Académique Documents

Professionnel Documents

Culture Documents

Pirith Potha

Transféré par

Amila Viraj GunarathnaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pirith Potha

Transféré par

Amila Viraj GunarathnaDroits d'auteur :

Formats disponibles

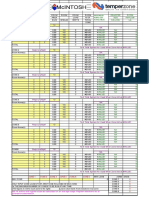

Specifications

ENGINE SPECIFICATIONS

Engine Fuel Type Oil Capacity: Crankcase & Oil Filter w/Bypass Oil Filter Oil Type* TK 3.74 No. 2 Diesel fuel under normal conditions 9 quarts (8.6 liters) 10 quarts (9.6 liters) Fill to full mark on dipstick API Type CF-4 or CG-4 or better API Synthetic type CF-4, CG-4 or better after first 500 hours Multigrade Oil Ambient Temperature SAE 5W-30 -22 to +86 F (-30 to +30 C) SAE 10W-30 -4 to +86 F (-20 to +30 C) SAE 10W-40 -4 to +104 F (-20 to +40 C) SAE 15W-40 +5 to +104 F (-15 to +40 C) 1625 25 rpm 2425 25 rpm 35 to 60 psig (241 to 414 kPa) 0.0079 in. (0.20 mm) 0.0079 in. (0.20 mm) Room temperature 14 BTDC 1706 psig (11720 kPa) 10 3 psig (69 21 kPa)shutdown 220 5.0 F (104 3 C)shutdown 180 to 190 F (82 to 88 C) 4 quarts (3.81 liters) with overflow tank 10 psig (69 kPa) Belts to compressor, fans, 12 V alternator, water pump and electric motor (jackshaft)

Oil Viscosity*

Engine rpm: Low Speed Operation High Speed Operation Engine Oil Pressure Intake Valve Clearance Exhaust Valve Clearance Valve Setting Temperature Timing Injection Pump Injection Nozzle Pressure Low Oil Pressure Sensor High Coolant Temperature Sensor Engine Thermostat Coolant System Capacity Radiator Cap Pressure Drive

*Multi-viscosity weight oil with the recommended API classification may be used based on the ambient temperature. The above recommendations are written for mineral oil based lubricants.

R-134a REFRIGERATION SYSTEM

Compressor Model Refrigerant Charge Compressor Oil Charge Compressor Oil Type: R-134a (Solest 35) Suction Pressure Regulator Setting Special Setting MD-II Single Phase Heat/Defrost Method:Engine Operation Electric Operation High Pressure Cutout X214 8 lb. 5 oz. (3.77 kg) R-134a 66 oz. (1.95 liters)* TK No. 203-413 (Ester base) required 18 psig (124 kPa) 18 psig (124 kPa) Hot gas Hot gas and electric heater strips (Model 50) 325 +25/-0 psig (2088 + 172/0 kPa) Automatically reset @ 200 20 psig (1379 138 kPa)

Specifications (Rev. 04/03)

R-404A REFRIGERATION SYSTEM

X214 7.5 lb. (3.4 kg) R-404A 66 oz. (1.95 liters)* TK No. 203-413 (Ester base) required 20 psig (138 kPa) 20 psig (138 kPa) Hot gas Hot gas and electric heater strips (Model 50) 450 +10/-25 psig (3103 +69/-172 kPa) Automatically reset @ 375 38 psig (2585 262 kPa) NOTE: Compressors are equipped with an oil filter. Every 2 years of operation or whenever there is a major service procedure performed, both the compressor oil filter and filter-drier must be changed. *When the compressor is removed from the unit, oil level should be noted or the oil removed from the compressor should be measured so that the same amount of oil can be added before placing the replacement compressor in the unit. Compressor Model Refrigerant Charge Compressor Oil Charge Compressor Oil Type: R-404A (Solest 35) Suction Pressure Regulator Setting Special Setting MD-II Single Phase Heat/Defrost Method: Engine Operation Electric Operation High Pressure Cutout

ENGINE CLUTCHHILLIARD (Prior April 1997)

Model Engagement Dynamic Torque TK No. 107-257 (Dwg. No. 5D44655G01) 900 100 rpm 66 ft-lb (89.5 Nm) minimum @ 1600 rpm

ENGINE CLUTCHHILLIARD (Starting April 1997)

Model Engagement Dynamic Torque TK No. 107-272 (Dwg. No. 2C21375G01) 600 100 rpm 66 ft-lb (89.5 Nm) minimum @ 1600 rpm

BELT TENSION

Tension No. on TK Gauge 204-427 New Belt Field Reset 75 3 70 3 72 3 67 3 55 3 50 3 55 3 50 3 1/2 in. (13 mm) deflection

Engine/Compressor Compressor/Jackshaft (Electric Motor) Compressor/Evaporator Fan/Alternator Alternator/Evaporator Fan Water Pump

NOTE: These are the original factory settings. Because it is difficult to use the TK gauge 204-427 in the field, adjust each belt to allow 1/2 inch (13 mm) deflection at the center of the longest span. NOTE: Belts should be tensioned cold and again tensioned cold after 10 hours of unit running.

Specifications (Rev. 04/03)

ELECTRICAL CONTROL SYSTEM

Control System Voltage Battery Charging System Voltage Regulator Setting Alternator/Regulator Capacitor Alternator/Output Capacitor 12.5 Vdc 12 V 23 amp brush type integral alternator 14 V @ 70 F (21.1 C) 4.7 fd 50 Vdc 0.5 fd 100 Vdc

NOTE: Disconnect components from unit circuit to check resistance.

ELECTRICAL COMPONENTS

Current Draw (Amps) Resistance at 12.5 Vdc (Ohms) 8.3 1.5 0.15 18 to 25 0.5 to 0.7 0.9 to 1.1 11 to 13 0.657 19 90 to 105 (cranking) 5.68 2.2 50 amp 5 amp (approx.) 2.5 (approx.) 8.5 amp (approx.) 1.5 (approx.)

Glow Plug Fuel Solenoid: Pull In Hold In Pilot Solenoid Starter Motor Damper Solenoid DC Circuit Breakers High Speed Solenoid Electric Standby Reset Solenoid

Electrical Standby Compressor Motors (Model 50 Unit Only)

Horsepower Full Load (amps) Locked Rotor Amps Unit Full Load* Amps

Voltage/Phase/Frequency

Kilowatts

rpm

230/1/60 230/3/60 460/3/60 380/3/50 220/3/50

5 5 5 4.2 4.2

3.7 3.7 3.7 3.1 3.1

1750 1750 1750 1450 1450

18 14.4 7.2 7.3 12.7

80 58 58 55 55

25 21 12 12 12.7

*w/Heater Strips Electric Heater Strips (Optional): Number Watts (each)

3 750

STANDBY POWER REQUIREMENTS

Supply Circuit Breaker Extension Cord Size 30 amp/230 V 20 amp/460 V Up to 50 ft12 gauge 75 ft10 gauge

AIR SWITCH

Air Switch Setting 0.7 0.05 in. (17.78 1.3 mm) H2O

Vous aimerez peut-être aussi

- Ground Power Unit: GA ModelDocument17 pagesGround Power Unit: GA ModelAngelica Nava0% (1)

- 2004 Infiniti G35 Coupe Quick Reference SpecsDocument17 pages2004 Infiniti G35 Coupe Quick Reference Specsnikkon1100% (2)

- HATZ Engine 2G40 - EDocument8 pagesHATZ Engine 2G40 - EIAN.SEMUT100% (1)

- IEEE Guide For AC Generator ProtectionDocument76 pagesIEEE Guide For AC Generator ProtectionOmar Chayña VelásquezPas encore d'évaluation

- Thermoking Engine SpecsDocument6 pagesThermoking Engine SpecsMark Dwayne Fulmer75% (4)

- Cat 3512 1280HP A RatingDocument4 pagesCat 3512 1280HP A RatingingjoseosunaPas encore d'évaluation

- Brushless AlternatorDocument10 pagesBrushless AlternatorArun GouthamPas encore d'évaluation

- G3512 SpecDocument4 pagesG3512 SpecnunkpPas encore d'évaluation

- Atkinson Tractor Service Shop Manual Unit 1 - Engine and Ancilliary EquipmentDocument26 pagesAtkinson Tractor Service Shop Manual Unit 1 - Engine and Ancilliary EquipmentDavid Kelly100% (1)

- Gti Gti Rfi XP Di GTX 4 Tec SC LTD SC We RXP 4 Tec SC Tehnicheskie DannyeDocument22 pagesGti Gti Rfi XP Di GTX 4 Tec SC LTD SC We RXP 4 Tec SC Tehnicheskie DannyeAlexandru DiaconuPas encore d'évaluation

- DC MachinesDocument43 pagesDC Machinessupriyaditi100% (1)

- Diesel Engine MitsubishiDocument4 pagesDiesel Engine MitsubishiMarbun Benny100% (1)

- Why Aircraft Electrical Systems Operate at 400 HZ FrequencyDocument1 pageWhy Aircraft Electrical Systems Operate at 400 HZ Frequencysofyan_shahPas encore d'évaluation

- Specification Sheetapril 2016v3300 T E2bg2Document4 pagesSpecification Sheetapril 2016v3300 T E2bg2Richard Enciso JimenezPas encore d'évaluation

- Cat 3306B DITA PropulsionDocument40 pagesCat 3306B DITA PropulsionStroe VladPas encore d'évaluation

- CaterpilarDocument4 pagesCaterpilarpangestu66100Pas encore d'évaluation

- RS 2003 ADD Training MatDocument220 pagesRS 2003 ADD Training Matmliugong91% (11)

- Diesel GeneratorDocument17 pagesDiesel GeneratorJames Tnecniv AlbortePas encore d'évaluation

- ERRU (Electronic Rectification and Regulating Unit)Document19 pagesERRU (Electronic Rectification and Regulating Unit)Dilpal50% (2)

- 0186 ESP DSP 025 047 0007 - Rev04 - GeneratorDocument57 pages0186 ESP DSP 025 047 0007 - Rev04 - GeneratorBraulio Garces100% (1)

- GE Wind BrochureDocument16 pagesGE Wind BrochurecampinensPas encore d'évaluation

- Stage-I ALARMSDocument73 pagesStage-I ALARMSNikhilPas encore d'évaluation

- Petroleum Engine Caterpillar Engine Specifications: V-8, 4-Stroke-Cycle DieselDocument4 pagesPetroleum Engine Caterpillar Engine Specifications: V-8, 4-Stroke-Cycle DieselRichard Gregorio Huamani HuamanPas encore d'évaluation

- BMGS.260.S6B Pta PDFDocument4 pagesBMGS.260.S6B Pta PDFbang nal100% (1)

- C18 Fire Pump 597 BKW 800 BHP 1750 RPM PDFDocument5 pagesC18 Fire Pump 597 BKW 800 BHP 1750 RPM PDFDenis JimenezPas encore d'évaluation

- Cat 3616 (50-60hz) - JulDocument7 pagesCat 3616 (50-60hz) - JulLei YinPas encore d'évaluation

- Frequently Asked Electrical Engineering Interview QuestionsDocument2 pagesFrequently Asked Electrical Engineering Interview Questionsveeru_virenderPas encore d'évaluation

- S6A3MPTKDocument3 pagesS6A3MPTKvikas_ojha54706100% (6)

- Compressor BITZER Open TypeDocument6 pagesCompressor BITZER Open Typejorge castilloPas encore d'évaluation

- Goldwind 15MW Product Brochure 2013Document4 pagesGoldwind 15MW Product Brochure 2013diegoxis24Pas encore d'évaluation

- 12V 4000 M73/M73L Diesel Engines: For Fast Vessels With High Load Factors (1B)Document3 pages12V 4000 M73/M73L Diesel Engines: For Fast Vessels With High Load Factors (1B)derfgthPas encore d'évaluation

- Caterpillar 3606 2425kVA GensetDocument6 pagesCaterpillar 3606 2425kVA GensetMuhammad Irfan KhanPas encore d'évaluation

- Caterpillar-3516C HD Marine EngineDocument4 pagesCaterpillar-3516C HD Marine EngineViswanathan Damodaran100% (4)

- SGSM 3000, SGCM 3000, SGCO 3000 53414-4-MM, Rev 4 09-08-1Document2 pagesSGSM 3000, SGCM 3000, SGCO 3000 53414-4-MM, Rev 4 09-08-1Adam SamyPas encore d'évaluation

- S4S-Z3DT65SP (SPC-S4S-407 Rev 0) MEE StandardDocument17 pagesS4S-Z3DT65SP (SPC-S4S-407 Rev 0) MEE StandardPutra kurnia WijayaPas encore d'évaluation

- 3612Document6 pages3612Chandrashekar PatigePas encore d'évaluation

- Product oDocument10 pagesProduct oAngela AllenPas encore d'évaluation

- Cooler DetailsDocument11 pagesCooler DetailsLoganathan ThulasiPas encore d'évaluation

- 8 - Data & Specifications 3Document21 pages8 - Data & Specifications 3agvass100% (1)

- MSB 97e55 001 PDFDocument12 pagesMSB 97e55 001 PDFAutof FerreiraPas encore d'évaluation

- CSH9573-180 R134a t0 TC 50 13.2.23 PDFDocument6 pagesCSH9573-180 R134a t0 TC 50 13.2.23 PDFWali Ahmed KhanPas encore d'évaluation

- Catalogo Generador Cat 3512Document6 pagesCatalogo Generador Cat 3512pamg50% (1)

- Cat C175-16 - Jul 2010Document6 pagesCat C175-16 - Jul 2010Lei YinPas encore d'évaluation

- Taylor Power SystemsDocument4 pagesTaylor Power SystemsTeresa CarterPas encore d'évaluation

- Customer: HVN Type: A330 Rev. Date: Oct 01/11 Manual: AMM Selected Effectivity: ALL 71-00-00-860-817-A - Engine Operation Limits and GuidelinesDocument7 pagesCustomer: HVN Type: A330 Rev. Date: Oct 01/11 Manual: AMM Selected Effectivity: ALL 71-00-00-860-817-A - Engine Operation Limits and GuidelinesLê Viết DũngPas encore d'évaluation

- G3512le PDFDocument4 pagesG3512le PDFandrey7219100% (1)

- Fan Secimi HesabıDocument11 pagesFan Secimi HesabıOguzhanKPas encore d'évaluation

- Grupos Electrogenos Marinos Cat 3508bDocument2 pagesGrupos Electrogenos Marinos Cat 3508bYerko VillcaPas encore d'évaluation

- Generator SetDocument4 pagesGenerator Setbiz2721Pas encore d'évaluation

- OSNA8571 R717 t0 - 33 TC 32Document5 pagesOSNA8571 R717 t0 - 33 TC 32Rajkumar GulatiPas encore d'évaluation

- Specificatie Motor Robot170Document1 pageSpecificatie Motor Robot170aiulica20Pas encore d'évaluation

- Oska8581 KDocument16 pagesOska8581 KGökay DalPas encore d'évaluation

- 4jh5e EspecificacionesDocument2 pages4jh5e EspecificacionesFrederik CañabiPas encore d'évaluation

- E5801 1 01 05 - Oil Air Coolers El Neu PDFDocument11 pagesE5801 1 01 05 - Oil Air Coolers El Neu PDFFolpoPas encore d'évaluation

- (Lehw0191-00) 3512c (HD) Ataac With DGBDocument4 pages(Lehw0191-00) 3512c (HD) Ataac With DGBvictor.ciprianiPas encore d'évaluation

- Diesel GensetDocument4 pagesDiesel GensetErwin GunawanPas encore d'évaluation

- Features: How To Order (AOC-08 Models Only)Document4 pagesFeatures: How To Order (AOC-08 Models Only)CarmenLinoBedoyaPas encore d'évaluation

- Model: T1900 Diesel GensetDocument5 pagesModel: T1900 Diesel Gensetengnajeeb75Pas encore d'évaluation

- CSH8581-125 - Fișă TehnicăDocument3 pagesCSH8581-125 - Fișă TehnicăLiviu PopaPas encore d'évaluation

- 80 KW John DeereDocument4 pages80 KW John DeereReynaldo VillarrealPas encore d'évaluation

- 4CES-9 R404A t0 - 7 TC 45Document4 pages4CES-9 R404A t0 - 7 TC 45Tedy ChriswandaPas encore d'évaluation

- Gas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyDocument3 pagesGas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyEzequiel Juarez BenítezPas encore d'évaluation

- CSH8583-125 - Fișă TehnicăDocument4 pagesCSH8583-125 - Fișă TehnicăLiviu PopaPas encore d'évaluation

- Energy-Saving and Easy Maintenance: Printed in Japan (H)Document6 pagesEnergy-Saving and Easy Maintenance: Printed in Japan (H)Bánh Cuốn Tôm ThịtPas encore d'évaluation

- BitzerDocument6 pagesBitzerDee RajaPas encore d'évaluation

- 5336T3TCAElec97-108-120BasicIss1 - 97, 108, 120 KW, Tier3Document4 pages5336T3TCAElec97-108-120BasicIss1 - 97, 108, 120 KW, Tier3aiulica20Pas encore d'évaluation

- For Assessment of Action WorkDocument9 pagesFor Assessment of Action WorkGenelle Mae MadrigalPas encore d'évaluation

- Cat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Document4 pagesCat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Oghale B. E. OmuaborPas encore d'évaluation

- Gep22 4Document4 pagesGep22 4RktBatam100% (1)

- Heat Load Cal Sheet NewDocument2 pagesHeat Load Cal Sheet NewAmila Viraj GunarathnaPas encore d'évaluation

- VRV Vs Split TypeDocument1 pageVRV Vs Split TypeAmila Viraj GunarathnaPas encore d'évaluation

- AB-055 5th Class SyllabusDocument7 pagesAB-055 5th Class SyllabusAmila Viraj GunarathnaPas encore d'évaluation

- Air Conditioning SystemDocument33 pagesAir Conditioning SystemAmila Viraj GunarathnaPas encore d'évaluation

- Ac GeneratorsDocument7 pagesAc GeneratorsAnkur SheelPas encore d'évaluation

- Alternator Warning Light PDFDocument4 pagesAlternator Warning Light PDFEriflonaPas encore d'évaluation

- Sgw250ss Rev 2 Manual Honda Gx610vxdDocument92 pagesSgw250ss Rev 2 Manual Honda Gx610vxdYew LimPas encore d'évaluation

- Unit VDocument23 pagesUnit VDhaval PatelPas encore d'évaluation

- Induction Motor Drive PDFDocument8 pagesInduction Motor Drive PDFSwostik RoutPas encore d'évaluation

- Owner S and Operator S Manual: Vertical, Water-Cooled 4-Cycle Diesel EngineDocument48 pagesOwner S and Operator S Manual: Vertical, Water-Cooled 4-Cycle Diesel EnginethuanPas encore d'évaluation

- 2275 KVA Prime-HV (Low Emission)Document6 pages2275 KVA Prime-HV (Low Emission)Anas Basarah100% (1)

- BASIC ELECTRICAL ENGINEERING Module 2Document40 pagesBASIC ELECTRICAL ENGINEERING Module 2cinema masterPas encore d'évaluation

- 11 MGS0650B 50Hz HC6GDocument4 pages11 MGS0650B 50Hz HC6GAbelRamadhanPas encore d'évaluation

- Microgrid Dynamic Performance Improvement Using A Doubly Fed Induction Wind GeneratorDocument9 pagesMicrogrid Dynamic Performance Improvement Using A Doubly Fed Induction Wind GeneratorDhinesh BaluPas encore d'évaluation

- Review of Related LiteratureDocument20 pagesReview of Related LiteratureMarkChristianRobleAlmazanPas encore d'évaluation

- Automatic Engine Control Unit Operators Manual: Kutai Electronics Industry Co., LTDDocument11 pagesAutomatic Engine Control Unit Operators Manual: Kutai Electronics Industry Co., LTDalexanderPas encore d'évaluation

- Generator LogDocument4 pagesGenerator LogFELIXENGIPLASCOMPas encore d'évaluation

- Armature Windings, Number of Conductors, Types of SlotsDocument7 pagesArmature Windings, Number of Conductors, Types of Slotssrinimeha@gmail.comPas encore d'évaluation

- Exciters PDFDocument44 pagesExciters PDFAnonymous 0ocPZmNg50% (2)

- AED Notes SECTION BDocument8 pagesAED Notes SECTION BShivam RaiPas encore d'évaluation

- Single Phase Induction MotorDocument13 pagesSingle Phase Induction MotorEdmondPas encore d'évaluation

- 2017 Balmar CatalogDocument36 pages2017 Balmar Catalognospam2000Pas encore d'évaluation

- Internship ReportDocument32 pagesInternship ReportAdit RajPas encore d'évaluation