Académique Documents

Professionnel Documents

Culture Documents

Cable Dressing

Transféré par

peterpinion9822Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cable Dressing

Transféré par

peterpinion9822Droits d'auteur :

Formats disponibles

Problems Associated With Cable Dressing

When Network or optical cables are installed in a building or cabinet, the task of fitting cables into an organised bundle is called cable dressing. This dressed bundle is called a loom. A dressed loom of cables is typically a bundle of cables with the outermost cables - that is, the visible cables made to look neat and organised with cable lengths running parallel to one another. Manually untangling the cables in the bundle and then manipulating the outermost cables to achieve straight parallel lines is the work of a skilled tradesman and is only generally undertaken by an experienced cabling engineer. Even with the most experienced cabling engineer, the dressing task is laborious and time consuming with the end result being a neat loom of cables on the outside, but always a disorganised array in the middle of the loom. The cablecomb makes the dressing of cable looms fast and precise. It also ensures that cable lengths throughout its cross-section are supported in parallel to one another. In its simplicity, the cablecomb is a tool with a number of holes punched into it, the ratio and hole configuration assists in the loom of cables being kept in order and in a pre-defined pattern, aiding the shape of the loom. To aid loading of the cablecomb, the holes are numbered in a specific sequence. This numbered hole configuration ensures that each cable appears in its correct position and orientation when the cablecomb is unloaded at the patch panel. When manually dressing a loom of cables, it is impossible to maintain the position of all cables in the loom continuously along the looms entire length right up to the point of termination onto a patch panel. It then becomes apparent that because the cables are not in any organised sequence, they appear randomly and most likely in the wrong order. This leaves the cabling engineer with the onerous task of making a tangled cable bundle look neat and organised. This problem further compounds the task of terminating the cables onto a patch panel where the cables should ideally be in a numerical sequence, sorted into odd and even numbers and more importantly, should appear from the loom in the right order and correct position. Supporting a variety of patch panels and uses, the cablecomb is available in 16, 24, 32, 48 and 96 port versions. The cablecomb was designed to support category 3, 4, 5, 5E, 6 and 7 cabling. However, it can also support any cable type (media, telephony, audio and fibre cables). The cablecomb is NOT to be used on any type of live electrical cables. Since cables from a loom dressed by hand do not appear in an organised sequential manner, this makes the operation to terminate the cables a needlessly untidy and awkward task. In addition as the cables have to be individually manipulated to form a neat loom, problems can arise when tying the loom structure together, and without any means of keeping the cables in a particular order or position, the cables will naturally tend to mix-up and intertwine. The problem is further compounded when dressing cables from underneath a wiring cabinet, a wiring frame or from a floor or ceiling void. This is because it is not possible to maintain the alignment of the looms outermost cables such that they are prevented from crossing each other. Subsequently, the cable lengths will fail to run parallel with each other. This makes the loom of dressed cables look untidy and unprofessionally installed with cables crossing each other. Cablecomb solves this problem by loading cables into correctly numbered holes. The individual cables are threaded through the holes and when all the cables have been threaded, the tool is pulled back up the lengths of cable towards the beginning of the loom. The cablecomb holds the cables in the most suitable spacing to one another, where upon a plastic cable tie can be fitted to maintain the looms shape. The cablecomb is moved along the looms length in stages with additional plastic ties being fitted to maintain the looms shape. The cables are then removed from the cablecomb in the correct order and orientation, ready to be terminated. The cablecomb also helps in forming a completed loom around any awkward shapes and angles that may be present in an installation. For example, in a wiring cabinet, the length of loom that may be required might be from under the floor or from a ceiling void, along a cable tray and up to a patch panel. The cabling engineer simply pulls the required length of cable through the cablecomb before using the tool to

dress the cables. The cablecomb also helps maintain the correct bend radius of the cables as specified by the cable manufacturer. The aim of the cabling engineer is to a achieve a dressed loom of cables where the individual cables do not cross each other, always running parallel so that the dressed loom of cables is free of any tangled cables. The individual cables can then be removed from the loom in their correct order and position and individually terminated. This manual method of dressing cables is very time consuming and demands great skill. The loom of cables at the patch panel can still remain somewhat untidy, depending on the individual skill of the engineer assigned to dressing the cables. Cablecomb enables the work of the cabling engineer to be carried out efficiently, with consistent results being achieved even by engineers unskilled and unfamiliar with cable dressing. Amazingly high professional standards are achieved in a comparatively short time. By using the cablecomb, highly skilled engineers are no longer required for cable dressing, thus ensuring their skills can be focused on more important work and projects. In the hands of a newly trained engineer, cablecomb enables work of a highly professional standard to become the norm for the industry, not the exception, efficiently and effectively.

Vous aimerez peut-être aussi

- Design & Fabrication Guide For Metal Framed Railings: August 1, 2007Document36 pagesDesign & Fabrication Guide For Metal Framed Railings: August 1, 2007Sagar SangraulaPas encore d'évaluation

- Subsurface Cable Construction Techniques and Best PracticesDocument13 pagesSubsurface Cable Construction Techniques and Best PracticespahiescorpPas encore d'évaluation

- 113-Article Text-467-2-10-20200107 PDFDocument6 pages113-Article Text-467-2-10-20200107 PDFjosejohn1Pas encore d'évaluation

- Application Note Fiber Optic Cable InstalllationDocument7 pagesApplication Note Fiber Optic Cable InstalllationAbduBuserPas encore d'évaluation

- The FOA Reference For Fiber Optics-Installing Fiber Optic Cable - Bend RadiusDocument6 pagesThe FOA Reference For Fiber Optics-Installing Fiber Optic Cable - Bend RadiusHabibSadeghiPas encore d'évaluation

- HSQR Microwave Hardware Installation ChecklistDocument8 pagesHSQR Microwave Hardware Installation ChecklistJay SingsonPas encore d'évaluation

- Cable Trays Design Refference DocumentDocument6 pagesCable Trays Design Refference DocumentTimothy LeonardPas encore d'évaluation

- Binary OperationDocument5 pagesBinary OperationRuth FerolinoPas encore d'évaluation

- SteeringPt1 04Document22 pagesSteeringPt1 04Neo ZaoPas encore d'évaluation

- Making Network Cables and Connectors ObjectiveDocument5 pagesMaking Network Cables and Connectors ObjectiveTayyaba HussainPas encore d'évaluation

- TLE 10 EPAS Week3Document6 pagesTLE 10 EPAS Week3Sittie Fahieda Aloyodan100% (2)

- RPA114 Balustrade Catalogue - 72dpiDocument52 pagesRPA114 Balustrade Catalogue - 72dpiMikePas encore d'évaluation

- Cable Tray System Overview - PAKTECHPOINTDocument13 pagesCable Tray System Overview - PAKTECHPOINTtaibi aliPas encore d'évaluation

- GROUP10 - Assignment 1.2 Practice Set 2 - Network Media - ADocument26 pagesGROUP10 - Assignment 1.2 Practice Set 2 - Network Media - AShyne HazyPas encore d'évaluation

- Installing Underground Fibre Optic CableDocument4 pagesInstalling Underground Fibre Optic CableAmir SalahPas encore d'évaluation

- 1armoured CableDocument23 pages1armoured CableScala PinkerPas encore d'évaluation

- Ethernet Cable Color Codes and Crimping Methods ExplainedDocument26 pagesEthernet Cable Color Codes and Crimping Methods ExplainedDiorella PaguioPas encore d'évaluation

- 01 Guidelines For Fiber Optic Cable InstDocument14 pages01 Guidelines For Fiber Optic Cable InstAdrián NavarroPas encore d'évaluation

- Build Double Bazooka PDFDocument11 pagesBuild Double Bazooka PDFAtin surelawatinPas encore d'évaluation

- Making Ethernet CablesDocument11 pagesMaking Ethernet CablesEdz BarbsPas encore d'évaluation

- LESSON 2 - Topic 2 - Laying Out CablesDocument4 pagesLESSON 2 - Topic 2 - Laying Out CablesMichael LaguitanPas encore d'évaluation

- Twisted HarnessDocument6 pagesTwisted Harnessasser_salehPas encore d'évaluation

- Cable Bus PDFDocument16 pagesCable Bus PDFsamyfouadPas encore d'évaluation

- Fiber Installation GuideDocument12 pagesFiber Installation GuideTahar HajjiPas encore d'évaluation

- Cab Solar Brochure 5.20.2016Document4 pagesCab Solar Brochure 5.20.2016miguelpaltinoPas encore d'évaluation

- How to Create Network CablesDocument42 pagesHow to Create Network CablesAko-ang Batang Ekis100% (2)

- Learning Activity Sheet In: Computer Systems ServicingDocument12 pagesLearning Activity Sheet In: Computer Systems ServicingCarvalds 0315100% (1)

- Cabling and Wiring System: 1. GeneralDocument12 pagesCabling and Wiring System: 1. GeneralcRi SocietyPas encore d'évaluation

- Suspension Bridge Technical DataDocument9 pagesSuspension Bridge Technical DatamohammedPas encore d'évaluation

- Topic 5 - Wiring SystemsDocument20 pagesTopic 5 - Wiring SystemsVictorPas encore d'évaluation

- CHATSWORTH Pathway, USADocument8 pagesCHATSWORTH Pathway, USAMohammed Jawwad HussainPas encore d'évaluation

- Network Cabling Design Best PracticesDocument40 pagesNetwork Cabling Design Best PracticesThomas Or0% (1)

- Cable Tray ExcellentDocument27 pagesCable Tray Excellentraja kumarPas encore d'évaluation

- Make Your Own Cat5Document8 pagesMake Your Own Cat5sudheerkvbPas encore d'évaluation

- Crimp and Test UTP Cables DemonstrationDocument6 pagesCrimp and Test UTP Cables DemonstrationYow Han LeePas encore d'évaluation

- Network Cabling Design Best Practices GuideDocument45 pagesNetwork Cabling Design Best Practices GuideJhonrenz ManabatPas encore d'évaluation

- 2.1-5 Raceway Power PointDocument14 pages2.1-5 Raceway Power PointLouie BacuñoPas encore d'évaluation

- Core 10Document18 pagesCore 10eleno m. estoquePas encore d'évaluation

- Cable Design and Testing SolutionsDocument2 pagesCable Design and Testing Solutionsmy_khan20027195Pas encore d'évaluation

- Making Network Cables and Connectors ObjectiveDocument7 pagesMaking Network Cables and Connectors ObjectiveTayyaba HussainPas encore d'évaluation

- Cables_Trays_G+TDocument5 pagesCables_Trays_G+TSuresh PasumarthiPas encore d'évaluation

- IBC 2016 Brochure HRDocument16 pagesIBC 2016 Brochure HRAw HvPas encore d'évaluation

- Lab Sheet 01Document5 pagesLab Sheet 01yuwarajaPas encore d'évaluation

- W Engn30Document22 pagesW Engn30r81157946Pas encore d'évaluation

- Ethernet Cable Color - Code Standards & Methods of Crimping: Presented By: Maria Diorella PaguioDocument26 pagesEthernet Cable Color - Code Standards & Methods of Crimping: Presented By: Maria Diorella PaguioDiorella PaguioPas encore d'évaluation

- Fibre Optic - Installation ChecklistDocument46 pagesFibre Optic - Installation ChecklistCyprian Metobo100% (1)

- Guidelines For Fiber Optic Cable InstallationDocument14 pagesGuidelines For Fiber Optic Cable InstallationBrielle ManuelPas encore d'évaluation

- CSS4-Q1 Module 1Document9 pagesCSS4-Q1 Module 1Lielanie NavarroPas encore d'évaluation

- Homac RAB 350 Series Aluminum Flood-Seal Multi-Port ConnectorsDocument4 pagesHomac RAB 350 Series Aluminum Flood-Seal Multi-Port ConnectorsLuis GalánPas encore d'évaluation

- Cable Lacing Techniques and ToolsDocument3 pagesCable Lacing Techniques and ToolsrxhornPas encore d'évaluation

- RishabhDocument25 pagesRishabhRishabh KumarPas encore d'évaluation

- Submarine Power Cables-ABBDocument16 pagesSubmarine Power Cables-ABBSang-Deok Lee100% (1)

- Learning Activity Sheet In: Computer Systems ServicingDocument12 pagesLearning Activity Sheet In: Computer Systems ServicingCarvalds 0315Pas encore d'évaluation

- How to make an Ethernet Cat5 cableDocument6 pagesHow to make an Ethernet Cat5 cableJim9870Pas encore d'évaluation

- Fiber Optic CableDocument21 pagesFiber Optic CableMehdi RabbaniPas encore d'évaluation

- Arrow Broschuere Cable and Wire - CopieDocument72 pagesArrow Broschuere Cable and Wire - CopieBassem BouzraraPas encore d'évaluation

- Macramé for Beginners and Beyond: 24 Easy Macramé Projects for Home and GardenD'EverandMacramé for Beginners and Beyond: 24 Easy Macramé Projects for Home and GardenÉvaluation : 4.5 sur 5 étoiles4.5/5 (7)

- White Paper Industry 4 0 EN 1 04Document16 pagesWhite Paper Industry 4 0 EN 1 04peterpinion9822Pas encore d'évaluation

- EncryptingFiles encFSDocument3 pagesEncryptingFiles encFSpeterpinion9822Pas encore d'évaluation

- Fault Analysis-Electronic Equipment Troubleshooting & Repair - PSMBDocument3 pagesFault Analysis-Electronic Equipment Troubleshooting & Repair - PSMBpeterpinion98220% (1)

- Goodyear Winter Survey Press Release 2015 FinalDocument3 pagesGoodyear Winter Survey Press Release 2015 Finalpeterpinion9822Pas encore d'évaluation

- Maryland Funding Opportunities: Your Passion. Our Technology. Student Success. CL9352Document20 pagesMaryland Funding Opportunities: Your Passion. Our Technology. Student Success. CL9352peterpinion9822Pas encore d'évaluation

- OpenSuse13 1Document1 pageOpenSuse13 1peterpinion9822Pas encore d'évaluation

- Super Sound: SupercolliderDocument7 pagesSuper Sound: Supercolliderpeterpinion9822Pas encore d'évaluation

- Docu59923 - VMAX3 TimeFinder SnapVX and Microsoft SQL Server White Paper PDFDocument49 pagesDocu59923 - VMAX3 TimeFinder SnapVX and Microsoft SQL Server White Paper PDFJorge Alberto Largaespada GonzalezPas encore d'évaluation

- Line 6 - Spider 3 - 1508-3012-HD75Document68 pagesLine 6 - Spider 3 - 1508-3012-HD75Francisco PerezPas encore d'évaluation

- Panasonic Cordless Phone 13Jan2019-KX-TGD390B-TGD390C - PNQX8061YA-Manual PDFDocument36 pagesPanasonic Cordless Phone 13Jan2019-KX-TGD390B-TGD390C - PNQX8061YA-Manual PDFHoPas encore d'évaluation

- Ansys Icepak BrochureDocument4 pagesAnsys Icepak Brochurejagadees21Pas encore d'évaluation

- LR-02 Manual EnglishDocument24 pagesLR-02 Manual EnglishCharliie RooseveltPas encore d'évaluation

- CustomerGas Engine Training Catalogue 2007Document18 pagesCustomerGas Engine Training Catalogue 2007docrafi50% (2)

- Stega PDFDocument12 pagesStega PDFKyRSaHTPas encore d'évaluation

- 0000518A Circuit Breaker PaperDocument5 pages0000518A Circuit Breaker PaperRicardo HerreraPas encore d'évaluation

- Pioneer - Avic n1 - Avic x1r crt3423Document312 pagesPioneer - Avic n1 - Avic x1r crt3423psapwell100% (1)

- 9mm!ূຌዡገ๕ۉ࿋ഗ Rotary Potentiometers With Metal Shaft Series: WH9011A-1-18TDocument26 pages9mm!ূຌዡገ๕ۉ࿋ഗ Rotary Potentiometers With Metal Shaft Series: WH9011A-1-18TpeterfunPas encore d'évaluation

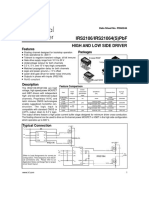

- IRS2106/IRS21064 high and low side driver datasheetDocument25 pagesIRS2106/IRS21064 high and low side driver datasheetmohamedPas encore d'évaluation

- Mobile DRAM Standard FormulationDocument5 pagesMobile DRAM Standard FormulationGajanand RajaputPas encore d'évaluation

- Sony XM 4501Document4 pagesSony XM 4501Thiago BressaniPas encore d'évaluation

- EPP and TLE Content Matrix PDFDocument2 pagesEPP and TLE Content Matrix PDFLynn PlacidoPas encore d'évaluation

- ANT ATD4516R5 2031 DatasheetDocument4 pagesANT ATD4516R5 2031 Datasheetangga meas100% (2)

- Ka1458 Reemplaso 5532Document10 pagesKa1458 Reemplaso 5532Heriberto Flores AmpiePas encore d'évaluation

- Handbook of Nanophase and Nano Structured Materials 4Document344 pagesHandbook of Nanophase and Nano Structured Materials 4mohayman100% (2)

- Troubleshoot EV100 LX SCR Control IssuesDocument33 pagesTroubleshoot EV100 LX SCR Control IssuesMigue Angel Rodríguez CastroPas encore d'évaluation

- Power Amplifier: Service ManualDocument20 pagesPower Amplifier: Service ManualLeonardo MarraffiniPas encore d'évaluation

- Framos Flyer Tof en FinDocument4 pagesFramos Flyer Tof en FinCamilo Andres Ardila OrtizPas encore d'évaluation

- Snack & Drink Vending MachinesDocument14 pagesSnack & Drink Vending MachinesAbel TeferaPas encore d'évaluation

- All-In-One Compressed Air StationDocument6 pagesAll-In-One Compressed Air StationAlexandru Bogdan FilipPas encore d'évaluation

- Bucket BrigadeDocument11 pagesBucket BrigadezluiznetoPas encore d'évaluation

- Stylish and Robust Slimline Plus Range Offers Ease of Installation and AffordabilityDocument14 pagesStylish and Robust Slimline Plus Range Offers Ease of Installation and Affordabilitybenghoe77Pas encore d'évaluation

- NR Test Block MD1701S CatalogDocument3 pagesNR Test Block MD1701S CatalogccmbuxPas encore d'évaluation

- Fiery Cws Cofigure Color Work StationDocument90 pagesFiery Cws Cofigure Color Work StationAli VatanPas encore d'évaluation

- HP Spectre 13 Maintenance and Service Guide PDFDocument81 pagesHP Spectre 13 Maintenance and Service Guide PDFDzung NguyenPas encore d'évaluation

- ATOP Pick To Light Systems - Boreal Technologies PDFDocument2 pagesATOP Pick To Light Systems - Boreal Technologies PDFWagner MontielPas encore d'évaluation

- Check List For Acdb: Document NoDocument2 pagesCheck List For Acdb: Document NoJaswant SutharPas encore d'évaluation

- Manual 802Document38 pagesManual 802Ludovic OuedraogoPas encore d'évaluation