Académique Documents

Professionnel Documents

Culture Documents

27

Transféré par

indira_singaramDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

27

Transféré par

indira_singaramDroits d'auteur :

Formats disponibles

Process Biochemistry 35 (1999) 213 219 www.elsevier.

com/locate/procbio

Thermostable alkaline protease from Bacillus bre6is and its characterization as a laundry detergent additive

Uttam Chand Banerjee *, Rajesh Kumar Sani, Wamik Azmi, Raman Soni

Biochemical Engineering Research and Process De6elopment Center, Institute of Microbial Technology, Sector 39 -A, Chandigarh 160036, India Received 1 February 1999; accepted 9 April 1999

Abstract An alkaline protease from a facultatively thermophilic and alkalophilic strain of Bacillus bre6is has been studied. The enzyme from a shake ask culture displayed maximum activity at pH 10.5 and 37C. The extracellular production of the enzyme, its thermostable nature and compatibility with most commercial detergents are features which suggest its application in detergent industry. The organism utilized several carbon sources for the production of proteases, lactose was the best substrate followed by glucose and sucrose. Among the various organic nitrogen sources, soyabean meal was found to be the best. The protease was stable at 25C for 288 h whereas, at 50 and 60C, the half lives were 60 and 7 h, respectively. The thermostability of the protease was enhanced by modifying its microenvironment. Acetate salts of Ca2 + and Na+ increased thermostability and protected against autolysis. Addition of Ca2 + (10 mM) and glycine (1 M) individually and in combination was found to be effective in increasing the half life of protease by many folds. The enzyme retained more than 50% activity after 4 days at 60C in the presence of both Ca2 + (10 mM) and glycine (1 M). The enzyme showed compatibility at 60C with commercial detergents such as Aerial Microshine, Surf excel, Surf Ultra and Rin in the presence of Ca2 + and glycine. This enzyme improved the cleaning power of various detergents. It could remove blood stains completely when used with detergents in the presence of Ca2 + and glycine. 1999 Elsevier Science Ltd. All rights reserved.

Keywords: Alkaline protease; Thermostability; Bacillus bre6is; Detergent compatibility

1. Introduction Proteases are one of the most important industrial enzymes, accounting for nearly 60% of total world wide enzyme sales [13]. Of these, alkaline proteases are employed primarily as cleansing additives. Among the various proteases, bacterial proteases are the most signicant, compared with animal and fungal proteases [1]. Ideally, proteases used in a detergent formulation should have a high level of activity over a broad range of pH and temperatures. Alkaline proteases from high yielding strains have been studied extensively. The major draw back of enzymes recovered from thermophiles are their instability at alkaline pH, whereas enzymes from alkalophiles confer stability in a wide pH range

* Corresponding author. Tel.: +91-172-690908; fax: + 91-172690585. E-mail address: banerjeeuc@mailexcite.com (U.C. Banerjee)

but are usually thermolabile [4,5]. Thus it is desirable to search for new proteases with novel properties from as many different sources as possible. In this report we examine the efcacy of the enzyme, recovered from Bacillus a newly isolated strain of bre6is, in the presence of standard commercial detergents. Further, characterization of this enzyme and the effect of various co-factors or additives on the stability at higher temperature and in alkaline pH range was carried out.

2. Materials and methods

2.1. Chemicals

All medium components were obtained from Hi-Media, Bombay, India. Azocasein and glycine were purchased from Sigma Chemical Co., St. Louis, MO, USA. Other chemicals were of reagent grade and were com-

0032-9592/99/$ - see front matter 1999 Elsevier Science Ltd. All rights reserved. PII: S 0 0 3 2 - 9 5 9 2 ( 9 9 ) 0 0 0 5 3 - 9

214

U.C. Banerjee et al. / Process Biochemistry 35 (1999) 213219

mercially available. Various detergents used in this study were purchased from a local market.

2.4. Temperature and pH studies

The temperature-activity prole was studied by assaying protease activity in a temperature range of 2575C at pH 10.5 while the pH-activity prole was studied in a pH range of 6.012.0 at 60C using 50 mM buffers of different pHs (6.06.5, sodium acetate; 7.08.0, Tris HCl and 8.512.0, NaOH/glycine). The thermostability prole was studied by incubating the enzyme preparation at various temperatures (25, 30, 37, 50 and 60C) in NaOH/glycine buffer (50 mM, pH 10.5) for different time period and measured the residual activity at 60C. Effect of various additives (inorganic salts and metal ions) on the thermostability of protease activity was determined by incubating the enzyme in the presence of additives at 50 and 60C for 30 min. Samples withdrawn at various intervals were immediately ice cooled and the residual activity (%) was determined under standard assay conditions (60C, pH 10.5). pH stability prole was determined by incubating equal volumes of enzyme with buffers in the pH range of 6.012.0 for 1 h at 60C and the residual activity (%) determined at pH 10.5 by standard assay procedure. The effect of various metal ions and inhibitors on enzyme activity was studied by incubating the enzyme preparation at 60C with different concentrations of metal ions and inhibitors and the residual activity was determined after 1 h.

2.2. Microorganism and culture conditions

Bacillus bre6is used in the present study was isolated from water samples collected from hot springs at Manikaran (Himachal Pradesh, India) after extensive screening at various temperatures (37, 50 and 60C) and pHs (8.0, 9.0 and 10.0) on nutrient agar plates supplemented with 0.2% skim milk powder. The strain was identied by the Microbial Type Culture Collection and Gene Bank (MTCC), Chandigarh, India and given the accession no. MTCC B0016. The organism was maintained on nutrient agar plates and stored at 4C, while the stock was maintained in 10% glycerol at 70C. Various carbon sources (1%, w/v) including glucose, lactose, sucrose, maltose and starch and various organic nitrogen sources (1%, w/v) including yeast extract, beef extract, meat extract, peptone, biopeptone, yeast autolysate, soyabean meal, soyatose, soyapeptone and casein were used in this study. The liquid medium used for the production of alkaline protease had the following composition (%, w/v): sucrose 1.0, soyabean meal 1.0, calcium acetate 0.01, KH2PO4 0.1, MgSO47H2O 0.01 and CaCl22H2O 0.01. The pH of the medium was adjusted to 10.5 with 10% (w/v) Na2CO3 solution. The effect of temperature and pH on enzyme production was studied at 37 and 50C and in a pH range of 9.0 11.0. Experiments were carried out in 500 ml Erlenmeyer ask containing 100 ml medium. After inoculation with B. bre6is (12 h growth), the asks were incubated for 96 h in a temperature controlled (37C) shaking incubator (200 rpm). Duplicate asks were withdrawn at regular intervals and analysed for growth (OD600) and pH. The contents were then centrifuged (10 000g, 4C, 20 min) and the cell free supernatant was used for determining extracellular protease activity.

2.5. Detergent stability

The stability of the enzyme with and without additives in the presence of detergents was determined by incubating the enzyme (3000 U/ml) at 60C with various common detergent preparations (7 mg/ml) and the residual activity determined at regular intervals up to 3 h.

2.6. Washing test with protease preparation 2.3. Assay methods

Alkaline protease activity was determined by the modied method of Longo et al. [6]. A total of 20 ml of 5% (w/v) azocasein in NaOH/glycine buffer (50 mM, pH 10.5) was incubated at 37C with 460 ml of the same buffer. After 5 min, 20 ml of appropriately diluted enzyme was added to the above mixture and incubated at 60C for 30 min. The reaction was stopped by adding 500 ml trichloroacetic acid (10%, w/v) and the mixture allowed to cool for 15 min on ice. This mixture was centrifuged and 800 ml supernatant was mixed with the 200 ml NaOH (1.8 N) in a tube and the absorbance was read at 420 nm. Enzyme activity was expressed as azo units, where one unit (U) is dened as the amount of enzyme required to increase 0.1 absorbance at 420 nm per hour under assay conditions (60C, pH 10.5). Application of protease as a detergent additive was studied on white cotton cloth pieces (4 4 cm) stained with human blood. The stained cloth pieces were taken in separate asks. The following sets were prepared: 1. Flask with distilled water (100 ml)+ stained cloth (cloth stained with blood) 2. Flask with distilled water (100 ml) + 1 ml detergent (7 mg/ml) 3. Flask with distilled water (100 ml) +1 ml detergent (7 mg/ml) +2 ml enzyme solution The above asks were incubated at 50C for 15 min. After incubation, cloth pieces were taken out, rinsed with water and dried. Visual examination of various pieces exhibited the effect of enzyme in removal of stains. Untreated cloth pieces stained with blood were taken as control.

U.C. Banerjee et al. / Process Biochemistry 35 (1999) 213219

215

3. Results and discussion

strain seems to be a novel one being capable of growing over a wide pH and temperature range.

3.1. Isolation and characterization of alkaline protease producing strain

Bacterial strains were isolated from a hot spring and screened for hyper protease producers at pH 9.0, 10.0 and 11.0. From 50 samples screened on nutrient agar plates supplemented with skim milk powder (0.2%), some bacterial strains that grew in the presence of skim milk powder at various alkaline pHs, were selected on the basis of zone of clearance around the colonies. Five strains were isolated from the samples screened. The proteolytic activity of these strains were checked at various pHs and temperatures and nally one strain was selected as the most potent producer of proteolytic enzyme (data not shown). The isolated alkalophilic thermostable proteolytic strain was a spore forming Gram-positive rod and identied as Bacillus bre6is. This

Table 1 Production of alkaline protease by Bacillus bre6is using different carbon sources Carbon sources Time (h) Maximum alkaline protease activity (U/ml) 3125 3150 3455 650 2688 2016

3.2. Optimization of en6ironmental conditions on enzyme production in shake ask

Among various carbon sources tested, lactose produced the maximum (3455 U/ml) protease activity (Table 1). With glucose and sucrose as carbon source, the maximum activities obtained were 3125 and 3150 U/ml, respectively. Moderate to good amount of protease activity was produced in the presence of starch (2688 U/ml) and maltose (2016 U/ml) Highest production of enzyme activity on various carbon sources was achieved at different times of fermentation. Sucrose, being the cheapest carbon source was used for enzyme production in subsequent experiments. In a similar study Fujiwara and Yamamoto [7] showed that glucose and starch were the best carbon sources for protease production by Bacillus sp. no. 221 while lactose and sucrose were not very effective. Fujiwara et al. [8] also reported glucose (1%, w/v) as the best carbon source for protease production by Bacillus sp. B18. Phadatare et al. [9] reported that sucrose was used as a carbon source for growth and protease production by Conidobolus coronatus. Easalp et al. [10] reported that although glucose could not support for maximum protease production in B. subtilis, yet it emerged as a better substrate than maltose, starch and galactose. Enzyme production was also affected by the type of nitrogen sources used. Among the various organic nitrogen sources used, the maximum enzyme activity (2240 U/ml) was obtained when soyabean meal was used in the medium (Fig. 1). Moderate levels of enzyme activities were obtained when biopeptone, meat extract, tryptone, malt extract, yeast extract, tryptose and yeast autolysate were used as nitrogen source. Peptone was the poorest organic nitrogen source for alkaline protease production. Our results corroborate the previous reports showing the preference of Bacillus sp. for soyabean meal [2,7,11]. On the other hand, Phadatare et al. [9] reported the enhancement of protease production in C. coronatus by organic nitrogen sources like tryptone, peptone, yeast extract, skim milk and soybean meal. Enzyme production was substantially improved when calcium acetate, CaCl2 and MgSO4 were used to supplement the medium along with KH2PO4. The increase of enzyme production was small when these salts were used individually. Enzyme production in the absence of these salts was sufciently low, thereby indicating the requirements of acetate and some metal ions (Ca2 + and Mg2 + ) for protease production by B. bre6is (data not shown). A combination of sodium acetate and calcium chloride not only produced better enzyme activity but acted as a protectant against autolysis and thereby

Glucose Sucrose Lactose Galactose Starch Maltose

72 60 48 72 60 60

Fig. 1. Maximum alkaline protease production by B. bre6is using various organic nitrogen sources (1%, w/v): (1, control; 2, peptone; 3, soyatose; 4, soyabean meal; 5, Soyapeptone; 6, tryptose; 7, yeast extract; 8, biopeptone; 9, meat extract; 10, yeast autolysate; 11, malt extract; and 12, tryptone).

216

U.C. Banerjee et al. / Process Biochemistry 35 (1999) 213219

Table 2 Effect of initial pH and temperature on the production of alkaline protease by Bacillus bre6is Initial pH Maximum alkaline protease activity (U/ ml) 37C 9.0 10.0 10.5 11.0 1670 2100 2370 290 50C 805 970 1135 110

formis MIR 29. The maximum production of protease activity (2370 U/ml) by B. bre6is was observed at 37C and pH 10.5 while at 50C and pH 10.5, it produced (1135 U/ml) half of the enzyme activity (Table 2). At the lower and higher pH, the enzyme activity reduced considerably.

3.3. Characterization of the enzyme

Protease activity increased progressively with temperature and maximum activity was obtained at 60C (Fig. 2a). Enzyme activity decreased at temperatures higher than 60C. It is reported [14,15] that a number of alkaline proteases isolated from Bacillus sp. have high optimal temperatures for their activity. This is an important characteristic for the use of alkaline proteases as detergent additives. Similar to our results, two important alkaline proteases of the detergent industry, subtilisin Carlberg, produced by B. licheniformis and subtilisin Novo or Bacterial Protease Nagase (BPN), produced by B. amyloliquefaciens, also showed optimum temperature of 60C [14]. The pH-activity prole of the enzyme is shown in Fig. 2(b). At pH 6.5, only 22% of the maximum enzyme activity was obtained, increasing to 65 and 77% at pH 7.0 and 7.5, respectively. Maximum enzyme activity was observed at pH 10.5 and an increase in pH beyond 10.5 brought about a decline in protease activity resulting in 18% activity at pH 12.5. These ndings are in accordance with several earlier reports showing pH optima of 1010.5 for protease from Bacillus sp., Thermus aquaticus, Xanthomonas maltophila and Vibrio metschniko6ii [1518]. The important detergent enzymes, substilisin Carlberg and substilisin Novo or BPN also showed maximum activity at pH 10.5 [14].

Fig. 2. (a) Effect of temperature on alkaline protease activity by B. bre6is. (b) Effect of pH on alkaline protease activity by B. bre6is.

increased the shelf-life of the enzyme. These results corroborate the earlier ndings of metal ions enhancing the production and stabilizing the activity of protease enzyme [12]. Ferrero et al. [13] reported the use of trisodium citrate along with MgSO4, CaCl2, MnSO4 and ZnSO4 for protease production by Bacillus licheni-

Fig. 3. Thermostability of alkaline protease activity from B. bre6is at various temperatures.

U.C. Banerjee et al. / Process Biochemistry 35 (1999) 213219

217

Fig. 4. Thermostability of alkaline protease activity from B. bre6is in presence of CaCl2 and glycine at 60C: ( , control;

, enzyme + CaCl2; , enzyme+glycine; , enzyme+glycine + CaCl2). Table 3 Effect of various metal ions and chemicals on alkaline protease activity by Bacillus bre6is a Residual alkaline protease activity (%) Metal ions and chemicals Concentration (mM) 1 Control ZnCl2 CaCl2 NaCl MgSO4 KCl MnSO4 AgNO3 HgCl2 FeSO4 CoCl2 CdCl2 NiCl2 CuSO4 Ca(CH3COOH)2 SDS EDTA Urea

a

2 100 30 105 80 90 95 114 0 15 50 72 0 0 0 100 32 20 94

5 100 10 110 75 90 92 120 0 0 43 70 0 0 0 140 30 16 92

10 100 0 120 64 82 90 124 0 0 32 62 0 0 0 135 18 8 90

100 37 99 86 91 100 107 10 43 60 74 18 15 19 100 40 26 95

The activity is expressed as a percentage of the activity level in the absence of metal ions and chemicals. The enzyme was preincubated with metal ion (60C, 5 min). Separate blanks with individual metal ions and chemicals were prepared.

Thermostability prole (Fig. 3) indicated that the enzyme was stable at 25C for 288 h whereas it retained about 70% of its maximum activity at 30 and 37C. It exhibited half lives of 60 and 7 h at 50 and 60C, respectively. Addition of CaCl2 (10 mM) and glycine (1

M), individually and in combination, improved the thermostability of the enzyme (Fig. 4). The enzyme retained more than 50% of its maximum activity after 4 days at 60C in the presence of CaCl2 and glycine. Thermostability studies of protease activity in the published literatures showed enzyme with a half-life of 25 min at 60C [15], 23 min at 60C [18] and 10 min at 60C [14,19,20]. Yamagata et al. [20] also reported thermostable protease having 100% stability upto 55C for 10 min. Kobayashi et al. [21] showed that alkaline serine protease of Bacillus sp. KSM-K16 remained stable for 10 min at 50 and 60C. Ferrero et al. [13] also reported thermostable protease from B. licheriformis MIR 29 showing 100% stability upto 70C for 10 min. Compared to these ndings, the B. Bre6is protease showed much higher thermostability at 60C. The enzyme showed high pH stability being 100% stable at pH 10.5 and 92% at pH 11 and 11.5 for 1 h (data not shown). Further increase in pH resulted in a signicant decline in protease activity. These results corroborate the earlier observations on protease from Bacillus alcalophilus sub sp. halodurans exhibiting 100% stability over a pH range of 510 [22]. They also reported that protease activity was reduced to 50% at pH 11 and was completely inactivated at pH 13 after 10 min incubation at 55C. Takami et al. [23] reported alkaline serine protease from Bacillus sp. AH-101 showing stability over a wide range of pH 513 after 10 min incubation at 60C. They reported 80% enzyme activity in the pH range 59 which increased to 90% at pH 1011.5. Compared to these ndings, protease produced by B. bre6is was much more stable at high pH. In vitro studies using different concentrations of metal ions showed a pronounced effect on enzyme activity (Table 3). Ag+ resulted in the complete loss of activity at 1 mM concentration, followed by Zn2 + and Hg2 + . Residual activity in the presence of urea was 95% whereas with SDS it was 40%. Activity was stimulated by calcium acetate, CaCl2 and MnSO4. Addition of magnesium salt, however, resulted in some loss of activity but its presence during growth and enzyme production was essential. Ca2 + and Mn2 + have been shown previously to enhance protease activity [24] while the role of Ca2 + in the stabilization of protease has been reported from Thermus sp. subtilisin and Bacillus sp. [21,22,25,26]. Protease from B. bre6is showed stability and compatibility with a wide range of commercial detergents at 50 and 60C in the presence of CaCl2 and glycine as stabilizers (Table 4). The enzyme retained about 60% activity after 1.5 h in the presence of Surf Excel at 60C and was completely inactivated after 3 h in the absence of any stabilizer (Fig. 5). However, the addition of CaCl2 (10 mM) and glycine (1 M), individually and in combination, was very effective in improving the stability where it retained 58% activity even after 3 h.

218

U.C. Banerjee et al. / Process Biochemistry 35 (1999) 213219

Table 4 Compatibility of alkaline protease activity from Bacillus bre6is with commercial detergents in the presence of glycine and CaCl2a Relative residual alkaline protease activity (%) Time (h) 0 0.5 1.0 1.5 2.0 2.5 3.0 Control 100 92 90 85 82 80 75 Surf Excel 100 89 85 81 73 70 58 Surf Ultra 100 88 84 78 72 65 55 Aerial Microshine 100 85 80 76 70 65 55 Rin 100 85 80 78 60 53 44

a The activity is expressed as a percentage of the activity level in the absence of detergents. The enzyme was preincubated with individual detergent (60C, 5 min). Separate blanks with individual detergent in the presence of glycine and CaCl2 were prepared.

The enzyme retained more than 50% activity with most of the detergents tested even after 3 h incubation at 60C after the supplementation of CaCl2 and glycine

(Table 4). Bhosale et al. [27] reported high activity alkaline protease from C. coronatus showing compatibility at 50C, in the presence of 25 mM CaCl2, with a variety of commercial detergents. They reported that their enzyme preparation retained 16% activity in Revel, 11.4% activity in Ariel and 6.6% activity in Wheel. Comparing these results, the B. bre6is enzyme was signicantly more stable in commercial detergents. As the protease produced by our isolate, B. bre6is, was stable over a wide range of pH and temperature and also showed compatibility with various commercial detergents tested, it was used as an additive in detergent, to check the contribution of the enzyme in improving the washing performance of the detergent. The supplementation of the enzyme preparation in two detergents i.e. Surf Excel and Rin could signicantly improve the cleansing performance towards the blood stains (Fig. 6).

Acknowledgements

Fig. 5. Compatibility of alkaline protease from B. bre6is with Surf Excel: ( , Control;

, Enzyme + glycine+ detergent; , enzyme+ CaCl2 + detergent; , enzyme + glycine +CaCl2 + detergent; ", enzyme+ detergent).

Authors gratefully acknowledge the assistance provided by the Department of Science and Technology and the Council of Scientic and Industrial Research, India. Communication no. IMT-010/98.

References

[1] Ward OP. Proteolytic enzymes. In: Moo-Young M, editor. Comprehensive Biotechnology, vol. 3. Oxford: Pergamon, 1985:789 818. [2] Kalisz HM. Microbial proteinases. In: Fiechter A, editor. Advances in Biochemical Engineering/Biotechnology, vol. 36. Berlin: Springer-Verlag, 1988:1 65. [3] Outtrup H, Boyce COL. Microbial proteases and biotechnology. In: Fogarty WM, Kelly CT, editors. Microbial enzymes and biotechnology. New York: Elsevier Science, 1990:227 54. [4] Grifn HL, Greene RV, Cotta MA. Isolation and characterization of an alkaline protease from the marine shipworrn bacterium. Curr Microbiol 1992;24:111 7.

Fig. 6. Washing performance of alkaline protease from B. bre6is in presence of detergent. (A, Cloth stained with blood; B, blood stained cloth washed with detergent only; and C, blood stained cloth washed with detergent and enzyme.)

U.C. Banerjee et al. / Process Biochemistry 35 (1999) 213219 [5] Lee JK, Kim YO, Kim HK, Park YS, Oh TK. Purication and characterization of a thermostable alkaline protease from Thermoactinomyces sp. E79 and the DNA sequence of the encoding gene. Biosci Biotechnol Biochem 1996;60:8406. [6] Longo A, Novella I, Garcia LA, Diaz M. Diffusion of protease in calcium alginate beads. Enzyme Microb Technol 1992;14:586 90. [7] Fujiwara N, Yamarnoto K. Production of alkaline protease in low cost medium by alkalophilic Bacillus sp. and properties of the enzyme. J Ferment Technol 1987;65:3458. [8] Fujiwara N, Masui A, Imanaka T. Purication and properties of the highly thermostable alkaline protease from an alkalophilic and thermophilic Bacillus sp. J Biotechnol 1993;30:24556. [9] Phadatare SU, Deshpande VV, Srinivasan MC. High activity alkaline protease from Conidiobolus coronatus (NCL 86.8.20): enzyme production and compatibility with commercial detergents. Enzyme Microb Technol 1993;15:726. [10] Basalp A, Ozeengiz G, Alaeddinglin NG. Changes in patterns of alkaline serine protease and Bacilysin formation caused by common effectors of sporulation in Bacillus subtilis 168. Curr Microbiol 1992;24:129 35. [11] Tsai Y, Juang R, Lin S, Chen S, Yamasaki M, Tamura G. Production and further characterization of an alkaline elastase produced by alkalophilic Bacillus strain Ya-B. Appl Environ Microbiol 1988;54:315661. [12] Janssen PH, Peek K, Morgan HW. Effect of culture conditions on the production of a extracellular proteinase by Thermus sp. Rt41A. Appl Microbiol Biotechnol 1994;41:4006. [13] Ferrero MA, Castro GR, Abate CM, Baigori MD, Singeriz F. Thermostable alkaline proteases of Bacillus licheniformis MIR 29: isolation, production and characterization. Appl Microbiol Biotechnol 1996;45:32732. [14] Horikoshi K. Enzymes of alkalophiles. In: Microbial Enzyme and Biotechnology, 2nd, 1990:27594. [15] Durham DR, Stewart DB, Stellway EJ. Novel alkaline and heat-stable serine proteases from alkalophilic Bacillus sp. strain GX6638. J Bacteriol 1987;169:27628. [16] Matsuzawa M, Tokugawa K, Hamaoki M, Mizoguehi M, Taguchi H, Terada I, Kwon T, Ohta T. Purication and charac-

219

[17]

[18]

[19]

[20]

[21]

[22]

[23]

[24]

[25] [26]

[27]

terization of agualysin I (thermophilic alkaline serine protease) produced by Thermus aquaticus YT-I. J Biochem 1988;171:441 7. Debette J. Isolation and characterization of an extracellular protease produced by a soil strain of Xanthomonas maltophila. Curr Microbiol 1991;22:85 90. Kwon YT, Kim JO, Moon SY, Lee HH, Rho HM. Extracellular alkaline protease from alkalophilic Vibrio metschniko6i strain RH 530. Biotechnol Lett 1994;16:413 8. Chu MI, Lee C, Li TS. Production and degradation of alkaline protease in batch cultures of Bacillus subtilis ATCC 14416. Enzyme Microb Technol 1992;14:755 61. Yamagata Y, Ichishima E. A new alkaline serine protease from alkalophilic Bacillus sp.: cloning, sequencing and characterization of an intracellular protease. Curr Microbiol 1995;30:357 66. Kobayashi T, Hakamada Y, Hitomi J, Koike K, Ito S. Purication of alkaline proteases from a Bacillus strain and their possible inter relationship. Appl Microbiol Biotechnol 1996;45:6371. Takii Y, Taguchi H, Shimoto H, Suzuki Y. Bacillus stearothermophilus KP 1236 neutral protease with strong thermostability comparable to thermolysin. Appl Microbiol Biotechnol 1987;27:186 91. Takami H, Akiba T, Horikoshi K. Production of extremely thermostable alkaline protease from Bacillus sp. no. AH-101. Appl Microbiol Biotechnol 1989;30:120 4. Coolbear T, Daniel RM, Morgan HW. The enzymes from extreme thermophiles: bacterial sources, thermostabilities and industrial relevance. Adv Biochem Eng Biotechnol 1992;45:58 90. Zamost BL, Nielsen HK, Starnes RL. Thermostable enzymes for industrial applications. J Ind Microbiol 1991;8:71 82. Dhandapani R, Vijayaragvan R. Production of thermophilic, extracellular alkaline protease by Bacillus stearothermophilus AP 4. World J Microbiol Biotechnol 1994;10:33 5. Bhosale SH, Rao MB, Deshpande VV, Srinivasan MC. Thermostability of high-activity alkaline protease from Conidiobolus coronatus (NCL 86.8.20). Enzyme Microb Technol 1995;17:136 9.

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Austin Journal of Veterinary Science & Animal HusbandryDocument2 pagesAustin Journal of Veterinary Science & Animal HusbandryAustin Publishing GroupPas encore d'évaluation

- NCP Ineffective Tissue PerfusionDocument7 pagesNCP Ineffective Tissue Perfusionapi-283753722100% (3)

- Science - Week 3-8Document104 pagesScience - Week 3-8Gian Paul BolantePas encore d'évaluation

- OsazoneDocument6 pagesOsazonekylePas encore d'évaluation

- USP 2015-Dsc-Chapters-561-616-1010-1092Document54 pagesUSP 2015-Dsc-Chapters-561-616-1010-1092anna100% (1)

- Photosynthesis and Cellular Respiration Review Questions PDFDocument2 pagesPhotosynthesis and Cellular Respiration Review Questions PDFDave KhylPas encore d'évaluation

- Biochemistry Compiled Notes LecDocument41 pagesBiochemistry Compiled Notes LecZiaPas encore d'évaluation

- Metodologia Do AmidoDocument20 pagesMetodologia Do AmidoViviane SouzaPas encore d'évaluation

- Amylase Activity of Starch Degrading BacDocument13 pagesAmylase Activity of Starch Degrading BacRaisya RagilPas encore d'évaluation

- Final 1Document7 pagesFinal 1Murti GutoPas encore d'évaluation

- Cambridge International AS & A Level: Biology 9700/52 October/November 2021Document11 pagesCambridge International AS & A Level: Biology 9700/52 October/November 2021lllllisaPas encore d'évaluation

- Intertek Article - Honey Authenticity - SonderdruckDocument8 pagesIntertek Article - Honey Authenticity - SonderdruckmaralexPas encore d'évaluation

- Part I: Anatomy and Physiology of The Digestive SytemDocument8 pagesPart I: Anatomy and Physiology of The Digestive SytemArchie CabachetePas encore d'évaluation

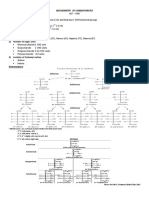

- Biochemistry of Carbohydrates PDFDocument7 pagesBiochemistry of Carbohydrates PDFAshley Beatriz Pascual100% (1)

- MicronutrientsDocument21 pagesMicronutrientsJohn Paolo OcampoPas encore d'évaluation

- Aerobic Anaerobic Fermentation1Document16 pagesAerobic Anaerobic Fermentation1Ken AguilaPas encore d'évaluation

- OCR As and A Level Biology A SB 1 Answers - Combined - FinalDocument60 pagesOCR As and A Level Biology A SB 1 Answers - Combined - FinalMahdi Hasan Y12E33% (3)

- Fehling A and BDocument5 pagesFehling A and BXiao MiePas encore d'évaluation

- Fasting: 1 What Is A Fast?Document6 pagesFasting: 1 What Is A Fast?Asadullah HassanPas encore d'évaluation

- Biology Form 4 Chapter 4 Version 2Document16 pagesBiology Form 4 Chapter 4 Version 2alpha centauriPas encore d'évaluation

- Components of FoodDocument37 pagesComponents of Foodrathee1966Pas encore d'évaluation

- 0620 s05 QP 3Document16 pages0620 s05 QP 3patriciaisfPas encore d'évaluation

- Chemsheets A2 1095 Polymers 1Document24 pagesChemsheets A2 1095 Polymers 1jnfjngsdjPas encore d'évaluation

- Brochure Fillings Bakery Nov2021Document16 pagesBrochure Fillings Bakery Nov2021Iris EnzymesPas encore d'évaluation

- Chemistry 14 Biomolecules PDFDocument19 pagesChemistry 14 Biomolecules PDFinfinilifePas encore d'évaluation

- 2.2 WaterDocument32 pages2.2 WaterHelena GlanvillePas encore d'évaluation

- Problemario Prácticas TermoDocument35 pagesProblemario Prácticas TermoEsaú RSPas encore d'évaluation

- KAPS Exam Paper For Australian Pharmaceutical Council ExamDocument40 pagesKAPS Exam Paper For Australian Pharmaceutical Council ExampiPas encore d'évaluation

- Anti Back Staining AgentDocument4 pagesAnti Back Staining AgentshoyebPas encore d'évaluation

- Chem 31.1 Post Lab 3Document61 pagesChem 31.1 Post Lab 3Belle AnasarioPas encore d'évaluation