Académique Documents

Professionnel Documents

Culture Documents

SICK FFU Product Information

Transféré par

Luchito EbrDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SICK FFU Product Information

Transféré par

Luchito EbrDroits d'auteur :

Formats disponibles

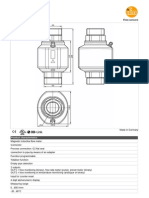

Ultrasonic flowmeter FFU

Non-contact flow measurement

P r o d U c t I n F o r m at I o n

FFU

Flow sensors

non-contact flow measurement

Product description

The non-contact, ultrasonic flow sensor FFU detects the flow volumes of conductive and non-conductive liquids. Swimming against the current requires more strength than with the current this is the simple fact on which ultrasonic flow measurement according to the phase difference process is based. The device has a compact design, and its wide range of possible applications means it can also be used in restricted spaces. The seal-free sensor design, with high-quality polysulfone (Ultrason S) combined with enclosure rating IP 67, not only makes it possible to use the device in harsh ambient conditions, but also guarantees high process reliability. The large text display also helps ensure simple, fast and problem-free commissioning.

at a glance

Flow sensor for conductive and nonconductive liquids No moving parts, compact design Process temperature up to 80 C, process pressure up to 10 bar High chemical resistance thanks to seal-free sensor design

Large display with membrane keyboard

Integrated teaching tube detection Easy-to-clean, hygienic variants

available (EHEDG certification and conformance with FDA), CIP capable

Your benefits

Maintenance-free flow sensor; saves

maintenance costs Adjustable measuring ranges, reduced number of variants Can be used for conductive and nonconductive liquids fewer variants and lower storage costs

Straight measuring tube reduces

pressure loss, thus saving energy costs Sensor without seals increases process reliability and availability Flexible measurement system for all industries

additional information

Detailed technical data. . . . . . . . . . . . .3 Ordering information. . . . . . . . . . . . . . .5 Dimensional drawings . . . . . . . . . . . . .6 Connection type and diagram . . . . . . .9 Recommended accessories . . . . . . . . .9 Operation . . . . . . . . . . . . . . . . . . . . . . 10 Mouting instructions . . . . . . . . . . . . . 10

LeveL sensors | sICK

8013865/2010-11-02 Subject to change without notice

Flow sensors

FFU

detailed technical data

Features

nW 10 measuring principle medium nominal width measuring tube Process temperature Process pressure EHEdG approval

Ultrasonic sensor Fluids NW 10 0 C ... +80 C Max. 10 bar l Max. 6 bar NW 15 NW 20 NW 25

nW 15

nW 20

nW 25

Performance

nW 10 minimum flow maximum flow Inlet zone outlet zone conductivity accuracy reproducibility resolution

0.3 l/min 21 l/min 10 cm 0 cm No limitation 2 % (of final value) 0.5 % 0.003 l/min 0.006 l/min 0.012 l/min 0.03 l/min

nW 15

0.9 l/min 36 l/min 30 cm 5 cm

nW 20

3.5 l/min 60 l/min 50 cm 10 cm 5 l/min

nW 25

240 l/min 80 cm 20 cm

Mechanics

nW 10 Process connection

G 1/2 1/2 NPT Clamp 11864 PSU PSU 340 g 350 g 420 g 460 g

nW 15

G 3/4 3/4 NPT Clamp 11864

nW 20

G1 1 NPT Clamp 11864

nW 25

G 1 1/4 1 1/4 NPT Clamp 11864

Wetted parts Housing material Weight

8013865/2010-11-02 Subject to change without notice

LeveL sensors | sICK

FFU

Flow sensors

Electronics

Supply voltage 1) ripple

2) 3)

18 V DC ... 30 V DC 5 Vpp 180 mA 5s III M12x1, 5-pin M12x1, 8-pin (depending on type) 1 analog output: 4 mA 20 mA, 0 mA 20 mA current flow, 1 pulse/status output: PNPtransistor output for flow rate meter, empty pipe detection, flow monitoring / 1 analog output: 4 mA 20 mA, 0 mA 20 mA current flow, 2 pulse/status output: PNPtransistor output for flow rate meter, empty pipe detection, flow monitoring, 1 digital input (depending on type) 0 kHz ... 10 kHz 1s Vs - 2 V 2V < 100 mA 1H 100 nF Filter off 100 ms, filter low 300 ms, filter medium 1 s, filter strong 4.2 s IP 67 < 500 Ohm 3.8 mA ... 4 mA 20 mA ... 20.5 mA

Power consumption Initialization time Protection class

Electrical connection

Electronics 1)

Impuls/frequency output Puls width Signal voltage HIGH Signal voltage LoW output current Inductive load capacitive load response time 4) Enclosure rating output load Lower signal level Upper signal level

1) 2)

All connections are polarity protected. All outputs are overload and short-circuit protected. May not exceed or fall short of VS tolerances. 3) Without load. 4) Analog output and display.

Ambient data

ambient temperature, operation ambient temperature, storage

0 C ... +60 C 20 C ... +70 C

LeveL sensors | sICK

8013865/2010-11-02 Subject to change without notice

Flow sensors

FFU

ordering information

Type code

tube size 10 15 20 25 NW 10 NW 15 NW 20 NW 25 Sensor material 1 PSU black Process connector G1 N1 C1 Pipe thread G acc. to ISO 228 Thread NPT Clamp (DIN11864-3) BKS form A Electronics IO SR Current output, 1 transmitter output, M12x1, 5-pin Current output, 2 transmitter output, 1 signal input, M12x1, 8-pin

FFU

Electronics: 1 analog output: 4 mA 20 mA, 0 mA 20 mA current flow, 1 pulse/status output: PNP-transistor output for flow rate meter,

empty pipe detection, flow monitoring

Electrical connection: M12x1, 5-pin

Process pressure

Max. 10 bar Max. 6 bar

Process connection

G 1/2 G 3/4 G1 G 1 1/4

nominal width measuring tube

NW 10 NW 15 NW 20 NW 25

maximum flow

21 l/min 36 l/min 60 l/min 240 l/min

model name

FFUS10-1G1IO FFUS15-1G1IO FFUS20-1G1IO FFUS25-1G1IO

Part no.

6041737 6041249 6041738 6041739

Electronics: 1 analog output: 4 mA 20 mA, 0 mA 20 mA current flow, 2 pulse/status output: PNP-transistor output for flow rate meter,

empty pipe detection, flow monitoring, 1 digital input

Electrical connection: M12x1, 8-pin

Process pressure

Max. 10 bar Max. 6 bar

Process connection

G 1/2 G 3/4 G1 G 1 1/4

nominal width measuring tube

NW 10 NW 15 NW 20 NW 25

maximum flow

21 l/min 36 l/min 60 l/min 240 l/min

model name

FFUS10-1G1SR FFUS15-1G1SR FFUS20-1G1SR FFUS25-1G1SR

Part no.

6043743 6043744 6043745 6043746

8013865/2010-11-02 Subject to change without notice

LeveL sensors | sICK

FFU

Flow sensors

dimensional drawings

NW 10, process connection G 1/2

M12x1 5 (0.20)

NW 15, process connection G 3/4

M12x1

14.7 (0.58)

5 (0.20)

14.7 (0.58)

84 (3.31)

84 (3.31)

G 1/2

G 1/2

83.1 (3.27)

G 3/4

G 3/4 147 (5.79)

12 (0.47)

All dimensions in mm (inch)

All dimensions in mm (inch)

NW 20, process connection G 1

M12x1 5 (0.20)

NW 25, process connection G 1 1/4

M12x1 5 (0.20)

14.7 (0.58)

84 (3.31)

14.7 (0.58)

84 (3.31)

G 1 1/4

94.2 (3.70)

G 1 1/4

G1

G1

16.6 (0.65)

All dimensions in mm (inch)

All dimensions in mm (inch)

LeveL sensors | sICK

8013865/2010-11-02 Subject to change without notice

21 (0.83)

160 (6.30)

168 (6.61)

98.6 (3.88)

13.2 (0.52)

147 (5.79)

84.3 (3.32)

Flow sensors

FFU

NW 10, Clamp (DIN 11864-3)

M12x1 5 (0.20)

NW 15, Clamp (DIN 11864-3)

M12x1 5 (0.20)

14.7 (0.58)

14.7 (0.58)

Clamp (DIN 11864-3 ) DN 10 34 (1.34) 34 (1.34)

84 (3.31)

34 1.34)

Clamp (DIN 11864-3 ) DN 15 34 (1.34)

84 (3.31)

88.1 (3.74)

17 (0.67)

Dimensions in mm (inch)

All dimensions in mm (inch)

NW 20, Clamp (DIN 11864-3)

M12x1

NW 25, Clamp (DIN 11864-3)

M12x1 5 (0.20)

5 (0.20)

14.7 (0.58)

14.7 (0.58)

Clamp (DIN 11864-3 ) DN 20 50.5 1.99) 50.5 1.99)

84 (3.31)

Clamp (DIN 11864-3 ) DN 25 50.5 1.99) 50.5 1.99)

84 (3.31)

102.8 (4.05)

25.2 (0.99)

All dimensions in mm (inch)

All dimensions in mm (inch)

8013865/2010-11-02 Subject to change without notice

LeveL sensors | sICK

25.2 (0.99)

7

162 (6.34)

170 (6.69)

102.8 (4.05)

17 (0.67)

149 (5.87)

149 (5.87)

88.1 (3.74)

FFU

Flow sensors

NW 10, 1/2 NPT

M12x1 5 (0.20)

NW 15, 3/4 NPT

M12x1

14.7 (0.58)

5 (0.20)

84 (3.31)

14.7 (0.58)

84 (3.31)

1/2" NPT

1/2" NPT

3/4" NPT

3/4" NPT 147 (5.79)

83.1 (3.27)

12 (0.47)

All dimensions in mm (inch)

All dimensions in mm (inch)

NW 20, 1 NPT

M12x1 5 (0.20)

NW 25, 1 1/4 NPT

M12x1

14.7 (0.58)

5 (0.20)

84 (3.31)

14.7 (0.58)

84 (3.31) 1 1/4" NPT 1 1/4" NPT

1" NPT

1" NPT

94.4 (3.72)

16.8 (0.66)

All dimensions in mm (inch)

All dimensions in mm(inch)

LeveL sensors | sICK

8013865/2010-11-02 Subject to change without notice

21.3 (0.84)

160 (6.30)

168 (6.61)

98.9 (3.89)

13.3 (0.52)

147 (5.79)

84.4 (3.32)

Flow sensors

FFU

connection type and diagram

1 5 3 4

2 3 8 4 5

1 7 6

1 L+: Supply voltage 2 Q1: Digital output PNP/NPN 3 M: Ground 4 C: Communication 5 QA: Analog current output

1 L+: Supply voltage 2 Q1: Digital output PNP/NPN 3 M: Ground 4 Q2: Digital output PNP/NPN 5 QA: Analog current output 6 C: Communication 7 IN1: Digital input 8 No function

recommended accessories

Plug connectors and cables

Brief description

Cable, M12, 5-pin, straight connector female with molded cable, 2 m, PVC Cable, M12, 5-pin, straight connector female with molded cable, 2 m, PUR halogen free Cable, M12, 5-pin, straight connector female with molded cable, 5 m, PVC Cable, M12, 5-pin, straight connector female with molded cable, 5 m, PUR halogen free Cable, M12, 5-pin, straight connector female with molded cable, 10 m, PVC Cable, M12, 5-pin, straight connector female with molded cable, 10 m, PUR halogen free Cable, M12, 5-pin, angled connector female with molded cable, 2 m, PVC Cable, M12, 5-pin, angled connector female with molded cable, 2 m, PUR halogen free Cable, M12, 5-pin, angled connector female with molded cable, 5 m, PVC Cable, M12, 5-pin, angled connector female with molded cable, 5 m, PUR halogen free Cable, M12, 5-pin, angled connector female with molded cable, 10 m, PUR halogen free Cable, M12, 8-pin, straight connector female with molded cable, 2 m, PVC Cable, M12, 8-pin, straight connector female with molded cable, 2 m, PUR halogen free Cable, M12, 8-pin, straight connector female with molded cable, 5 m, PVC Cable, M12, 8-pin, straight connector female with molded cable, 5 m, PUR halogen free Cable, M12, 8-pin, straight connector female with molded cable, 10 m, PVC Cable, M12, 8-pin, straight connector female with molded cable, 10 m, PUR halogen free Cable, M12, 8-pin, angled connector female with molded cable, 2 m, PVC Cable, M12, 8-pin, angled connector female with molded cable, 2 m, PUR halogen free Cable, M12, 8-pin, angled connector female with molded cable, 5 m, PVC Cable, M12, 8-pin, angled connector female with molded cable, 5 m, PUR halogen free Cable, M12, 8-pin, angled connector female with molded cable, 10 m, PUR halogen free

model name

DOL-1205-G02M DOL-1205-G02MC DOL-1205-G05M DOL-1205-G05MC DOL-1205-G10M DOL-1205-G10MC DOL-1205-W02M DOL-1205-W02MC DOL-1205-W05M DOL-1205-W05MC DOL-1205-W10MC DOL-1208-G02MA DOL-1208-G02MC DOL-1208-G05MA DOL-1208-G05MC DOL-1208-G10MA DOL-1208-G10MC DOL-1208-W02MA DOL-1208-W02MC DOL-1208-W05MA DOL-1208-W05MC DOL-1208-W10MC

Part no.

6008899 6025906 6009868 6025907 6010544 6025908 6008900 6025909 6009869 6025910 6025911 6020633 6035620 6020993 6035621 6022152 6035622 6020992 6035623 6021033 6035624 6035625

8013865/2010-11-02 Subject to change without notice

LeveL sensors | sICK

FFU

Flow sensors

operation

Select parameter or chance values by using the arrow keys

Set: Save settings Esc: Leaving current selection level / menu item Display information: Current flow value in l/min

Volume in l Bar graph with percentage value of current

measurement range Setting of:

Analog output Pulse output Status output

Measurement unit Creeping flow Medium calibration

mounting instructions

In applications where the flowmeter is exposed to high temperatures (t 60C), the device should be mounted upside down:

Correct positioning

Flow direction

False positioning

Tube has to be fully filled

Inlet and outlet paths

In order to receive an accurate volume measurement, it is necessary to observe inlet and outlet paths. The diameter of the tube - as given by the process connector of the FFU - should not change directly in front of the device and directly after the device. Minimum inlet and outlet paths are: Device nominal width Inlet path Outlet path 1/2 20 cm 0 cm 3/4 30 cm 5 cm 1 50 cm 10 cm 1 1/4 60 cm 10 cm

10

LeveL sensors | sICK

8013865/2010-11-02 Subject to change without notice

Flow sensors

FFU

notes

8013865/2010-11-02 Subject to change without notice

LeveL sensors | sICK

11

8013865/2011-01-21 LW/FD (2010-11) WB USmod de35

Worldwide presence with subsidiaries in the following countries: australia Belgium/Luxembourg Brasil cesk republika china danmark deutschland Espaa France Great Britain India Israel Italia Japan nederland norge

sterreich Polska republic of Korea republika Slovenija romnia russia Schweiz Singapore Suomi Sverige taiwan trkiye United arab Emirates USa/canada/mxico

Please find detailed addresses and additional representatives and agencies in all major industrial nations at www.sick.com

Handed over by:

our Business Segment Expertise

Factory automation With its intelligent sensors, safety systems, and automatic identification applications, SICK provides comprehensive solutions for factory automation. Logistics automation Sensors made by SICK form the basis for automating material flows and the optimization of sorting and warehousing processes. Process automation Optimized system solutions from SICK ensure efficient acquisition of environmental and process data in many industrial processes.

Non-contact detecting, counting, classifying, and positioning of any type of object Accident protection and personal safety using sensors, as well as safety software and services

Automated identification with barcode and RFID reading devices for the purpose of sorting and target control in industrial material flow Detecting volume, position, and contours of objects and surroundings with laser measurement systems

Precise measurement of gases, liquids and dust concentrations for continuous monitoring of emissions and the acquisition of process data in production processes Gas flow measurements with maximum accuracy thanks to compact gas meters

SICK AG | Waldkirch | Germany | www.sick.com

Vous aimerez peut-être aussi

- Jsa - Cable TerminationDocument4 pagesJsa - Cable TerminationSantos Rex73% (15)

- Electromagnetic Flow Meter: Q&T Instrument Co.,LtdDocument58 pagesElectromagnetic Flow Meter: Q&T Instrument Co.,LtdJoan RodriguezPas encore d'évaluation

- Harmony Radio, R2.8: Order Codes ReferenceDocument51 pagesHarmony Radio, R2.8: Order Codes ReferenceRalaivao Solofohery Dieu-donnéPas encore d'évaluation

- Production of BiodieselDocument49 pagesProduction of Biodieselteja100% (1)

- Ffus10-1g1io Flow SensorDocument12 pagesFfus10-1g1io Flow SensorsujingthetPas encore d'évaluation

- F3 00 EngDocument15 pagesF3 00 Engobiwan2009Pas encore d'évaluation

- FTU230EDocument4 pagesFTU230Ejohn_ab12000Pas encore d'évaluation

- Omega Insertion Fmg-550Document3 pagesOmega Insertion Fmg-550savagedlovePas encore d'évaluation

- Sika Flow MetersDocument27 pagesSika Flow MetersdnkPas encore d'évaluation

- Kty Sick SensorDocument12 pagesKty Sick SensorDavid MartinPas encore d'évaluation

- Flomat EngDocument8 pagesFlomat Engalex.amaral9292Pas encore d'évaluation

- Data Sheet KATflow 110 V10 E0803Document4 pagesData Sheet KATflow 110 V10 E0803Chevronelle100% (1)

- 934-2360 GBDocument5 pages934-2360 GB95008456Pas encore d'évaluation

- 694 Pressure Sensor HubaDocument5 pages694 Pressure Sensor HubaduiechPas encore d'évaluation

- Model LF-100: Ultrasonic Micro Liquid Flow MeterDocument2 pagesModel LF-100: Ultrasonic Micro Liquid Flow MeterCindy MateusPas encore d'évaluation

- Calorimetres SHARKY 775 Heat MeterDocument7 pagesCalorimetres SHARKY 775 Heat MeterJoan AymerichPas encore d'évaluation

- Eurosonic 2000Document75 pagesEurosonic 2000Sandra Carr100% (1)

- DS PE A 10 Product Profile en Us 52381Document2 pagesDS PE A 10 Product Profile en Us 52381behnamatgPas encore d'évaluation

- Product Data Sheet: M-Series® M5000Document4 pagesProduct Data Sheet: M-Series® M5000Carlos GilPas encore d'évaluation

- Ultrasonic Level TransmitterDocument8 pagesUltrasonic Level TransmitterTan Ren Zong100% (1)

- Submersible Liquid Level Transmitters Type LS-10, LH-10: ApplicationsDocument4 pagesSubmersible Liquid Level Transmitters Type LS-10, LH-10: ApplicationsDragos NojeaPas encore d'évaluation

- Thermal Dispersion Flow SwitchDocument12 pagesThermal Dispersion Flow SwitchKrishna KumarPas encore d'évaluation

- Ftb300 SeriesDocument1 pageFtb300 SeriesbmanojkumarPas encore d'évaluation

- The Right Choice Flow Sensors Flow Meters From Ifm 2016 EnglishDocument25 pagesThe Right Choice Flow Sensors Flow Meters From Ifm 2016 Englishifm electronicPas encore d'évaluation

- Electromagnetic Flow Monitor Magphant: Hauser EndressDocument8 pagesElectromagnetic Flow Monitor Magphant: Hauser EndressWildan Syahrir RPas encore d'évaluation

- Pressure Transmitter For General Industrial Applications Model A-10Document7 pagesPressure Transmitter For General Industrial Applications Model A-10brunotavernaPas encore d'évaluation

- ABB - FXE4000 - Medidor EletromagneticoDocument48 pagesABB - FXE4000 - Medidor Eletromagneticoalex_julienePas encore d'évaluation

- UP56 Ultrasonic Level Sensor: Tough, Non-Contact, Pressure-ResistantDocument8 pagesUP56 Ultrasonic Level Sensor: Tough, Non-Contact, Pressure-ResistantLisandra CamachoPas encore d'évaluation

- Rev4 PDFDocument4 pagesRev4 PDFMargaret DaughertyPas encore d'évaluation

- FM and FMC Approved!: Model Ft2 Gas Mass Flowmeter & Temperature TransmitterDocument4 pagesFM and FMC Approved!: Model Ft2 Gas Mass Flowmeter & Temperature TransmitterMonica AguilarPas encore d'évaluation

- VDSHJ402 Sonometer 1100 DS 1111 PressDocument12 pagesVDSHJ402 Sonometer 1100 DS 1111 PressCristi SoarecePas encore d'évaluation

- Electromagnetic Flowmeter Type MAGNETOFLOW™ M2000: DescriptionDocument4 pagesElectromagnetic Flowmeter Type MAGNETOFLOW™ M2000: DescriptionAlphatech1Pas encore d'évaluation

- Ultrasonic Flow MeterDocument2 pagesUltrasonic Flow MeterKrishnudu Nalla0% (1)

- SONDAR 5000 ManualDocument44 pagesSONDAR 5000 ManualovadircPas encore d'évaluation

- Flow Sensors: Product CharacteristicsDocument5 pagesFlow Sensors: Product CharacteristicsToanaircompressorPas encore d'évaluation

- 18 Sensor Proximity SwitchDocument88 pages18 Sensor Proximity SwitchPrince Rao MuaazPas encore d'évaluation

- McCrometer UM06-UM08Document2 pagesMcCrometer UM06-UM08Hera LuceroPas encore d'évaluation

- DS LM2001 GB 23583Document10 pagesDS LM2001 GB 23583melisaBPas encore d'évaluation

- High-Quality Pressure Transmitter For General Industrial Applications Model S-10Document8 pagesHigh-Quality Pressure Transmitter For General Industrial Applications Model S-10gliga vasilePas encore d'évaluation

- DS FSV430 450 en eDocument44 pagesDS FSV430 450 en eGiles HarperPas encore d'évaluation

- RotorFlow RFS - DatasheetDocument4 pagesRotorFlow RFS - DatasheetRynoJoubertPas encore d'évaluation

- Wika DS - Pe8160 - GB - 1631Document8 pagesWika DS - Pe8160 - GB - 1631Francisco Mozart B. MeirellesPas encore d'évaluation

- VDSHL202 Sonometer 2100 DS 1109 PressDocument16 pagesVDSHL202 Sonometer 2100 DS 1109 PressCristi SoarecePas encore d'évaluation

- Ultrasonic Flowmeter: Katflow 160Document4 pagesUltrasonic Flowmeter: Katflow 160ChevronellePas encore d'évaluation

- Modmag M-Series m5000 Product Data Sheet Mag-Ds-00175-EnDocument4 pagesModmag M-Series m5000 Product Data Sheet Mag-Ds-00175-EnNAHASALI11Pas encore d'évaluation

- Sick-Traductoare de Nivel HidrostaticeDocument4 pagesSick-Traductoare de Nivel HidrostaticeChioibasNicolaePas encore d'évaluation

- Brosur EuromagDocument4 pagesBrosur EuromagAnnisa Dipva MaryamPas encore d'évaluation

- Dong Ho Do Luu Luong FlomagDocument2 pagesDong Ho Do Luu Luong FlomagNguyễn Công BìnhPas encore d'évaluation

- DS Turbine Flow SensorsDocument43 pagesDS Turbine Flow SensorsdnkPas encore d'évaluation

- SS 23.400 ATEX en PDFDocument2 pagesSS 23.400 ATEX en PDFJharey Japon ReynosaPas encore d'évaluation

- Ultrasonic Flow Meter 201 and 221Document14 pagesUltrasonic Flow Meter 201 and 221royPas encore d'évaluation

- Flow Meter ManualDocument70 pagesFlow Meter Manualrommel duranPas encore d'évaluation

- 177232D1Document6 pages177232D1Muhammad Usman SindhuPas encore d'évaluation

- 2100 Rev H English ManualDocument2 pages2100 Rev H English ManualJuan HernándezPas encore d'évaluation

- Catalog of Vortex (Tianjin China.)Document23 pagesCatalog of Vortex (Tianjin China.)Waqas JawaidPas encore d'évaluation

- Dss020 Standard Us enDocument13 pagesDss020 Standard Us enMilenko TulencicPas encore d'évaluation

- Sitrans FM Mag 5000 6000 Flow Transmitters IcDocument12 pagesSitrans FM Mag 5000 6000 Flow Transmitters IcGUZMAN0% (1)

- Dss030 Standard Eubvbhc enDocument10 pagesDss030 Standard Eubvbhc enManjit SinghPas encore d'évaluation

- TECSIS Pressure TransmitterDocument4 pagesTECSIS Pressure TransmitterVijendraAgarPas encore d'évaluation

- Beginning Digital Electronics through ProjectsD'EverandBeginning Digital Electronics through ProjectsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Hall-Effect Sensors: Theory and ApplicationD'EverandHall-Effect Sensors: Theory and ApplicationÉvaluation : 5 sur 5 étoiles5/5 (1)

- T BeamDocument17 pagesT BeamManojPas encore d'évaluation

- Metrologic Colombia S.A.S. Medellín Medellín Colombia: Oferta Economica CO20233ADocument3 pagesMetrologic Colombia S.A.S. Medellín Medellín Colombia: Oferta Economica CO20233AJulian MoraPas encore d'évaluation

- ADM3346A Midterm Fall 2010 SolutionDocument10 pagesADM3346A Midterm Fall 2010 SolutionJohn BecksPas encore d'évaluation

- Read Me - CADWorx Plant 2019 SP2 HF1Document4 pagesRead Me - CADWorx Plant 2019 SP2 HF1Himanshu Patel (Himan)Pas encore d'évaluation

- Compt I A Network Plus 008Document902 pagesCompt I A Network Plus 008trainmPas encore d'évaluation

- Incident Log - TemplateDocument10 pagesIncident Log - TemplateRajaPas encore d'évaluation

- Ammonia Material BalanceDocument7 pagesAmmonia Material BalanceSiva KumarPas encore d'évaluation

- Claims Reserving With R: Chainladder-0.2.10 Package VignetteDocument60 pagesClaims Reserving With R: Chainladder-0.2.10 Package Vignetteenrique gonzalez duranPas encore d'évaluation

- Standard Operating Procedure Template - Single PageDocument1 pageStandard Operating Procedure Template - Single PagetesPas encore d'évaluation

- Adaptation Fom Squirrels GamesDocument2 pagesAdaptation Fom Squirrels GamesDenny Boy MochranPas encore d'évaluation

- Bảo MậtDocument2 pagesBảo MậtMinh Nghia PhamPas encore d'évaluation

- Treatment of Dairy Waste Water Using Adsorbents From Solid WasteDocument7 pagesTreatment of Dairy Waste Water Using Adsorbents From Solid WasteIJRASETPublicationsPas encore d'évaluation

- Lesson Worksheet: 6.1A MeanDocument7 pagesLesson Worksheet: 6.1A Meanwaiman fuPas encore d'évaluation

- Invoice SummaryDocument2 pagesInvoice SummarymuPas encore d'évaluation

- Aling MODEDocument29 pagesAling MODEBojan PetronijevicPas encore d'évaluation

- BF2207 Exercise 6 - Dorchester LimitedDocument2 pagesBF2207 Exercise 6 - Dorchester LimitedEvelyn TeoPas encore d'évaluation

- Business Ethics Final Work Brief 2Document6 pagesBusiness Ethics Final Work Brief 2KALIZA TRESSY MEGHANPas encore d'évaluation

- Train TicketDocument2 pagesTrain TicketGautam KumarPas encore d'évaluation

- Notice: Customhouse Broker License Cancellation, Suspension, Etc.Document2 pagesNotice: Customhouse Broker License Cancellation, Suspension, Etc.Justia.comPas encore d'évaluation

- MetasploitDocument9 pagesMetasploitDhamlo KheralaPas encore d'évaluation

- My Linux Attack Commands-ADocument51 pagesMy Linux Attack Commands-Aapogee.protectionPas encore d'évaluation

- Mas MockboardDocument7 pagesMas MockboardMaurene DinglasanPas encore d'évaluation

- Lease Contract AddendumDocument1 pageLease Contract AddendumjasonPas encore d'évaluation

- BrochureDocument8 pagesBrochurevacmanilaPas encore d'évaluation

- L11 Single Phase Half Controlled Bridge ConverterDocument19 pagesL11 Single Phase Half Controlled Bridge Converterapi-19951707Pas encore d'évaluation

- Tactical Radio BasicsDocument46 pagesTactical Radio BasicsJeff Brissette100% (2)