Académique Documents

Professionnel Documents

Culture Documents

5.04 - Bunkering

Transféré par

Anil Kumar SharmaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

5.04 - Bunkering

Transféré par

Anil Kumar SharmaDroits d'auteur :

Formats disponibles

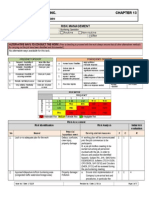

RISK ASSESSMENT FORM

Ships/Dept. Name: Work / Activity Details : BUNKERING Sect.1. Risk Assessment Table

Severity** Rating (A) of consequences with (Refer Table in Sect.2) existing controls

RA-01

Rev No.* 00 Date: XX-XX-XXXX

xxx

RA no*:

New Likelihood Rating(B1) (after additional control)

New Severity Rating(A1) (after additional control)

Residual Risk ( A1 x B1)

Likelihood** Rating (B) (Refer Table in Sect.2)

Sub Task/Activity

Hazards Identified

RA Criteria (People/Environment/ Property/Process)

Consequences

Existing Control Measures

Additional Controls (if any)

Person Responsible

Approach of bunker barge

Wrong approach of Barge.

Property

Collision Damage to ship structure

1.Necessary fendering and closely observing the approach of bunker barge, 2. Ship side clear on the intended side of barge berthing. 3.Weather conditions monitored 4.Communication established with barge. 5. Duty Officer & other Qualified Personnel standby.

1. Master to personally supervise Bunker Barge Movements. 2. Engines standby.

Master

Prior approach of barge

Environment

Oil pollution from ruptured fuel tank

As above + SOPEP gear ready

Rev: 01

Page 1 of 8

Decision to proceed with work Y/N

Agreed time frame

Risk Level** (A X B)

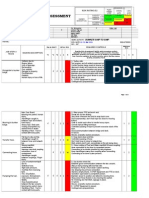

RISK ASSESSMENT FORM

Severity** Rating (A) of consequences with existing controls

RA-01

New Likelihood Rating(B1) (after additional control)

New Severity Rating(A1) (after additional control)

Residual Risk ( A1 x B1)

Likelihood** Rating (B) (Refer Table in Sect.2)

Sub Task/Activity

Hazards Identified

RA Criteria (People/Environment/ Property/Process)

Consequences

Existing Control Measures

Additional Controls (if any)

Person Responsible

Mooring Operation double banking

Rope over -tensioning, parting and related accidents

People

Personal Injury

1.Supervised by Duty Officer 2.Mooring ropes in good condition 3.Safe Mooring practices 4.Good communication 5.PPEs

(Refer Table in Sect.2)

Moorings not tended to changing draft/tide

Environment

Relative movement between own vessel and barge resulting in hose rupture and pollution.

Frequent tending of moorings supervised by Duty Officer

Opening connections, fitting spool piece/hose.

Oil spill from manifold/hose or from connection during bunkering Use of wrong or worn out tools during securing of connections Unsafe Hose Crane operation

Environment

Pollution/Fines

People

Personal Injury

1. Bunkering Checklist followed. 2.High level of Supervision. 3. Experienced personnel involved in bunkering operation. 4. New joints used and all bolts fitted. 1.Proper tools kept ready prior operation. 2.PPEs 3.Controls as above 1.Crane operated by experienced person. 2.Sling checked for wear & tear 3.Good communication Damage to crane or ship fittings

1.People 2.Property

1.Personal Injury 2.Property

4 3

1 1

4 3

Rev: 01

Page 2 of 8

Decision to proceed with work Y/N

Agreed time frame

Risk Level** (A X B)

RISK ASSESSMENT FORM

Severity** Rating (A) of consequences with existing controls

RA-01

New Likelihood Rating(B1) (after additional control)

New Severity Rating(A1) (after additional control)

Residual Risk ( A1 x B1)

Likelihood** Rating (B) (Refer Table in Sect.2)

Sub Task/Activity

Hazards Identified

RA Criteria (People/Environment/ Property/Process)

Consequences

Existing Control Measures

Additional Controls (if any)

Person Responsible

Damage 1)Sufficient Qualified personnel & strict manifold watch under C/Es supervision through out bunkering. 2)Compliance to SMS bunkering procedures and checklist TEC/006. 3) Bunker lines pressure tested & maintained as per PMS. 4) SOPEP Gear standby 5) Soundings taken instead of relying on remote gauges. 6) Compliance to bunker policy on max. intake per tank. 1.PPEs 2. Good Lighting 3.Prompt cleaning 4.Cordon off slippery areas 1.Elimination of Ignition sources 2.Intrinsically safe equipments 3.No smoking signs. 4.Precautions against overflow 1. Addnl. Special precautions as given in TOM- 2.02.07 watch for signs of fatigue, stay clear of airpipes, against wind direction when ullaging, gas tests on deck, medical emergency equipment ready.

(Refer Table in Sect.2)

Receiving Bunkers

Leakage or overflow of oil

Environment

Oil Pollution

1.CE personally checking line settings prior every interruptions in operations. 2. CE closely monitoring topping up. 3. Scupper plugs checked for effective sealing.

Ch. Engnr.

People

Slips and Falls from spilled oil

Flammable atmosphere

People/Property

Fire/ Explosion

Exposure to H2S when taking bunkers with high sulphur content

People

Personal Injury

Rev: 01

Page 3 of 8

Decision to proceed with work Y/N

Agreed time frame

Risk Level** (A X B)

RISK ASSESSMENT FORM

Severity** Rating (A) of consequences with existing controls

RA-01

New Likelihood Rating(B1) (after additional control)

New Severity Rating(A1) (after additional control)

Residual Risk ( A1 x B1)

Likelihood** Rating (B) (Refer Table in Sect.2)

Sub Task/Activity

Hazards Identified

RA Criteria (People/Environment/ Property/Process)

Consequences

Existing Control Measures

Additional Controls (if any)

Person Responsible

Bunker Quantity and Quality disputes

Ineffective monitoring may result in receiving less quantity bunkers

Process

Off-hire/claims

1. Bunker barge soundings to be checked before & after bunkering. 2. NOP issued 1. Samples to be collected & sealed /signed as per SMS procedures and sent to lab for analysis. 2. NOP issued 3. Bunkers not to be consumed until confirmation received from lab that fuel is fit for use. 4. Minimum reserve of old stock bunkers maintained. 5. Mixing with previous bunkers avoided. 1..Bunker shore lab analysis includes tests for high TAN to detect fatty acids and further tests if TAN high. TOM -1.11.03 2. Controls as above Hose to be emptied and valves closed, Suitable spill containments to be in place, Proper communication to be established with barge personnel

(Refer Table in Sect.2)

Bunker quality Off spec.

Property

Damage to Engines

Presence of high fatty acids in bunkers of W. African coast

Property

Damage to Engines

Hose Disconnection

Leakage of oil on deck

Environment Pollution

Rev: 01

Page 4 of 8

Decision to proceed with work Y/N

Agreed time frame

Risk Level** (A X B)

RISK ASSESSMENT FORM

Severity** Rating (A) of consequences with existing controls

RA-01

New Likelihood Rating(B1) (after additional control)

New Severity Rating(A1) (after additional control)

Residual Risk ( A1 x B1)

Likelihood** Rating (B) (Refer Table in Sect.2)

Sub Task/Activity

Hazards Identified

RA Criteria (People/Environment/ Property/Process)

Consequences

Existing Control Measures

Additional Controls (if any)

Person Responsible

Wrong or worn tools, improper use

People

Personal Injury

Same as for opening hose connection above All bolts fitted tightly. Joint condition ensured good 3. Supervision by Duty Engineer.

(Refer Table in Sect.2)

Manifold Blank not fitted back properly

Environment

Pollution - from leaks when bunker taken on other manifold

2.

Casting off the barge

Mooring related accidents

People

Personal Injury

Same as described above for Mooring operation.

*Numbering guidance: a. New RA No. if it is a fresh case. b. Old RA No. with new date if no change is hazards. c. Old RA No. inserting Rev. No & new date if there are additional Hazards (Refer Sect 1.6 of RA/MOC Manual for details) ** Refer RA Matrix (Sect.2 Table 1,2,3,4 of this Form and Sec. 1.5 of the RA/MOC Manual) for Hazards / Consequences Evaluation(Likelihood/Severity) to People, Environment and/or Property / Commercial aspects as applicable to arrive at ratings of (A) & (B). *** Refer Risk Level table (Sect.2 Table 5 of this form) and Sect 1.4.7 of the RA & MOC Manual .If results are either in yellow or red consider additional measures to mitigate the risk. Contingency Plans to limit the impact of unplanned occurrences/ failure of control measures to be discussed and recorded in the section below. During review of the RA process, if scope for improvement of the documented QHSE procedure for the operation/activity is identified, same should be recorded in the comments section below and office notified for appropriate action. Contingency Plans : Comments : Signed: Ref. Contingency Plans Manual Sec. 2.03.01.01 Oil Pollution

Rev: 01

Page 5 of 8

Decision to proceed with work Y/N

Agreed time frame

Risk Level** (A X B)

RISK ASSESSMENT FORM

Head of The Department Reviewers Comments: Signed: Date

RA-01

Name / Position / Signature

Date

SECT 2: Risk Ranking Matrices & Risk Level Tables

(Severity of)Consequence-A TABLE 1 : SHIPBOARD - PEOPLE FAC: First Aid Case Likelihood Of Consequence)-B Rating Happened several times per annum in a location/ship (Very likely) Happened several times per annum within the company (Likely) Happened within our company at least once (Unlikely) Heard Within the industry (Highly unlikely) 5 4 3 2 1 5 4 3 2 LTI: Lost Time Incident 2 10 8 6 4 Hospital: Injury requiring Hospitalization or LTI >24hours 3 15 12 9 6 Perm Disability: Injury resulting in permanent disability 4 20 16 12 8 Fatality: Injury resulting in death 5 25 20 15 10

Never heard within the industry (Almost NIL chances)

(Severity of)Consequence-A TABLE 2 : SHIPBOARD -ENVIRONMENT Likelihood Of Consequence)-B Rating

Happened several times per annum in a location/ship (Very likely) Happened several times per annum within the company (Likely) Happened within our company at least once (Unlikely) Heard Within the industry (Highly unlikely) Nil to Sea: Contained onboard Sheen on Sea: Evidence of loss to sea Les than 1m3 to Sea 1 to 5 m3 to Sea More than 5 m3 to Sea

5 4 3 2

1 5 4 3 2

2 10 8 6 4

3 15 12 9 6

4 20 16 12 8

5 25 20 15 10

Never heard within the industry (Almost NIL chances)

TABLE 3 : SHIPBOARD -PROPERTY / COMMERCIAL USD 1000, Customer Complaint / off hire < 2 hours > USD 1000 < USD 5000 / Off Hire< 4 Hours / slight damage

(Severity of)Consequence-A > USD 5000 < USD 10000 / Off hire > 4 hours / cargo contamination / > USD 10000 < USD 100000 / P&I or H&M claim / off hire > one day > USD 100000, P&I or H&M claim / off hire > one week

Rev: 01

Page 6 of 8

RISK ASSESSMENT FORM

Likelihood Of Consequence)-B Rating

Happened several times per annum in a location/ship (Very likely) Happened several times per annum within the company (Likely) Happened within our company at least once (Unlikely) Heard Within the industry (Highly unlikely)

RA-01

moderate damage 3 15 12 9 6 4 20 16 12 8 5 25 20 15 10

5 4 3 2

1 5 4 3 2

2 10 8 6 4

Never heard within the industry (Almost NIL chances)

Rev: 01

Page 7 of 8

RISK ASSESSMENT FORM

TABLE 4 :

RA-01

(Severity of) Consequence (To be defined)\#* - A Negligible

Rating 1 5 4 3 2 1

RA - MATRIX FOR MOC Likelihood Of Consequences-B

Minor

2 10 8 6 4 2

Moderate

3 15 12 9 6 3

Major

4 20 16 12 8 4

Catastrophic

5 25 20 15 10 5

Very likely Likely Unlikely Highly unlikely Almost NIL chances

5 4 3 2 1

Table 5: Risk Levels 1-7

Meaning

Action

Tolerable

Risk is acceptable and job can be undertaken. Consideration may be given for further reduction of risk if reasonably possible. However, in case value is above 4, continuous monitoring is required to ensure existing controls are maintained.

8 - 11

Moderate

Efforts are to be made to reduce the risk by placing additional controls with an aim to bring down Risk Level to Green zone. Vessel: If the risk cannot still be brought down to green zone, job can be undertaken but with continuous and heightened monitoring. Office may be contacted for advice if deemed necessary. MOC: The approving Authority or HOD may be suitably consulted.

12 - 25

Substantial

Efforts are to be made to reduce the risk to green/yellow rating by placing additional controls and taking appropriate action as defined above. However in case final risk level remains in Red zone, work is not to be started without obtaining permission from the office. Office will advise the vessel about the action to be taken. For MOC the approving authority or HOD are to be consulted.

#*Note: The Severity and Likelihood of consequences may be interpreted/ evaluated under People, Environmental and Commercial aspects as applicable using the guidance for the Shipboard Operation Matrix detailed in Sec 1.5.1, 1.5.2 and 1.5.3 of the RA & MOC Manual and in Risk Level Matrices/Table preceding this page of this Form.

Rev: 01

Page 8 of 8

Vous aimerez peut-être aussi

- RA 002 - BunkeringDocument5 pagesRA 002 - Bunkeringdassi99Pas encore d'évaluation

- RA 002 - D.O. Tank Inspection and CleaningDocument6 pagesRA 002 - D.O. Tank Inspection and Cleaningdassi99100% (1)

- Risk Assessment No. 08 BUNKERING IN GENERAL Rev. 02 20.03.09Document2 pagesRisk Assessment No. 08 BUNKERING IN GENERAL Rev. 02 20.03.09Devi Ratna Pratiwi91% (11)

- Risk Assessment No. 07 BUNKER SHIP TO SHIP Rev. 02 20.03.09Document3 pagesRisk Assessment No. 07 BUNKER SHIP TO SHIP Rev. 02 20.03.09Devi Ratna Pratiwi83% (6)

- Risk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Document5 pagesRisk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Devi Ratna Pratiwi78% (9)

- Excessive ListDocument2 pagesExcessive ListVenugopal Rajagopal100% (1)

- Spillages Through Pumproom Sea ValvesDocument12 pagesSpillages Through Pumproom Sea ValvesGamalMahran50% (2)

- Risk Assessment: Bunkering in GeneralDocument2 pagesRisk Assessment: Bunkering in Generaloto saviour0% (1)

- Job Risk Assesment OfftakeDocument7 pagesJob Risk Assesment OfftakeIhwan Asrul100% (1)

- Risk Assessment No. 24 MOORING TO WHARF - VESSELS Rev. 02 28.1Document3 pagesRisk Assessment No. 24 MOORING TO WHARF - VESSELS Rev. 02 28.1Devi Ratna Pratiwi100% (5)

- Risk Assessment No. 02 ANCHOR HANDLING, RETREVING CRUCIFIX BDocument5 pagesRisk Assessment No. 02 ANCHOR HANDLING, RETREVING CRUCIFIX BDevi Ratna Pratiwi100% (2)

- A-080 Handover Chief EngDocument4 pagesA-080 Handover Chief EngShanAlan100% (2)

- Risk Assessment No. 04 ANCHOR HANDLING, RUNNING, SUIT CASE BUDocument3 pagesRisk Assessment No. 04 ANCHOR HANDLING, RUNNING, SUIT CASE BUDevi Ratna PratiwiPas encore d'évaluation

- Example DrillsDocument60 pagesExample DrillsDrago Dragic100% (5)

- Risk Assessment No. 42 WORKING OVER-SIDE Rev. 02 28.12.09Document2 pagesRisk Assessment No. 42 WORKING OVER-SIDE Rev. 02 28.12.09Devi Ratna Pratiwi80% (5)

- Cargo Tank Cleaning Guide EnglDocument1 pageCargo Tank Cleaning Guide EnglSat Partner100% (3)

- Tanker Operation ProcedureDocument2 pagesTanker Operation ProcedureAnand KhotPas encore d'évaluation

- CO Handing Over NotesDocument7 pagesCO Handing Over Notesalive2flirt100% (2)

- Tank Cleaning Methods Onboard Chemical TankersDocument6 pagesTank Cleaning Methods Onboard Chemical TankersJeet SinghPas encore d'évaluation

- Mooring Risk Assessment Form 0917Document6 pagesMooring Risk Assessment Form 0917Quân NguyễnPas encore d'évaluation

- ER06 BunkeringDocument2 pagesER06 BunkeringNang D. VuPas encore d'évaluation

- 4.8 Bunker Line Test ProcedureDocument2 pages4.8 Bunker Line Test ProcedureGouri100% (2)

- RA Export 20230303-171712 (TEMPLATE-04 Haz) - ID230303164833 - Rev2023-03-03 - Cargo & Ballast Works - Ballast Water Treatment System FailureDocument3 pagesRA Export 20230303-171712 (TEMPLATE-04 Haz) - ID230303164833 - Rev2023-03-03 - Cargo & Ballast Works - Ballast Water Treatment System FailureHarman Sandhu100% (3)

- Crude Oil Washing Check List: Before C.O.WDocument2 pagesCrude Oil Washing Check List: Before C.O.Wopytnymoryak100% (1)

- Chemical Tanker OperationsDocument12 pagesChemical Tanker OperationsJeet Singh75% (4)

- Risk Assessment No. 03 ANCHOR HANDLING, RETRIEVING, SUIT CASDocument2 pagesRisk Assessment No. 03 ANCHOR HANDLING, RETRIEVING, SUIT CASDevi Ratna Pratiwi80% (5)

- Muster List and Cabin Cards - To Be PostedDocument9 pagesMuster List and Cabin Cards - To Be PostedIndra PratamaPas encore d'évaluation

- Vessel S Guide To Vetting InspectionsDocument11 pagesVessel S Guide To Vetting Inspectionsmatan55100% (5)

- Shipboard Marine Pollution Emergency Plan (Smpep)Document44 pagesShipboard Marine Pollution Emergency Plan (Smpep)capt_wal1137Pas encore d'évaluation

- Bunker CalculationDocument9 pagesBunker CalculationDhanasekar Gajendrababu100% (5)

- PT Berlian Laju Tanker TBK: Tank Cleaning GuideDocument66 pagesPT Berlian Laju Tanker TBK: Tank Cleaning Guideandri wirawan100% (1)

- Join DrillDocument2 pagesJoin Drillbinsar800% (1)

- Dry Docking SafetyDocument3 pagesDry Docking SafetyAnil Kumar100% (1)

- Standard Procedures For Tank CleaningDocument7 pagesStandard Procedures For Tank CleaningDhitya Agil Harnowo100% (1)

- Know Your Ship: Bitumen/ Asphalt CarriersDocument2 pagesKnow Your Ship: Bitumen/ Asphalt CarriersNeeraj Kumar80% (5)

- BP High Risk ObservationDocument9 pagesBP High Risk ObservationSadiqul HaquePas encore d'évaluation

- 09 - Cargo Heating - Operational Advice PDFDocument4 pages09 - Cargo Heating - Operational Advice PDFrpichoPas encore d'évaluation

- Chief Officer Standing OrdersDocument3 pagesChief Officer Standing OrdersEdsel LoganPas encore d'évaluation

- Tanker ManualDocument205 pagesTanker ManualIuri Dudinov100% (1)

- 9 Engineering Watch (Underway) 1Document41 pages9 Engineering Watch (Underway) 1Rishav RajPas encore d'évaluation

- SMM Manual - 25-Mar-21Document239 pagesSMM Manual - 25-Mar-21Anonymous 1l8njob100% (3)

- Risk Assessment No. 25 PAINTING in GENERAL Rev. 02 20.03.09Document2 pagesRisk Assessment No. 25 PAINTING in GENERAL Rev. 02 20.03.09Devi Ratna Pratiwi89% (9)

- Near Miss - OCIMF Definition: Working AloftDocument10 pagesNear Miss - OCIMF Definition: Working AloftНина РыбкинаPas encore d'évaluation

- G138 Shipboard WorkingDocument3 pagesG138 Shipboard WorkingJeet SinghPas encore d'évaluation

- ISPS Drills and Exercises 1Document5 pagesISPS Drills and Exercises 1dmzoly_7085% (13)

- DCOM Dry CargoDocument352 pagesDCOM Dry CargoVasiMacovei100% (2)

- Company Internal Navigational Audit Checklist Ver 9Document13 pagesCompany Internal Navigational Audit Checklist Ver 9sandeepkumar2311100% (2)

- Garbage MANUALDocument36 pagesGarbage MANUALmouloud miloudPas encore d'évaluation

- Risk Assessment No. 43 ENTRY INTO ENCLOSED SPACES Rev. 02 20Document3 pagesRisk Assessment No. 43 ENTRY INTO ENCLOSED SPACES Rev. 02 20Devi Ratna Pratiwi100% (13)

- Crude Oil WashingDocument60 pagesCrude Oil Washingmadhav sai100% (10)

- Shipboard Marine Pollution Prevention Plan (SMPEP)Document43 pagesShipboard Marine Pollution Prevention Plan (SMPEP)Nathalia margarita GomezPas encore d'évaluation

- RA Templates - Tank CleaningDocument26 pagesRA Templates - Tank Cleaningkoib78981% (16)

- Risk Assessment No. 48 USE OF ELECTRICITY Rev. 02 28.12.09Document1 pageRisk Assessment No. 48 USE OF ELECTRICITY Rev. 02 28.12.09Devi Ratna Pratiwi0% (1)

- SIRE 2.0 - Strategic Goal & Objectives: Tentative RoadmapDocument14 pagesSIRE 2.0 - Strategic Goal & Objectives: Tentative Roadmapugur100% (5)

- RA 002 - HFO Line Pressure TestDocument4 pagesRA 002 - HFO Line Pressure Testdassi99100% (1)

- Conversion Table For PressureDocument4 pagesConversion Table For Pressuredassi99Pas encore d'évaluation

- Appendix C Geo Tech Risk RegDocument8 pagesAppendix C Geo Tech Risk RegLuthfieSangKaptenPas encore d'évaluation

- IRP 22 Hazard and Risk Assessment Register: Column Headings Column LetterDocument29 pagesIRP 22 Hazard and Risk Assessment Register: Column Headings Column LetterKhuda Buksh100% (2)

- Assessment No 47 Demolition Basin E40Document4 pagesAssessment No 47 Demolition Basin E40Rochdi Bahiri0% (1)

- Risk Asses 116 - Boiler Hydro Test LP3Document5 pagesRisk Asses 116 - Boiler Hydro Test LP3Rochdi BahiriPas encore d'évaluation

- Defensive DrivingDocument323 pagesDefensive DrivingImroze Habib100% (1)

- The Tire Blowout CaseDocument3 pagesThe Tire Blowout CaseAleks OpsPas encore d'évaluation

- ManholeDocument8 pagesManholehutuguoPas encore d'évaluation

- MartinA CallaghanDocument2 pagesMartinA CallaghanpresbaPas encore d'évaluation

- Momentum Worksheet PacketDocument10 pagesMomentum Worksheet PacketsmexiiloriPas encore d'évaluation

- Icao Sms Handout 04 - (r13) 09 (E)Document13 pagesIcao Sms Handout 04 - (r13) 09 (E)barreto104Pas encore d'évaluation

- Pismeni Iz EngleskogDocument3 pagesPismeni Iz EngleskogJasmina PetrovicPas encore d'évaluation

- United States Court of Appeals, Third CircuitDocument5 pagesUnited States Court of Appeals, Third CircuitScribd Government DocsPas encore d'évaluation

- Capt Harun Oral QDocument23 pagesCapt Harun Oral QNyo Thant100% (4)

- List of Potential Emergency Situations/incidents: 8.4 Emergency Preparedness and ResponseDocument1 pageList of Potential Emergency Situations/incidents: 8.4 Emergency Preparedness and ResponseSHANTNU GUPTA0% (1)

- Chapter4 PDFDocument12 pagesChapter4 PDFCindyPas encore d'évaluation

- TNTDocument4 pagesTNTrahmatPas encore d'évaluation

- NTSB Preliminary Report On Mokulele PlaneDocument3 pagesNTSB Preliminary Report On Mokulele PlaneHawaii News NowPas encore d'évaluation

- SeebachanDocument11 pagesSeebachanDavid TPas encore d'évaluation

- Helicopter Safety OffshoreDocument114 pagesHelicopter Safety OffshoreGustavo VillegasPas encore d'évaluation

- Fernando vs. CADocument2 pagesFernando vs. CAPia SarconPas encore d'évaluation

- Physics of BilliardsDocument11 pagesPhysics of BilliardsedrescanoyPas encore d'évaluation

- DO 132 Guidelines in MOSHDocument28 pagesDO 132 Guidelines in MOSHbat mananaPas encore d'évaluation

- Bookgrt 13 (1) PDFDocument6 pagesBookgrt 13 (1) PDFbatambintanPas encore d'évaluation

- Stabilized Constant Descent Angle NPA'sDocument25 pagesStabilized Constant Descent Angle NPA'sVitaliiPas encore d'évaluation

- MD 11 PDFDocument4 pagesMD 11 PDFMcDonnell Douglas MD-11Pas encore d'évaluation

- Blizzard of Glass Book Report 1Document3 pagesBlizzard of Glass Book Report 1api-269004789Pas encore d'évaluation

- Project Title: Design of Traffic Control DevicesDocument28 pagesProject Title: Design of Traffic Control DevicesMoses KaswaPas encore d'évaluation

- Jsa For Weld and GrindingDocument6 pagesJsa For Weld and GrindingTanzeel LiaqatPas encore d'évaluation

- Rail Safety CanadaDocument26 pagesRail Safety CanadaBruno ThiemePas encore d'évaluation

- Incident Report PDFDocument3 pagesIncident Report PDFPURNENDU DASHPas encore d'évaluation

- SQ006 ReportDocument0 pageSQ006 ReportMartin GohPas encore d'évaluation

- Fire HazardDocument65 pagesFire HazardRohit Sharma75% (4)

- Maryland Driver's Manual - 2013Document45 pagesMaryland Driver's Manual - 2013DMV_exam_GUIDE_comPas encore d'évaluation

- Accident PreventionDocument2 pagesAccident PreventionVikas SinghPas encore d'évaluation