Académique Documents

Professionnel Documents

Culture Documents

TDS - Super Gel-X

Transféré par

Fabián Alejandro Araya HernándezDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TDS - Super Gel-X

Transféré par

Fabián Alejandro Araya HernándezDroits d'auteur :

Formats disponibles

l i n i n g T E C h n O l O g i E s | r E M E D i AT i O n T E C h n O l O g i E s | D r i l l i n g s Y s T E M s | B u i l D i n g E n V E l O P E | C O n T r A C T i n g s E r V i C E s

TECHniCal DaTa

sUpEr gEl-x

HigH YiElD BEnToniTE

DEsCripTion

suPEr gEl-X is an easy mixing, high viscosity 200 bbl yield freshwater drilling fluid produced from the highest grade Wyoming sodium bentonite. suPEr gEl-X is certified to nsF/Ansi standard 60, Drinking Water Treatment Chemicals - health Effects.

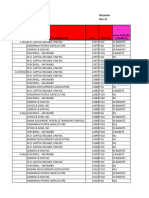

drilling fluid and slurry trenching super gel-x mixing ratio in pounds (kg) per 100 gallons (380 liters) of water Condition normal Conditions sand and gravel Fluid loss Control Property Viscosity FAnn 600 rpm Viscosity FAnn 6 rpm Viscosity FAnn 3 rpm Yield - 42 gal bbl of 15 cps slurry/ton Marsh Funnel, seconds/quart Apparent Viscosity (AV) Plastic Viscosity (PV) Yeild Point, lb/100 ft2 Filtrate, 30 minutes @ 100 psi, mi Filter Cake, in ph general prOperties Property Moisture % Free swell Plate Water Absorption specific gravity Bulk Density noncompacted Bulk Density Compacted grit % (<75 micron) Particle sizing Typical Value 7.5% 29 ml 810.05% 2.5 g/cc 53 lbs/ft3 72 lbs/ft3 2.8% 70% Min passing #200 mesh sieve specification/Procedure ACC TP-2006 AsTM D-5890 AsTM E946-92 generally recognized ACC TP-1005 ACC TP-1005 4.0% Max - ACC TP-2004 ACC TP-1015 lbs (kg) of suPEr gEl-X 15 - 25 lbs (7 - 11 kg) 25 - 35 lbs (11 - 16 kg) 35 - 40 lbs (16 - 22.5 kg) Typical Value 35 cps 14 cps 13 cps 217 41 seconds 17 5 21 25 ml 2/32 9.0 % solids 1.8 - 2.9% 2.9 - 4.0% 4.0 - 4.6% specification/Procedure 30 cps Min - ACC TP-2055 ACC TP-2055 ACC TP-2055

rECommEnDED UsE CHaraCTErisTiCs

May be used for all types of freshwater mud rotary drilling.

slurry prOpOrties - 2.78% sOlids

Cools and lubricates bit helps prevent loss circulation highly concentrated for maximum yield Mixes quickly and easily reduces solids and increases lifting power removes cuttings stabilizes boreholes helps prevent loss circulation

D r i l l i n g F lu i D s

200 Min - ACC TP-2001 ACC TP-1014 15 Min - ACC TP-2005 ACC TP-2005 ACC TP-2005 ACC TP-2003 n/A ACC TP-1018

mixing anD appliCaTion

Mixing ratios are based on 200 bbl yield material using freshwater. level of water purity will affect bentonite performance. Prior to mixing, acidic and hard water should be treated with sODA Ash to a ph of 8.5-9.5. For best results, add suPEr gEl-X slowly through a jet/hopper mixer.

paCkaging

50 lb (22.7 kg) bags, 48 per pallet, 1 ton or 2 ton supersacks, or bulk. All pallets are plastic-wrapped.

2870 Forbs Avenue, Hoffman Estates, IL 60192 847.851.1800 | 800.527.9948 | cetco.com/dpg

iMPOrTAnT: The information contained herein supersedes all previous versions, and is believed to be accurate and reliable. For the most up-to-date information, please visit cetco.com/dpg. CETCO accepts no responsibility for the results obtained through the application of this information. All weights are approximate. CETCO reserves the right to update information without notice. rEV 1/11

2011 CETCO

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Collet Chuck Catalog 2007 PDFDocument28 pagesCollet Chuck Catalog 2007 PDFAlexandru Marius-catalinPas encore d'évaluation

- Essential Statistics For The Behavioral Sciences 1st Edition Privitera Solutions ManualDocument7 pagesEssential Statistics For The Behavioral Sciences 1st Edition Privitera Solutions Manualspinifexcandock8zf100% (26)

- Forrester Roi StudyDocument30 pagesForrester Roi StudymcgettsPas encore d'évaluation

- Binder Modul WMS 10Document52 pagesBinder Modul WMS 10sandhiakhmadPas encore d'évaluation

- Abstract (Lab 2) Ionization ConstantDocument12 pagesAbstract (Lab 2) Ionization Constantmirdza94Pas encore d'évaluation

- Effect of Temperature on Chemical ReactionDocument8 pagesEffect of Temperature on Chemical ReactionnajihahPas encore d'évaluation

- Ne7207 Nis Unit 2 Question BankDocument2 pagesNe7207 Nis Unit 2 Question BankalgatesgiriPas encore d'évaluation

- Nov. AbwDocument50 pagesNov. Abwjbyarkpawolo70Pas encore d'évaluation

- Math Tutoring Announcement for 4th Year Literary StudentsDocument5 pagesMath Tutoring Announcement for 4th Year Literary Studentsabed azzamPas encore d'évaluation

- Self-Coached Climber - The Guide To Movem - Dan M (1) HagueDocument376 pagesSelf-Coached Climber - The Guide To Movem - Dan M (1) HagueBill Frisch100% (1)

- Si™ Command Language (SCL) Software Manual: For 1240I 3540I 7080I Bl7080I Blsi7080 Si-100 Si2035 Si3540 Si5580Document23 pagesSi™ Command Language (SCL) Software Manual: For 1240I 3540I 7080I Bl7080I Blsi7080 Si-100 Si2035 Si3540 Si5580Agenor CarvalhoPas encore d'évaluation

- 11 Risks and Rates of Return KEYDocument12 pages11 Risks and Rates of Return KEYkPas encore d'évaluation

- IOP Conference Series: Materials Science and EngineeringDocument9 pagesIOP Conference Series: Materials Science and EngineeringMahesh MPas encore d'évaluation

- Impact of GIC On Power TransformersDocument141 pagesImpact of GIC On Power TransformersAkash Verma100% (1)

- PSD60-2R: Operation ManualDocument22 pagesPSD60-2R: Operation ManualOscar SantanaPas encore d'évaluation

- Design of Weirs and BarragesDocument42 pagesDesign of Weirs and BarragesDivyaSlp100% (2)

- IMME19 Schedule PDFDocument39 pagesIMME19 Schedule PDFVikram JainPas encore d'évaluation

- Kollidon 30 Technical InformationDocument10 pagesKollidon 30 Technical InformationhomarearisugawaPas encore d'évaluation

- Job 1 SksoDocument5 pagesJob 1 SksoFajAr OkTaPas encore d'évaluation

- XI-Opt. Syllabus (2023-24)Document29 pagesXI-Opt. Syllabus (2023-24)INDERDEEPPas encore d'évaluation

- Artificial Intelligence in The GPs Office A Retrospective Study On Diagnostic AccuracyDocument13 pagesArtificial Intelligence in The GPs Office A Retrospective Study On Diagnostic Accuracymarj611582Pas encore d'évaluation

- Effect of Bond Administration On Construction Project DeliveryDocument7 pagesEffect of Bond Administration On Construction Project DeliveryOlefile Mark MolokoPas encore d'évaluation

- Proportional Chopper Amplifier VB-3A: Min MaxDocument5 pagesProportional Chopper Amplifier VB-3A: Min MaxryujoniPas encore d'évaluation

- PID CONTROL SIMULATIONDocument6 pagesPID CONTROL SIMULATIONadrianordsPas encore d'évaluation

- Design of Three Span Steel Composite FlyoverDocument85 pagesDesign of Three Span Steel Composite FlyoverStructural SpreadsheetsPas encore d'évaluation

- Final Project Regenerative BrakingDocument6 pagesFinal Project Regenerative Brakingdims irifiyinPas encore d'évaluation

- Malpresentation and MalpositionDocument33 pagesMalpresentation and MalpositionPeprah Ondiba100% (1)

- Inductive Proximity Sensors: Brett Anderson ECE 5230 Assignment #1Document27 pagesInductive Proximity Sensors: Brett Anderson ECE 5230 Assignment #1Rodz Gier JrPas encore d'évaluation

- Jurnal IlmiahDocument12 pagesJurnal IlmiahROSSITAPas encore d'évaluation

- Lecture 01Document18 pagesLecture 01priyasonu049Pas encore d'évaluation