Académique Documents

Professionnel Documents

Culture Documents

01 624isodock EN 1-D-12-E 1.0.0 CD

Transféré par

doom212Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

01 624isodock EN 1-D-12-E 1.0.0 CD

Transféré par

doom212Droits d'auteur :

Formats disponibles

Solutions that work

Doc.-No.: 01_624Isodock_EN_1-D-12-E_1.0.0.doc Date: Security level: 2007-03-07 1

Product data sheet

Crawford 624 Isodock

Page: 1 / 7 Folder: 1-D-12

Product data sheet

Crawford 624 Isodock Hydraulic dock leveller with telescopic lip Serial no.: A4100124 Load capacity: see specification plate

We reserve the right to alter technical specifications

Solutions that work

Doc.-No.: 01_624Isodock_EN_1-D-12-E_1.0.0.doc Date: Security level: 2007-03-07 1

Product data sheet

Crawford 624 Isodock

Page: 2 / 7 Folder: 1-D-12

Crawford 624 Isodock for temperature controlled warehouses

The new Crawford 624 Isodock is a further development of the proven ISO-system which had been developed especially for temperature controlled warehouses. Compared to a standard solution the new loading system saves up to 75% of energy costs. The new all-in-one, ready-to-install unit including the complete insulation is suspended in a single work processing into the dock ceiling. The new movable insulation which consists of polyurethan foam and FCKW-free sections and which encapsulate the loading bay downwards allow to achieve considerable savings in energy. time and installation costs can be minimised because a ulterior installation of the panel sealings under the platform is not longer necessary. There is also another advantage: the insulated sectional door is driven directly onto the insulation which is installed underneath the dock leveller. This way the door height is less important than with the former ISO-system and now it is possible to operate the door either by an electric drive or manually. With the new Crawford 624 Isodock encasing works on the anti freezing apron of the pit are even easier than before. The gap for the door is only necessary for the upper area. Thanks to this new design the force of impact of a lorry which arrives at the loading bay and which had always been a big problem is conducted directly in the building through the buffers. This allows to reduce not only costs for energy but also building costs. Like the former insulated loading bay the new loading bay is also suitable for tail-lifts.

NL OL GL NW LH A B LE Nominal length Overall length (NL + LE) Gradient length (OL - 140) Nominal width Leveller height Level equalisation above dock Level equalisation below dock Lip extension

According to EN 1398 the dock leveller is not allowed to be operated outside the permissible gradient range of 12.5 % (approx. 7). The gradient range may only be exceeded if the operator ensures that the danger of slipping has been eliminated (for example due to dry and clean surfaces).

All dimensions in mm

N o m i n a l 2000

Leveller height Pit depth Level equalisation above dock Level equalisation below dock Overall length Gradient length 830 850 380 460 3000 2860

l e n g t h 3000

900 920 520 450 4000 3860

2500

830 850 450 450 3500 3360

Nominal width for all sizes: Extension for all sizes: Load capacity for all sizes:

2000, 2200 und 2400 mm 1000 mm 60 kN

We reserve the right to alter technical specifications

Solutions that work

Doc.-No.: 01_624Isodock_EN_1-D-12-E_1.0.0.doc Date: Security level: 2007-03-07 1

Product data sheet

Crawford 624 Isodock

Page: 3 / 7 Folder: 1-D-12

OPTIONS

Surface Standard colour RAL 5010 Off standard colour RAL XXXX Hot galvanized Hydraulic Equipment Low noise hydraulic unit Three hydraulic cylinders Low temperature oil BIO oil (Environment) Lip options Lip length 1000 mm Steel lip bevelled, 40 mm Stee lip bevelled, 60 mm Energy & Ergonomics EPDM seal Slip Protection / Noise Reduction

= standard

= option

Lip material

steel

aluminium

Lip options

standard

tapered; s=100 mm

tapered; ss=150 mm

2 retracting tongues; z=140 mm

4 retracting tongues; zz=140 mm

Drawings show steel model.

We reserve the right to alter technical specifications

Solutions that work

Doc.-No.: 01_624Isodock_EN_1-D-12-E_1.0.0.doc Date: Security level: 2007-03-07 1

Product data sheet

Crawford 624 Isodock

Page: 4 / 7 Folder: 1-D-12

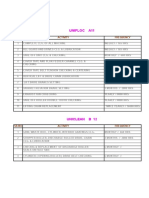

CONTROL UNITS

SuperVISION 205A

SuperVISION i205

SuperVISION i305

OPTIONS

Control Options Integrated door control Integrated dock shelter control Integrated door / dock shelter control Limit switch cross traffic position Auto retraction Voltage 400 V Voltage 230 V Cable harness, 7m Cable extension Infrared Interface On/off dock shelter control Safety Options hafa SafeGuard Automatic return in cross traffic position Auto button Mains isolator Emergency stop push button External emergency stop push button hafaEYE or traffic light** Wheel chock Service Options Maintenance indicator Fault indicator Facility Management BUS Network Interface Crawford Dock Management Equipment Dock light Interlocking leveller/ door (photocell) = standard = option = not available -* -* -* -*

* only available as equipment but not in connection with a control unit ** depends on site situation (see hafaEYE restriction)

We reserve the right to alter technical specifications

Solutions that work

Doc.-No.: 01_624Isodock_EN_1-D-12-E_1.0.0.doc Date: Security level: 2007-03-07 1

Product data sheet

Crawford 624 Isodock

Page: 5 / 7 Folder: 1-D-12

Pit design, model Crawford 624 Isodock

1 2 3 4 5 Electrical controls included Conduit wiring, internal diameter 70, angles 45 (by others) Plain steel dowel 20; up to 200 long (by others) Angle 120x80x10 (by others) Note! After installation this rebate must be carefully grouted with C25 concrete (by others). Adjust correct horizontally level for the leveller by adjusting the screws. Square cornered Rear detail Side detail Finished floor level Yard level 1% slope Minimum depth required for tail-lift recess 3000 (recommended)

6 7 8 9 10 11 12 13

The wall-thickness has to be dimensioned under consideration of the vehicle impact-force F. Recommended: WT 300 ! The horizontal impact load F must be absorbed by the structure not by the leveller frame! F1 = 57kN cross traffic F2 = 45kN emergency stop Note! Do not deviate from the measurements given. The pit walls must be vertical. The corners of the pit must be square (diagonals must be equal). The preparation of the pit and dowels by others. NL PL NW PW LH DW DH DOH WT Nominal length Pit length (=NL + 20) Nominal width Pit width (NW + 60) Leveller height Door width Dock height Door overall height Wall-thickness

N o m i n a l Pit length Leveller height PL LH e Lf2 2000 2020 830 1850 290

l e n g t h 2500 2520 830 1850 760

N L 3000 3020 900 2100 1000 Pit width PW

N o m i n a l 2000 2060

w i d t h 2200 2260

N W 2400 2460

We reserve the right to alter technical specifications

Solutions that work

Doc.-No.: 01_624Isodock_EN_1-D-12-E_1.0.0.doc Date: Security level: 2007-03-07 1

Product data sheet

Crawford 624 Isodock

Page: 6 / 7 Folder: 1-D-12

Electrical preparations (by others)

13 Control box 14 Conduit for wiring internal diameter 70, angles 45 (by others) 35 Optional safety switch on sectional door to isolate leveller when door is closed *) 36 Mains isolator (only for control box with emergency stop. By others) *) 37 Mains supply: 3 / N / PE AC 50 Hz 230/400 V Mains fuse: D0 10 A gL Motor power: 1,5 kW 38 Cable: 7 x 0,75 mm 39 Motor-cable: 4 x 1,5 mm *) Non standard

35 13

36 37 39 38

14

For exact requirements, please ask for our individual installation drawings.

We reserve the right to alter technical specifications

Solutions that work

Doc.-No.: 01_624Isodock_EN_1-D-12-E_1.0.0.doc Date: Security level: 2007-03-07 1

Product data sheet

Crawford 624 Isodock

Page: 7 / 7 Folder: 1-D-12

Standard Buffer Buffer, model RS

1 plate (galvanized) 2 buffer 400x80x70 Art.-no.: R0060139

Buffer, model RB

1 plate (galvanized) 2 buffer 500x250x90 Art.-no.: R0060104 1 plate (galvanized) 2 buffer 500x250x140 Art.-no.: R0060103

Buffer, model RB 1,5

1 box (galvanized) 2 buffer 500x250xD 3 buffer 250x250xD left D = 90 Art.-no.: R0060136 D=140 Art.-no.: R0060151 right D=90 Art.-no.: R0060137 D=140 Art.-no.: R0060152

Reinforced Buffer Buffer protection plate for model RB

Buffer, model RB with sloping box

1 box (galvanized) 2 buffer 500x250x90 Art.-no.: R0060170

Steel Spring Buffer

1 plate (galvanized) 2 steel spring 3 buffer 130x125 Art.-no: R0060177

1 box (galvanized) 2 buffer 500x250x140 Art.-no.: R0060170

Hx160x150 H=600 or 800

Protection plate (galvanized) 485x235x15 D=140 Art.-no.: 0R060173 D=90 Art.-no.: 0R060172

Protection plate (galvanized) 485x235x15 D=140 Art.-no.: 0R060175 D=90 Art.-no.: 0R060174

Special Buffer Height-adjustable Buffer, model EBH

Art.-no.: R0060134 D=90 or D=140

Floating Buffer, model EBF

Art.-no.: R0060135 D=90 or D=140

Option: Steel Spring Buffer 600x160x220 1 plate (galvanized) 2 steel spring 3 buffer 130x125

All sizes in mm [HxBxD]. We reserve the right to alter technical specifications

Vous aimerez peut-être aussi

- Eaton CoilDocument28 pagesEaton Coilramana3339Pas encore d'évaluation

- For Harsh and Hazardous Locations: Exe EnclosuresDocument79 pagesFor Harsh and Hazardous Locations: Exe EnclosuresSimon LyonPas encore d'évaluation

- HS25 Incremental EncoderDocument4 pagesHS25 Incremental Encoderoswaldo58Pas encore d'évaluation

- Bimed Ex Stars PDFDocument38 pagesBimed Ex Stars PDFtony6868Pas encore d'évaluation

- Model 770 Ordering GuideDocument2 pagesModel 770 Ordering GuideSkiFy AlexPas encore d'évaluation

- H25 Incremental EncoderDocument4 pagesH25 Incremental EncoderEdgar AllamPas encore d'évaluation

- Craig & Derricott Isolators & Switch Disconnectors CatalogueDocument40 pagesCraig & Derricott Isolators & Switch Disconnectors CataloguerocketvtPas encore d'évaluation

- SmacnaDocument32 pagesSmacnaamo3330100% (13)

- Irlr120, Irlu120, Sihlr120, Sihlu120: Vishay SiliconixDocument11 pagesIrlr120, Irlu120, Sihlr120, Sihlu120: Vishay Siliconix786908Pas encore d'évaluation

- Catalogo Contactores en Vacio MitsubichiDocument16 pagesCatalogo Contactores en Vacio MitsubichiWalter CataldoPas encore d'évaluation

- 2Document14 pages2WormInchPas encore d'évaluation

- Coil Electronics ControlDocument28 pagesCoil Electronics ControlNippur de LagashPas encore d'évaluation

- Aislador Epoxi Catalogo 2011 ENGDocument56 pagesAislador Epoxi Catalogo 2011 ENGmk116dPas encore d'évaluation

- BEI Drawworks Encoder HS35Document2 pagesBEI Drawworks Encoder HS35Alexander Fraile100% (1)

- Radox 4 GKW - AX Traction CableDocument3 pagesRadox 4 GKW - AX Traction CableNagendra KumarPas encore d'évaluation

- Enclosed Circuit Breakers: Cutler-HammerDocument8 pagesEnclosed Circuit Breakers: Cutler-HammermekoxxxPas encore d'évaluation

- Catalogue ANSI PostDocument20 pagesCatalogue ANSI PostElectricEngineeringPas encore d'évaluation

- Planos Testlane para Linea Liviana PDFDocument15 pagesPlanos Testlane para Linea Liviana PDFJuana Layme SierraPas encore d'évaluation

- PPC Catálogo Aislador Soporte ANSIDocument28 pagesPPC Catálogo Aislador Soporte ANSIMateo AlvezPas encore d'évaluation

- Micafil Bushing Test TapDocument8 pagesMicafil Bushing Test TapscribdkkkPas encore d'évaluation

- Allen Bradley 700 hk32z24Document6 pagesAllen Bradley 700 hk32z24Fabro CoronelPas encore d'évaluation

- JVC DR-MV1S VCR-DVDDocument75 pagesJVC DR-MV1S VCR-DVDCaptain444100% (1)

- Lithonia TWAC CutsheetDocument2 pagesLithonia TWAC CutsheetslapyakPas encore d'évaluation

- Alfa Laval Alfa-V VDD: Industrial Dry Coolers V-TypeDocument2 pagesAlfa Laval Alfa-V VDD: Industrial Dry Coolers V-TypemoghanmogaPas encore d'évaluation

- Anexo C - Nexans-Euromold-MV-Separable-Connectors-and-Bushings - Interface-E PDFDocument20 pagesAnexo C - Nexans-Euromold-MV-Separable-Connectors-and-Bushings - Interface-E PDFAnonymous zd86j8vVPas encore d'évaluation

- ZVP4525GDocument8 pagesZVP4525GAlexander AnotherSituation MartinsonPas encore d'évaluation

- 1N5231B Zener DiodeDocument3 pages1N5231B Zener DiodeCzar LimPas encore d'évaluation

- Chainflex Data CablesDocument9 pagesChainflex Data CablesigusukPas encore d'évaluation

- Record Plus Catalogue en Export Ed09-14Document252 pagesRecord Plus Catalogue en Export Ed09-14ohoboho79100% (1)

- CM Bu9000 Eng Bushings 3Document36 pagesCM Bu9000 Eng Bushings 3ing.dmanriq27100% (1)

- Lapp - Olflex Robust FD CDocument5 pagesLapp - Olflex Robust FD CShashank SaxenaPas encore d'évaluation

- DuroSite® LED Area Light - UL CSADocument16 pagesDuroSite® LED Area Light - UL CSAGESDAREPas encore d'évaluation

- Relays IceCubeDocument34 pagesRelays IceCubeOscar Danilo Alaniz MartinezPas encore d'évaluation

- Cooling TowerDocument72 pagesCooling TowerRobert Nixon100% (1)

- Craig & Derricott IsolatorDocument32 pagesCraig & Derricott IsolatorAdam Thong Chee HungPas encore d'évaluation

- Aislador Epoxi Catalogo 2011 ENG PDFDocument56 pagesAislador Epoxi Catalogo 2011 ENG PDFWalter CataldoPas encore d'évaluation

- Igus CDocument4 pagesIgus CJames ValenzuelaPas encore d'évaluation

- New Generation Series: FeaturesDocument4 pagesNew Generation Series: FeaturesKhánh DươngPas encore d'évaluation

- Motor Ys11Document3 pagesMotor Ys11mspd2003Pas encore d'évaluation

- DBXLH 6565C VTMDocument5 pagesDBXLH 6565C VTMTomas KriukelisPas encore d'évaluation

- ARI-Strainer: Strainer - Screen and Supporting Basket Made of Stainless SteelDocument6 pagesARI-Strainer: Strainer - Screen and Supporting Basket Made of Stainless SteelEmnPas encore d'évaluation

- Datasheet229 PDFDocument12 pagesDatasheet229 PDFkenljPas encore d'évaluation

- Ecofit Type DS Square D, WestinghouseDocument2 pagesEcofit Type DS Square D, WestinghousehaiqalPas encore d'évaluation

- TD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Document2 pagesTD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Rupesh DesaiPas encore d'évaluation

- JVC LCD Lt-42dp8b Lt-42p80bg - P Chassis Fl5Document95 pagesJVC LCD Lt-42dp8b Lt-42p80bg - P Chassis Fl5ngoclinhdtddPas encore d'évaluation

- Sadev Classic FXR enDocument38 pagesSadev Classic FXR enPeter DudasPas encore d'évaluation

- 1404 - Arctic DP 4 Pages - VfinalDocument4 pages1404 - Arctic DP 4 Pages - Vfinalsajithv78Pas encore d'évaluation

- Industrial LightingDocument6 pagesIndustrial LightingTonni SultanaPas encore d'évaluation

- M-00-D05 Urs Chiller (-0 C) - R1Document17 pagesM-00-D05 Urs Chiller (-0 C) - R1dhanu_lagwankar100% (1)

- Valvetop D-Series With AS-interface: Installation, Operation & Maintenance ManualDocument16 pagesValvetop D-Series With AS-interface: Installation, Operation & Maintenance ManualAdeel RazaPas encore d'évaluation

- Radox 4 Gkw-Ax 1800V MM S Traction Cable: Product DescriptionDocument5 pagesRadox 4 Gkw-Ax 1800V MM S Traction Cable: Product DescriptionRudy IndrawanPas encore d'évaluation

- Dse PN MetricDocument29 pagesDse PN MetricSuman DeyPas encore d'évaluation

- DSI DYWIDAG Geotechnical-Product-Range en 02Document40 pagesDSI DYWIDAG Geotechnical-Product-Range en 02akajsiPas encore d'évaluation

- Ockside Ooring Ollard: Product Code: AE-1016Document1 pageOckside Ooring Ollard: Product Code: AE-1016bayuargoPas encore d'évaluation

- RIP TechnologyDocument16 pagesRIP TechnologyMárcio Vieira SilvaPas encore d'évaluation

- Amarex N: Submersible Motor Pumps DN 50 To 100Document44 pagesAmarex N: Submersible Motor Pumps DN 50 To 100Ben RahierPas encore d'évaluation

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Vessel Requirement DetailsDocument11 pagesVessel Requirement DetailsFxgPas encore d'évaluation

- Bamboo Bridge Bamboo Bridge Bamboo Bridge Bamboo Bridge Bamboo BridgeDocument10 pagesBamboo Bridge Bamboo Bridge Bamboo Bridge Bamboo Bridge Bamboo Bridgeavabhyankar9393Pas encore d'évaluation

- Unit 4 General Test: Listen To The Conversations. Then Choose The Word or Phrase That Correctly Completes Each SentenceDocument5 pagesUnit 4 General Test: Listen To The Conversations. Then Choose The Word or Phrase That Correctly Completes Each SentenceAngel Cardenas100% (5)

- Certified True Copy: Bill of Lading For Ocean Transport or Multimodal TransportDocument4 pagesCertified True Copy: Bill of Lading For Ocean Transport or Multimodal TransportAndrea MuñozPas encore d'évaluation

- Curriculum Vitae: Rakesh Kumar GuptaDocument3 pagesCurriculum Vitae: Rakesh Kumar Guptachitranjan4kumar-8Pas encore d'évaluation

- Annamayya Project Capacity: 2.234 TMC FRL: 203.600 Delivery Level: 204.600Document1 pageAnnamayya Project Capacity: 2.234 TMC FRL: 203.600 Delivery Level: 204.600Guru MogaralaPas encore d'évaluation

- Hirarc LiftingDocument1 pageHirarc LiftingAmir Syahir75% (4)

- Map Greenbelt RockwellDocument1 pageMap Greenbelt RockwellvierlyPas encore d'évaluation

- Bulk Carrier Condition Survey ReportDocument33 pagesBulk Carrier Condition Survey Reportalxgam100% (1)

- BP Disaster Averted Gulf of Mexico 2005Document24 pagesBP Disaster Averted Gulf of Mexico 2005Kim HedumPas encore d'évaluation

- Captain Vartul DixitDocument40 pagesCaptain Vartul DixitAman GautamPas encore d'évaluation

- Besmak Components PVTDocument17 pagesBesmak Components PVTSadham BabuPas encore d'évaluation

- Alignment of Railway Track Nptel PDFDocument18 pagesAlignment of Railway Track Nptel PDFAshutosh MauryaPas encore d'évaluation

- Tagumpay Nagaño High School Diversion, San Leonardo Nueva Ecija 3102Document3 pagesTagumpay Nagaño High School Diversion, San Leonardo Nueva Ecija 3102Hazel AbitriaPas encore d'évaluation

- Iizwjp - Suarsi Suarsi MRDocument1 pageIizwjp - Suarsi Suarsi MRYafiePas encore d'évaluation

- Cooking Oil DisposalDocument1 pageCooking Oil DisposalKorawit Kongsan100% (1)

- DE 2512/10 OCT/FRA-LHR: - Not For Real World NavigationDocument56 pagesDE 2512/10 OCT/FRA-LHR: - Not For Real World NavigationHendrikPas encore d'évaluation

- Santiago CalatravaDocument12 pagesSantiago Calatravadplpthk1502Pas encore d'évaluation

- Traffic Speed Count SheetDocument12 pagesTraffic Speed Count SheetKahinyika Ndiritu NjugunaPas encore d'évaluation

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- Transpo Law Midterms FocusDocument20 pagesTranspo Law Midterms FocusRia Evita RevitaPas encore d'évaluation

- Evaluation of Subgrade Strength and Flexible Pavement Designs ForDocument160 pagesEvaluation of Subgrade Strength and Flexible Pavement Designs ForAbdullah AhmadPas encore d'évaluation

- Yamaha ReportDocument79 pagesYamaha ReportvishalPas encore d'évaluation

- Manual Pajero4x4steereingDocument42 pagesManual Pajero4x4steereingGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- 2 Maintenance Schdule Blow Room, Carding DecDocument15 pages2 Maintenance Schdule Blow Room, Carding DecBHASKAR MITRAPas encore d'évaluation

- Gmail - Booking Confirmation On IRCTC, Train - 22840, 17-Feb-2023, 2S, BBS - ANGLDocument1 pageGmail - Booking Confirmation On IRCTC, Train - 22840, 17-Feb-2023, 2S, BBS - ANGLBarun AgarwalPas encore d'évaluation

- Toyota Motor Company Crisis Plan PDFDocument24 pagesToyota Motor Company Crisis Plan PDFKaoutar Fadel100% (1)

- Bus Capacity EstimationDocument13 pagesBus Capacity Estimationjaya krishnaPas encore d'évaluation

- The Advantage in The Greek Shipping IndustryDocument26 pagesThe Advantage in The Greek Shipping IndustryNikos Anta Tagalhs100% (1)

- U&M ARM550 E01Document165 pagesU&M ARM550 E01Augusto Oliveira100% (2)