Académique Documents

Professionnel Documents

Culture Documents

Wall Thickness Calculation (ISBL #150) Rev-1

Transféré par

putut_hsTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Wall Thickness Calculation (ISBL #150) Rev-1

Transféré par

putut_hsDroits d'auteur :

Formats disponibles

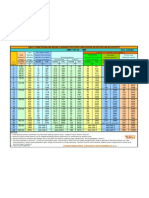

CALCULATION OF PIPE WALL THICKNESS FOR WELDED & SMLS PIPE

PROJECT NAME

SERVICE CLASS

COR. ALL.(CA)

:

:

:

PIPE PROPERTIES:

Size (In.) Specification

1/2 ~ 24

A106 GR. B

Size (In.)

P

T

S

Y

1/2 ~ 24

RCC OFF GAS TO PROPYLENE PROJECT

A1A

1.6

(MM)

Weld Type

SMLS

Joint Eff.(E)

1

[F1]

(kg/cm2)

(Oc)

(kg/cm2)

20

38

1406

0.4

[F1]

EQUATION :

(ASME B31.3)

WHERE,

t

D

S

P

T

Y

CA

E

P.D

t=

+ CA

2(S.E + P.Y)

NPS

(Inch.)

0.5

0.75

1

1.5

2

3

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

D

(mm)

21.3

26.7

33.4

48.3

60.3

88.9

114.3

168.3

219.1

273.1

323.9

355.6

406.4

457

508

559

610

660

711

762

813

864

914

965

1016

1067

1118

1168

1219

Design

Condition

96675475.xls.ms_office A1A

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

-

Calc. Thick.

t (mm)

1.75

1.79

1.84

1.94

2.03

2.23

2.41

2.79

3.15

3.53

3.89

4.11

4.47

4.83

5.19

5.55

5.91

-

= PRESSURE DESIGN THICKNESS

= OUTSIDE DIAMETER OF PIPE

= ALLOWABLE STRESS OF PIPE

= DESIGN PRESSURE

= DESIGN TEMPERATURE

= FACTOR

= CORROSION ALLOWANCE

= WELDING JOINT FACTOR

Nominal Thick.

SCH. NO.

S-80

S-80

S-80

S-80

S-80

S-40

S-40

S-40

S-40

S-40

STD

STD

STD

STD

STD

STD

STD

(mm)

3.73

3.91

4.55

5.08

5.54

5.49

6.02

7.11

8.18

9.27

9.53

9.53

9.53

9.53

9.53

9.53

9.53

-

Thick. Tol.

Min. Thick

Thick.

(%)

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

(mm)

3.26

3.42

3.98

4.45

4.85

4.80

5.27

6.22

7.16

8.11

8.34

8.34

8.34

8.34

8.34

8.34

8.34

-

Allow. (mm)

1.51

1.63

2.15

2.50

2.82

2.58

2.86

3.43

4.01

4.58

4.45

4.22

3.86

3.51

3.15

2.79

2.42

-

Sheet 1 of 11

CALCULATION OF PIPE WALL THICKNESS FOR WELDED & SMLS PIPE

PROJECT NAME

SERVICE CLASS

COR. ALL.(CA)

:

:

:

PIPE PROPERTIES:

Size (In.) Specification

1/2 ~ 24

30

36

Weld Type

SMLS

DSAW

DSAW

A106 GR. B

API 5L GR. B

API 5L GR. B

(note 1)

Size (In.)

P

T

S

Y

RCC OFF GAS TO PROPYLENE PROJECT

A1D

1.6

(MM)

30

36

20

38

1406

0.4

20

110

1406

0.4

13.7

110

1406

0.4

[F1]

[F2]

[F3]

+ CA

2(S.E + P.Y)

D

(mm)

21.3

26.7

33.4

48.3

60.3

88.9

114.3

168.3

219.1

273.1

323.9

355.6

406.4

457

508

559

610

660

711

762

813

864

914

965

1016

1067

1118

1168

1219

(kg/cm2)

(Oc)

(kg/cm2)

t

D

S

P

T

Y

CA

E

P.D

NPS

[F1]

[F2]

[F3]

WHERE,

t=

(Inch.)

0.5

0.75

1

1.5

2

3

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

1

0.95

0.95

(note 1)

1/2 ~ 24

EQUATION :

(ASME B31.3)

Joint Eff.(E)

Design

Condition

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F2

F3

Calc. Thick.

t (mm)

1.75

1.79

1.84

1.94

2.03

2.23

2.41

2.79

3.15

3.53

3.89

4.11

4.47

4.83

5.19

5.55

5.91

7.27

6.27

-

= PRESSURE DESIGN THICKNESS

= OUTSIDE DIAMETER OF PIPE

= ALLOWABLE STRESS OF PIPE

= DESIGN PRESSURE

= DESIGN TEMPERATURE

= FACTOR

= CORROSION ALLOWANCE

= WELDING JOINT FACTOR

Nominal Thick.

SCH. NO.

S-80

S-80

S-80

S-80

S-80

S-40

S-40

S-40

S-40

S-40

STD

STD

STD

STD

STD

STD

STD

XS

XS

(mm)

3.73

3.91

4.55

5.08

5.54

5.49

6.02

7.11

8.18

9.27

9.53

9.53

9.53

9.53

9.53

9.53

9.53

12.70

12.70

-

Thick. Tol.

Min. Thick

Thick.

(%)

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

(mm)

3.26

3.42

3.98

4.45

4.85

4.80

5.27

6.22

7.16

8.11

8.34

8.34

8.34

8.34

8.34

8.34

8.34

11.11

11.11

-

Allow. (mm)

12.5

12.5

1.51

1.63

2.15

2.50

2.82

2.58

2.86

3.43

4.01

4.58

4.45

4.22

3.86

3.51

3.15

2.79

2.42

3.84

4.84

-

Note 1.

This Licensor's pipe thickness is not full flange rated. We consider line condition on the line list.

96675475.xls.ms_office A1D

Sheet 2 of 11

CALCULATION OF PIPE WALL THICKNESS FOR WELDED & SMLS PIPE

PROJECT NAME

SERVICE CLASS

COR. ALL.(CA)

:

:

:

PIPE PROPERTIES:

Size (In.) Specification

1/2 ~ 24

A106 GR. B

Size (In.)

P

T

S

Y

1/2 ~ 24

RCC OFF GAS TO PROPYLENE PROJECT

A1E

3.2

(MM)

Weld Type

SMLS

Joint Eff.(E)

1

[F1]

(kg/cm2)

(Oc)

(kg/cm2)

20

38

1406

0.4

[F1]

EQUATION :

(ASME B31.3)

WHERE,

t

D

S

P

T

Y

CA

E

P.D

t=

+ CA

2(S.E + P.Y)

NPS

(Inch.)

0.5

0.75

1

1.5

2

3

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

D

(mm)

21.3

26.7

33.4

48.3

60.3

88.9

114.3

168.3

219.1

273.1

323.9

355.6

406.4

457

508

559

610

660

711

762

813

864

914

965

1016

1067

1118

1168

1219

Design

Condition

96675475.xls.ms_office A1E

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

Calc. Thick.

t (mm)

3.35

3.39

3.44

3.54

3.63

3.83

4.01

4.39

4.75

5.13

5.49

5.71

6.07

6.43

6.79

7.15

7.51

-

= PRESSURE DESIGN THICKNESS

= OUTSIDE DIAMETER OF PIPE

= ALLOWABLE STRESS OF PIPE

= DESIGN PRESSURE

= DESIGN TEMPERATURE

= FACTOR

= CORROSION ALLOWANCE

= WELDING JOINT FACTOR

Nominal Thick.

SCH. NO.

S-160

S-80

S-80

S-80

S-80

S-40

S-40

S-40

S-40

S-40

STD

STD

STD

STD

STD

STD

STD

(mm)

4.78

3.91

4.55

5.08

5.54

5.49

6.02

7.11

8.18

9.27

9.53

9.53

9.53

9.53

9.53

9.53

9.53

-

Thick. Tol.

Min. Thick

Thick.

(%)

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

(mm)

4.18

3.42

3.98

4.45

4.85

4.80

5.27

6.22

7.16

8.11

8.34

8.34

8.34

8.34

8.34

8.34

8.34

-

Allow. (mm)

0.83

0.03

0.55

0.90

1.22

0.98

1.26

1.83

2.41

2.98

2.85

2.62

2.26

1.91

1.55

1.19

0.82

-

Sheet 3 of 11

CALCULATION OF PIPE WALL THICKNESS FOR WELDED & SMLS PIPE

PROJECT NAME

SERVICE CLASS

COR. ALL.(CA)

:

:

:

RCC OFF GAS TO PROPYLENE PROJECT

A1K

3.2

(MM)

PIPE PROPERTIES:

Size (In.) Specification

1/2 ~ 24

26 ~ 30

Weld Type

SMLS

DSAW

A106 GR. B

API 5L Gr. B

Joint Eff.(E)

1

0.95

[F1]

[F2]

(note 1)

Size (In.)

P

T

S

Y

1/2 ~ 24

26 ~ 30

20

38

1406

0.4

3.5

427

759.3

0.4

[F1]

[F2]

EQUATION :

(ASME B31.3)

(kg/cm )

O

( c)

(kg/cm2)

WHERE,

t

D

S

P

T

Y

CA

E

P.D

t=

+ CA

2(S.E + P.Y)

NPS

(Inch.)

0.5

0.75

1

1.5

2

3

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

D

(mm)

21.3

26.7

33.4

48.3

60.3

88.9

114.3

168.3

219.1

273.1

323.9

355.6

406.4

457

508

559

1

610

660

711

762

813

864

914

965

1016

1067

1118

1168

1219

Design

Condition

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F2

F2

F2

Calc. Thick.

t (mm)

3.35

3.39

3.44

3.54

3.63

3.83

4.01

4.39

4.75

5.13

5.49

5.71

6.07

6.43

6.79

7.15

7.51

4.80

4.92

5.05

-

= PRESSURE DESIGN THICKNESS

= OUTSIDE DIAMETER OF PIPE

= ALLOWABLE STRESS OF PIPE

= DESIGN PRESSURE

= DESIGN TEMPERATURE

= FACTOR

= CORROSION ALLOWANCE

= WELDING JOINT FACTOR

Nominal Thick.

SCH. NO.

S-160

S-80

S-80

S-80

S-80

S-40

S-40

S-40

S-40

S-40

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

(mm)

4.78

3.91

4.55

5.08

5.54

5.49

6.02

7.11

8.18

9.27

9.53

9.53

9.53

9.53

9.53

9.53

9.53

9.53

9.53

9.53

-

Thick. Tol.

Min. Thick

Thick.

(%)

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

(mm)

4.18

3.42

3.98

4.45

4.85

4.80

5.27

6.22

7.16

8.11

8.34

8.34

8.34

8.34

8.34

8.34

8.34

8.34

8.34

8.34

-

Allow. (mm)

0.83

0.03

0.55

0.90

1.22

0.98

1.26

1.83

2.41

2.98

2.85

2.62

2.26

1.91

1.55

1.19

0.82

3.54

3.42

3.29

-

Note 1.

This Licensor's pipe thickness is not full flange rated. We consider line condition on the line list.

96675475.xls.ms_office A1K

Sheet 4 of 11

CALCULATION OF PIPE WALL THICKNESS FOR WELDED & SMLS PIPE

PROJECT NAME

SERVICE CLASS

COR. ALL.(CA)

:

:

:

PIPE PROPERTIES:

Size (In.) Specification

1/2 ~ 24

A106 GR. B

Size (In.)

P

T

S

Y

1/2 ~ 24

RCC OFF GAS TO PROPYLENE PROJECT

A1MR

3.2

(MM)

Weld Type

SMLS

Joint Eff.(E)

1

[F1]

(kg/cm2)

(Oc)

(kg/cm2)

20

38

1406

0.4

[F1]

EQUATION :

(ASME B31.3)

WHERE,

t

D

S

P

T

Y

CA

E

P.D

t=

+ CA

2(S.E + P.Y)

NPS

(Inch.)

0.5

0.75

1

1.5

2

3

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

D

(mm)

21.3

26.7

33.4

48.3

60.3

88.9

114.3

168.3

219.1

273.1

323.9

355.6

406.4

457

508

559

610

660

711

762

813

864

914

965

1016

1067

1118

1168

1219

Design

Condition

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

96675475.xls.ms_office A1MR

Calc. Thick.

t (mm)

3.35

3.39

3.44

3.54

3.63

3.83

4.01

4.39

4.75

5.13

5.49

5.71

6.07

6.43

6.79

7.15

7.51

-

= PRESSURE DESIGN THICKNESS

= OUTSIDE DIAMETER OF PIPE

= ALLOWABLE STRESS OF PIPE

= DESIGN PRESSURE

= DESIGN TEMPERATURE

= FACTOR

= CORROSION ALLOWANCE

= WELDING JOINT FACTOR

Nominal Thick.

SCH. NO.

S-160

S-80

S-80

S-80

S-80

S-40

S-40

S-40

S-40

S-40

STD

STD

STD

STD

STD

STD

STD

(mm)

4.78

3.91

4.55

5.08

5.54

5.49

6.02

7.11

8.18

9.27

9.53

9.53

9.53

9.53

9.53

9.53

9.53

-

Thick. Tol.

Min. Thick

Thick.

(%)

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

(mm)

4.18

3.42

3.98

4.45

4.85

4.80

5.27

6.22

7.16

8.11

8.34

8.34

8.34

8.34

8.34

8.34

8.34

-

Allow. (mm)

0.83

0.03

0.55

0.90

1.22

0.98

1.26

1.83

2.41

2.98

2.85

2.62

2.26

1.91

1.55

1.19

0.82

-

Sheet 5 of 11

CALCULATION OF PIPE WALL THICKNESS FOR WELDED & SMLS PIPE

PROJECT NAME

SERVICE CLASS

COR. ALL.(CA)

:

:

:

PIPE PROPERTIES:

Size (In.) Specification

1/2 ~ 24

A106 GR. B

Size (In.)

P

T

S

Y

1/2 ~ 24

RCC OFF GAS TO PROPYLENE PROJECT

A1N

3.2

(MM)

Weld Type

SMLS

Joint Eff.(E)

1

[F1]

(kg/cm2)

(Oc)

(kg/cm2)

20

38

1406

0.4

[F1]

EQUATION :

(ASME B31.3)

WHERE,

t

D

S

P

T

Y

CA

E

P.D

t=

+ CA

2(S.E + P.Y)

NPS

(Inch.)

0.5

0.75

1

1.5

2

3

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

D

(mm)

21.3

26.7

33.4

48.3

60.3

88.9

114.3

168.3

219.1

273.1

323.9

355.6

406.4

457

508

559

610

660

711

762

813

864

914

965

1016

1067

1118

1168

1219

Design

Condition

96675475.xls.ms_office A1N

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

Calc. Thick.

t (mm)

3.35

3.39

3.44

3.54

3.63

3.83

4.01

4.39

4.75

5.13

5.49

5.71

6.07

6.43

6.79

7.15

7.51

-

= PRESSURE DESIGN THICKNESS

= OUTSIDE DIAMETER OF PIPE

= ALLOWABLE STRESS OF PIPE

= DESIGN PRESSURE

= DESIGN TEMPERATURE

= FACTOR

= CORROSION ALLOWANCE

= WELDING JOINT FACTOR

Nominal Thick.

SCH. NO.

S-160

S-80

S-80

S-80

S-80

S-40

S-40

S-40

S-40

S-40

STD

STD

STD

STD

STD

STD

STD

(mm)

4.78

3.91

4.55

5.08

5.54

5.49

6.02

7.11

8.18

9.27

9.53

9.53

9.53

9.53

9.53

9.53

9.53

-

Thick. Tol.

Min. Thick

Thick.

(%)

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

(mm)

4.18

3.42

3.98

4.45

4.85

4.80

5.27

6.22

7.16

8.11

8.34

8.34

8.34

8.34

8.34

8.34

8.34

-

Allow. (mm)

0.83

0.03

0.55

0.90

1.22

0.98

1.26

1.83

2.41

2.98

2.85

2.62

2.26

1.91

1.55

1.19

0.82

-

Sheet 6 of 11

CALCULATION OF PIPE WALL THICKNESS FOR WELDED & SMLS PIPE

PROJECT NAME

SERVICE CLASS

COR. ALL.(CA)

:

:

:

PIPE PROPERTIES:

Size (In.) Specification

1/2 ~ 24

A106 GR. B

Size (In.)

P

T

S

Y

1/2 ~ 24

RCC OFF GAS TO PROPYLENE PROJECT

A1NR

3.2

(MM)

Weld Type

SMLS

Joint Eff.(E)

1

[F1]

(kg/cm2)

(Oc)

(kg/cm2)

20

38

1406

0.4

[F1]

EQUATION :

(ASME B31.3)

WHERE,

t

D

S

P

T

Y

CA

E

P.D

t=

+ CA

2(S.E + P.Y)

NPS

(Inch.)

0.5

0.75

1

1.5

2

3

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

D

(mm)

21.3

26.7

33.4

48.3

60.3

88.9

114.3

168.3

219.1

273.1

323.9

355.6

406.4

457

508

559

610

660

711

762

813

864

914

965

1016

1067

1118

1168

1219

Design

Condition

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

96675475.xls.ms_office A1NR

Calc. Thick.

t (mm)

3.35

3.39

3.44

3.54

3.63

3.83

4.01

4.39

4.75

5.13

5.49

5.71

6.07

6.43

6.79

7.15

7.51

-

= PRESSURE DESIGN THICKNESS

= OUTSIDE DIAMETER OF PIPE

= ALLOWABLE STRESS OF PIPE

= DESIGN PRESSURE

= DESIGN TEMPERATURE

= FACTOR

= CORROSION ALLOWANCE

= WELDING JOINT FACTOR

Nominal Thick.

SCH. NO.

S-160

S-80

S-80

S-80

S-80

S-40

S-40

S-40

S-40

S-40

STD

STD

STD

STD

STD

STD

STD

(mm)

4.78

3.91

4.55

5.08

5.54

5.49

6.02

7.11

8.18

9.27

9.53

9.53

9.53

9.53

9.53

9.53

9.53

-

Thick. Tol.

Min. Thick

Thick.

(%)

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

(mm)

4.18

3.42

3.98

4.45

4.85

4.80

5.27

6.22

7.16

8.11

8.34

8.34

8.34

8.34

8.34

8.34

8.34

-

Allow. (mm)

0.83

0.03

0.55

0.90

1.22

0.98

1.26

1.83

2.41

2.98

2.85

2.62

2.26

1.91

1.55

1.19

0.82

-

Sheet 7 of 11

CALCULATION OF PIPE WALL THICKNESS FOR WELDED & SMLS PIPE

PROJECT NAME

SERVICE CLASS

COR. ALL.(CA)

:

:

:

PIPE PROPERTIES:

Size (In.) Specification

1/2 ~ 24

30

36

Weld Type

SMLS

EFW

EFW

A333 GR. 6

A671 GR. CC60 CL.22

A671 GR. CC60 CL.22

Size (In.)

P

T

S

Y

RCC OFF GAS TO PROPYLENE PROJECT

A2A

1.6

(MM)

1/2 ~ 24

30

36

20

38

1406

0.4

20

38

1406

0.4

20

38

1406

0.4

[F1]

[F2]

[F3]

EQUATION :

(ASME B31.3)

+ CA

2(S.E + P.Y)

D

(mm)

21.3

26.7

33.4

48.3

60.3

88.9

114.3

168.3

219.1

273.1

323.9

355.6

406.4

457

508

559

610

660

711

762

813

864

914

965

1016

1067

1118

1168

1219

[F1]

[F2]

[F3]

(kg/cm2)

(Oc)

(kg/cm2)

t

D

S

P

T

Y

CA

E

P.D

NPS

1

1

1

WHERE,

t=

(Inch.)

0.5

0.75

1

1.5

2

3

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

Joint Eff.(E)

Design

Condition

96675475.xls.ms_office A2A

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F2

F3

Calc. Thick.

t (mm)

1.75

1.79

1.84

1.94

2.03

2.23

2.41

2.79

3.15

3.53

3.89

4.11

4.47

4.83

5.19

5.55

5.91

6.99

8.06

-

= PRESSURE DESIGN THICKNESS

= OUTSIDE DIAMETER OF PIPE

= ALLOWABLE STRESS OF PIPE

= DESIGN PRESSURE

= DESIGN TEMPERATURE

= FACTOR

= CORROSION ALLOWANCE

= WELDING JOINT FACTOR

Nominal Thick.

SCH. NO.

S-80

S-80

S-80

S-80

S-80

S-40

S-40

S-40

S-40

S-40

STD

STD

STD

STD

STD

STD

STD

STD

STD

(mm)

3.73

3.91

4.55

5.08

5.54

5.49

6.02

7.11

8.18

9.27

9.53

9.53

9.53

9.53

9.53

9.53

9.53

9.53

9.53

-

Thick. Tol.

Min. Thick

Thick.

(%)

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

(mm)

3.26

3.42

3.98

4.45

4.85

4.80

5.27

6.22

7.16

8.11

8.34

8.34

8.34

8.34

8.34

8.34

8.34

9.23

9.23

-

Allow. (mm)

0.3 MM

0.3 MM

1.51

1.63

2.15

2.50

2.82

2.58

2.86

3.43

4.01

4.58

4.45

4.22

3.86

3.51

3.15

2.79

2.42

2.24

1.17

-

Sheet 8 of 11

CALCULATION OF PIPE WALL THICKNESS FOR WELDED & SMLS PIPE

PROJECT NAME

SERVICE CLASS

COR. ALL.(CA)

:

:

:

PIPE PROPERTIES:

Size (In.) Specification

1/2 ~ 2

3 ~ 24

30

Weld Type

SMLS

EFW

EFW

A312 GR. TP 304

A312 GR. TP 304

A358 GR. 304, DW

Size (In.)

P

T

S

Y

RCC OFF GAS TO PROPYLENE PROJECT

A21L

0

(MM)

1/2 ~ 2

3 ~ 24

30

19

38

1406

0.4

19

38

1406

0.4

19

38

1406

0.4

[F1]

[F2]

[F3]

EQUATION :

(ASME B31.3)

+ CA

2(S.E + P.Y)

D

(mm)

21.3

26.7

33.4

48.3

60.3

88.9

114.3

168.3

219.1

273.1

323.9

355.6

406.4

457

508

559

610

660

711

762

813

864

914

965

1016

1067

1118

1168

1219

[F1]

[F2]

[F3]

(kg/cm2)

(Oc)

(kg/cm2)

t

D

S

P

T

Y

CA

E

P.D

NPS

1

0.8

0.85

WHERE,

t=

(Inch.)

0.5

0.75

1

1.5

2

3

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

Joint Eff.(E)

Design

Condition

F1

F1

F1

F1

F1

F2

F2

F2

F2

F2

F2

F2

F2

F2

F2

F2

F2

F3

96675475.xls.ms_office A21L

Calc. Thick.

t (mm)

0.14

0.18

0.22

0.32

0.41

0.75

0.96

1.41

1.84

2.29

2.72

2.98

3.41

3.83

4.26

4.69

5.12

6.02

-

= PRESSURE DESIGN THICKNESS

= OUTSIDE DIAMETER OF PIPE

= ALLOWABLE STRESS OF PIPE

= DESIGN PRESSURE

= DESIGN TEMPERATURE

= FACTOR

= CORROSION ALLOWANCE

= WELDING JOINT FACTOR

Nominal Thick.

SCH. NO.

S-40S

S-40S

S-40S

S-40S

S-40S

S-10S

S-10S

S-10S

S-10S

S-10S

S-10S

S-10S

S-10S

S-10S

S-10S

S-10S

S-10S

S-10S

(mm)

2.77

2.87

3.38

3.68

3.91

3.05

3.05

3.40

3.76

4.19

4.57

4.78

4.78

4.78

5.54

5.54

6.35

7.92

-

Thick. Tol.

Min. Thick

Thick.

(%)

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

(mm)

2.42

2.51

2.96

3.22

3.42

2.67

2.67

2.98

3.29

3.67

4.00

4.18

4.18

4.18

4.85

4.85

5.56

7.62

-

Allow. (mm)

0.3 MM

2.28

2.33

2.73

2.90

3.02

1.92

1.71

1.56

1.45

1.38

1.28

1.20

0.77

0.35

0.59

0.16

0.44

1.60

-

Sheet 9 of 11

CALCULATION OF PIPE WALL THICKNESS FOR WELDED & SMLS PIPE

PROJECT NAME

SERVICE CLASS

COR. ALL.(CA)

:

:

:

PIPE PROPERTIES:

Size (In.) Specification

1/2 ~ 24

Weld Type

SMLS

A335 GR. P11

Size (In.)

P

T

S

Y

RCC OFF GAS TO PROPYLENE PROJECT

A54A

1.6

(MM)

Joint Eff.(E)

1

[F1]

1/2 ~ 24

2

20.2

420

1057.41

0.4

(kg/cm )

O

( c)

(kg/cm2)

[F1]

EQUATION :

(ASME B31.3)

WHERE,

t

D

S

P

T

Y

CA

E

P.D

t=

+ CA

2(S.E + P.Y)

NPS

(Inch.)

0.5

0.75

1

1.5

2

3

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

D

(mm)

21.3

26.7

33.4

48.3

60.3

88.9

114.3

168.3

219.1

273.1

323.9

355.6

406.4

457

508

559

610

660

711

762

813

864

914

965

1016

1067

1118

1168

1219

Design

Condition

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

96675475.xls.ms_office A54A

Calc. Thick.

t (mm)

1.80

1.85

1.92

2.06

2.17

2.44

2.68

3.20

3.68

4.19

4.67

4.97

5.45

5.93

6.42

6.90

7.38

-

= PRESSURE DESIGN THICKNESS

= OUTSIDE DIAMETER OF PIPE

= ALLOWABLE STRESS OF PIPE

= DESIGN PRESSURE

= DESIGN TEMPERATURE

= FACTOR

= CORROSION ALLOWANCE

= WELDING JOINT FACTOR

Nominal Thick.

SCH. NO.

S-80

S-80

S-80

S-80

S-80

S-40

S-40

S-40

S-40

S-40

STD

STD

STD

STD

STD

STD

STD

(mm)

3.73

3.91

4.55

5.08

5.54

5.49

6.02

7.11

8.18

9.27

9.53

9.53

9.53

9.53

9.53

9.53

9.53

-

Thick. Tol.

Min. Thick

Thick.

(%)

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

(mm)

3.26

3.42

3.98

4.45

4.85

4.80

5.27

6.22

7.16

8.11

8.34

8.34

8.34

8.34

8.34

8.34

8.34

-

Allow. (mm)

1.46

1.57

2.06

2.39

2.68

2.36

2.58

3.03

3.48

3.92

3.67

3.37

2.89

2.41

1.92

1.44

0.96

-

Sheet 10 of 11

CALCULATION OF PIPE WALL THICKNESS FOR WELDED & SMLS PIPE

PROJECT NAME

SERVICE CLASS

COR. ALL.(CA)

:

:

:

PIPE PROPERTIES:

Size (In.) Specification

1/2 ~ 24

A106 GR. B

Size (In.)

P

T

S

Y

1/2 ~ 24

RCC OFF GAS TO PROPYLENE PROJECT

A1NRX

3.2

(MM)

Weld Type

SMLS

Joint Eff.(E)

1

[F1]

(kg/cm2)

(Oc)

(kg/cm2)

20

38

1406

0.4

[F1]

EQUATION :

(ASME B31.3)

WHERE,

t

D

S

P

T

Y

CA

E

P.D

t=

+ CA

2(S.E + P.Y)

NPS

(Inch.)

0.5

0.75

1

1.5

2

3

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

D

(mm)

21.3

26.7

33.4

48.3

60.3

88.9

114.3

168.3

219.1

273.1

323.9

355.6

406.4

457

508

559

610

660

711

762

813

864

914

965

1016

1067

1118

1168

1219

Design

Condition

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

F1

96675475.xls.ms_office A1NRX

Calc. Thick.

t (mm)

3.35

3.39

3.44

3.54

3.63

3.83

4.01

4.39

4.75

5.13

5.49

5.71

6.07

6.43

6.79

7.15

7.51

-

= PRESSURE DESIGN THICKNESS

= OUTSIDE DIAMETER OF PIPE

= ALLOWABLE STRESS OF PIPE

= DESIGN PRESSURE

= DESIGN TEMPERATURE

= FACTOR

= CORROSION ALLOWANCE

= WELDING JOINT FACTOR

Nominal Thick.

SCH. NO.

S-160

S-80

S-80

S-80

S-80

S-40

S-40

S-40

S-40

S-40

STD

STD

STD

STD

STD

STD

STD

(mm)

4.78

3.91

4.55

5.08

5.54

5.49

6.02

7.11

8.18

9.27

9.53

9.53

9.53

9.53

9.53

9.53

9.53

-

Thick. Tol.

Min. Thick

Thick.

(%)

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

(mm)

4.18

3.42

3.98

4.45

4.85

4.80

5.27

6.22

7.16

8.11

8.34

8.34

8.34

8.34

8.34

8.34

8.34

-

Allow. (mm)

0.83

0.03

0.55

0.90

1.22

0.98

1.26

1.83

2.41

2.98

2.85

2.62

2.26

1.91

1.55

1.19

0.82

-

Sheet 11 of 11

Vous aimerez peut-être aussi

- ASME B36 10M Tableau Des DimensionsDocument2 pagesASME B36 10M Tableau Des DimensionsMichel LupienPas encore d'évaluation

- En 1092-1 PN-16 Steel Pipe Flange - ValviasDocument5 pagesEn 1092-1 PN-16 Steel Pipe Flange - ValviasHoria ZecheruPas encore d'évaluation

- API DimensionsDocument2 pagesAPI Dimensionsemmas18Pas encore d'évaluation

- SteelDocument449 pagesSteelmrraee4729Pas encore d'évaluation

- Schedule Table of ASME&SJISDocument3 pagesSchedule Table of ASME&SJISJihwan LeePas encore d'évaluation

- 5-NF EN 10216-2 Tube Sans Soudure Aciers Non Alliés 2014Document95 pages5-NF EN 10216-2 Tube Sans Soudure Aciers Non Alliés 2014Nicolas PELTIER100% (1)

- Estimation NPSH Disponible Rev1Document1 pageEstimation NPSH Disponible Rev1jolofboyPas encore d'évaluation

- Paragraphe Pca Cgem Covid 19Document19 pagesParagraphe Pca Cgem Covid 19Carlos EduardoPas encore d'évaluation

- HDPE Pipe (PE100) - Weight & RateDocument2 pagesHDPE Pipe (PE100) - Weight & RateCivil EngineeringPas encore d'évaluation

- Test CalcDocument13 pagesTest CalcWaqas Waqas100% (1)

- Procedure DP Lala Abdia 8x40 GZ1Document17 pagesProcedure DP Lala Abdia 8x40 GZ1Tayyeb Ouis100% (1)

- Exemple Calcul Epaisseur PipeDocument2 pagesExemple Calcul Epaisseur PipeAB BECH100% (1)

- Miter BendDocument5 pagesMiter BendArindom Kundu100% (1)

- DN02 SM L DS 0019.PDF DataDocument23 pagesDN02 SM L DS 0019.PDF Datasivaguruswamy thangaraj0% (1)

- Supportage TuyauteriesDocument19 pagesSupportage TuyauteriesNguefo StyvePas encore d'évaluation

- Dims Spiral Wound Gaskets EN 1514 (DIN Gaskets)Document5 pagesDims Spiral Wound Gaskets EN 1514 (DIN Gaskets)Emil Florin TutaPas encore d'évaluation

- Note de Calcul Butees Coudes Horizontaux 112Document7 pagesNote de Calcul Butees Coudes Horizontaux 112frfgg1456Pas encore d'évaluation

- Mdnac - Mur de Cloture Note de Calculs Ok1Document17 pagesMdnac - Mur de Cloture Note de Calculs Ok1Chega KitubanzaPas encore d'évaluation

- Poteaux en Béton ArméDocument2 pagesPoteaux en Béton ArméBrahim MabasPas encore d'évaluation

- Abaques de Dimensionnement Pour La Résistance Au Feu Des Solives de Plancher Non Protégées Connectées À Des Dalles Mixtes-1999Document14 pagesAbaques de Dimensionnement Pour La Résistance Au Feu Des Solives de Plancher Non Protégées Connectées À Des Dalles Mixtes-1999sautier_thomasPas encore d'évaluation

- Note de Calcul FondDocument4 pagesNote de Calcul FondMarouane EzzaimPas encore d'évaluation

- NC Xn13-Xn18-Ind BDocument12 pagesNC Xn13-Xn18-Ind BDAKING GAMINGPas encore d'évaluation

- NOTE Calcul Mantaya POUR TIRAGEDocument219 pagesNOTE Calcul Mantaya POUR TIRAGEabdelouahab guedjaliPas encore d'évaluation

- These BilalDocument17 pagesThese BilalYahia BobPas encore d'évaluation

- Exp VentDocument2 pagesExp VentBenhmaida HananPas encore d'évaluation

- Exercice 2 Corrigé VDocument4 pagesExercice 2 Corrigé VrabiiPas encore d'évaluation

- Assemblage Pied de Poteau TronDocument4 pagesAssemblage Pied de Poteau Tronsabaksousou100% (1)

- TOPOGRAPHIE OUED IMEDRI - 1 - TabulationsDocument7 pagesTOPOGRAPHIE OUED IMEDRI - 1 - TabulationsAyoub HoussainePas encore d'évaluation

- Epaisseur Tube Acier & InoxDocument1 pageEpaisseur Tube Acier & InoxMaroiene100% (1)

- Hypothèse de CalculDocument3 pagesHypothèse de CalculRiadh Trabelsi100% (3)

- Poteau en Beton ArmeDocument8 pagesPoteau en Beton ArmeHabibMoussaMohamedPas encore d'évaluation

- Note de Calcul Support Tuyautrie ExecutionDocument12 pagesNote de Calcul Support Tuyautrie ExecutionMed Samai100% (2)

- Note de Calcul Gare de Racleur Depart ExecutionDocument9 pagesNote de Calcul Gare de Racleur Depart ExecutionMed SamaiPas encore d'évaluation

- Poteau AncastréDocument9 pagesPoteau AncastrésoumayaPas encore d'évaluation

- Ansi c37.32-1996Document1 pageAnsi c37.32-1996Addin Ruano100% (1)

- TP #02 Convection Libre Et ForcéeDocument5 pagesTP #02 Convection Libre Et ForcéeMoussa BourenanePas encore d'évaluation

- Pipe Size AsmeDocument2 pagesPipe Size AsmetalparadipakPas encore d'évaluation

- 1035H02C1S PDFDocument8 pages1035H02C1S PDFMohamedPas encore d'évaluation

- Note de Calculs Dalot Du 16 09 2014Document15 pagesNote de Calculs Dalot Du 16 09 2014aladia610Pas encore d'évaluation

- Note de Calcul TribuneDocument88 pagesNote de Calcul TribuneOussama AMARIPas encore d'évaluation

- Examen HydrauliqueDocument6 pagesExamen HydrauliquePaul-Elie DossouPas encore d'évaluation

- Choisir Une Sous-Nuance D'acier PDFDocument7 pagesChoisir Une Sous-Nuance D'acier PDFmihaidelianPas encore d'évaluation

- Accouplement RotexDocument22 pagesAccouplement RotexlordofwarPas encore d'évaluation

- GGGGGGDocument9 pagesGGGGGGMouhaPas encore d'évaluation

- NC080427DP01 - Instabilité Par Flambement Selon EC3Document3 pagesNC080427DP01 - Instabilité Par Flambement Selon EC3DarkedgePas encore d'évaluation

- TD5+Solution Alimentation en Eau PotableDocument8 pagesTD5+Solution Alimentation en Eau Potableabekhti abdelkhalek100% (1)

- Etude Climatique Pour Un Hangar À 2 VersantsDocument30 pagesEtude Climatique Pour Un Hangar À 2 VersantsFarid TataPas encore d'évaluation

- Etude D'un Mur de Soutènement D'un Remblai RoutierDocument12 pagesEtude D'un Mur de Soutènement D'un Remblai RoutierBritany laraPas encore d'évaluation

- Pied de Poteau Articule PDFDocument4 pagesPied de Poteau Articule PDFKarim OuPas encore d'évaluation

- Actions Ponts 2005 2Document65 pagesActions Ponts 2005 2aliouecheamerPas encore d'évaluation

- Itec Bar GT p11fDocument2 pagesItec Bar GT p11fruterboyPas encore d'évaluation

- Standardi ČelikaDocument8 pagesStandardi ČelikaZoran HajdukovPas encore d'évaluation

- 02 Lignes Aeriennes HTADocument30 pages02 Lignes Aeriennes HTANoureddine DibessePas encore d'évaluation

- 24 GRP Tag - DuDocument39 pages24 GRP Tag - DuShreyas GaurPas encore d'évaluation

- EC2PoincDal CorrigéDocument4 pagesEC2PoincDal CorrigéWael MakPas encore d'évaluation

- Cataloguerails 2011 PDFDocument12 pagesCataloguerails 2011 PDFValentin GuillotPas encore d'évaluation

- Etude Du Pont À PoutresDocument149 pagesEtude Du Pont À PoutresGhassen Zarrouk80% (5)

- 1) Evaluation Des Charges de La Toiture Non AccessibleDocument35 pages1) Evaluation Des Charges de La Toiture Non AccessibleAhmadPas encore d'évaluation

- Vérification D'un Poteau Mixte Rectangulaire Suivant L'eurocode 4 Calcul de L'amplification Du 2ème OrdreDocument1 pageVérification D'un Poteau Mixte Rectangulaire Suivant L'eurocode 4 Calcul de L'amplification Du 2ème OrdremakakkPas encore d'évaluation

- Examen Unifié - Béton Armé 2020-2021Document3 pagesExamen Unifié - Béton Armé 2020-2021ouafiyaelPas encore d'évaluation

- Etude Numérique D'un Capteur Solaire Thermique PlanDocument82 pagesEtude Numérique D'un Capteur Solaire Thermique PlanIBrahim Benamara100% (3)

- L Eau Dans Notre Environnement Serie D Exercices Non Corriges 9Document2 pagesL Eau Dans Notre Environnement Serie D Exercices Non Corriges 9Home erriahiPas encore d'évaluation

- Exercice: 1: Année Scolaire 2022/2023Document22 pagesExercice: 1: Année Scolaire 2022/2023Adam StatiPas encore d'évaluation

- TP StatistiqueDocument2 pagesTP StatistiqueHamza GhardanePas encore d'évaluation

- Renforcement PH - Acide Fort Et Tampon 2022Document5 pagesRenforcement PH - Acide Fort Et Tampon 2022GueyePas encore d'évaluation

- CHAPITRE I - Simulateurs en GP - 2021Document9 pagesCHAPITRE I - Simulateurs en GP - 2021Roudaina BenzeguirPas encore d'évaluation

- Meca EPFLDocument38 pagesMeca EPFLNejib Ghazouani100% (1)

- 01-Propriétés Des Différents États de La MatièreDocument8 pages01-Propriétés Des Différents États de La MatièreDaoudiPas encore d'évaluation

- TechniqueDocument8 pagesTechniquepaire animePas encore d'évaluation

- Etude Et Comparaison Entre Un Concentrateur Solaire Parabolique Et Cylindro-Parabolique.Document100 pagesEtude Et Comparaison Entre Un Concentrateur Solaire Parabolique Et Cylindro-Parabolique.Oumayma ElkanouniPas encore d'évaluation

- MGDocument219 pagesMGChiheb Kaaniche100% (1)

- Cours PSVDocument60 pagesCours PSValphaidedjibrillaPas encore d'évaluation

- Source D'informationDocument65 pagesSource D'informationBouz IkramPas encore d'évaluation

- MAEPDocument2 pagesMAEPAkabli YounesPas encore d'évaluation

- Vitoux P. 2008 NanocompositesDocument217 pagesVitoux P. 2008 NanocompositesniebelungenPas encore d'évaluation

- TP N°3Document3 pagesTP N°3Abdelwahab.gfPas encore d'évaluation

- Cours Hydraulique 2Document101 pagesCours Hydraulique 2Yassine Abouelhouda80% (5)

- Introduction Sur Les Mécaniques Des FluidesDocument10 pagesIntroduction Sur Les Mécaniques Des FluidesKhattou MouadPas encore d'évaluation

- Thèse - Ciment PétrolierDocument255 pagesThèse - Ciment PétroliertarekhocinePas encore d'évaluation

- Exp 3&4-1st Law-ClosedDocument4 pagesExp 3&4-1st Law-ClosedChakib MedPas encore d'évaluation

- Pfe GC 0206Document132 pagesPfe GC 0206Ahmed El EuchiPas encore d'évaluation

- Complexes ElAlemDocument14 pagesComplexes ElAlemayoub dahbiPas encore d'évaluation

- L'aluminium Dans Le BTPDocument43 pagesL'aluminium Dans Le BTPSamer BousabaPas encore d'évaluation

- Structure Amel LydiaDocument24 pagesStructure Amel Lydialydia saoudiPas encore d'évaluation

- Biochimie Structurale G2 BM SyllabusDocument97 pagesBiochimie Structurale G2 BM Syllabuslaurentkalambayi850Pas encore d'évaluation

- HRG 191222 Update1Document15 pagesHRG 191222 Update1Aji YudhaPas encore d'évaluation

- Info 4 MecanicaDocument10 pagesInfo 4 MecanicajosetoapantaPas encore d'évaluation

- Chimie1 Atomistique 2020 Chapitre2Document32 pagesChimie1 Atomistique 2020 Chapitre2Dang Hoang DungPas encore d'évaluation

- ForageDocument35 pagesForagejohn ngandouPas encore d'évaluation

- Fiche Technique Double VitrageDocument18 pagesFiche Technique Double VitrageTiouti Abderrahmane100% (1)