Académique Documents

Professionnel Documents

Culture Documents

L&T Bhilai Gtp-01 Dated 24-04-12

Transféré par

ashokbathwalDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

L&T Bhilai Gtp-01 Dated 24-04-12

Transféré par

ashokbathwalDroits d'auteur :

Formats disponibles

Technology GmbH

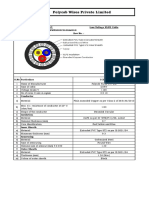

LARSEN & TOUBRO LIMITED ECC Division - EDRC

INSTRUMENT DATA SHEET FOR SIGNAL SCREEN CABLE FOR BHILAI SINTER PLANT SP#3B

Rev 0

Date 01/11/11

Prepared PBI/GMT

Checked SMV

Approval DCH

Description FIRST ISSUE

1P X 1.0 Sq. MM

Manufacturer Name

2P X 1.0 Sq. MM

4P X 1.0 Sq. MM

6P X 1.0 Sq. MM

M/s T C Communication Pvt. Ltd.,

Applicable Standard Type Voltage Grade Conductor a) Material b) Area( approx.) No of Strands/ Approx Dia of each Strand Primary Insulation a) Material b) Type c) Thickness(Nom.) d) Lay/ Twist per meter( for pair) Individual Pair Shielding a) Material b) Type c) Thickness(Nom.) d) Overlap e) Coverage f) Drain wire, Size /No. of strand/ Approx. Dia of each Strand Overall Shielding. a) Material b) Type c) Thickness(nom.) d) Overlap e) Coverage f) Drain wire, Size /No. of strand/ Approx. Dia of each Strand

BS: 5308 Part-II/86, IS 1554( Part-1)/88, IS : 8130/ 84, IS : 5831/84, IS : 3975, ASTM-D-2863, ASTM-D-2843, IEC-60754-1, IEEE-383 HR PVC Insulated, Individual Pair and Overall Shielded, HR PVC Inner Sheathed, G.I. Wire armoured and Overall FR PVC sheathed signal cables (Single Pair shall have only overall Screen) 600V

Stranded & Circular Electrolytic Annealed Tinned Copper as per IS:8130/84 1.0 Sq..mm 1.0 Sq..mm 7/0.43 mm 1.0 Sq..mm 1.0 Sq..mm

HR PVC Type-C confirmed to IS:5831/84 Extruded 0.6 mm 0.6 mm 0.6 mm 0.6 mm

Cores Twisted to form Pair, 10 Twists per mtrs.

Aluminium Mylar Tape Helical 0.05 mm 25% 100% 0.05 mm 25% 100% 0.05 mm 25% 100% 0.05 mm 25% 100%

Annealed Tinned copper, 0.518 Sq.mm( 20AWG)/ 7 / 0.3 ( continuously in contact with Shield)

Aluminium Mylar Tape Helical 0.05 mm 25% 100% 0.05 mm 25% 100% 0.05 mm 25% 100% 0.05 mm 25% 100%

Annealed Tinned copper, 0.518 Sq.mm( 20AWG)/ 7 / 0.3( continuously in contact with Shield)

Job Name: BHILAI SINTER PLANT SP#3B

L&T Document-No. : O10195-GS-I-D-24036

Sub-Vendor

Rev. 0

Sheet No 1 of 3

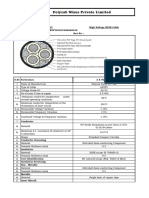

Technology GmbH

LARSEN & TOUBRO LIMITED ECC Division - EDRC

INSTRUMENT DATA SHEET FOR SIGNAL SCREEN CABLE FOR BHILAI SINTER PLANT SP#3B

Inner Sheath Material Type Thickness Dia Over Inner Sheath Armouring Material Size( Norm.) Dia Over Armouring Outer Sheath Material Type Thickness Dia Over outer Sheath( with +/2.0 mm tolerance) Core Identification Colours Of Core Innner Jacket Outer Jacket Continuous Length/ Drum Max. and Min. Possible variation length Elecl.Characteristic Max DC Resistance of Complete Cable at 20 degree C as per BS Max. Mutual Capacitance at 1 KHz a) Core to core b) Core to Screen Max Mutual inductance Max L/R ratio 250 pF/Mtr 400 pF/Mtr 1mH/Km 25H/ 18.2 Ohm/Km 18.2 Ohm/Km 18.2 Ohm/Km 18.2 Ohm/Km Pair Colour: White & Blue. Also Numbering shall be provided on each pair at a regular interval of 250mm for pair identification Black Blue 500/1000 meter or single length in case of quantity less than 1000 meter or balance length. Packing shall be done in non-returnable drums. 500/1000 meters with +5%, -0% tolerance or single legth with+5%, -0% tolerance in case of quantity less than 1000 meters or balance length, overall quantity tolerance +/- 2% 1.24 mm 13.5 mm 1.24 mm 15.5 mm FR PVC Type ST2 confirmed to IS:5831/84 Extruded 1.40 mm 19.0 mm 1.56 22.0 mm 1.4 mm 10.30 mm Galvanized Steel round wire 1.4 mm 12.30 mm 1.4 mm 15.50 mm 1.6 mm 18.40 mm 0.8 mm 7.50 mm 0.8 mm 9.50 mm HR PVC Type ST2 confirmed to IS:5831/84 Extruded 0.8 mm 12.70 mm 0.8 mm 15.20 mm

Job Name: BHILAI SINTER PLANT SP#3B

L&T Document-No. : O10195-GS-I-D-24036

Sub-Vendor

Rev. 0

Sheet No 2 of 3

Technology GmbH

LARSEN & TOUBRO LIMITED ECC Division - EDRC

INSTRUMENT DATA SHEET FOR SIGNAL SCREEN CABLE FOR BHILAI SINTER PLANT SP#3B

Test & Inspection a) General Cable Size Total Legth Additional Information a) Rip Cord b) Minimum Insulation Resistance at 20 Degee of Complete Cable. c) High Voltage Test Shall be provided below inner sheath 25M/KM Core to core:1.5 KV rms for 1 Min Core to Screen:- 0.5 KV per 1 Min Manufacturer's Name, Year of Manufacture, Voltage Grade, Conductor Material, No.of Pair, Conductor Size, Type of insulation shall be embossed on outer sheath of cables. Also sequential length marking shall be provided on outer sheath of cable in interval not exceeding 625mm. 1P X 1.0 Sq. MM 1500 As Per Manufacturer Standard, IS 1554-Part-1, 1988 2P X 1.0 Sq. MM 1500 4P X 1.0 Sq. MM 4000 6P X 1.0 Sq. MM 2000

d) Marking on Outer Sheath

e) FR Properties of Outer sheath i) Minimum Oxygen Index as per ASTM-D-2863 ii) Minimum Tempearture Index as per ASTM-D-2863 iii) Flammability test on Complete Cable 29% 250 Deg C As per IEC-332-1

Job Name: BHILAI SINTER PLANT SP#3B

L&T Document-No. : O10195-GS-I-D-24036

Sub-Vendor

Rev. 0

Sheet No 3 of 3

Vous aimerez peut-être aussi

- Gear Geometry & Profile TheoryDocument24 pagesGear Geometry & Profile Theoryansh1983100% (2)

- Eddy 2Document8 pagesEddy 2mahetrpPas encore d'évaluation

- BK10 - HVAC - MTO For Installation of Fire Damper & Instruments REV.0 (20!07!2011)Document4 pagesBK10 - HVAC - MTO For Installation of Fire Damper & Instruments REV.0 (20!07!2011)vamcodongPas encore d'évaluation

- Criticism On EDS - 1703029 - ShaurabhDocument2 pagesCriticism On EDS - 1703029 - Shaurabhsabey22991Pas encore d'évaluation

- WEF Technology and Innovation The Next Economic Growth Engine PDFDocument33 pagesWEF Technology and Innovation The Next Economic Growth Engine PDFPiroch RudolfPas encore d'évaluation

- Feasibility Analysis of 5MW Osmanabad Solar PV Power ProjectDocument52 pagesFeasibility Analysis of 5MW Osmanabad Solar PV Power ProjectAnkur PathakPas encore d'évaluation

- AEMDocument49 pagesAEMRamesh100% (1)

- Radio Navigation QBDocument64 pagesRadio Navigation QBVijay Samuel J100% (3)

- Shipping DepartmentDocument169 pagesShipping DepartmentPrakash_K_Pas encore d'évaluation

- Polycab 10mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 10mm 3 Core Copper Armoured Cable Specification SheetbharathPas encore d'évaluation

- Eddy Current Tubing DentingDocument54 pagesEddy Current Tubing Dentingaldeanucu100% (3)

- Asterisk Admin Guide 13.5Document857 pagesAsterisk Admin Guide 13.5Pedro VargasPas encore d'évaluation

- International Strategic Alliances: After Studying This Chapter, Students Should Be Able ToDocument19 pagesInternational Strategic Alliances: After Studying This Chapter, Students Should Be Able Toaidatabah100% (1)

- Instrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsPas encore d'évaluation

- Instrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsPas encore d'évaluation

- Cable Type BS5308Document2 pagesCable Type BS5308Jitendra MahidaPas encore d'évaluation

- DS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstDocument3 pagesDS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstAppzPas encore d'évaluation

- Gauranteed Techncial Particulars (GTP)Document2 pagesGauranteed Techncial Particulars (GTP)Kibria SiddiquePas encore d'évaluation

- Rallison Electricals Pvt. LTD.: Customer: M/S Exicom Tele Systems Technical Data SheetDocument1 pageRallison Electricals Pvt. LTD.: Customer: M/S Exicom Tele Systems Technical Data SheetAbhishek SoodPas encore d'évaluation

- FFB CableDocument3 pagesFFB CableNaveed IrshadPas encore d'évaluation

- 0 75px1tscnarmdDocument2 pages0 75px1tscnarmdnmpkumarPas encore d'évaluation

- 33 KV Data SheetDocument4 pages33 KV Data Sheetcherif yahyaoui0% (1)

- Technical Data - 2019EBDocument4 pagesTechnical Data - 2019EBManoj AgarwalPas encore d'évaluation

- LT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02Document2 pagesLT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02y8jkfz98m9Pas encore d'évaluation

- 10X4 A2xfy (FRLS) Alum ArmdDocument2 pages10X4 A2xfy (FRLS) Alum ArmdParth DhobiPas encore d'évaluation

- 3107A TechdataDocument2 pages3107A TechdataComercial FirenoPas encore d'évaluation

- Technical Data SheetDocument10 pagesTechnical Data SheetaqazamPas encore d'évaluation

- 1PX12PSCNARMDDocument1 page1PX12PSCNARMDJainam ShahPas encore d'évaluation

- Product:: Inst, 1 Tri #16 STR BC, PVC Ins E1, OS, BLK PVC JKT, 300V PLTC ITC CMGDocument2 pagesProduct:: Inst, 1 Tri #16 STR BC, PVC Ins E1, OS, BLK PVC JKT, 300V PLTC ITC CMGJORGE ALOR RODRIGUEZPas encore d'évaluation

- Instrumentation CablesDocument5 pagesInstrumentation Cablesmehdi227Pas encore d'évaluation

- Hmnjopl PDFDocument1 pageHmnjopl PDFAjay PrajapatiPas encore d'évaluation

- Cable TriadaDocument4 pagesCable TriadaRaymundo Maldonado AlvarezPas encore d'évaluation

- 10X4 A2xfy Alum - ArmdDocument2 pages10X4 A2xfy Alum - ArmdParth DhobiPas encore d'évaluation

- Technical Data - CABLE 2P X 1 SQMMDocument1 pageTechnical Data - CABLE 2P X 1 SQMMManoj AgarwalPas encore d'évaluation

- KABEL 1030A 16 AWG @305 BELDEN - Belden 1030A 16AWG E-CatalogueDocument3 pagesKABEL 1030A 16 AWG @305 BELDEN - Belden 1030A 16AWG E-Catalogueanton baskoroPas encore d'évaluation

- TD 2016327Document1 pageTD 2016327jajakaPas encore d'évaluation

- Loose Tube, Outdoor Aerial (Fig8) FO Cable 4-12-24 SM Tech Spec MLT Dry Core Dry Core SJDocument5 pagesLoose Tube, Outdoor Aerial (Fig8) FO Cable 4-12-24 SM Tech Spec MLT Dry Core Dry Core SJPetyo GeorgievPas encore d'évaluation

- 400PX3CHT33UEFLATDocument2 pages400PX3CHT33UEFLATjayesh95395Pas encore d'évaluation

- 1 Triad AbcDocument4 pages1 Triad AbcAnamulKabirPas encore d'évaluation

- 1.-1032A TechdataDocument2 pages1.-1032A TechdataJORGE ALOR RODRIGUEZPas encore d'évaluation

- Technical Data Sheets & Cross Sectional Details of 33kV XLPE CablesDocument4 pagesTechnical Data Sheets & Cross Sectional Details of 33kV XLPE CablesRamaKrishna APas encore d'évaluation

- Document No PCPL-0532-4-407-04-09-1 Cables Data Sheet Section 4 Page 1 of 4Document4 pagesDocument No PCPL-0532-4-407-04-09-1 Cables Data Sheet Section 4 Page 1 of 4tceterexPas encore d'évaluation

- Technical Specification - Instrument Cable - WP4Document7 pagesTechnical Specification - Instrument Cable - WP4nnPas encore d'évaluation

- APPENDIX A.1 - Ojas Infra - Chichester SS - MV Cable TDSDocument4 pagesAPPENDIX A.1 - Ojas Infra - Chichester SS - MV Cable TDSSanjay GadhavePas encore d'évaluation

- LT Power Cable - Data SheetDocument9 pagesLT Power Cable - Data SheetAnagha DebPas encore d'évaluation

- Datasheet For Cable: 1 Pair Overall Shielded Armoured Cable, Type F (Single Pair Cable Shall Have Only Overall Shielding)Document4 pagesDatasheet For Cable: 1 Pair Overall Shielded Armoured Cable, Type F (Single Pair Cable Shall Have Only Overall Shielding)AnamulKabirPas encore d'évaluation

- Datasheet Swa 3X20 + 3X350 600VDocument2 pagesDatasheet Swa 3X20 + 3X350 600VKamal ArreazaPas encore d'évaluation

- PTB35 50SHDocument2 pagesPTB35 50SHDelhibabu GovindPas encore d'évaluation

- Ultrasonic Sensors: Ultrasonic Sensor Disk, 7.000 X 0.195 MM, 245 PCS./ TubeDocument8 pagesUltrasonic Sensors: Ultrasonic Sensor Disk, 7.000 X 0.195 MM, 245 PCS./ TubeFaisal ur RehmanPas encore d'évaluation

- Cable SpecificationDocument8 pagesCable Specificationsiddhi srivastavaPas encore d'évaluation

- Cable C Conector 7000-08041-6301000 MDocument3 pagesCable C Conector 7000-08041-6301000 MRodrigo LPas encore d'évaluation

- Wdu 2Document5 pagesWdu 2José SoaresPas encore d'évaluation

- Title Document No. Date Rev.: 5.8 GHZ 0.405" 11 DB 90Document2 pagesTitle Document No. Date Rev.: 5.8 GHZ 0.405" 11 DB 90Raja KalyanPas encore d'évaluation

- Electrical Documentation For Radar Level TransmitterDocument6 pagesElectrical Documentation For Radar Level TransmittersatfasPas encore d'évaluation

- TDS For Telecom Cable (Doc No 26076-110-EFX-436-L0003) - Sept 2023Document22 pagesTDS For Telecom Cable (Doc No 26076-110-EFX-436-L0003) - Sept 2023Basten M H SilitongaPas encore d'évaluation

- Index/ Revisions Status: Revision History/ Description Revision History/ DescriptionDocument10 pagesIndex/ Revisions Status: Revision History/ Description Revision History/ DescriptionmithunceaPas encore d'évaluation

- 3073F Techdata PDFDocument2 pages3073F Techdata PDFErik Alberto FajardoPas encore d'évaluation

- Polycab 300mm 3 Core Aluminium Armoured Cable Specification SheetDocument2 pagesPolycab 300mm 3 Core Aluminium Armoured Cable Specification SheetZIRWA ENTERPRISESPas encore d'évaluation

- SL 012S PeDocument2 pagesSL 012S PeNikhil KumarPas encore d'évaluation

- RE 2Y (ST) HDocument24 pagesRE 2Y (ST) HmritsoudisPas encore d'évaluation

- Technical Data Sheet: Belden Wire & Cable B.VDocument2 pagesTechnical Data Sheet: Belden Wire & Cable B.VMohammed Salman MirzaPas encore d'évaluation

- Part Number: 8103: RS-232/422 Low Cap, #24-3pr, FPO, O/A Foil+Braid, PVC JKT, CM, 100Document3 pagesPart Number: 8103: RS-232/422 Low Cap, #24-3pr, FPO, O/A Foil+Braid, PVC JKT, CM, 100Marco ApellidoPas encore d'évaluation

- CTC AstaDocument1 pageCTC AstafaharaPas encore d'évaluation

- Instrumentation Cable: ApplicationDocument2 pagesInstrumentation Cable: Applicationbakien-canPas encore d'évaluation

- 1502SB TechdataDocument3 pages1502SB TechdataMoncef MAACHIPas encore d'évaluation

- 1x300 SQ MM & 1x240 SQ MM (33kV HT Cable)Document4 pages1x300 SQ MM & 1x240 SQ MM (33kV HT Cable)anamulk_1Pas encore d'évaluation

- Document ID: TE/QMS/F/02 Rev. No.: 00 - Issued Date: 02/04/2018Document1 pageDocument ID: TE/QMS/F/02 Rev. No.: 00 - Issued Date: 02/04/2018dhanishlPas encore d'évaluation

- Part Number: 3107A: RS485, 2 PR #22 STR TC, PO Ins, OS+TC BRD, PVC JKT, CMDocument3 pagesPart Number: 3107A: RS485, 2 PR #22 STR TC, PO Ins, OS+TC BRD, PVC JKT, CMSapta AjiePas encore d'évaluation

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsD'EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercPas encore d'évaluation

- Infra GDocument10 pagesInfra GMeynard AspaPas encore d'évaluation

- (Vol VIII), 2006 Rules For Classification and Construction of WIG CRAFT, 2006Document179 pages(Vol VIII), 2006 Rules For Classification and Construction of WIG CRAFT, 2006Anonymous ma0HXq2iXPas encore d'évaluation

- Infra Water QMS PPR Aug 2019Document55 pagesInfra Water QMS PPR Aug 2019Kumar AbhishekPas encore d'évaluation

- Attachment 2 - Asbestos Removal Control Plan (Prac 182) : RiardaDocument3 pagesAttachment 2 - Asbestos Removal Control Plan (Prac 182) : RiardaadlydhylaPas encore d'évaluation

- Germanisher LloydsDocument390 pagesGermanisher LloydsSting TejadaPas encore d'évaluation

- Bisleri Consumer BehaviourDocument113 pagesBisleri Consumer Behaviourgirishkumarg0% (1)

- Building Appraisal Platinum Plaza BhopalDocument6 pagesBuilding Appraisal Platinum Plaza BhopalNiteesh Kumar Patel0% (1)

- UNIT I 1.2 Process Planning and Production PlanningDocument52 pagesUNIT I 1.2 Process Planning and Production Planningprof_panneerPas encore d'évaluation

- 2011 Penn West Seal 11377Document42 pages2011 Penn West Seal 11377GKeddy85Pas encore d'évaluation

- 1 DescriptionDocument20 pages1 DescriptionManish SharmaPas encore d'évaluation

- SAP MM (Procurement) FUNCTIONAL CONSULTANT - Support ProjectDocument2 pagesSAP MM (Procurement) FUNCTIONAL CONSULTANT - Support Projectsonu8700Pas encore d'évaluation

- Needle SiliconizatonDocument5 pagesNeedle SiliconizatonIlayaraja BoopathyPas encore d'évaluation

- Mumbai Port Trust: Civil Engineering DepartmentDocument96 pagesMumbai Port Trust: Civil Engineering Departmentsuji91Pas encore d'évaluation

- HYCHEM Catalogue BookDocument32 pagesHYCHEM Catalogue Bookengage4u2020Pas encore d'évaluation

- Awards GuideDocument76 pagesAwards GuidedoombuggyPas encore d'évaluation

- SteelMaster 1200WF BrochureDocument4 pagesSteelMaster 1200WF BrochureSatish VishnubhotlaPas encore d'évaluation

- Imaging Opportunities in SAP Modules: Session 405Document71 pagesImaging Opportunities in SAP Modules: Session 405Mohan GanganalaPas encore d'évaluation

- Chapter 1 - Introduction To Production ManagementDocument12 pagesChapter 1 - Introduction To Production ManagementRohit BadgujarPas encore d'évaluation

- Máquina Moer Alumina PDFDocument36 pagesMáquina Moer Alumina PDFDulce GabrielPas encore d'évaluation

- Topics of LecturesDocument6 pagesTopics of LecturesKiky RizkyPas encore d'évaluation