Académique Documents

Professionnel Documents

Culture Documents

Factor Influencing Air Reqd For Bio Reactor

Transféré par

dinkad29Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Factor Influencing Air Reqd For Bio Reactor

Transféré par

dinkad29Droits d'auteur :

Formats disponibles

Environmental Dynamics Inc.

Technical Bulletin 134

Factors Influencing Air Requirements to Treat Wastewater

Aeration Systems

Bulletin Brief Technical Presentation

When developing an aeration system design it is necessary to have sufficient data to allow the many factors, which influence process air (oxygen) requirements to be properly evaluated. Some of the factors to be considered including those listed below: *Refer to EDI Technical Bulletin 128 to estimate your oxygen requirements. 1. 2. Depth of bioreactor. Type of diffuser (efficiency) a. Fine b. Medium c. Coarse bubble Energy level in the bio reactor(Hp/1000 Ft3). Organic Loading to the reactor: a. Type waste b. Concentration c. Total # or Kg Loading Type of wastewater Process to be supported by aeration i.e. extended aeration, actuated sludge, partial mix lagoon etc. Site elevation Waste temperature Submergence depth of diffuser Dissolved oxygen concentration to be maintained in the bioreactor

Geometry of diffusers in aeration basin or bioreactor.

3.

4. 5.

6. 7. 8. 9. 10. 11.

FACTS 1. Once the process oxygen requirements*for treating your wastewater are known, the air volume can be calculated to provide oxygen for your treatment system. Process oxygen may be reported as AOR (actual oxygenation rate or requirements). All aeration devices measure performance under IDEAL conditions known as standard conditions. (SOR or Standard Oxygenation Rate). It is much more difficult to transfer oxygen in to wastewater under field conditions vs. the IDEAL standard conditions.

2. 3.

Technical Bulletins are presented as a service by Environmental Dynamics Inc. of Columbia, Missouri.

CT050100

Environmental Dynamics Inc.

Technical Bulletin 134

2 4. 5. 6. Efficiencies of aeration devices under standard conditions are presented as SOTE (standard oxygen transfer efficiency). SOTE can be presented as % oxygen transfer or as a SOR ie, #O2/Hp hr or (Kg/Kw hr). To convert efficiencies measured under standard conditions to field or actual conditions, IDEAL or SOTE values must be reduced by a field correction factor. This factor is generally referred to as AOR/SOR or actual oxygenation rate/standard oxygenation rate = Field performance/clean water performance. Typical adjustments for AOR/SOR are 0.3 to 0.6. i.e., field transfers for oxygen are only 30% to 60% the efficiency measured under standard or ideal conditions by the manufacturer. (See technical analysis of AOR/SOR computations below). Caution - One of the greatest potential errors in estimation air requirements is the effect of elevation. Please note plants operating at more that 500 ft (155 m) elevation must have careful consideration of elevation effects on AOR/SOR see attached analysis.

7.

8.

Adjust Clean Water Transfer Characteristics for Field Conditions: AOR/SOR=a[B(Cs) (Cmin)]1.024(T-20) 9.17 where:

a= Alpha. Process water volumetric mass transfer coefficient/Clean water volumetric mass Transfer coefficient.

B= T=

CsCmin=

Beta. Ratio of solubility of oxygen in process water to clean water. Wastewater temperature in degrees C. Calculate for both summer and winter conditions to determine controlling AOR/SOR. Oxygen saturation in clean water at temperature and elevation. Minimum dissolved oxygen to be maintained in system.

Calculate Airflow Requirements: Or SOR or #O2/AOR=SCFM (SOTE as decimal) 1.036 cfm=SOR as lb 02/hr/SOTE (1.036)

For questions regarding this technical reference document, contact Environmental Dynamics

For specific information on aeration system selection considerations, contact EDI at 573474-9456.

Technical Bulletins are presented as a service by Environmental Dynamics Inc. of Columbia, Missouri.

CT050100

Environmental Dynamics Inc.

Technical Bulletin 134

Technical Bulletins are presented as a service by Environmental Dynamics Inc. of Columbia, Missouri.

CT050100

Vous aimerez peut-être aussi

- Furniture Layout New Admin LaboratoryDocument1 pageFurniture Layout New Admin Laboratorydinkad29Pas encore d'évaluation

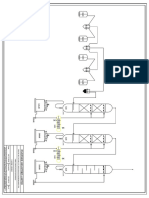

- Green Scrubber Modified p&Id-ModelDocument1 pageGreen Scrubber Modified p&Id-Modeldinkad29Pas encore d'évaluation

- NH3 Condensor ModelDocument1 pageNH3 Condensor Modeldinkad29Pas encore d'évaluation

- ETP Layout For EIA-ModelDocument1 pageETP Layout For EIA-Modeldinkad29Pas encore d'évaluation

- Scrubber For AmmoniaDocument1 pageScrubber For Ammoniadinkad29Pas encore d'évaluation

- M.S Patta For Green Filter Press 1200Document1 pageM.S Patta For Green Filter Press 1200dinkad29Pas encore d'évaluation

- Design for Screw Flight ParametersDocument2 pagesDesign for Screw Flight Parametersdinkad29Pas encore d'évaluation

- Mass Balance CPC Blue CrudeDocument4 pagesMass Balance CPC Blue Crudedinkad29Pas encore d'évaluation

- Bar UnitDocument1 pageBar Unitdinkad29Pas encore d'évaluation

- Tremix Flooring PDFDocument4 pagesTremix Flooring PDFdinkad29Pas encore d'évaluation

- Green Chlorine ScrubberDocument1 pageGreen Chlorine Scrubberdinkad29Pas encore d'évaluation

- Heat Mass BalanceDocument14 pagesHeat Mass Balancedinkad29100% (1)

- Temp Vs Dissolved OxygenDocument1 pageTemp Vs Dissolved Oxygendinkad29Pas encore d'évaluation

- Tremix Flooring PDFDocument4 pagesTremix Flooring PDFdinkad29Pas encore d'évaluation

- Design of Steel StructuresDocument26 pagesDesign of Steel StructuresMfon UdoitaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Master of Science in Environmental Engineering - Ceec704 Duration of Study: 1.5 - 2 Years/ 3 - 4 SemestersDocument3 pagesMaster of Science in Environmental Engineering - Ceec704 Duration of Study: 1.5 - 2 Years/ 3 - 4 SemestersikhwanstoragePas encore d'évaluation

- A Visit Report On Sewage PlantDocument16 pagesA Visit Report On Sewage PlantYuvraj Rasal92% (13)

- Clarifier Settling Tank PDFDocument25 pagesClarifier Settling Tank PDFvenustasiaPas encore d'évaluation

- Ashok Leyland LTDDocument24 pagesAshok Leyland LTDMaa Maa100% (1)

- Integrated Lake Basin Management (ILBM) FrameworkDocument28 pagesIntegrated Lake Basin Management (ILBM) FrameworkucupPas encore d'évaluation

- How Is Paint Made? - Community RePaintDocument6 pagesHow Is Paint Made? - Community RePaintTargenix Bio Analtical ServicesPas encore d'évaluation

- ARCHITECTURAL SCIENCE (PLUMBING) 8th PDFDocument13 pagesARCHITECTURAL SCIENCE (PLUMBING) 8th PDFEyoel Yo'otaPas encore d'évaluation

- Membrane Filtration (Hach)Document44 pagesMembrane Filtration (Hach)fontianika100% (1)

- Cluster Development Initiative LTD., Tripura Industrial Development Corporation TRIPURA (PDFDrive)Document107 pagesCluster Development Initiative LTD., Tripura Industrial Development Corporation TRIPURA (PDFDrive)Rajender BishtPas encore d'évaluation

- STP Adequacy Report - To SubmitDocument7 pagesSTP Adequacy Report - To SubmitJagannathan SPas encore d'évaluation

- B eDocument908 pagesB egayatri_vyas1Pas encore d'évaluation

- Sewage Works Design Standard PDFDocument43 pagesSewage Works Design Standard PDFmishtinilPas encore d'évaluation

- Water Treatment Equipment - Monroe EnvironmentalDocument20 pagesWater Treatment Equipment - Monroe Environmentaltallef001Pas encore d'évaluation

- Everything you need to know about drinking waterDocument36 pagesEverything you need to know about drinking waterMatt OverbyPas encore d'évaluation

- FRANKEetal SolutionstomitigateodourandH2S IWAodour2017 WithpagenumbersDocument12 pagesFRANKEetal SolutionstomitigateodourandH2S IWAodour2017 WithpagenumbersMi doremiPas encore d'évaluation

- M-51 Seawage Treatment PlantDocument88 pagesM-51 Seawage Treatment Plantrajish2014100% (2)

- Prospects For A Self-Sustainable Sewage Treatment System: A Case Study On Full-Scale UASB System in India's Yamuna River BasinDocument10 pagesProspects For A Self-Sustainable Sewage Treatment System: A Case Study On Full-Scale UASB System in India's Yamuna River BasinPagla Chulke NePas encore d'évaluation

- Royal Decree 115-2001 Law On Protection of Sources of Potable Water From PollutionDocument21 pagesRoyal Decree 115-2001 Law On Protection of Sources of Potable Water From Pollutionasex4uPas encore d'évaluation

- Pool, Jacuzzi and Water Feature Design GuideDocument194 pagesPool, Jacuzzi and Water Feature Design GuideMiguel Angel100% (1)

- Environmental Impact AssessmentDocument26 pagesEnvironmental Impact AssessmentLimbaji shindePas encore d'évaluation

- Sequence Batch ReactorDocument18 pagesSequence Batch Reactorcatherinejoaquin100% (2)

- Microbial Fog PDFDocument2 pagesMicrobial Fog PDFaashishPas encore d'évaluation

- Wastewater Treatment Plant Design - Lecture 3 - Water and Wastewater ConsumptionDocument25 pagesWastewater Treatment Plant Design - Lecture 3 - Water and Wastewater ConsumptionAQ UAPas encore d'évaluation

- Integrated Cement Orient Cement ChittapurDocument38 pagesIntegrated Cement Orient Cement Chittapurdurgesh25Pas encore d'évaluation

- Water TreatmentDocument18 pagesWater TreatmentJake CabatinoPas encore d'évaluation

- Operation and Maintenance of Water Treatment Plant at BNP Campus Dewas, India: A Case StudyDocument5 pagesOperation and Maintenance of Water Treatment Plant at BNP Campus Dewas, India: A Case StudyPrashant ChougulePas encore d'évaluation

- Force Main SewersDocument8 pagesForce Main SewersljupkaPas encore d'évaluation

- Modeling and Monitoring CoastalDocument249 pagesModeling and Monitoring Coastalwindy candrayanaPas encore d'évaluation

- TO T HET Reatment of Tannery EffluentsDocument23 pagesTO T HET Reatment of Tannery EffluentsViswanath KapavarapuPas encore d'évaluation

- Wastewater Treatment Plant & Fire Protection Service CompanyDocument20 pagesWastewater Treatment Plant & Fire Protection Service CompanyYung TanjungPas encore d'évaluation