008/2008-018-project-finance-magazine-applauds-record-number-of-eibprojects-in-2007.htm , visited 19th April 2011. Euro Traveller, Languedoc Roussillon in The South Of France - The Secret's Out, 2006. Foster & Partners projects, http://www.fosterandpartners.com/projects/1158/Default.aspx, visited 26th April 2011 Fotopedia, Millau Viaduct, http://www.fotopedia.com/wiki/Millau_Viaduct., visited 20th April 2011. Fredrick P. Vandome, et al, Agnes F. McBrewster, et al, John Miller (2009). Millau Viaduct. French entre Tarn & Aveyron, The Millau Viaduct - A World Recold Breaker. Godfrain, J 2006, The Millau Viaduct Larzacs Eiffel Tower, Seminar Entrepeneurs, towns and regions, Ecole de Paris du Management, Montparnasse, Paris. IBELL, T. Bridge Engineering Department of Architecture and civil Engineering University of Bath, Bath UK

23

HEF1000 Professional Skills Component

Icon eye Magazine, Millau Viaduct, March 2005. Infotua, April 2004, Thematic case study 2, Steel Civil Engineering Structures: Viaducts, bridges, footbridges, http://www.otua.org/pdf/dossier2_ponts_english.pdf, visited 20th April 2011 Julia Dubreuil, The Millau Viaduct Portfolio. Jonathan Glancey, Gurdian UK, Come fly with me, 16th November 2004 Legrand, M (2002) La concession du Millau Viaduct . PCM Dcembre 2002. National Geographic Mega Structures The Millau Bridge. NY Times, International, Europe, The Millau Viaduct, 17th December 2004 The Press, Pillars in the mist - the rise of the Millau Viaduct, 11th December 2004. Richard Green, The Sunday Times, Visiting The Millau Viaduct, 7th August 2009. Road traffic technology, Millau Viaduct, France, http://www.roadtraffictechnology.com/projects/millau_viaduct/, Visited 23rd April 2011. Steel Bridge, The design and the construction of the Millau Viaduct, 23rd June 2005. Steel Construction, Millau Viaduct: A Bridge Taller Than the Eiffel Tower, April 2005. Structure Mag, Frances Millau Orthotropic Steel Viaduct, October 2005. Suite 101, Western European Travel, The Dramatic Millau Viaduct In Southern France, September 2010. The Millau Viaduct, Eiffage, http://www./leviaducdemillau.com/english/index.html, visited 20th December 2011. The Telegraph, Sir Norman Foster's stunning motorway bridge never fails to elicit a chorus of 'wows', 25th February 2011. Viaduc de Millau, http://en.structurae.de/structures/data/index.cfm?id=s0000351, visited 19th April 2011.

24

The Millau Viaduct

Vous aimerez peut-être aussi

- Beca Carter Hollings & Ferner: Job Name: Job No Subject: Page No: BY: DateDocument2 pagesBeca Carter Hollings & Ferner: Job Name: Job No Subject: Page No: BY: DateSharyn PolleyPas encore d'évaluation

- Footing J17218 (Recovered)Document9 pagesFooting J17218 (Recovered)eco protectionPas encore d'évaluation

- Box CulvertDocument89 pagesBox CulvertTeguh Joko PamujiPas encore d'évaluation

- Ooo Ooo Oooooooooo Oooo Ooooooooo Oo OooDocument3 pagesOoo Ooo Oooooooooo Oooo Ooooooooo Oo Oootejaswini shahapurkarPas encore d'évaluation

- Structural Calculation Stability Analysis of Weir SidewallDocument8 pagesStructural Calculation Stability Analysis of Weir Sidewalltini100% (1)

- HPC Bridge Views SummaryDocument16 pagesHPC Bridge Views SummaryWaheed AhmadPas encore d'évaluation

- Kiriş KirişDocument26 pagesKiriş Kirişcaner_kurtoglu-1Pas encore d'évaluation

- CC Wall - EeDocument25 pagesCC Wall - Eemadhu sudhanPas encore d'évaluation

- College of Engineering: WWW - Ijce.ac - inDocument25 pagesCollege of Engineering: WWW - Ijce.ac - inThulasi Raman KowsiganPas encore d'évaluation

- Civil Structural CalculationsDocument2 pagesCivil Structural Calculations3d arch viewsPas encore d'évaluation

- Beam Ledge Supporting Steel BeamDocument2 pagesBeam Ledge Supporting Steel Beamfaizan ashiquePas encore d'évaluation

- Slab DesignDocument3 pagesSlab DesignMagdy BakryPas encore d'évaluation

- Isolated FootingsDocument30 pagesIsolated FootingsBanda 007Pas encore d'évaluation

- Geotechnical Investigation Kargil ProposalDocument71 pagesGeotechnical Investigation Kargil ProposalJack DoverPas encore d'évaluation

- Elements of Soil Mechanics, 8th Edition Example 7.2Document20 pagesElements of Soil Mechanics, 8th Edition Example 7.2SULUNGPas encore d'évaluation

- DESIGN-CBR Training MercuDocument6 pagesDESIGN-CBR Training MercuDani RamdaniPas encore d'évaluation

- Calculation Sheet: Section Properties: Longitudinal Section A L1 X Y (MM) (MM) Grillage MemberDocument30 pagesCalculation Sheet: Section Properties: Longitudinal Section A L1 X Y (MM) (MM) Grillage MemberJennifer HudsonPas encore d'évaluation

- Footing Design - Studio AoartmentDocument47 pagesFooting Design - Studio AoartmentMUKESH RAJENDRAPas encore d'évaluation

- Culvert Design 1Document66 pagesCulvert Design 1kanishkaPas encore d'évaluation

- Axial and Lateral Load Piles (Fem) 1.4Document61 pagesAxial and Lateral Load Piles (Fem) 1.4victorPas encore d'évaluation

- PCC Retaining Wall From Km. 0.000 To Km. 0.375) : B e B F PDocument3 pagesPCC Retaining Wall From Km. 0.000 To Km. 0.375) : B e B F PDasari ArunaPas encore d'évaluation

- Comb WalkayDocument37 pagesComb Walkayramesh_madkatte1082Pas encore d'évaluation

- Stilling Basin Training WallDocument7 pagesStilling Basin Training Wallsatyakam0601050Pas encore d'évaluation

- Ko (1-Sinø) : Reinforced Earth StructureDocument9 pagesKo (1-Sinø) : Reinforced Earth StructureAnonymous jLLjBdrPas encore d'évaluation

- Development of Maa Samleswari at Sambalpur Design of Slab - Pilgrim Facility Two Way SlabDocument2 pagesDevelopment of Maa Samleswari at Sambalpur Design of Slab - Pilgrim Facility Two Way Slabselvakumar sPas encore d'évaluation

- Sojitz-L&T Consortium: Safe Bearing Capacity CalculationDocument4 pagesSojitz-L&T Consortium: Safe Bearing Capacity Calculation906rahulPas encore d'évaluation

- Design Concrete Bridge (Quiz 1)Document11 pagesDesign Concrete Bridge (Quiz 1)Jamaica MarambaPas encore d'évaluation

- CRW 13MRDocument25 pagesCRW 13MRraghu kiranPas encore d'évaluation

- Hgiel 1129 Dve 9 HW 291+100 Fly DN 02Document189 pagesHgiel 1129 Dve 9 HW 291+100 Fly DN 02Chandan SharmaPas encore d'évaluation

- Gardez - Khost Bridge No. 5 I - GIRDER 0.600 X 1.450 X 25.700 MDocument5 pagesGardez - Khost Bridge No. 5 I - GIRDER 0.600 X 1.450 X 25.700 MBrian UrciaPas encore d'évaluation

- Feasibility Study and Construction of Two No Bridges at KM 23 & 27 On Ara Bigwani Road Dera Ismail KhanDocument10 pagesFeasibility Study and Construction of Two No Bridges at KM 23 & 27 On Ara Bigwani Road Dera Ismail KhanAziz ul HakeemPas encore d'évaluation

- TCC15 Resistance of Retaining MembersDocument9 pagesTCC15 Resistance of Retaining MembersMelinda GordonPas encore d'évaluation

- Examen - Zapata ConectadaDocument9 pagesExamen - Zapata ConectadaJesus CahuiPas encore d'évaluation

- Desain AbutmentDocument75 pagesDesain AbutmentLouce PatriciaPas encore d'évaluation

- Vertical Drain Rev 1.0Document32 pagesVertical Drain Rev 1.0Koko Putra AriadiPas encore d'évaluation

- Reinforcement of A Basement WallDocument8 pagesReinforcement of A Basement WallZein FarahPas encore d'évaluation

- Footing J1922018 v1Document15 pagesFooting J1922018 v1eco protectionPas encore d'évaluation

- Desain Kantilever WallDocument10 pagesDesain Kantilever WallFajar WahyuPas encore d'évaluation

- Slab Design 2 Way IsDocument3 pagesSlab Design 2 Way IsRam LanghePas encore d'évaluation

- 5-Jul-19 Beam - : Material Load FactorsDocument1 page5-Jul-19 Beam - : Material Load FactorsPhuc DaominhPas encore d'évaluation

- Loads: Dead Load of SuperstructureDocument4 pagesLoads: Dead Load of SuperstructureMuhammad HasanPas encore d'évaluation

- 4 - 9 Puente Viga Losa Phusca 8.00MDocument27 pages4 - 9 Puente Viga Losa Phusca 8.00MMirian JustoPas encore d'évaluation

- Case:: 12 Construction Stage Trans Seismic CaseDocument9 pagesCase:: 12 Construction Stage Trans Seismic CaseMadhurimaMitraPas encore d'évaluation

- Sheet Pile 2 Report r1Document10 pagesSheet Pile 2 Report r1jackcoolsPas encore d'évaluation

- Flood Wall PN KhannaDocument2 pagesFlood Wall PN KhannaSushmit SharmaPas encore d'évaluation

- Calculo EstriboDocument18 pagesCalculo EstriboJhoseph Gonzáles Ramírez100% (1)

- 2007 - 01 Sewer Installation by Pipejacking in The Urban Areas of Hong Kong Part IDocument14 pages2007 - 01 Sewer Installation by Pipejacking in The Urban Areas of Hong Kong Part IAldro SopiohPas encore d'évaluation

- Structural CalcsDocument48 pagesStructural CalcsNasir Ullah100% (1)

- M MM MM MM MM: A tfl-1 tfl-2 TDocument14 pagesM MM MM MM MM: A tfl-1 tfl-2 TAR SmackPas encore d'évaluation

- Description: Structure Design of Bridge: Project Title Mini ProjectDocument11 pagesDescription: Structure Design of Bridge: Project Title Mini ProjectYasir IqbalPas encore d'évaluation

- Box Culvert 2x 2.5mDocument10 pagesBox Culvert 2x 2.5mAntony Eric Martin KusumadinataPas encore d'évaluation

- Retaining Wall's Input Soil Parameter's InputDocument4 pagesRetaining Wall's Input Soil Parameter's InputRajasekaranRegunathanPas encore d'évaluation

- Retaining Wall 03Document13 pagesRetaining Wall 03HanafiahHamzahPas encore d'évaluation

- Earth Pressure CalcDocument3 pagesEarth Pressure Calcsuman_civilPas encore d'évaluation

- 5.604-SLRB - AbutmentDocument12 pages5.604-SLRB - AbutmentnagasrichPas encore d'évaluation

- Design of Substructure 4 PileDocument328 pagesDesign of Substructure 4 PileisurupushPas encore d'évaluation

- 12.2 M PSC GirderDocument18 pages12.2 M PSC GirdermithunPas encore d'évaluation

- MillauDocument10 pagesMillauAnanth GarikapatiPas encore d'évaluation

- BridgesDocument18 pagesBridgesCristi Pop100% (1)

- Cable Bridge PDFDocument9 pagesCable Bridge PDFJam PelPas encore d'évaluation

- Gregory Queen ElizabethDocument10 pagesGregory Queen ElizabethDoriel Rios GavaPas encore d'évaluation

- Bridge EngineeringDocument10 pagesBridge EngineeringLaeek PatelPas encore d'évaluation

- Define of Bridge: Introduction To Bridge EngineeringDocument4 pagesDefine of Bridge: Introduction To Bridge EngineeringASSEFAGETNETPas encore d'évaluation

- Puente de La Unidad MonterreyDocument5 pagesPuente de La Unidad MonterreySteel_catPas encore d'évaluation

- Cable StructuresDocument28 pagesCable StructuresChuzell LasamPas encore d'évaluation

- Structural Analysis of BridgesDocument35 pagesStructural Analysis of BridgesRafa OchoaPas encore d'évaluation

- Cable Force Tuning Tutorial FinalDocument23 pagesCable Force Tuning Tutorial FinalAnonymous DNb6yWERfB50% (2)

- Bridge ConstructionDocument32 pagesBridge ConstructionCivilEngClub80% (5)

- Sect 03Document67 pagesSect 03abdikarim_omarPas encore d'évaluation

- HowStuffWorks - How Bridges WorkDocument6 pagesHowStuffWorks - How Bridges WorkomuletzzPas encore d'évaluation

- Steel Bridges by Metwally Abu-HamdDocument281 pagesSteel Bridges by Metwally Abu-HamdAhmed Hamdy HusseinPas encore d'évaluation

- OresundDocument29 pagesOresundomariPas encore d'évaluation

- Asymmetric and Curved Cable-Stayed Bridges: IABSE Symposium Report January 2001Document9 pagesAsymmetric and Curved Cable-Stayed Bridges: IABSE Symposium Report January 2001Keya PathakPas encore d'évaluation

- Cable Stayed BridgeDocument12 pagesCable Stayed Bridgeaditya2053Pas encore d'évaluation

- Different Methods of Bridge Construction and Their Selection (Printed)Document25 pagesDifferent Methods of Bridge Construction and Their Selection (Printed)Muhammad FarooqPas encore d'évaluation

- Cable-Stayed Bridge - Wikipedia, The Free EncyclopediaDocument14 pagesCable-Stayed Bridge - Wikipedia, The Free EncyclopediasunnymaniaggarwalPas encore d'évaluation

- SED 17 Extradosed BridgesDocument159 pagesSED 17 Extradosed BridgesZakee Mohamed100% (2)

- Blast Loading On Anchorage Zones in Cable-Stayed BridgesDocument402 pagesBlast Loading On Anchorage Zones in Cable-Stayed BridgesEfrain SueldoPas encore d'évaluation

- Maintenance and Inspection of Bridge Stay Cable Systems: Conference PaperDocument13 pagesMaintenance and Inspection of Bridge Stay Cable Systems: Conference PaperikrusmostPas encore d'évaluation

- A Critical Analysis of Arthur Ravenel Jr. Bridge New Cooper River BridgeDocument7 pagesA Critical Analysis of Arthur Ravenel Jr. Bridge New Cooper River BridgeHoàng LongPas encore d'évaluation

- Manual - de - Inspección PUENTESDocument117 pagesManual - de - Inspección PUENTESjaijaj jajPas encore d'évaluation

- Chapter 4: Erection Methods of Cable Stayed BridgeDocument5 pagesChapter 4: Erection Methods of Cable Stayed Bridgedebjyoti_das_6100% (1)

- Construction Method of Steel BridgeDocument95 pagesConstruction Method of Steel BridgeAce Joker100% (2)

- Industrial Training PresentationDocument22 pagesIndustrial Training Presentationsachin palPas encore d'évaluation

- 60 Towers Pylons Unit 6A-B 17Document36 pages60 Towers Pylons Unit 6A-B 17Rafael ScudelariPas encore d'évaluation

- Cable Suspension BridgeDocument25 pagesCable Suspension BridgeNavik BhandariPas encore d'évaluation

- Anqing Yangtze River Railway Bridge, ChinaDocument7 pagesAnqing Yangtze River Railway Bridge, ChinaAngel RondillaPas encore d'évaluation

- Cable-Stayed Glass Façades - 15 Years of Innovation at The Cutting EdgeDocument9 pagesCable-Stayed Glass Façades - 15 Years of Innovation at The Cutting Edgemuhammed_bulanPas encore d'évaluation

- Tổng hợp tải trọng Summation phần mềm MIDASDocument8 pagesTổng hợp tải trọng Summation phần mềm MIDASAnonymous DNb6yWERfBPas encore d'évaluation