Académique Documents

Professionnel Documents

Culture Documents

Formwork Checklist2007

Transféré par

nayakyaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Formwork Checklist2007

Transféré par

nayakyaDroits d'auteur :

Formats disponibles

Formwork activities in construction sample site safety checklist

Inspected by: Site address: Record no: Date of inspection:

Note: This checklist is a guide only and may be used to assist in determining compliance with safety requirements for formwork activities in construction. Further information can be obtained by contacting Workplace Health and Safety Queensland (1300 369 915) or www.deir.qld.gov.au

Formwork safety issues 1. Formwork drawings provided (drawings to include engineer/formwork designer certification) Verification that the formwork structure complies with the design of the formwork system (pre pour inspections)

2.

3.

Back propping details (plans and elevations including tying in)

4.

Engineer certification for lifting points for column boxes and wall shutters

5.

Design documentation for jump form

Compliance indicators and Code/Regulation/Act reference Drawings to be readily available on site. Drawings signed by professional engineer (non basic system)/formwork designer (basic system). Formwork Code sections 2.2.2, 2.2.5 Pre pour sign off by professional engineer/formwork designer/competent person. Checklists and certificates similar to Appendix 3 and 4 completed and on site. Formwork Code section 2.2.5, Appendix 3 and 4 Specific plans or notes on drawings to be readily available on site. Back propping to be completed as per drawings Formwork Code sections 2.2.3, 2.2.5 Specific drawings/certification provided by professional engineer nominating lifting point details to be readily available on site. Certification should verify structural adequacy of lifting apparatus and the means for attachment to load (usually welded or bolted) Work practices reflect drawings Formwork Code section 4.4.5 Drawings specific to the jump form to be readily available on site. Drawings signed by professional engineer. Work practices reflect drawings. Formwork Code section 8.7

Compliant (yes/no)

Action required

Page 1 of 7

Formwork activities in construction sample site safety checklist

Formwork safety issues 6. Design documentation for perimeter containment screening Compliance indicators and Code/Regulation/Act reference Drawings specific to the perimeter containment screening to be readily available on site. Drawings signed by a professional engineer if screening is a part of a non basic formwork system or proprietary item. Formwork Code section 2.2.3 Drawings signed by professional engineer (non basic system)/formwork designer (basic system). Drawings to be readily available on site. Work practices reflect drawings. Formwork Code sections 2.2.2, 2.2.5 Drawings/certification readily available on site certified by formwork designer/professional engineer that variations comply with AS 3610 Formwork structure reflects variations to initial design drawings. Formwork Code section 2.2.5 Work method statement readily available and addresses relevant risks (falls from height). Work practices reflect work method statement Formwork Code section 4.3.1 WQHS Regulations 1997 sections 157, 191, 194 Drawings/certification from professional engineer that surface to be used for stacking of forms is capable of withstanding loads and details of how loads are to be applied. Work practices reflect drawings/certification. Formwork Code section 3.2.2 Designated access ways provided (hazard tape/other visual methods). Persons instructed in the use of the access ways. Access ways clear of rubbish, plant and materials. Formwork Code section 3.2.1, WHS Regulation 1997 s174(2)(b)&(c),s200(2)(d)&(e) Compliant (yes/no) Action required

7.

Certification of the maximum loads from stacked materials that the formwork structure can withstand

8.

Design variations certified eg: Braces left off Frame extensions No base plates on frames Flat jacks in lieu of U heads Work method statements adequate for purpose (e.g. formwork stripping)

9.

10. A frame shutter storage racks &/or shutter storage areas engineer designed

11. Access in and around formwork structure

Page 2 of 7

Formwork activities in construction sample site safety checklist

Formwork safety issues 12. Systems of material storage in and around formwork structure Compliance indicators and Code/Regulation/Act reference Materials stored so as to minimise manual tasks hazards, trip hazards and the potential for falling objects. Smaller components such as U-heads, couplers, base plates and Z-bars contained in material boxes. Components stored so as to provide access to designated walkways. Formwork Code section 3.2.2, WHS Regulation 1997 s174(2)(c),s200 2(e) The provision of rubbish skips and wheel barrow that are moved as work progresses. Rubbish stored so as to provide access to designated walkways. Rubbish removed at regular intervals. Formwork Code section 3.2.3, WHS Regulation 1997 s174(2)(b),s200 2 (d) The provision of rubbish skips, brooms etc on the working deck. The provision of spill kits for excess form oil. Formwork Code section 3.2.3, WHS Regulation 1997 s174(2)(b),s200 2 (d) Stripping area condoned off with signs and barricades. Formwork Code section 4.3.4 Persons erecting framing over 4m high produce evidence of either scaffold certificate or that they are a trainee (up to date log book) Formwork Code section 4.1.3, WHS Regulation 1997 s17(1), (2), (3), 21, 22, 24, 25 Minimum of two planks (450mm width) used for workers to stand on under 2m high. Formwork Code section 4.1 Compliant (yes/no) Action required

13. Systems of rubbish storage and removal in and around formwork structure

14. Form decks clean and clear e.g. no excess form oil, sawdust

15. Barricades/signs for stripping areas

16. Erectors of framing over 4m high are holders of basic scaffold certificate/trainees

17. Minimum width 450mm work platform used for framing work under 2m

Page 3 of 7

Formwork activities in construction sample site safety checklist

Formwork safety issues 18. False deck used Compliance indicators and Code/Regulation/Act reference False deck same area as floor being formed (inside and between frames). Captive planks secured against uplift and slipping. Gaps do not exceed 225mm. Formwork Code section 4.1. Edge protection complies with Regulation (top rail, mid rail, toe boards/top rail, mesh guards). Edge protection in place prior to formwork activities or barricade in place at least 1.8m back from edge. False deck provided no more than 2.0m below formwork deck. If no false deck in place minimum of 4 joists laid out at 450mm centres beside and 1.8m in front. Formwork Code section 2.2.3, 4.1.6 & 4.1.7, WHS Regulation 1997 s216 Ply covers used which are firmly secured by bolting/concrete nailing. Ply covers which are marked with bright paint to signify that there is a hole under. Formwork Code section 4.1.9 Edge protection complies with Regulation (top rail, mid rail, toe boards/top rail, mesh guards). Formwork Code section 7.2, 8.2, WHS Regulation 1997 s216 Screening complies with Regulation ( gaps between screens no more than 25mm, fitted with a catch platform/deflector shields, made of mesh sheeting, plywood or timber, mesh pattern to be no more than 50mmx50mm with prescribed lining or 25mm x 25mm for square openings/25mm x 50mm for other openings). Top of screening to be no less than 1.2m higher than poured slab. Formwork Code section 5.1.1, WHS Regulation 1997 s179, 184 Compliant (yes/no) Action required

19. Edge protection/fall protection to decks

20. Penetrations securely covered

21. For work on wall forms-gaps less than 225mm or edge protection installed

22. Perimeter containment screening

Page 4 of 7

Formwork activities in construction sample site safety checklist

Formwork safety issues 23. Joist spacing no more than 450mm to deck where no false deck used 24. Provision for retrieval of injured worker from work areas within jump form system Compliance indicators and Code/Regulation/Act reference If no false deck in place minimum of 4 joists laid out at 450mm centres beside and 1.8m in front. Formwork Code section 4.1.7, Details of retrieval method (dedicated hatches, tripod etc) included in jump form design drawings. Work procedure for retrieval of injured worker readily available and workers aware of process. Formwork Code section 2.2.3, 8 Designated access ways provided. Persons instructed in the use of the access ways. Access ways clear of rubbish, plant and materials. Ladders secured and used as per Regulation. Access hatches/trapdoors closed when not in use. Formwork Code section 8.1, WHS Regulation 1997 s174(2)(b)&(c) ,s200(2)(d)&(e) Chemical toilet supplied and serviced on top of jump form. Clean drinking water available at least on top of jump form. First aid equipment readily available. Formwork Code section 8.6 All penetrations to work platforms securely covered by ply/mesh. Controls in place to prevent a persons fall when placing reinforcing steel/pouring concrete to wall void areas. Formwork Code section 8.2 Documentation readily available to verify details of bracing elements. Work practices as per documentation. Competent person sign off prior to removal of any bracing. Any anchors used to be as per design and manufacturers requirements. Formwork Code section 7.1 Compliant (yes/no) Action required

25. Access to, from and within jump form system

26. Amenities supplied to jump form (water, toilet, first aid kit)

27. Work platforms

28. Column/wall bracing (pre and post pour)

Page 5 of 7

Formwork activities in construction sample site safety checklist

Formwork safety issues 29. PPE used in areas of excessive noise Compliance indicators and Code/Regulation/Act reference Hearing protection of Class 2 or 3 rating worn in areas of excessive noise. Workers trained in correct use of hearing protection. Formwork Code section 6.1, WHS Act 1995 s36 Engineering controls such as dust extraction or a wet process. Use of respirators. Workers trained in correct use of PPE. Formwork Code section 6.2, WHS Act 1995 s36 PC or formwork contractor has records of tool box talks readily available. Work practices reflect work method statements/work procedures. Formwork Code section 3.3, WHS Regulation 1997 s168, 191, 193, 194 Cranes, hoists, pallet jacks and trolleys in use. Formwork Code section 6.3 Compliant (yes/no) Action required

30. Effective control measure used for exposure to silica dust

31. Regular Tool Box Talks held to maintain awareness levels of hazards, risks, controls

32. Use of mechanical means for movement of formwork equipment/materials (overstressing injuries)

Page 6 of 7

Formwork activities in construction sample site safety checklist

Definitions. Professional Engineer A person who is a registered professional engineer under the Professional Engineers Act 2002 (Qld); and who has appropriate experience and competence in the design of formwork. Formwork designer A person who is competent in designing formwork and who holds a relevant degree in engineering or building or has successfully completed courses in formwork design and has appropriate experience in this field. Competent person In relation to performing an inspection or other task for a control measure is a person who has acquired, through training, qualifications or experience the knowledge and skills to do the work in a safe way, including (i) sound knowledge of relevant Australian Standards, relevant codes of practice and other relevant legislation; and (ii) sound knowledge of, and competence in, the risk management process for the erecting, altering and dismantling of formwork, including o hazard identification and risk assessment; and o measures to control exposure to risks; and o safe work practices and procedures; and o how to plan and prepare formwork. Basic formwork system A basic formwork system includes: standard formwork frames which have a known tested loading capacity spaced at no more than the recommended distances apart for a normal floor thickness with bearer, joists and formboard on top of them; and specially manufactured and designed formwork systems with proprietary formwork components and rated load calculations in line with the manufacturers specifications. Non basic formwork system Formwork systems which exceed the description of a basic formwork system are, for the purposes of this Code, categorised as non-basic formwork systems. The Code requires that a professional engineer is the only person who may certify: the design of all temporary or permanent formwork structures categorised as non-basic formwork systems; and any back propping used for either basic formwork systems or non-basic formwork systems.

Page 7 of 7

Vous aimerez peut-être aussi

- Blast Furnace Slag Aggregate: World Class Experience. World Class ServiceDocument2 pagesBlast Furnace Slag Aggregate: World Class Experience. World Class ServiceLeilani JohnsonPas encore d'évaluation

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- REACTIVE POWDER CONCRETE - DocxwDocument8 pagesREACTIVE POWDER CONCRETE - Docxwsalman kPas encore d'évaluation

- Human Factors & Virtual Reality: Simone ColomboDocument62 pagesHuman Factors & Virtual Reality: Simone ColombouakhiljayaramPas encore d'évaluation

- Project Charter Template 03Document2 pagesProject Charter Template 03shyam052089Pas encore d'évaluation

- Resource Efficiency in Aluminium SectorDocument7 pagesResource Efficiency in Aluminium Sectorkundan SinghPas encore d'évaluation

- 7.5 - Types of Cost, Revenue and Profit, Short-Run and Long-Run Production (S)Document150 pages7.5 - Types of Cost, Revenue and Profit, Short-Run and Long-Run Production (S)l PLAY GAMESPas encore d'évaluation

- What Is Sustainability Reporting?Document35 pagesWhat Is Sustainability Reporting?antoncitraPas encore d'évaluation

- Sustainability Report 2017 PT GMF AeroAsia TBK PDFDocument186 pagesSustainability Report 2017 PT GMF AeroAsia TBK PDFElsaDayeraPas encore d'évaluation

- MATRIK KORESPONDENSI ISO 45K SeriesDocument13 pagesMATRIK KORESPONDENSI ISO 45K Seriesmypusri1678Pas encore d'évaluation

- The Role of Internal Audit in CSR Reporting Practices and The Ethical ConsiderationsDocument43 pagesThe Role of Internal Audit in CSR Reporting Practices and The Ethical ConsiderationsAnnisha0% (1)

- Kritik Jurnal?: Dr. Muhammad Sofwan MahmudDocument12 pagesKritik Jurnal?: Dr. Muhammad Sofwan Mahmudwhy daPas encore d'évaluation

- Reduction in New Business DiscrepancyDocument85 pagesReduction in New Business DiscrepancyN E E R A J S I N G HPas encore d'évaluation

- 8-IWRE 416-Formwork and FalseworkDocument41 pages8-IWRE 416-Formwork and Falseworkally IsayaPas encore d'évaluation

- KuliahUmum-UPNVJ Prof. Harwin Saptoadi 21120Document29 pagesKuliahUmum-UPNVJ Prof. Harwin Saptoadi 21120ulfa hanifah nurhalizaPas encore d'évaluation

- POWER QUALITY Session 1Document8 pagesPOWER QUALITY Session 1Waluyo Jati SoemowidagdoPas encore d'évaluation

- Sales Management-Chapter 8Document12 pagesSales Management-Chapter 8furqaan tahirPas encore d'évaluation

- DM Fadg 2017 PDFDocument51 pagesDM Fadg 2017 PDFCristian Camilo Mantilla OviedoPas encore d'évaluation

- Procedure of Energy SavingDocument13 pagesProcedure of Energy SavingPeter DefPas encore d'évaluation

- Index of U.S. Energy Security Risk: Assessing America's Vulnerabilities in A Global Energy MarketDocument90 pagesIndex of U.S. Energy Security Risk: Assessing America's Vulnerabilities in A Global Energy MarketU.S. Chamber of CommercePas encore d'évaluation

- 7 - GHG PresentationDocument39 pages7 - GHG PresentationSheryl MH-PradaPas encore d'évaluation

- Erosion and Sedimentation Control Rev 0Document35 pagesErosion and Sedimentation Control Rev 0MohamedOmar83Pas encore d'évaluation

- AIGA 058 - 13 Safe Preparation of Compressed Oxidant Gas MixturesDocument40 pagesAIGA 058 - 13 Safe Preparation of Compressed Oxidant Gas MixturesVan SotPas encore d'évaluation

- Building Science and TechnologyDocument67 pagesBuilding Science and Technologykaleem zargarPas encore d'évaluation

- HSBC - Corporate Social ResponsibilityDocument36 pagesHSBC - Corporate Social ResponsibilityNajjar7Pas encore d'évaluation

- Accident Investigation - 5 PDFDocument10 pagesAccident Investigation - 5 PDFLal DhwojPas encore d'évaluation

- LEED Zero Program Guide Net Zero WaterDocument12 pagesLEED Zero Program Guide Net Zero WaterYasin KhanPas encore d'évaluation

- Book ListDocument2 pagesBook ListnulluzerPas encore d'évaluation

- Presentation On Human Resource PlanningDocument34 pagesPresentation On Human Resource PlanningTanvir Mohammad Saddaf100% (1)

- ISO DGuide 83 (E) PDFDocument15 pagesISO DGuide 83 (E) PDFEdison Benítez SalazarPas encore d'évaluation

- Green Cement R22Document24 pagesGreen Cement R22povhiePas encore d'évaluation

- Cement - Introduction and TypesDocument24 pagesCement - Introduction and TypesHarish KumarPas encore d'évaluation

- SS 535-2018Document51 pagesSS 535-2018Michael NgoPas encore d'évaluation

- BLDG3012 - Week 2 PDFDocument37 pagesBLDG3012 - Week 2 PDFQingyang PanPas encore d'évaluation

- How To Choose The Right Cleaning Supplier Ebook (Integral UK)Document17 pagesHow To Choose The Right Cleaning Supplier Ebook (Integral UK)Tannice HemmingPas encore d'évaluation

- Sustainable INFRASTAR Reference Manual Guideline PDFDocument131 pagesSustainable INFRASTAR Reference Manual Guideline PDFJinSoon TanPas encore d'évaluation

- Welcome To Sheq FoundationDocument8 pagesWelcome To Sheq FoundationElla AgbettorPas encore d'évaluation

- Employer: Consultant: Contractor: Road Development Authority Central Engineering Consultancy Bureau CATIC/MAGA/A-35Document4 pagesEmployer: Consultant: Contractor: Road Development Authority Central Engineering Consultancy Bureau CATIC/MAGA/A-35ලහිරු විතානාච්චිPas encore d'évaluation

- Business Ethics & Professional ResponsibilityDocument272 pagesBusiness Ethics & Professional ResponsibilityEqraChaudharyPas encore d'évaluation

- ErosionSedFlyer PDFDocument2 pagesErosionSedFlyer PDFrishiPas encore d'évaluation

- Daily Inspection Checklist - SFLBDocument3 pagesDaily Inspection Checklist - SFLBAdriana EscobarPas encore d'évaluation

- EUROPUMP ATEX Guide - LL - 28012008Document11 pagesEUROPUMP ATEX Guide - LL - 28012008hazarderPas encore d'évaluation

- Safety Management in The Construction Industry:: SmartmarketDocument56 pagesSafety Management in The Construction Industry:: SmartmarketLouie MirandaPas encore d'évaluation

- PRO-1400-0000-002 Incident Investigation Reporting and ClassificationDocument12 pagesPRO-1400-0000-002 Incident Investigation Reporting and Classificationrodman823100% (2)

- Construction Materials DescriptionDocument69 pagesConstruction Materials DescriptionAlejandra De LeonPas encore d'évaluation

- Guidelines For Safe Storage of Flammable Materials CabinetsDocument12 pagesGuidelines For Safe Storage of Flammable Materials Cabinetsdhrit_wPas encore d'évaluation

- Design Reference Guide: Industrial FacilitiesDocument34 pagesDesign Reference Guide: Industrial Facilitiesnoreta hasanPas encore d'évaluation

- 2020-11-02 ESG Discussion PaperDocument154 pages2020-11-02 ESG Discussion PaperAdriana CarpiPas encore d'évaluation

- Seminar Presentation On Green ConcreteDocument22 pagesSeminar Presentation On Green ConcreteMOHINI JAISWALPas encore d'évaluation

- Bsi Ppe Factsheet Uk enDocument2 pagesBsi Ppe Factsheet Uk enRahul KrishnaPas encore d'évaluation

- 3 Jim Joy. ICMM Critical Control ManagementDocument34 pages3 Jim Joy. ICMM Critical Control ManagementLuis Olle ArrolaPas encore d'évaluation

- MBSA Conference 08122016Document29 pagesMBSA Conference 08122016nrhdyhzmnPas encore d'évaluation

- Green RE For Commercial BuildingDocument102 pagesGreen RE For Commercial BuildingMohd RizalPas encore d'évaluation

- Hseplan 200615062050Document169 pagesHseplan 200615062050Mohammad AshpakPas encore d'évaluation

- We Are Not The FirstDocument159 pagesWe Are Not The Firstabdulaziz.a.alkalbaniPas encore d'évaluation

- 1-Introduction To Sustainable Development and EngineeringDocument11 pages1-Introduction To Sustainable Development and Engineeringsborland3784Pas encore d'évaluation

- Formwork Activities in Construction - Sample Site Safety ChecklistDocument7 pagesFormwork Activities in Construction - Sample Site Safety ChecklistatiPas encore d'évaluation

- 7-Method Statement For Gypsum PartitionDocument9 pages7-Method Statement For Gypsum Partitionozyoclown100% (5)

- Hyundai Al-Form Installation ManualDocument41 pagesHyundai Al-Form Installation Manualrezka muhsonyPas encore d'évaluation

- Snake Control 101: The Basics of Keeping Snakes AwayDocument8 pagesSnake Control 101: The Basics of Keeping Snakes AwaynayakyaPas encore d'évaluation

- Crane Safety PPTDocument32 pagesCrane Safety PPTnayakya100% (1)

- Ergonomics in WeldingDocument28 pagesErgonomics in Weldingnayakya100% (1)

- Hot TappingDocument21 pagesHot TappingnayakyaPas encore d'évaluation

- Emergency ExitDocument1 pageEmergency ExitnayakyaPas encore d'évaluation

- Accident Investigation - The Six Key Questions: Question 1: WHODocument2 pagesAccident Investigation - The Six Key Questions: Question 1: WHOnayakyaPas encore d'évaluation

- Rita.04.Hazard Symbols KeyDocument14 pagesRita.04.Hazard Symbols KeyyogasanaPas encore d'évaluation

- Each First Aid Kits Should Include The Following ItemsDocument1 pageEach First Aid Kits Should Include The Following ItemsnayakyaPas encore d'évaluation

- Face MaskDocument1 pageFace MasknayakyaPas encore d'évaluation

- Electrical HazardsDocument48 pagesElectrical HazardsnayakyaPas encore d'évaluation

- Hot Environments - Health EffectsDocument1 pageHot Environments - Health EffectsnayakyaPas encore d'évaluation

- Head Protection - Hard Hats: Guide For DiscussionDocument1 pageHead Protection - Hard Hats: Guide For DiscussionnayakyaPas encore d'évaluation

- Transportation Tuesday: A Slight Mistake or Distraction While Driving Could Lead To An AccidentDocument7 pagesTransportation Tuesday: A Slight Mistake or Distraction While Driving Could Lead To An AccidentnayakyaPas encore d'évaluation

- What Can Be Done?: Why Is The Sea Level Rising?Document2 pagesWhat Can Be Done?: Why Is The Sea Level Rising?nayakyaPas encore d'évaluation

- Why Are Trenches DangerousDocument3 pagesWhy Are Trenches DangerousnayakyaPas encore d'évaluation

- Fire Extinguisher Basic Training: Review QuizDocument2 pagesFire Extinguisher Basic Training: Review QuiznayakyaPas encore d'évaluation

- Root Cause Analysis Example Near Miss Asphalt Drop FULLDocument9 pagesRoot Cause Analysis Example Near Miss Asphalt Drop FULLnayakya100% (1)

- How Does Actuators WorksDocument2 pagesHow Does Actuators WorksnayakyaPas encore d'évaluation

- Appraisal Phrases Positive Characteristics:: Characteristics That Show PotentialDocument2 pagesAppraisal Phrases Positive Characteristics:: Characteristics That Show PotentialnayakyaPas encore d'évaluation

- Safety Method StatementDocument14 pagesSafety Method StatementnayakyaPas encore d'évaluation

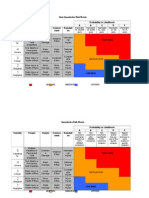

- Simi-Quantitative Risk Matrix Probability or Likelihood A B C D E Severity People Assets Environ Ment Reputati OnDocument2 pagesSimi-Quantitative Risk Matrix Probability or Likelihood A B C D E Severity People Assets Environ Ment Reputati OnnayakyaPas encore d'évaluation

- CoW PolicyDocument13 pagesCoW PolicynayakyaPas encore d'évaluation

- Functions of Safety CommitteeDocument2 pagesFunctions of Safety CommitteenayakyaPas encore d'évaluation

- Aspen HYSYS Simulation of CO2 Removal by Amine Absorption From A Gas Based Power PlantDocument9 pagesAspen HYSYS Simulation of CO2 Removal by Amine Absorption From A Gas Based Power PlantLina1929Pas encore d'évaluation

- What Is Ergonomics?Document2 pagesWhat Is Ergonomics?nayakyaPas encore d'évaluation

- Conseal 250Document2 pagesConseal 250Rabih GergesPas encore d'évaluation

- CLT USA-Chapter-3 0Document35 pagesCLT USA-Chapter-3 0Adam BartonPas encore d'évaluation

- Masonry Manual 2007Document96 pagesMasonry Manual 2007lbss2200880% (5)

- Seminar Presentation On Cable Stayed BridgeDocument26 pagesSeminar Presentation On Cable Stayed BridgeSijan ShresthaPas encore d'évaluation

- Vidhan BhavanDocument10 pagesVidhan Bhavanaastha545Pas encore d'évaluation

- Bo ConceptsDocument12 pagesBo ConceptsshaanviPas encore d'évaluation

- Vlan Provisioning Security Guidance At-A-Glance v8r1Document15 pagesVlan Provisioning Security Guidance At-A-Glance v8r1karthikav3Pas encore d'évaluation

- Material HeritageDocument5 pagesMaterial HeritageAxx A AlPas encore d'évaluation

- CAN Protocol: Desd at Sunbeam InfotechDocument3 pagesCAN Protocol: Desd at Sunbeam InfotechKomal ChougulePas encore d'évaluation

- GROHE Sanitary SystemsDocument135 pagesGROHE Sanitary SystemsKadiri OlanrewajuPas encore d'évaluation

- Viewsonic - vg730m-5-Vs10383 - (Copia Conflictiva de Sylvan-Mesa 2013-01-30)Document96 pagesViewsonic - vg730m-5-Vs10383 - (Copia Conflictiva de Sylvan-Mesa 2013-01-30)sylvan_Pas encore d'évaluation

- Lifetime Support Applications 069216Document57 pagesLifetime Support Applications 069216logiuxPas encore d'évaluation

- Free Download VOLVO PROSIS Part & Repair 2015 PatchDocument4 pagesFree Download VOLVO PROSIS Part & Repair 2015 PatchEngematsu KomatsuPas encore d'évaluation

- MPLS in Mobile BackhualDocument88 pagesMPLS in Mobile Backhual万尼杨100% (1)

- Effect of Stirrups (PARTE 01) PDFDocument18 pagesEffect of Stirrups (PARTE 01) PDFDanPas encore d'évaluation

- Drafting Module 10 Ab 2nd QDocument20 pagesDrafting Module 10 Ab 2nd QKC JaymalinPas encore d'évaluation

- Emlab: Installation GuideDocument64 pagesEmlab: Installation GuidekgskgmPas encore d'évaluation

- Speed Dowel Brochure 0811 ReducedDocument4 pagesSpeed Dowel Brochure 0811 ReducedwilliamptyPas encore d'évaluation

- SAP HANA Commvault Best PracticesDocument2 pagesSAP HANA Commvault Best PracticesDevender5194Pas encore d'évaluation

- Civil Rate Analysis 0 72-73 Kathmandu To Be UpdatedDocument697 pagesCivil Rate Analysis 0 72-73 Kathmandu To Be UpdatedAnonymous 3fQZqsGIu79% (62)

- Brkarc 3003Document77 pagesBrkarc 3003Pepito CortizonaPas encore d'évaluation

- Architecture of IndonesiaDocument4 pagesArchitecture of Indonesiachengliii.luluPas encore d'évaluation

- Weblogic Portal JSF WhitepaperDocument152 pagesWeblogic Portal JSF WhitepaperwangpchomebuyPas encore d'évaluation

- Theta Newsletter Spring 2010Document6 pagesTheta Newsletter Spring 2010mar335Pas encore d'évaluation

- LED Solutions Catalogue 2011Document537 pagesLED Solutions Catalogue 2011stewart_douglas574Pas encore d'évaluation

- Liquid Process Piping Design Strategy R2Document16 pagesLiquid Process Piping Design Strategy R2Masood Khan100% (1)

- Eero SaarinenDocument16 pagesEero SaarinenSaunokPas encore d'évaluation

- Technical Drawing StandardsDocument20 pagesTechnical Drawing StandardsGeorge Maliaris57% (14)

- Proposed Additional Septic Vault: Boundary LineDocument1 pageProposed Additional Septic Vault: Boundary LineRheyJun Paguinto AnchetaPas encore d'évaluation

- Hardware and Software RequirementsDocument11 pagesHardware and Software Requirementsaless2056Pas encore d'évaluation