Académique Documents

Professionnel Documents

Culture Documents

Bel 401

Transféré par

Divyansh RajDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bel 401

Transféré par

Divyansh RajDroits d'auteur :

Formats disponibles

ABSTRACT

INTRODUCTION

Lipases have come into prominance because of new and novel applications in oleo-chemistry, detergent formulation, organic synthesis and nutrition. Lipases belong to the class of serine hydrolases and therefore do not require any cofactor The natural substrates of lipases are triacylglycerols, which have very low solubility in water. Under natural conditions lipases catalyse thte hydrolysis of ester bonds at the interface between an insoluble substrate phase and the aqueous phase where the enzyme remains dissolved (Figure1). Under certain experimental conditions such as in the presence of traces of water, they are capable of reversing the reaction. The reverse recation leads to esterification and formation of glycerides from fatty acids and glycerol (fig 2). The occurence of lipase catalysed reactions at an interface between the substrate and the aqueous phase generates scientic challenges in the assay and kinetic analaysis in the reaction .

The usual industrial lipases are special classes of esterase enzymes that acts on fats and oils, and hydrolyse them into the subbstituted glycerides and fatty acids, and hydrolyse them in steps into the substituted glycerides and fatty acids, and finally on total hydrolysis into glycerol and fatty acids. BACTERIAL LIPASESgenerally bacterial lipases are glycoproteins but some extracellular bacterial lipases are lipoproteins. The production of extracellular lipases from bacteria is often dependent on nitrogen and carbon sources, inorganic salts, presence of lipids, temperature and availability of oxygen. Different genera of bacteria including streptomyces spp. produce lipase but the following genera have been well exploited for lipase production: Achromobacter spp., alcaligenes spp., arthrobacter spp., Pseudomonas spp. and Chromobacterium spp.

FUNGAL LIPASESfungi has been valued as an importantant source of lipase due to the foollowing properties : thermal stability, pH stability, substrate specificity and activity in organic solvents.Fungal lipases have benefits over bacterial ones due to the fact that present day benefits over bacterial ones due to the fact that present day technology favours the use of batch fermentation and low cost extraction methods. The chief producers of commercial lipases are aspergillus niger, A.terreus, A. carneus, Candida cylindracea, Humicola languginosa, Mucor miehei, rhizopus arrhizus, R. delemar.

Production of Extracellular Lipase from Aspergillus niger by Solid-State Fermentation

Lipases occur widely in bacteria, yeasts and fungi. Fungi are broadly recognized as one of the best lipase sources and are used widely in the

food industry. Aspergillus niger is among the most well known lipase producers. Studies on the production of extracellular lipases with A. niger have shown variations among different strains. However, the requirement for lipid carbon source remains essential for enzyme production.

SOLID STATE FERMENTATION

Solid State Fermentation (S.S.F) is a bio molecule manufacturing process used in the food, pharmaceutical, cosmetic, fuel and textile industries. These bio molecules are mostly metabolites generated by micro-organisms grown on a solid support selected for this purpose. This technology for the culture of microorganisms is an alternative to liquid or submerged fermentation, used predominantly for industrial purposes on a global scale. SSF has many advantages over submerged fermentation (SmF), including an economical use of space that is required for fermentation, simplification of the fermentation media, superior yields and no requirement for complex machinery. However, SSF has some limitations such as a poor pool of microorganisms capable of growth under restricted conditions and the controlling and monitoring of parameters such as temperature, pH, humidity and air flow. SUBSTRATE During the SmF the mineral growth medium (MGM) contained (in g/L): NaH2PO4 12, KH2PO4 2, MgSO47 H2O 0.3 and CaCl2 0.25. Ammonium sulphate at 1 % and olive oil at 2 % were used as nitrogen and carbon sources, respectively. It was also assayed with different combinations of olive oil and glucose following the feed scheme represented in Table 1.

Combination 6 was the most suitable carbon source for the Aspergillus niger lipase production.

Lipase production in SSF A mass of 5 g of wheat bran was taken in 250-mL Erlenmeyer flasks and moistened with 5 mL of sterilized salt solution of MGM (121 C for 30 min). After cooling, the flasks were inoculated with a spore suspension containing 107 spores/mL from a 7-day-old culture grown on MGM and incubated at 30 C for 7 days. After one week, 100 mL of distilled water were added to each flask and the mixture was shaken for 30 min

at room temperature to facilitate the extraction of enzyme from fermented wheat bran. At the end of the extraction, the suspension was squeezed through a double- -layered muslin cloth and it was centrifuged at 12 000 rpm for 5 min. The clear supernatant obtained was used as the extracellular enzyme.

BIOSYNTHETIC PATHWAY

IMPORTANT REGULATORY STEPS:

Effect of temperature

Effect of pH

CONCLUSION A. niger was the best producer of extracellular lipase and its synthesis is induced by the presence of a lipid source. Moderate enzyme activity (9.14 IU/g dss) was obtained in SSF using wheat bran, are amongst the highest extracellular lipase activities reported in the literature concerning fungal sources. This lipase has some properties in common with lipases from other A. niger strains. This enzyme is also stable over a broad pH range, 4 to 7, for a period of 24 hours at 30 C. Due to the fact that these microorganisms are generally recognized as safe (GRAS) for food, brewing and pharmaceutical applications, more research is necessary

to optimize the fermentative process in order to obtain higher lipase production through this strain. REFRENCES

Production of Extracellular Lipase from Aspergillus niger by Solid-State Fermentation

Gwen Falony1, Janny Coca Armas1*, Julio C. Dustet Mendoza1 and Jos L. Martnez Hernndez2**

http://www.wikipathways.org/index.php/Pathway:WP71 http://nopr.niscair.res.in/bitstream/123456789/5772/1/IJBT%204(4)%20437-445.pdf

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- AL-CHEM Chemistry of Carbon Compounds (97-02)Document24 pagesAL-CHEM Chemistry of Carbon Compounds (97-02)AmyLinPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Process Modeling and Simulation of Levulinate Esters Production Using Aspen HysysDocument17 pagesProcess Modeling and Simulation of Levulinate Esters Production Using Aspen HysysFun DuniyaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Soybean Motor OilDocument12 pagesSoybean Motor OilJessica FernandesPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Chemistry 2 For OCR - David Acaster PDFDocument247 pagesChemistry 2 For OCR - David Acaster PDFClint GreerPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- CHEM Chap-12 Ncert SolutionDocument39 pagesCHEM Chap-12 Ncert SolutionRohan Agrawal 961Pas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Chapter 13 AnswersDocument6 pagesChapter 13 AnswersMatt Wong80% (5)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Amino Acid EstersDocument9 pagesAmino Acid EsterskvsrskPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Modified Rosin Ester PreparationDocument17 pagesModified Rosin Ester PreparationRian Pratama AkbaPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Oleochemicals For ProcessingDocument23 pagesOleochemicals For ProcessingssmaniPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Carbon GroupDocument20 pagesCarbon GroupvasucristalPas encore d'évaluation

- 5070 w09 QP 4Document36 pages5070 w09 QP 4G M Ali KawsarPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- ALDEHYDE, KETONE AND CARBOXYLIC ACID - Practice Sheet & Solution - Vijeta 2023Document7 pagesALDEHYDE, KETONE AND CARBOXYLIC ACID - Practice Sheet & Solution - Vijeta 2023saksham kr mishraPas encore d'évaluation

- Experiment 8 Pre-Lab Comparative Reactions of Carboxylic Acid DerivativesDocument3 pagesExperiment 8 Pre-Lab Comparative Reactions of Carboxylic Acid Derivativesgian odell100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Wang 2007Document10 pagesWang 2007sri murti astutiPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- History of Polyester, Its Uses & ManufacturingDocument5 pagesHistory of Polyester, Its Uses & ManufacturingRezaul Karim TutulPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Reactions of TrichlorotriazineDocument16 pagesReactions of Trichlorotriazinebebo4gpaPas encore d'évaluation

- Table of Functional Group Priorities For Nomenclature - Master Organic ChemistryDocument23 pagesTable of Functional Group Priorities For Nomenclature - Master Organic ChemistryKanika SinghPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Unitop - Surfactants (Cas Nos)Document1 pageUnitop - Surfactants (Cas Nos)Alfredo MéndezPas encore d'évaluation

- 1860 5397 12 162 PDFDocument102 pages1860 5397 12 162 PDFIta AzmizakiyahPas encore d'évaluation

- Acids and Derivatives TutorialDocument18 pagesAcids and Derivatives TutorialChen ZhihaoPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- CARBON COMPOUND (Asid Carboxylic)Document24 pagesCARBON COMPOUND (Asid Carboxylic)Shirley SimonPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Recent Advancement in Deoxygenation of Fatty Acids Via Homogeneous Catalysis For Biofuel ProductionDocument12 pagesRecent Advancement in Deoxygenation of Fatty Acids Via Homogeneous Catalysis For Biofuel ProductionRoivan Salazar PalaciosPas encore d'évaluation

- AminesDocument8 pagesAminesryanmanubagPas encore d'évaluation

- Handbook of Biopolymers Advances and Multifaceted Applications (Ahmed, Shakeel Kanchi, Suvardhan Kumar Etc.)Document323 pagesHandbook of Biopolymers Advances and Multifaceted Applications (Ahmed, Shakeel Kanchi, Suvardhan Kumar Etc.)Tecuitlatl100% (3)

- Additives by Resin: Plastics SolutionsDocument11 pagesAdditives by Resin: Plastics SolutionsMubashir RasoolPas encore d'évaluation

- Contractubex - US20100247689A1Document14 pagesContractubex - US20100247689A1hana.hovorkovaPas encore d'évaluation

- Solid-Phase Synthesis of 1,4-Benzodiazepine-2,5-Diones. Library Preparation and Demonstration of Synthesis GeneralityDocument17 pagesSolid-Phase Synthesis of 1,4-Benzodiazepine-2,5-Diones. Library Preparation and Demonstration of Synthesis GeneralityVeronica Gonzalez RolonPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Finishing-Spin FinishDocument7 pagesFinishing-Spin FinishSethupathi K PPas encore d'évaluation

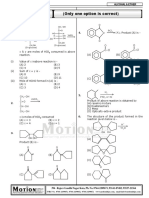

- Exercise - I (Only One Option Is Correct) : CH - OhDocument5 pagesExercise - I (Only One Option Is Correct) : CH - Ohd anjilappaPas encore d'évaluation

- US2465319Document7 pagesUS2465319Sebastian GonzalezPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)