Académique Documents

Professionnel Documents

Culture Documents

Poultry Slaughterhouse

Transféré par

itseaziDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Poultry Slaughterhouse

Transféré par

itseaziDroits d'auteur :

Formats disponibles

CASE STUDY WWT

POULTRY SLAUGHTERHOUSE

TANFLOC Organic Vegetable

Cationic coagulant / Flocculant for Wastewater Plant Poultry Slaughterhouse

TANAC

CHALLENGE / OPPORTUNITY A poultry slaughterhouse located in the south of Brazil, with a slaughter capacity of 150,000 birds per day was using 19,600 kg/month of aluminium sulphate and 12,600 kg/month of ash in the flotation system of its WWT with satisfactory cost and performance results. However, diluting these products (powder) and preparing many batches per day proved difficult. Another problem caused by the use of a metallic salt coagulant/flocculant in the flotation system was the great variation of the pH value of the treated effluent due to water alkalinity consumption requiring the use of alkalinizing agents. After performing a series of laboratory tests, T a n f l o c started to be used in a successful attempt to improve COD, G&O and cost reduction and optimize manpower.

Located in southern Brazil, Tanac is the worlds largest producer of mimosa vegetable extracts.

Tanac combines quality products and services with environmental preservation at all stages of the tannin production process.

Channelling strengths to reach common targets permanently involves all the members of the Tanac team. ISO 9001, ISO 14001, FSC an NSF certifications are the result of team work.

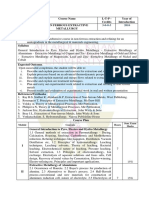

APPLICATION FLOWCHART

A quality product range developed to satisfy the needs of the companys clients and guarantee best results together with prompt delivery and permanent technical assistance: this is Tanacs profile.

CASE STUDY WWT

POULTRY SLAUGHTERHOUSE

WASTEWATER CHARACTERISTICS Out-flow 50 70 m/h COD 2.912 mg/l G&O 178 mg/l

TANFLOC Organic Vegetable

Cationic coagulant/Flocculant for Wastewater Plant Poultry Slaughterhouse T a n f l oc

The Tanfloc product range is essentially natural in origin and competitive when compared to products traditionally employed in water treatment with the additional advantage of being totally biodegradable allowing complete digestion at the various biological stages of the process. Thanks to their versatility, Tanfloc products have effective action on several types of water as well as various sorts of industrial effluent. They are usually employed in drinking water treatment and in the treatment of effluents from several sectors including the petrochemical, ceramic, food, sugar, metal and cellulose industries, oil refineries, mining and domestic sewage.

TREATMENT COMPARISSON

Coagulant Al2(SO4)3 Dosage Phisical aspect Polymer Alkalinizer 600 ppm Dry solid ------Soda ash

Tanfloc

270 ppm Liquid 2 ppm

---------

WASTEWATER AFTER TREATMENT

TREATMENT METALLIC COD 1.029 mg/l 576 mg/l G&O 70 mg/l 20 mg/l

Raw

Treated

Tanfloc

BENEFITS DERIVING FROM THE APPLICATION OF TANFLOC Reducing handling of 32,200 kg/month of powder chemical

products; 80,2% COD reduction; 88,7% G&O reduction; Rationalised manpower use; Generation of organic sludge for unrestricted use in farming land; Use of a biodegradable product compatible with the subsequent secondary treatment (activated sludge); Operator health and safety improvement by eliminating/reducing handling of chemical products; Eliminating the use of alkalinizing agents.

Tanfloc is compatible with most products on the market and may be used in combination with such products.

COST ANALYSIS

Products Al2(SO4)3 Soda ash Manpower 3 US$ 3X / m

Tanfloc works with minimal interference with the environment and offers various economic advantages.

T a n floc l oPolymer c Manpower

US$ X / m

3

Costs :

Total Cost Reduction:

40.7 %

Rev.Nov/08

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Comparison of Standards For Cooling Water Pipes (IS3589 vs. API5L)Document17 pagesComparison of Standards For Cooling Water Pipes (IS3589 vs. API5L)Anonymous gr5Pr9AVPas encore d'évaluation

- Heat Calculation by SG.Document26 pagesHeat Calculation by SG.TIRIANTO0% (2)

- 25CrMo4Document1 page25CrMo4Hans GoethePas encore d'évaluation

- Paint IndustryDocument2 pagesPaint IndustryitseaziPas encore d'évaluation

- Flocculation AuxiliaryDocument2 pagesFlocculation AuxiliaryitseaziPas encore d'évaluation

- Textile IndustryDocument2 pagesTextile IndustryitseaziPas encore d'évaluation

- Petrochemical PlantDocument2 pagesPetrochemical PlantitseaziPas encore d'évaluation

- MiningDocument2 pagesMiningitseaziPas encore d'évaluation

- RefineryDocument2 pagesRefineryitseaziPas encore d'évaluation

- Metal Mechanical IndustryDocument2 pagesMetal Mechanical IndustryitseaziPas encore d'évaluation

- Dairy 1Document2 pagesDairy 1itseaziPas encore d'évaluation

- Metal Mechanical IndustryDocument2 pagesMetal Mechanical IndustryitseaziPas encore d'évaluation

- MDFDocument2 pagesMDFitseaziPas encore d'évaluation

- Dairy Case StudyDocument2 pagesDairy Case StudyitseaziPas encore d'évaluation

- 2012 Promotion NewsletterDocument1 page2012 Promotion NewsletteritseaziPas encore d'évaluation

- ETP Onshore Crude Oil ExplorationDocument2 pagesETP Onshore Crude Oil ExplorationitseaziPas encore d'évaluation

- Textile IndustryDocument2 pagesTextile IndustryitseaziPas encore d'évaluation

- Dairy Case StudyDocument2 pagesDairy Case StudyitseaziPas encore d'évaluation

- Poultry SlaghterhouseDocument2 pagesPoultry SlaghterhouseitseaziPas encore d'évaluation

- RefineryDocument2 pagesRefineryitseaziPas encore d'évaluation

- MiningDocument2 pagesMiningitseaziPas encore d'évaluation

- Petrochemical PlantDocument2 pagesPetrochemical PlantitseaziPas encore d'évaluation

- ETP Onshore Crude Oil ExplorationDocument2 pagesETP Onshore Crude Oil ExplorationitseaziPas encore d'évaluation

- Paint IndustryDocument2 pagesPaint IndustryitseaziPas encore d'évaluation

- MDFDocument2 pagesMDFitseaziPas encore d'évaluation

- Flocculation AuxiliaryDocument2 pagesFlocculation AuxiliaryitseaziPas encore d'évaluation

- Anaerobic ReactorDocument1 pageAnaerobic ReactoritseaziPas encore d'évaluation

- Dairy Case StudyDocument2 pagesDairy Case StudyitseaziPas encore d'évaluation

- Domestic SewageDocument2 pagesDomestic SewageitseaziPas encore d'évaluation

- Dairy Case StudyDocument2 pagesDairy Case StudyitseaziPas encore d'évaluation

- Composting ProcessDocument1 pageComposting ProcessitseaziPas encore d'évaluation

- Desalinated Water Supply For Spence Growth Options Project: WPS, WPQ & PQRDocument8 pagesDesalinated Water Supply For Spence Growth Options Project: WPS, WPQ & PQRJosé BenjamínPas encore d'évaluation

- The Effect of Current On SMAW Welding To Tensile Strength and Micro Structure of Low Carbon SteelDocument5 pagesThe Effect of Current On SMAW Welding To Tensile Strength and Micro Structure of Low Carbon Steelmade dwi payanaPas encore d'évaluation

- CON3130 Module NotesDocument8 pagesCON3130 Module NotesEd PawliwPas encore d'évaluation

- EPAL TRW EPAL1 3edition Section2 Part1 GBDocument46 pagesEPAL TRW EPAL1 3edition Section2 Part1 GBGabriele AsnaghiPas encore d'évaluation

- 2K NTNK 101 Matt Coat TilDocument3 pages2K NTNK 101 Matt Coat TilpassqwertyPas encore d'évaluation

- Question M.TechDocument5 pagesQuestion M.TechBabuli KumarPas encore d'évaluation

- 639 Tippmann Tippmann Tank Regulator Manual ENGDocument2 pages639 Tippmann Tippmann Tank Regulator Manual ENGkimba worthPas encore d'évaluation

- Used Water SES 5 Construction of Tunnels Ancillaries 2012Document28 pagesUsed Water SES 5 Construction of Tunnels Ancillaries 2012Mark BenjiePas encore d'évaluation

- T - Cleats TACOS VOLTA BELTINGDocument2 pagesT - Cleats TACOS VOLTA BELTINGBluemonday BluemondayPas encore d'évaluation

- Synthesis of Acetanilide and Its Purification Through RecrystallizationDocument4 pagesSynthesis of Acetanilide and Its Purification Through RecrystallizationTeresa Saylo100% (1)

- International Process Plants: SSP4 InformationDocument25 pagesInternational Process Plants: SSP4 Information何恭彥Pas encore d'évaluation

- 02 Heubach No 00181 ZPA RZ Epoxy Dispersion WDocument2 pages02 Heubach No 00181 ZPA RZ Epoxy Dispersion WnanoPas encore d'évaluation

- Carbon Steel 1020: 1020 Machinability DuctilityDocument5 pagesCarbon Steel 1020: 1020 Machinability DuctilityBharath NarayananPas encore d'évaluation

- Process of Jewelry Manufacturing - CastingDocument3 pagesProcess of Jewelry Manufacturing - CastingS Sonia100% (1)

- 11 Chapter Reaction Kinetics Text Book Exercise PDFDocument14 pages11 Chapter Reaction Kinetics Text Book Exercise PDFBilal KhanPas encore d'évaluation

- Asme Section Ii A-2 Sa-814 Sa-814mDocument8 pagesAsme Section Ii A-2 Sa-814 Sa-814mdavid perezPas encore d'évaluation

- MT305 Nonferrous Extractive MetallurgyDocument2 pagesMT305 Nonferrous Extractive MetallurgyMerrin John VarkeyPas encore d'évaluation

- Kinetics and Heat TreatmentDocument38 pagesKinetics and Heat TreatmentRaul GutierrezPas encore d'évaluation

- Thermal Premium Top K Bpaf / H2510 / Hg65: Face MaterialDocument1 pageThermal Premium Top K Bpaf / H2510 / Hg65: Face MaterialTanjaPas encore d'évaluation

- !drilling Machine Geared Head InstructionDocument5 pages!drilling Machine Geared Head InstructionTiago PaivaPas encore d'évaluation

- Ien402 HW1 F22Document5 pagesIen402 HW1 F22Moh HPas encore d'évaluation

- Corrosion and Its PreventionsDocument21 pagesCorrosion and Its PreventionsWaldy Nur PatriaPas encore d'évaluation

- TTMA Series Flange AdaptersDocument1 pageTTMA Series Flange AdaptersKamalPas encore d'évaluation

- Continuous Casting of Steel and Simulation For Cost ReductionDocument6 pagesContinuous Casting of Steel and Simulation For Cost ReductionRitesh kumarPas encore d'évaluation

- Havi Rae Form Hf001Document2 pagesHavi Rae Form Hf001mevansmetreelPas encore d'évaluation

- EXOTHERMIC REACTION: Spontaneous Self-Heating: OfficialDocument3 pagesEXOTHERMIC REACTION: Spontaneous Self-Heating: OfficialGiovanni CocchiPas encore d'évaluation

- Specification For Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsDocument4 pagesSpecification For Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsJolettitoPas encore d'évaluation