Académique Documents

Professionnel Documents

Culture Documents

Thermocouple Experiment Explores Transient Response

Transféré par

Sarfaras Ali KDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Thermocouple Experiment Explores Transient Response

Transféré par

Sarfaras Ali KDroits d'auteur :

Formats disponibles

ME 411 Experiment 1 Winter 2011

1

Experiment 1: Response Characteristics of Thermocouples

Objective:

In this experiment students explore fundamentals of thermocouple performance. Specifically this

experiment will give students experience constructing and testing thermocouples and also give

them practical experience assessing how the gauge (diameter) of the wire affects the response

characteristics when measuring fluid temperatures. In the process of implementing this experiment

students will gain further experience programming in LabView.

Theory:

Thermocouples are the physical implementation of a phenomenon known as the Seebeck Effect.

Specifically, when two dissimilar metals form a junction, a voltage will be created at that junction.

This voltage is a function of the junction temperature and the two metals involved. If the two metals

are copper and constantan the thermocouple is a T-Type. As needed, thermocouple charts can

be used to relate voltage to temperature. In systems where the sensed temperature may be

changing rapidly, it becomes crucial to understand the transient response characteristics of the

thermocouple.

It is important to note that when a thermocouple is directly connected to a voltage measuring

device (multimeter or Data Acquisition board--DAQ) it will register a voltage that is the addition of

the value resulting from the sensing end and any unintentional thermocouples that are created by

virtue of the connections at the voltage recording device (e.g., the constantan wire connected at the

copper terminal of the multimeter). This effect is relatively small if one is sensing very large

temperatures and the multimeter is at room temperature. In most cases, however, it is desirable to

avoid the unintentional thermocouple at the multimeter junction. This can be accomplished by

using Cold Junction Compensation CJC or by introducing a reference temperature bath (at 0

o

C, producing 0 mV) and ensuring that both wires being connected to the multimeter are of the

same metal (e.g., copper).

A thermocouple can be made simply by twisting two dissimilar metal wires together. In most cases

the junction is welded to bond the two wires permanently. The junction can also be formed by

adding a solder bead, although this increases the thermal mass of the thermocouple and

complicates the analysis because of the addition of a third material (solder). When a thermocouple

is inserted in a fluid there is convective heat transfer between the fluid and the thermocouple. If we

consider an idealized thermocouple as a sphere with diameter D we can apply the lumped

capacitance method to determine the transient temperature response of the junction. Specifically,

the energy balance on the spherical thermocouple is given by:

( ) ) (

6

2

3

sphere fluid sphere

T T D h T

t

D

C =

c

c

t

t

(1)

where and C are the density and specific heat capacity of the sphere, respectively. In the case of

a thermocouple that has been created using a solder bead to join the wires these values represent

a weighted average of the properties of the two metals and the solder bead. Further, the bead

shape may be more cylindrical than spherical. In such a case, the lumped capacitance approach

above must be modified to account for the surface area and volume of the cylinder. The heat

transfer coefficient h is a function of the fluid flow conditions. For natural convection in air the free

convection coefficient is typically on the order of 5 to 15 W/m

2

K but can be determined explicitly

ME 411 Experiment 1 Winter 2011

2

from heat transfer correlations found in most undergraduate heat transfer textbooks. Such

correlations are generally accurate to about +/- 20%.

If we define a new temperature variable u = (T

sphere

T

fluid

) the above equation can be simplified to:

)

6

(

CD

h

t

u u

- =

c

c

(2)

This first order ordinary differential equation has a simple exponential solution:

( )

(

|

|

.

|

\

|

+ =

|

|

.

|

\

|

=

=

CD

ht

T T T t T t

CD

h

xp e

initial sphere fluid initial sphere sphere

t

t

initial

u

u 6

exp 0 . 1 ) ( or

6

, ,

0

(3)

Given a plot of sphere temperature (thermocouple temperature) vs. time one would then expect an

exponential approach from an initial value to a final limit of the fluid temperature. The time constant

for this response is readily determined from the exponential term, noting that

h

CD

CD

ht

t

6

or

6

exp ) / exp(

t

t =

|

|

.

|

\

|

= (4)

There are several methods that could then be used to estimate the time constant and h. For

example, if one plots the natural log of theta vs. time the slope can be related to the time constant.

Equipment:

Each lab station is equipped with a variable temperature heater, a Pyrex beaker, a 24-bit

data acquisition unit, two different gauges of thermocouple wire and a standard glass

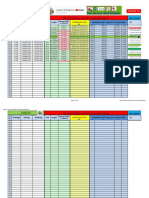

thermometer. Figure 1 shows the heater unit and the temperature DAQ card.

Figure 1. The heater unit (left) and the data acquisition unit (right).

A thermocouple can be constructed by twisting the two dissimilar metals (e.g., Copper and

Constantan in the case of a T-type thermocouple) and then welding or soldering the tip. Any

excess wire beyond the bead junction can be trimmed to make the thermocouple more spherical. A

thermocouple can be directly connected to a high precision multimeter and any applied

temperature condition will result in a change in the measured voltage. Typical thermocouple

voltage signals are on the order of millivolts, however, making it difficult to measure accurately

small changes in temperature, or to record temperature data in a data acquisition system. Many

data acquisition systems will consist of internal amplification, signal conditioning circuitry, and high

ME 411 Experiment 1 Winter 2011

3

resolution (e.g., > 18 bit representation of voltage input). In this experiment students need to

acquire temperature with a relatively low speed 24-bit data acquisition system. The bit resolution

implies that the range of possible continuous voltage input (+/-10 volts) is represented by only 2

n

(4096 for n=12) discrete levels. The 24-bit system is specifically designed for low voltage signals

and requires no amplification to use with thermocouples. It also includes an internal Cold Junction

Compensation feature that allows the software within LabView to compensate for the unintentional

thermocouple junction at the DAQ interface.

Procedure Outline:

First, fill a beaker/flask about 2/3 full with water and immediately start to heat the water up to

approximately 80

o

C. While it is heating up you will construct thermocouples and write the VI for the

experiment. Keep an eye on the water temperature and adjust the heater down so that the water

does not start to boil. To ensure you have sufficient time for the experiment one or two students

in each group can create thermocouples while the other(s) work of the virtual instruments.

Construct thermocouples

Each group will work with one fine gauge and one coarse-gauge thermocouple. The fine gauge

thermocouple will be either 30, 36, or 40 gauge. Students will be offered the option of welding their

own fine gauge thermocouples (likely 30 gauge) or selecting one that is prefabricated.

For the coarse gauge thermocouple (either 20 or 24 gauge) the bead should be made by first

twisting the wires together and then applying a drop of solder just where the wires meet. When cool

(~20 seconds) the excess wire can be snipped off using wire cutters. While use of a solder bead is

not ideal, it does a good job of holding the wires together and helps to highlight the time constant

issues associated with larger bead thermocouples. Later, when analyzing the transient response

you will need to estimate the average thermal properties of the bead composed of solder, and the

two thermocouple wire materials.

We will use the INTERNAL cold junction compensation of the data acquisition units so you do

not need to worry about creating a cold junction. The coarse-gauge thermocouple wire is likely to

be 24 gauge (0.020 dia), 20 gauge (0.032 dia) or larger. The fine gauge wire will be either 30

gauge (0.01 dia), 36 gauge (0.005 dia), or 40 gauge (0.0031 dia). It is important that you record

the wire diameter and estimate the effective dimensions (and volume) of the thermocouple bead.

The shape of the bead MAY be best approximated as a cylinder, in which case the analysis

presented above must be suitably modified.

Connect both thermocouples to the data acquisition unit screw terminals. Be sure to connect them

with the correct polarity (for T-type thermocouples the Copper wire clad in blue insulation - is

positive). Create a virtual instrument that is capable of reading both thermocouple channels

(probably Ai0 and Ai1) at the same time. The VI should be set to use the INTERNAL Cold Junction

Compensation for both. As a result, the maximum sampling frequency is 4 (=12/(2+1)) Hz.

The experiment involves exploring the transient response of the thermocouples and estimating

the free convection in air. The larger thermocouple should demonstrate a slower response to

changes in the temperature of the surroundings. You can apply equation 4 to estimate the heat

transfer coefficient for the thermocouple as it cools in air. If you determine that the thermocouple

junction is better modeled as a cylinder you will need to modify equation 4 as discussed earlier.

Prepare the VI

You will need to create a VI that reads both thermocouples at as fast a frequency as possible (4

hz). The samples should be stored in a file for later analysis. Be sure that the sampling VI obtains

sufficient data to fully explore the transient response (~ 30 to 60 seconds).

ME 411 Experiment 1 Winter 2011

4

Determine transient response

With the hot bath at ~80

o

C and the thermocouples submerged in this bath (for 15+ seconds),

initiate the sampling VI. Gently remove the thermocouples from the bath as the VI samples the

temperatures. Expose the thermocouples to ambient air until the sampling is complete. Be sure to

hold the thermocouples away from where they could be influenced by the heat rising from the bath,

and be careful not to shake the thermocouples.

Save the resulting data file with a unique name and take notes regarding the experiment conditions

that correspond to this name. Replace the thermocouples in the bath. Wait at least 15 seconds and

then repeat the sampling procedure just described several more times so that you have a total of 4

test caseseach with a unique name.

Now remove the beaker from the hot plate. Set the hot plate temperature to 100

o

C. Being careful

not to touch the hot plate with your hand place both thermocouple beads on the plate so that they

heat up. Leave them in contact with the plate for at least 30 seconds. Start the VI again and

sample as you remove the thermocouples from the hot plate and hold them still in air. Be sure that

you sample for at least a few seconds before removing the thermocouples from the plate. Give the

resulting file a unique name and repeat this measurement several times so that you have 4 sets of

data for this condition.

Take a quick look at the resulting text files to assure the data appear reasonable. Repeat any

experiments that appear to have any questionable data.

Turn off equipment

Be sure to turn off the heater. The teaching assistants will empty the flasks of hot water from

each station and/or prepare them for the next group.

ASSIGNMENT:

For this experiment you will write a complete report along the lines of the requirements specified in

class. This report should be no more than 6 pages including cover page, report text and all figures.

A separate appendix including sample data and calculations should also be included, but should be

no more than 4 pages long. If you have data files that are long you should include just a sample.

The following list of questions is intended as a general guide for students as they consider their

report write-up. Students should NOT set out to answer this specific set of questions, but rather use

them as a guide as they consider the analysis of their experimental data.

- What is the effective bead diameter (and volume) of both thermocouples and how should

the time constants be related? Is the thermocouple best modeled as a sphere or a

cylinder?

- What are the time constants for each thermocouple and what are the implications for the

types of transient measurements that can be taken with both?

- What is the best estimate of the free convection coefficient in (still) air? How do the results

of cooling a wet thermocouple differ from those for cooling a dry thermocouple? Why?

- Was the sampling frequency fine enough to determine the convection coefficients? How do

these estimates compare with published values for natural convection?

- If the same experiments were conducted in reverse, what might you expect? That is, if the

thermocouple was taken from air and heated rapidly by placing it in the water, could our

system capture the transient behavior?

Vous aimerez peut-être aussi

- Testing of Thermocouples PDFDocument6 pagesTesting of Thermocouples PDFbasdownloadPas encore d'évaluation

- Review of Analog Sensors/Transducers: Muhammad Zaigham Abbas ShahDocument16 pagesReview of Analog Sensors/Transducers: Muhammad Zaigham Abbas ShahAbdul Razaque MagsiPas encore d'évaluation

- Dielectric Oil Testing KitDocument2 pagesDielectric Oil Testing KitMohammed Imran100% (1)

- Rotor Hot Spot Treatment PDFDocument10 pagesRotor Hot Spot Treatment PDFramnadh803181Pas encore d'évaluation

- Nuclear (Atomic) Power Plant: Mr.B.RameshDocument31 pagesNuclear (Atomic) Power Plant: Mr.B.RameshDr. B. Ramesh0% (1)

- Reactor, Its Components, TypesDocument32 pagesReactor, Its Components, TypesAzhar AliPas encore d'évaluation

- 3512C Marine Engine TTC00001-UP (SEBP4534 - 23) - Bearing Clearance - CheckDocument4 pages3512C Marine Engine TTC00001-UP (SEBP4534 - 23) - Bearing Clearance - CheckMYO MINPas encore d'évaluation

- Diesel Engine ValvesDocument2 pagesDiesel Engine ValvesLaxman Singh SankhlaPas encore d'évaluation

- Feasibility of Nuclear Power Plant For JordanDocument25 pagesFeasibility of Nuclear Power Plant For JordanDr Ned Xoubi100% (3)

- Diesel Engine TestDocument9 pagesDiesel Engine TestSamuel Blandes RwegasiraPas encore d'évaluation

- Fiber Optic Photonic Thesis PDFDocument2 pagesFiber Optic Photonic Thesis PDFKim0% (1)

- Thermocouples Experiment: To Determine The Time Constant of A Typical Iron-Constantan Thermocouple.Document8 pagesThermocouples Experiment: To Determine The Time Constant of A Typical Iron-Constantan Thermocouple.Hafiz Tanveer50% (2)

- Risk Assessment 1Document1 pageRisk Assessment 1AfiaPas encore d'évaluation

- Thermocouples Definition PDFDocument4 pagesThermocouples Definition PDFmouPas encore d'évaluation

- Smoke in Cars SuvDocument9 pagesSmoke in Cars Suvgreg gabrielPas encore d'évaluation

- PLC Vs ControllerDocument4 pagesPLC Vs ControllerththeePas encore d'évaluation

- Hmi GxuDocument14 pagesHmi GxuGameR VanrenheitPas encore d'évaluation

- Obe Learner App Guide PDFDocument9 pagesObe Learner App Guide PDFAsmaael adnanPas encore d'évaluation

- EPA Exp RegistrationDocument22 pagesEPA Exp RegistrationFuaad DodooPas encore d'évaluation

- REM615 Appl 756885 ENlDocument168 pagesREM615 Appl 756885 ENlwilsonpamintuPas encore d'évaluation

- Uni-Line, Customisation Manual 4189340135 UKDocument45 pagesUni-Line, Customisation Manual 4189340135 UKdenilson.rodr1357Pas encore d'évaluation

- TTR SeriesDocument6 pagesTTR SeriesppuchihaPas encore d'évaluation

- Mitsubishi SU KUDocument2 pagesMitsubishi SU KUMd ShPas encore d'évaluation

- Concept Artist Who's Who Viktor AntonovDocument4 pagesConcept Artist Who's Who Viktor AntonovIsol-tePas encore d'évaluation

- ISO Standards and Brainstorming TechniquesDocument24 pagesISO Standards and Brainstorming TechniquesSiddharth ShahPas encore d'évaluation

- S7L1D-C4 Wdg.312 - Technical Data SheetDocument9 pagesS7L1D-C4 Wdg.312 - Technical Data Sheet3efoo0% (1)

- Schneider HMI GXODocument76 pagesSchneider HMI GXORohit DashrathiPas encore d'évaluation

- Voltage Divider BiasDocument4 pagesVoltage Divider BiasRememberMePas encore d'évaluation

- Winding Resistance Test Report-1250KVADocument1 pageWinding Resistance Test Report-1250KVAAhsan IqbalPas encore d'évaluation

- Ch24 DynModelsDocument155 pagesCh24 DynModelselectrical_1012000Pas encore d'évaluation

- Testing of Thermocouples For InhomogeneityDocument5 pagesTesting of Thermocouples For Inhomogeneityliam15111981Pas encore d'évaluation

- A Alternator DesignDocument6 pagesA Alternator DesignKathir RkpPas encore d'évaluation

- SIMATIC S5 Communication CableDocument8 pagesSIMATIC S5 Communication CableAlex GonzalezPas encore d'évaluation

- TMAXDocument90 pagesTMAXMohamad JadoPas encore d'évaluation

- LFC and Power Factor CorrectionDocument6 pagesLFC and Power Factor CorrectionswarnaPas encore d'évaluation

- Bearing Mounting - SKF Drive Up MethodDocument5 pagesBearing Mounting - SKF Drive Up Methodkuruvillaj2217Pas encore d'évaluation

- How thermocouples work and are used for temperature measurementDocument5 pagesHow thermocouples work and are used for temperature measurementJane Marek100% (1)

- A159109546795 PDFDocument95 pagesA159109546795 PDFSuneetha AsPas encore d'évaluation

- Advanced Fiber Optic Communication Lab SetupDocument9 pagesAdvanced Fiber Optic Communication Lab Setupkarthikeyan.vPas encore d'évaluation

- New Microsoft Word DocumentDocument8 pagesNew Microsoft Word Documentnis123bocharePas encore d'évaluation

- UNIT-1 ManagementDocument128 pagesUNIT-1 ManagementDeepa Shree100% (1)

- Arc Welding PPT FinishDocument50 pagesArc Welding PPT FinishmahendraPas encore d'évaluation

- Electrical Engineering Interview Questions on Thyristors and UPSDocument16 pagesElectrical Engineering Interview Questions on Thyristors and UPSvinoddeswal057100% (1)

- Download Expired Excel SheetDocument54 pagesDownload Expired Excel Sheetromanz_657710156Pas encore d'évaluation

- GTG 1383om Piel Sul 48mchpDocument18 pagesGTG 1383om Piel Sul 48mchpjohn smithyPas encore d'évaluation

- Ac FundamentalsDocument17 pagesAc FundamentalsRangpariya AmitPas encore d'évaluation

- Tan-Delta TestDocument2 pagesTan-Delta TestRakesh BabuPas encore d'évaluation

- Coe Electrical EngineeringDocument13 pagesCoe Electrical EngineeringManuelPas encore d'évaluation

- RUET student's report on Bangladesh's Ruppur Nuclear Power PlantDocument4 pagesRUET student's report on Bangladesh's Ruppur Nuclear Power PlantShafi Muhammad IstiakPas encore d'évaluation

- Permanent-Magnet Starter Motor (Automobile)Document3 pagesPermanent-Magnet Starter Motor (Automobile)prasad100% (1)

- Different Type of Air Standard (Otto and Diesel Cycle)Document23 pagesDifferent Type of Air Standard (Otto and Diesel Cycle)Irteza HossainPas encore d'évaluation

- Body BiasDocument7 pagesBody BiasSwaroop KumarPas encore d'évaluation

- Auto Transformer StarterDocument13 pagesAuto Transformer StarterarunPas encore d'évaluation

- ChE 154Document16 pagesChE 154DennisShinPas encore d'évaluation

- Experiment DescriptionDocument9 pagesExperiment DescriptionPutu Diah Prajna ParamitaPas encore d'évaluation

- Objectives: Temperature Measuring DevicesDocument8 pagesObjectives: Temperature Measuring DevicesSai Swaroop MandalPas encore d'évaluation

- Experiment 4: Temperature Measurements: Concepts Emphasized: Resistor Temperature Detector, Thermistor, and ThermocoupleDocument9 pagesExperiment 4: Temperature Measurements: Concepts Emphasized: Resistor Temperature Detector, Thermistor, and ThermocoupleKalyani KattaPas encore d'évaluation

- CFD analysis of heat transfer in a dry type transformerDocument7 pagesCFD analysis of heat transfer in a dry type transformerEnriqueGD100% (1)

- Thermistors in Homebrew ProjectsDocument5 pagesThermistors in Homebrew ProjectsSorin Mihai VassPas encore d'évaluation

- NETZSCH NEMO BY Pumps USADocument2 pagesNETZSCH NEMO BY Pumps USAWawan NopexPas encore d'évaluation

- Technical Data: That W IntoDocument5 pagesTechnical Data: That W Intoradium7Pas encore d'évaluation

- STATS Shortcut FormulaDocument3 pagesSTATS Shortcut Formulajeet sighPas encore d'évaluation

- Tetrahydrofuran: THF (Disambiguation)Document12 pagesTetrahydrofuran: THF (Disambiguation)Faris NaufalPas encore d'évaluation

- State-Of-The-Art CFB Technology For Utility-Scale Biomass Power PlantsDocument10 pagesState-Of-The-Art CFB Technology For Utility-Scale Biomass Power PlantsIrfan OmercausevicPas encore d'évaluation

- Math 2nd Year CompleteDocument369 pagesMath 2nd Year CompleteJabir Ali Siddique100% (1)

- Quizlet-Philippine Electrical CodeDocument2 pagesQuizlet-Philippine Electrical Codena zafira0% (1)

- Ground Plane AntennaDocument7 pagesGround Plane AntennaarijeetdguyPas encore d'évaluation

- CT Selection RequirementsDocument35 pagesCT Selection RequirementsRam Shan100% (1)

- Fire Strength Performance ofDocument3 pagesFire Strength Performance ofMarimuthu KannimuthuPas encore d'évaluation

- Chapter 11 - MatricesDocument39 pagesChapter 11 - MatricesJhagantini Palanivelu0% (1)

- TOS in PRE-CALCULUSDocument2 pagesTOS in PRE-CALCULUSSerjohnRapsingPas encore d'évaluation

- An Overview On Reliability, Availability, Maintainability and Supportability (RAMS) EngineeringDocument15 pagesAn Overview On Reliability, Availability, Maintainability and Supportability (RAMS) EngineeringKrinta AlisaPas encore d'évaluation

- Barium Strontium TitanateDocument15 pagesBarium Strontium Titanatekanita_jawwPas encore d'évaluation

- Eaton 290376 NZMH4 VE800 S1 en - GBDocument10 pagesEaton 290376 NZMH4 VE800 S1 en - GBkarthik01heroPas encore d'évaluation

- tc107 Research PaperDocument6 pagestc107 Research PaperAtharva BhidePas encore d'évaluation

- Scan Path DesignDocument54 pagesScan Path DesignGowtham HariPas encore d'évaluation

- Flender Technical HandbookDocument69 pagesFlender Technical HandbookAhmed Emad AhmedPas encore d'évaluation

- AOAC BAX Assay Listeria Monocytogenes RT 121402Document18 pagesAOAC BAX Assay Listeria Monocytogenes RT 121402Yesenia Borja ArroyoPas encore d'évaluation

- A Review On Promethee and Analytic Hierarchy Process With Its ApplicationDocument7 pagesA Review On Promethee and Analytic Hierarchy Process With Its Applicationkherrouf YOUNESPas encore d'évaluation

- Chapter 5Document14 pagesChapter 5bhavyaPas encore d'évaluation

- Migrating Your SQL Server Workloads To PostgreSQL - Part 3 - CodeProjectDocument6 pagesMigrating Your SQL Server Workloads To PostgreSQL - Part 3 - CodeProjectgfgomesPas encore d'évaluation

- Driver MC34152Document4 pagesDriver MC34152William RamírezPas encore d'évaluation

- EO and EO-2 Metric Bite Type Fittings: The Fitting AuthorityDocument62 pagesEO and EO-2 Metric Bite Type Fittings: The Fitting AuthorityZahir KhiraPas encore d'évaluation

- Intel Processor Diagnostic Tool HelpDocument44 pagesIntel Processor Diagnostic Tool HelprullfebriPas encore d'évaluation

- Chapter 5: Work, Energy and PowerDocument4 pagesChapter 5: Work, Energy and PowerPriyaa JayasankarPas encore d'évaluation

- Unit 2Document76 pagesUnit 2Mithila100% (1)

- Experiment03 PCM-DecodingDocument10 pagesExperiment03 PCM-DecodingMary Rose P Delos SantosPas encore d'évaluation

- Atmospheric, Gage, and Absolute PressureDocument13 pagesAtmospheric, Gage, and Absolute PressureJefrie Marc LaquioPas encore d'évaluation

- Reservoir Modelling & Simulation GuideDocument96 pagesReservoir Modelling & Simulation GuideyouungPas encore d'évaluation