Académique Documents

Professionnel Documents

Culture Documents

User Manual Forming Machine

Transféré par

Tony GohilDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

User Manual Forming Machine

Transféré par

Tony GohilDroits d'auteur :

Formats disponibles

Electro power Engineering RAJKOT

Use manual of Roll forming machine

SHREE HARI INDUSTRY. RAJKOT

With Regards, Mr.Kashyap Pithva | Electro Power Engineering| T +91 9510687577 | +91 281 2230678 | No:6,Divya Park,Opp:Mavdi fire Station,Mavdi Main Road,Rajkot-360004 | Gujarat | India | E:power.electro@yahoo.com | www.electropower.in|

AN ISO 9001:2008 CERTIFIED COMPANY www.electropower.in

Components:PLC:Make: - Delta Technical specification:- (1) DVP-14SS(8DI/6DO Transistor) (2) DVP-16 (8DI/8DO) HMI: Make: - Kinco Technical specification:-7Inch color Touch Screen HMI AC Drive:Make: - AC Tech Technical specification:- (1) 10HP 3 PH 60Hz (2) 1HP 3 PH 60Hz AC Servo Motor and Driver:Make: - AC Tech Technical specification:- 750Watt 1Phase 60Hz Contactor and MCB and OLR:Make: - ABB SMPS: Make: - Omron Technical specification:- 24 V @ 4.5Amp Terminal:Make: L max Technical specification:-2.5sqmm and 5sqmm Wire:Make: Finolex Technical specification:-0.75sqmm for control

AN ISO 9001:2008 CERTIFIED COMPANY www.electropower.in

Panel fabrication:-

Panel wiring: Detail Drawing is attach with this file

SET

v RUN

SE T ^ SET

O LR

OLR

v RUN

SE T ^ SET

1 HP AC DRI VE

1 0H P AC DRI VE

SERVO DR IVE

AN ISO 9001:2008 CERTIFIED COMPANY www.electropower.in

Operating detail of forming panel: Whole manual Push button is mounted in front green Push button panel in desk. Touch screen control having Two mode of operation 1. Manual control mode and 2. Auto control mode

Process Instruments:In This forming machine having control system as describe as below This forming having 1) D Coiler motor 1HP with AC Drive. 2) Feeder servo motor 750watt for accurate length feeding. 3) Compressor motor for operating pneumatic cylinder. 4) Pneumatic cylinder control solenoid for punching. 5) Loop zone for manage length and continues forming process. having two proxy sensor for upper limit and lower limit 6) Forming machine motor 10HP with AC Drive

AN ISO 9001:2008 CERTIFIED COMPANY www.electropower.in

7) Having length accuracy we use two limit switch one for slow speed and second for stop of forming process so we get accurate length of you product. 8) Having hydraulic cutting for length cutting of bar. Having hydraulic motor and we use two limit switch for sensing cutting sequence. Auto cycle description:First you have to set frequency and pulse in servo screen before start auto cycle. In auto cycle we having two Touch button One for auto/manual and one for auto cycle start and first for you have to press both then auto cycle start at that time compressor motor and hydraulic motor start at initially and then D-Coiler and servo start as per pulse and frequency given after completing length by servo hydraulic punching jack will down and punch on that after punch up input come then again D-coiler and servo start and process rapidly up to loop bottom sensor sensing. When bottom loop sensor sensing, forming start working and up to upper loop sensing. As per mounting length sensor for slow speed and final length forming slow when slow sensor sensing and stop while second end sensor activated and same time Hydraulic jack down for cutting and that jack having two sensor for up/down of jack. In auto this process continues working.

AN ISO 9001:2008 CERTIFIED COMPANY www.electropower.in

Vous aimerez peut-être aussi

- Proposal HMG-350JM SXKH Die Spotting PressDocument9 pagesProposal HMG-350JM SXKH Die Spotting Press846213Pas encore d'évaluation

- Linear Bearings-HiwinDocument0 pageLinear Bearings-Hiwinqi_1986Pas encore d'évaluation

- 132 EC - A 10 - VIT - Chennai - Meggger & Multimeter - JE QTNDocument4 pages132 EC - A 10 - VIT - Chennai - Meggger & Multimeter - JE QTNDr. Chandan SharmaPas encore d'évaluation

- Qoutation of Double Layer Roof Sheet Roll Forming MachineDocument8 pagesQoutation of Double Layer Roof Sheet Roll Forming MachineJHON SEGURA GONZALEZPas encore d'évaluation

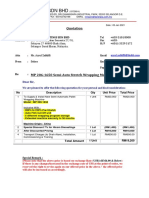

- Quot 1 Aditi Vinod PDFDocument5 pagesQuot 1 Aditi Vinod PDFVasoya Manoj0% (1)

- 12 MM Capacity 4-Roll Hydraulic Double Pinch Cum Pyramid Type Plate Bending MachineDocument19 pages12 MM Capacity 4-Roll Hydraulic Double Pinch Cum Pyramid Type Plate Bending MachineImamul HaquePas encore d'évaluation

- 5 - Double Layer Roll Forming MachineDocument6 pages5 - Double Layer Roll Forming MachineJHON SEGURA GONZALEZPas encore d'évaluation

- Oree Laser Quotation of or-PG 6025 12kw MAX (Three in One) Cynthia 20230105 - 230105 - 225357Document17 pagesOree Laser Quotation of or-PG 6025 12kw MAX (Three in One) Cynthia 20230105 - 230105 - 225357iqbal husseinPas encore d'évaluation

- Low Table/table Top Semi Automatic Carton Strapping Machine: Wz-443 GF, Naraina Village, New Delhi - 110028Document2 pagesLow Table/table Top Semi Automatic Carton Strapping Machine: Wz-443 GF, Naraina Village, New Delhi - 110028Shekhar SrivassPas encore d'évaluation

- CCL 108sg PBXDocument13 pagesCCL 108sg PBXpratipPas encore d'évaluation

- JRF-C&Z 70 - 300Document16 pagesJRF-C&Z 70 - 300Ravi ChandranPas encore d'évaluation

- ControlPanel MPC210 PriceListDocument4 pagesControlPanel MPC210 PriceListNamQuyPas encore d'évaluation

- Quot 15138801Document2 pagesQuot 15138801Anandha PadmanabhanPas encore d'évaluation

- Structural Steel Design DetailsDocument7 pagesStructural Steel Design DetailsJanya AssociatesPas encore d'évaluation

- XTR 0107 Rev1Document6 pagesXTR 0107 Rev1anand shekhawatPas encore d'évaluation

- No.:13Name:QNF450 Horizontal Packaging MachineDocument2 pagesNo.:13Name:QNF450 Horizontal Packaging MachineAmin Ali AminPas encore d'évaluation

- 5Kw Grid-Tied Hybrid PV System: Item No. Description Qty UnitDocument4 pages5Kw Grid-Tied Hybrid PV System: Item No. Description Qty UnitJess BergoniaPas encore d'évaluation

- Experimental and Computational Investigation of The Roll Forming ProcessDocument148 pagesExperimental and Computational Investigation of The Roll Forming Processakhilesh120Pas encore d'évaluation

- Quotation of Packaging MachineDocument2 pagesQuotation of Packaging MachineRavindra GuptaPas encore d'évaluation

- Project ReportDocument9 pagesProject ReportMohammad Shahid KhanPas encore d'évaluation

- Mars Quotation of Chicken Cage Welding Machine DP-AW-1200HDocument10 pagesMars Quotation of Chicken Cage Welding Machine DP-AW-1200HRobert AdrianPas encore d'évaluation

- High Speed Z Purlin MachineDocument6 pagesHigh Speed Z Purlin MachineChris RishbinPas encore d'évaluation

- 3 HP CompressorDocument3 pages3 HP Compressorgokul saravananPas encore d'évaluation

- Quotation For Coil WindingDocument7 pagesQuotation For Coil WindingserkaneyupPas encore d'évaluation

- Krishna ElectronicsDocument10 pagesKrishna Electronicsrishi070881100% (1)

- Techno-Commercial Proposal - Slitting Machine - Rev 01Document9 pagesTechno-Commercial Proposal - Slitting Machine - Rev 01Chandru ChristurajPas encore d'évaluation

- 421DG180A01Document51 pages421DG180A01Atiq_2909Pas encore d'évaluation

- CNC Gantry Milling Machine-160924Document2 pagesCNC Gantry Milling Machine-160924Cristian PavanPas encore d'évaluation

- SD300 Induction Heating Power Supply IGBT Control Card V2.0Document16 pagesSD300 Induction Heating Power Supply IGBT Control Card V2.0Arleth TrejoPas encore d'évaluation

- S & S Polymers. Tamil Nadu IndiaDocument10 pagesS & S Polymers. Tamil Nadu IndiaS & S PolymersPas encore d'évaluation

- Unit List ETPDocument13 pagesUnit List ETPAshishRaviPas encore d'évaluation

- Cut To Length TAIWANDocument18 pagesCut To Length TAIWANCentral InvertechPas encore d'évaluation

- NOVA Servo CatalogueDocument7 pagesNOVA Servo CatalogueDip Narayan BiswasPas encore d'évaluation

- MR - Samaksh Jhalani Machinery-FinalDocument45 pagesMR - Samaksh Jhalani Machinery-FinalSamaksh JhalaniPas encore d'évaluation

- Tube Mill PatraDocument30 pagesTube Mill PatraRitz HindustanPas encore d'évaluation

- Q1089 - Offer For Supply of Screw ConveyorDocument2 pagesQ1089 - Offer For Supply of Screw ConveyorashokPas encore d'évaluation

- 450VS+ Paper Cutting Machine QuotationDocument2 pages450VS+ Paper Cutting Machine QuotationnoriPas encore d'évaluation

- Part List PUTR + CAPACITOR BANK 250KVAR TRUST BUILDINGDocument2 pagesPart List PUTR + CAPACITOR BANK 250KVAR TRUST BUILDINGReynaldo TambaPas encore d'évaluation

- Gen - Assembly Dwg-Energy ChainDocument2 pagesGen - Assembly Dwg-Energy ChainJohn Renzel Rivera IIIPas encore d'évaluation

- Packing MachineDocument9 pagesPacking Machinemiha3la33Pas encore d'évaluation

- Quotation of 10 Ton For July-2013Document5 pagesQuotation of 10 Ton For July-2013SyedPas encore d'évaluation

- Copper & Aluminium Rod Continuous CastingDocument5 pagesCopper & Aluminium Rod Continuous CastingYonathan JonathanPas encore d'évaluation

- GWEIKE Quotation of 4020CRDocument18 pagesGWEIKE Quotation of 4020CRFY BaylonPas encore d'évaluation

- Quotation: 1.0. Automatic Spices Powder Packing MachineDocument3 pagesQuotation: 1.0. Automatic Spices Powder Packing MachineDnyaneshwar Dattatraya PhadatarePas encore d'évaluation

- TLD56 1325 Vacuum Table - CNC Router MachineDocument1 pageTLD56 1325 Vacuum Table - CNC Router MachineBroe CasPas encore d'évaluation

- Tube Bundle Detail Drawing 1200-E-4006: Document TitleDocument2 pagesTube Bundle Detail Drawing 1200-E-4006: Document TitleAnwar SadatPas encore d'évaluation

- Roll Forming Machine SpécificationDocument7 pagesRoll Forming Machine SpécificationIkram SarghiniPas encore d'évaluation

- Sintech Pumps For Sugar Processing PlantDocument18 pagesSintech Pumps For Sugar Processing Plantsahildhingra100% (2)

- Vibrating MotorDocument10 pagesVibrating MotorWahyu APas encore d'évaluation

- Rexnord Product Catalogue 2013 PDFDocument6 pagesRexnord Product Catalogue 2013 PDFMahasweta MitraPas encore d'évaluation

- Section MillDocument7 pagesSection MillArth SumaguePas encore d'évaluation

- Rotomotive Motor ManualDocument19 pagesRotomotive Motor ManualMiki SinghPas encore d'évaluation

- 010521-Q2009248-R2 - Hicom Diecastings - MP 206-1650Document5 pages010521-Q2009248-R2 - Hicom Diecastings - MP 206-1650azria17Pas encore d'évaluation

- Davi-MCA - FOUR ROLLDocument8 pagesDavi-MCA - FOUR ROLLبازرگانی راهیان کار و دانشPas encore d'évaluation

- SIEMENS Embebido CatDocument264 pagesSIEMENS Embebido Catbad boysPas encore d'évaluation

- Is 10261 Requirement For Settling Tank (Clarifier Equipment)Document16 pagesIs 10261 Requirement For Settling Tank (Clarifier Equipment)Muhaim K ShahulPas encore d'évaluation

- Sheet Rolling Machine - SynopsisDocument8 pagesSheet Rolling Machine - SynopsisTanviPas encore d'évaluation

- Project Report On Robotic ArmDocument28 pagesProject Report On Robotic Armpatel ketan84% (25)

- Stan Meyers Laser Accelerator Rebuild GuideDocument8 pagesStan Meyers Laser Accelerator Rebuild Guidepic2007Pas encore d'évaluation

- Variable Frequency DriveDocument2 pagesVariable Frequency Drivenksuthar5399Pas encore d'évaluation

- Internal Strength PositionDocument11 pagesInternal Strength PositionkulsoomalamPas encore d'évaluation

- Colebrook EquationDocument3 pagesColebrook EquationMuhammad Ghufran KhanPas encore d'évaluation

- Lab 11 12 ECA HIGH AND LOW PASSDocument32 pagesLab 11 12 ECA HIGH AND LOW PASSAmna EjazPas encore d'évaluation

- On Aircraft ComDocument24 pagesOn Aircraft ComAakriti GuptaPas encore d'évaluation

- Sterling Trader Pro en PDFDocument91 pagesSterling Trader Pro en PDFAyush ChaudhariPas encore d'évaluation

- Bobcat 3 Phase: Quick SpecsDocument4 pagesBobcat 3 Phase: Quick SpecsAnonymous SDeSP1Pas encore d'évaluation

- Introducing Maf and Mef Frameworks: Exploring Managed Addin FrameworkDocument9 pagesIntroducing Maf and Mef Frameworks: Exploring Managed Addin Frameworkkris2tmgPas encore d'évaluation

- Seminarski RadDocument32 pagesSeminarski RadAdmir KlinčevićPas encore d'évaluation

- Oracle® Auto Service Request: Exadata Database Machine Quick Installation Guide Release 5.0Document12 pagesOracle® Auto Service Request: Exadata Database Machine Quick Installation Guide Release 5.0ManifoldPas encore d'évaluation

- Chapter 17, E-Learning: 2001 Prentice Hall, Inc. All Rights ReservedDocument22 pagesChapter 17, E-Learning: 2001 Prentice Hall, Inc. All Rights ReservedmarianPas encore d'évaluation

- Harley DavidsonDocument40 pagesHarley Davidsonristosk100% (1)

- DS5000 User's GuideDocument120 pagesDS5000 User's Guidetinu_catarigPas encore d'évaluation

- Content Marketing Solution StudyDocument39 pagesContent Marketing Solution StudyDemand Metric100% (2)

- Reckitt Benkiser (Case Study) For SCMDocument13 pagesReckitt Benkiser (Case Study) For SCMDiptiman GuhaPas encore d'évaluation

- North Museum Science & Engineering Fair 2015 WinnersDocument9 pagesNorth Museum Science & Engineering Fair 2015 WinnersKarenShueyPas encore d'évaluation

- Control Cable SpecificationDocument8 pagesControl Cable Specificationloli2323Pas encore d'évaluation

- StatementDocument3 pagesStatementSachinBMetre87 SachinBMetrePas encore d'évaluation

- Definition of EbookDocument14 pagesDefinition of EbookNurul IzzahPas encore d'évaluation

- Topaz Towers In-Building DASDocument25 pagesTopaz Towers In-Building DASSudheera IndrajithPas encore d'évaluation

- MF 3854 WDDocument96 pagesMF 3854 WDRizwanAli100% (1)

- Bubble Point Temperature - Ideal Gas - Ideal Liquid: TrialDocument4 pagesBubble Point Temperature - Ideal Gas - Ideal Liquid: TrialNur Dewi PusporiniPas encore d'évaluation

- CV Product C-EtdDocument6 pagesCV Product C-EtdmrmskymanPas encore d'évaluation

- Operating System ComponentsDocument59 pagesOperating System ComponentsJikku VarUghesePas encore d'évaluation

- Pd-Coated Wire Bonding Technology - Chip Design, Process Optimization, Production Qualification and Reliability Test For HIgh Reliability Semiconductor DevicesDocument8 pagesPd-Coated Wire Bonding Technology - Chip Design, Process Optimization, Production Qualification and Reliability Test For HIgh Reliability Semiconductor Devicescrazyclown333100% (1)

- Sir - 11 - 21 Rate List 2022Document10 pagesSir - 11 - 21 Rate List 2022akshayPas encore d'évaluation

- Is Iec 60534 2 1 1998Document48 pagesIs Iec 60534 2 1 1998Sreeram PanigrahiPas encore d'évaluation

- Design Checklist-9 USACE AngineeringDocument15 pagesDesign Checklist-9 USACE AngineeringSankar CdmPas encore d'évaluation

- Suzuki G13ba EnginDocument4 pagesSuzuki G13ba EnginYoga A. Wicaksono0% (1)

- Vmware Validated Design 41 SDDC Architecture DesignDocument226 pagesVmware Validated Design 41 SDDC Architecture DesignmpuricePas encore d'évaluation

- Man Ssa Ug en 0698Document43 pagesMan Ssa Ug en 0698Andy LPas encore d'évaluation