Académique Documents

Professionnel Documents

Culture Documents

Hot-Pressed Sm2Fe17Nx Fe-Co Composites

Transféré par

electronenergyDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Hot-Pressed Sm2Fe17Nx Fe-Co Composites

Transféré par

electronenergyDroits d'auteur :

Formats disponibles

JOURNAL OF APPLIED PHYSICS 103, 07E123 2008

Hot-pressed Sm2Fe17Nx / Fe Co composites: Factors controlling densication and in situ nitrogenization of Sm2Fe17 phase

A. M. Gabay,a N. G. Akdogan, and G. C. Hadjipanayis

University of Delaware, Newark, Delaware 19716, USA

M. Marinescub and J. F. Liu

Electron Energy Corporation, Landisville, Pennsylvania 17538, USA

A. Ali

University of Engineering and Technology, Lahore 58490, Pakistan

Presented on 7 November 2007; received 11 September 2007; accepted 19 October 2007; published online 30 January 2008 The effects of powder preparation and conditions of hot pressing on the structure and density of consolidated Sm2Fe17Nx and Sm2Fe17Nx / Fe Co magnets have been studied. Densities achieved in the case of Sm2Fe17Nx powders prepared through a low-energy milling were higher than after a high-energy milling. The difference is mostly caused by the different particle size, and it can be eliminated by an additional low-energy milling of the coarse high-energy milled powder. The presence of a ductile soft magnetic phase greatly facilitates densication, leading to considerably higher absolute and relative densities in hot-pressed Sm2Fe17Nx / Fe0.65Co0.35 composites. We have found that during hot pressing, nitrogenization of the Sm2Fe17 phase may occur in situ if pressed together with FeCoN powders. Because FeCoN releases nitrogen below the decomposition temperature of Sm2Fe17Nx, we were able to fabricate the Sm2Fe17Nx / Fe0.65Co0.35 composite with the density up to 7.6 g / cm3 by hot-pressing mixtures of Sm2Fe17 and Fe0.65Co0.35 89N11 powders. 2008 American Institute of Physics. DOI: 10.1063/1.2831488

I. INTRODUCTION

The Sm2Fe17Nx nitrides exhibit excellent intrinsic magnetic properties.1,2 It is relatively easy to develop magnetic hardness in a Sm2Fe17Nx material by reducing its crystallite size, for instance, through a low-energy ball milling35 LEBM or a high-energy ball milling6 HEBM . Even more promising are nanostructured exchange-coupled magnets with Sm2Fe17Nx hard phase and a soft magnetic phase. The theory7 had predicted for the Sm2Fe17N3 / Fe65Co35 system a maximum energy product BH max of 137 MG Oe. Unfortunately, the Sm2Fe17Nx compound is unstable with respect to the mixture of SmN and Fe. This ternary nitride can be formed only via nitrogenization of the Sm2Fe17 parent compound at a temperature which is high enough to assure the diffusion of the N atoms, but low enough to prohibit the diffusion of the Sm and Fe atoms. Above 600 C, the dissociation of the Sm2Fe17Nx nitride becomes practically inevitable. Because of this structural instability, the Sm2Fe17Nx powders cannot be sintered in a traditional way. A few reported attempts to obtain fully dense Sm2Fe17Nx magnets included shock compression,811 sintering under a 3 GPa pressure,12 compression shearing,13 and eld-activated combustion;14 only the shock compression and high-pressure sintering could assure a nearly 100% density. Most commonly, the Sm2Fe17Nx powders are consolidated together with a nonmagnetic polymer or metal binder which dilutes the magnetization and dramatically reduces BH max. On the

a b

other hand, an exchange-coupled soft magnetic binder could simultaneously increase the BH max and solve the density problem. In this work, we show how the properties of hotpressed magnets depend on the powder preparation. We also show that addition of a soft magnetic phase greatly improves the magnet density.

II. EXPERIMENT

Electronic mail: gabay@physics.udel.edu. Also at the University of Delaware, Newark, Delaware 19716, USA.

Samarium-iron and SmFeCo alloys were prepared by arc and rf induction melting from pure metals allowing the appropriate excess of Sm to compensate the evaporation loss. The ingots were homogenized at 975 1050 C. Pulverizing techniques included crushing, grinding down to 325 mesh, LEBM with a rotary mill and HEBM with a SPEX-8000 mill. The HEBM powders were annealed at 700 C. Nitrogenization was performed in a nitrogen gas at 400 450 C. Soft magnetic FeN, FeCo, and FeCoN powders were synthesized by mechanical alloying from commercially available Fe, Co, and Fe3.5N powders. Consolidation of powders and powder blends was done under vacuum in a heated die with a pressure of 275 MPa. The hot-pressing temperature Thp was controlled via a voltage applied to the resistance heater. Design of the instrument did not allow us to measure Thp directly with sufcient accuracy; instead, the Thp values were calibrated based on various temperature-dependent processes, such as degradation of coercivity in SmCoFe CuZr magnets. The powder and hot-pressed alloys were characterized by x-ray diffraction XRD using the Cu K radiation, scanning electron microscopy SEM with the JEOL JSM-6330F

2008 American Institute of Physics

0021-8979/2008/103 7 /07E123/3/$23.00

103, 07E123-1

Author complimentary copy. Redistribution subject to AIP license or copyright, see http://jap.aip.org/jap/copyright.jsp

07E123-2

Gabay et al.

J. Appl. Phys. 103, 07E123 2008

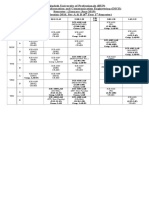

FIG. 2. Micrographs of Sm2.55Fe17N3 alloy powder a after HEBM followed by annealing and nitrogenization and b after additional LEBM for 6 h. FIG. 1. Density and relative coercivity of hot-pressed SmFeN powders vs processing temperature: 1 LEBM Sm2.1Fe17N2.7, 2 LEBM Sm2Zr0.1Fe17N2.7, 3 HEBM Sm2.3 Fe0.83Co0.17 17Nx, and 4 HEBM Sm2.44Zr0.1Fe17N3.3 after additional LEBM. Hc0 is the coercivity of powder prior to consolidation.

instrument, thermogravimetric analysis TGA with the PerkinElmer Diamond instrument heating in an argon ow at the rate 10 K / min , and magnetic measurements with a vibrating sample magnetometer and the Quantum Design Magnetic Property Measurement System. Pulsed eld of 100 kOe was used to magnetize some of the magnetically hard specimens. Density of the magnets was measured by a water immersion technique or, in the case of too porous specimens, derived from their outer dimensions.

III. RESULTS AND DISCUSSION A. Hot pressing of low-energy and high-energy milled SmFeN powders

As a result, the average particle size has decreased almost ten times see Fig. 2 b , and Hc decreased from 29.6 to 26.1 kOe. After consolidation, the density of the remilled HEBM material data 4 in Fig. 1 has increased by 5%6% and almost approached that of the LEBM powder. Though Hc was found to be 12%15% lower than without remilling, it was still equal to 18 kOe after consolidation at Thp = 550 C.

B. Hot-pressed Sm Fe N / Fe Co composites and in situ nitrogenization of the Sm2Fe17 phase

After optimization of milling, annealing and nitrogenization conditions, the LEBM anisotropic and HEBM isotropic powders used as precursor materials in this study showed a room-temperature intrinsic coercivity Hc of 7.7 and 29.6 kOe, respectively. In a good agreement with earlier reports,4,5 the low-energy milling for several hours produced single-crystal particles with an average size below 2 m. Figure 1 shows that the density of hot-pressed LEBM powders data 1 and 2 monotonically increases with increasing Thp, while Hc rst decreases rapidly and then, at Thp 500 C, it stabilizes at a value around 25% of the powder value i.e., at less than 2 kOe . Compared to the single crystalline LEBM particles, the nanostructured HEBM particles were coarse with their average size exceeding 10 m. The typical HEBM precursor powder is shown in Fig. 2 a . Such powder can retain more than 75% its original Hc after consolidation at Thp = 550 C data 3 in Fig. 1 . The coercivity of both LEMB and HEBM Sm2Fe17Nx powders is expected to be nucleation controlled and very sensitive to the grainboundary conditions. This may explain the greater decline of relative Hc in the LEBM powder: because the grain boundaries coincide with particle boundaries, they sustain greater chemical and structural damage during consolidation. However, because of its coarseness, the hot-pressed HEBM powder exhibits lower density for the same Thp. We had subjected this powder to an additional low-energy milling for 6 h, which is about half the typical LEBM time used in this study.

Our efforts to fabricate Sm2Fe17Nx-based hard/soft composite magnets originally included the magnetically soft iron nitrides. The metastable bcc Fe100yNy nitrides y 14 synthesized by mechanical alloying completely decomposed into Fe and N2 when heated to 600 700 C; this decomposition involved the intermediate -Fe4N phase. We have phase, found that Co substitution, which suppresses the markedly decreases the decomposition temperature. For instance, TGA detected that the Fe89N11 alloy began releasing N2 at 670 C, while in the Fe0.65Co0.35 89N11 alloy this occured at 450 C. Since dissociation of the ground Sm2.1Fe17N2.7 alloy starts, according to TGA, at 600 C, between 450 and 600 C the nitrogen gas released during decomposition of Fe0.65Co0.35 89N11 can interstitially modify the Sm2Fe17 compound. Figure 3 presents the XRD scans for Sm11Fe89 and Fe0.65Co0.35 89N11 powders blended in equal weight parts and hot pressed at different temperatures. The data show that the in situ nitrogenization of the Sm2Fe17 compound during hot pressing in vacuum! indeed occurs. The sample consolidated at Thp of 450 C exhibits two sets of reections of the Th2Zn17-type structure indicating the coexistence of nitrogen-free and fully nitrogenized 2:17 phases. After Thp of 570 C, XRD detects only the Sm2Fe17Nx nitride and the bcc FeCo N phase. After consolidation at Thp = 650 C, the Sm2Fe17Nx phase is no longer present, and the very broad peaks of the SmN nitride can be observed. The TMA heating curves recorded at 15 kOe and shown in the inset also indicate the transition from the low Curie temperature of the Sm2Fe17 compound to that of the 2:17 nitride with increasing Thp. Note the similarity of the TMA scans for composites obtained at 570 C from the Sm2.1Fe17 / Fe0.65Co0.35 89N11 blend and from the Sm2.1Fe17N2.8 / Fe0.65Co0.35 blend dash line . Both the XRD and TMA data suggest that nitrogeniza-

Author complimentary copy. Redistribution subject to AIP license or copyright, see http://jap.aip.org/jap/copyright.jsp

07E123-3

Gabay et al.

J. Appl. Phys. 103, 07E123 2008

FIG. 3. XRD and TMA scans of a Sm11Fe89 and Fe0.65Co0.35 89N11 dotted line powders and composites made from equal weight parts of these two powders by hot pressing at Thp of b 450 C, c 570 C, and d 650 C: 1 Sm2Fe17, 2 Sm2Fe17Nx, 3 -Fe, and 4 SmN. Dash line in inset is for Sm2.1Fe17N2.8 / Fe0.65Co0.35 blend hot pressed at Thp = 570 C.

FIG. 5. Densities and crystal structures of hot-pressed 50/ 50 powder blends: 1 ground Sm2.3 Fe0.83Co0.17 17 blended with Fe0.65Co0.35 89N11; 2 ground Sm2.1Fe17 blended with Fe0.65Co0.35 89N11; 3 HEBM Sm2.5Fe17 blended with Fe0.65Co0.35 89N11 and LEBM together; and 4 ground Sm2.1Fe17N2.8 blended with Fe0.65Co0.35. The regions I, II, and III indicate presence of Sm2Fe17, Sm2Fe17Nx, and SmN phases, respectively.

tion of Sm2Fe17 occurs as a two-phase process in which a fully nitrogenized phase precipitates from a nitrogen-free phase.15 Figure 4 shows the typical microstructures of the Sm2Fe17Nx / Fe Co composites obtained through the in situ nitrogenization. The more ductile FeCo phase lls the space between the hard Sm2Fe17Nx particles. This results in a dramatic increase of the density. Figure 5 presents densities of composites processed at different conditions, marking the regions within which the Sm2Fe17, Sm2Fe17Nx, and SmN phases have been observed. The graph includes data for the HEBM and annealed but not nitrogenized Sm2.5Fe17 alloy that had been low energy milled together with Fe0.65Co0.35 89N11 see also Fig. 4 a . It also shows, as a reference, the densities of composites made from Sm2.1Fe17N2.8 and Fe0.65Co0.35 alloys. For the same Thp values, all the Sm2Fe17Nx / Fe Co composites exhibit density both absolute and relative signicantly higher than the hotpressed Sm2Fe17Nx specimens. The same density enhancement was observed for composites with 25 wt. % FeCo phase. In the case of the Sm Co N / Fe Co composites, the additional low-energy milling did not increase the density. On the other hand, those composites which experienced the

in situ nitrogenization tend to exhibit slightly increased density values. In summary, the optimum technique of preparing Sm2Fe17Nx powders for hot-pressed isotropic single phase magnets includes the subsequent HEBM and LEBM stages. The hypothetical exchange-coupled SmFeN/FeCo nanocomposites fabricated by hot pressing will inherently have a superior density and they can be made starting from SmFe and FeCoN materials. The latter option, although it did not show clear advantage, may turn out to be useful when a prior nitrogenization of Sm2Fe17 is complicated e.g., in the case of sputtered SmFeN/FeCo multilayers .

ACKNOWLEDGMENTS

This work was supported by DoD through Army STTR Contract No. W911NF-06-C-0104.

J. M. D. Coey and H. Sun, J. Magn. Magn. Mater. 87, L251 1990 . M. Katter, J. Wecker, C. Kuhrt, L. Schultz, and R. Grssinger, J. Magn. Magn. Mater. 111, 293 1992 . 3 T. Iriyama, K. Kobayashi, N. Imaoka, T. Fukuda, H. Kato, and Y. Nakagawa, IEEE Trans. Magn. 28, 2326 1992 . 4 P. A. P. Wendhausen, B. Gebel, D. Eckert, and K.-H. Mller, J. Appl. Phys. 75, 6018 1994 . 5 K. Kobayashi, R. Skomski, and J. M. D. Coey, J. Alloys Compd. 222, 1 1995 . 6 K. Schnitzke, L. Schultz, J. Wecker, and M. Katter, Appl. Phys. Lett. 57, 2853 1990 . 7 R. Skomski and J. M. D. Coey, Phys. Rev. B 48, 15812 1993 . 8 B. P. Hu, X. L. Rao, J. M. Xu, G. C. Liu, Y.-Z. Wang, X. L. Dong, D. X. Zhang, and M. Cai, J. Appl. Phys. 74, 489 1993 . 9 H. Oda, K. Kondo, H. Uchida, Y. Matsumura, S. Tachibana, and T. Kawanabe, Jpn. J. Appl. Phys., Part 2 34, L35 1995 . 10 M. Leonowicz, W. Kaszuwara, E. Jezierska, D. Januszewski, G. Mendoza, H. A. Davies, and J. Paszula, J. Appl. Phys. 83, 6634 1998 . 11 T. Mashimo, X. Huang, S. Hirosawa, K. Makita, Y. Kato, S. Mitsudo, and M. Motokawa, J. Magn. Magn. Mater. 210, 109 2000 . 12 K. Machida, Y. Nakatani, G. Adachi, and A. Onodera, Appl. Phys. Lett. 62, 2874 1993 . 13 T. Saito, M. Fukui, and H. Takeishi, Scr. Mater. 53, 1117 2005 . 14 J. Ye, Y. Liu, G. Zhu, M. Chen, S. Gao, and M. Tu, J. Alloys Compd. 428, 350 2007 . 15 C. C. Colucci, S. Gama, C. A. Ribeiro, and L. P. Cardoso, J. Appl. Phys. 75, 6003 1994 .

2 1

FIG. 4. Backscattered electron SEM images of 50/ 50 powder blends hot pressed at Thp = 570 C: a ground Sm2.1Fe17 blended with Fe0.65Co0.35 89N11; b HEBM Sm2.5Fe17 blended with Fe0.65Co0.35 89N11 and LEBM together.

Author complimentary copy. Redistribution subject to AIP license or copyright, see http://jap.aip.org/jap/copyright.jsp

Vous aimerez peut-être aussi

- Thermal Stability and Performance Data SmCo PPMDocument8 pagesThermal Stability and Performance Data SmCo PPMelectronenergyPas encore d'évaluation

- Thermal Stability and Radiation Resistance of Sm-Co BasedDocument9 pagesThermal Stability and Radiation Resistance of Sm-Co Basedelectronenergy100% (1)

- Thermal Stability and Performance Data For Sm-Co 2 17 High-TemperatureDocument4 pagesThermal Stability and Performance Data For Sm-Co 2 17 High-TemperatureelectronenergyPas encore d'évaluation

- High Temperature Hybrid Radial Magnetic Bearing Systems Capable ofDocument5 pagesHigh Temperature Hybrid Radial Magnetic Bearing Systems Capable ofelectronenergyPas encore d'évaluation

- Design of Permanent Magnet Systems Using Finite Element AnalysisDocument5 pagesDesign of Permanent Magnet Systems Using Finite Element AnalysiselectronenergyPas encore d'évaluation

- Repm2006 A024Document5 pagesRepm2006 A024electronenergyPas encore d'évaluation

- High Temperature Hybrid Radial Magnetic Bearing Systems Capable ofDocument5 pagesHigh Temperature Hybrid Radial Magnetic Bearing Systems Capable ofelectronenergyPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 00.diesel Engine Power Plant Design PDFDocument4 pages00.diesel Engine Power Plant Design PDFmardirad100% (1)

- Auto CadDocument67 pagesAuto CadkltowerPas encore d'évaluation

- AMiT Products Solutions 2022 1 En-SmallDocument60 pagesAMiT Products Solutions 2022 1 En-SmallMikhailPas encore d'évaluation

- Contribution of Medieval MuslimDocument16 pagesContribution of Medieval Muslimannur osmanPas encore d'évaluation

- Formulae HandbookDocument60 pagesFormulae Handbookmgvpalma100% (1)

- Dpb6013 HRM - Chapter 3 HRM Planning w1Document24 pagesDpb6013 HRM - Chapter 3 HRM Planning w1Renese LeePas encore d'évaluation

- Class Routine Final 13.12.18Document7 pagesClass Routine Final 13.12.18RakibPas encore d'évaluation

- SoundsDocument61 pagesSoundsJemabel RosarioPas encore d'évaluation

- Hydrology Report at CH-9+491Document3 pagesHydrology Report at CH-9+491juliyet strucPas encore d'évaluation

- ANNEXESDocument6 pagesANNEXESKyzer Calix LaguitPas encore d'évaluation

- Er6f Abs 2013Document134 pagesEr6f Abs 2013Calibmatic JobPas encore d'évaluation

- Evidence MODULE 1 Evidence DefinitionDocument8 pagesEvidence MODULE 1 Evidence Definitiondave BarretoPas encore d'évaluation

- Moc3040 MotorolaDocument3 pagesMoc3040 MotorolaBryanTipánPas encore d'évaluation

- Centrifugal Pumps: Turbo Machines Amit Pathania Roll No:09309 Mechanical EngineeringDocument4 pagesCentrifugal Pumps: Turbo Machines Amit Pathania Roll No:09309 Mechanical EngineeringAmit PathaniaPas encore d'évaluation

- A New Procedure For Generalized Star Modeling Using Iacm ApproachDocument15 pagesA New Procedure For Generalized Star Modeling Using Iacm ApproachEdom LazarPas encore d'évaluation

- Mathematics4 q4 Week4 v4Document11 pagesMathematics4 q4 Week4 v4Morales JinxPas encore d'évaluation

- Causal Emergence - HoelDocument18 pagesCausal Emergence - HoelFelipe LopesPas encore d'évaluation

- Nissan Note E-Power 2022 Quick Guide ENDocument57 pagesNissan Note E-Power 2022 Quick Guide ENSarita EmmanuelPas encore d'évaluation

- CadburyDocument21 pagesCadburyramyarayeePas encore d'évaluation

- PCM 2.4l Turbo 5 de 5Document2 pagesPCM 2.4l Turbo 5 de 5Felix VelasquezPas encore d'évaluation

- Scope and Sequence 2020 2021...Document91 pagesScope and Sequence 2020 2021...Ngọc Viễn NguyễnPas encore d'évaluation

- The Technology Procurement HandbookDocument329 pagesThe Technology Procurement HandbookAlexander Jose Chacin NavarroPas encore d'évaluation

- CKRE Lab (CHC 304) Manual - 16 May 22Document66 pagesCKRE Lab (CHC 304) Manual - 16 May 22Varun pandeyPas encore d'évaluation

- Scan WV1DB12H4B8018760 20210927 1800Document6 pagesScan WV1DB12H4B8018760 20210927 1800Sergio AlvarezPas encore d'évaluation

- Manish Kumar: Desire To Work and Grow in The Field of MechanicalDocument4 pagesManish Kumar: Desire To Work and Grow in The Field of MechanicalMANISHPas encore d'évaluation

- Void Engineers (Convention: Mage The Ascension)Document6 pagesVoid Engineers (Convention: Mage The Ascension)Beth0% (1)

- MidsemDocument6 pagesMidsemAravind SomasundaramPas encore d'évaluation

- World Trends in Municipal Solid Waste ManagementDocument11 pagesWorld Trends in Municipal Solid Waste ManagementNeima EndrisPas encore d'évaluation

- En 1993 09Document160 pagesEn 1993 09Vio ChiPas encore d'évaluation

- GATE Chemical Engineering 2015Document18 pagesGATE Chemical Engineering 2015Sabareesh Chandra ShekarPas encore d'évaluation